Mit der zunehmenden Beliebtheit der LED-Lichttechnologie ist die Auswahl der richtigen Schutzlösung für LED-Streifen zu einem entscheidenden Faktor für die Produktzuverlässigkeit und den Anwendungsbereich geworden.

Dieser Artikel konzentriert sich auf drei technische gängige Lösungen - Silicone-Hohlextrusion, Silikonhüllen und Kunststoffhülsen -, die Kernmetriken wie wasserdichte Leistung, thermodynamische Eigenschaften und mechanische Festigkeit basierend auf den materialwissenschaftlichen Prinzipien und den Anforderungen der technischen Praxis systematisch analysieren.

Durch den Vergleich von experimentellen Daten und Anwendungsfällen der Industrie bietet es objektive Gründe für die Technologieauswahl in verschiedenen Szenarien, um Entscheidungsträgern bei der Entwicklung eines wissenschaftlichen Produktentwicklungsrahmens zu helfen.

Überblick über die drei wasserdichten Methoden

Unter wasserdichten LED-Streifen sind drei Prozesse am häufigsten: Hohle Silikonextrusion, Silikonhüllen und Kunststoffhüllen.

Bei der hohlen Silikonextrusion wird der LED-Streifen mit einer Silikonhülle koextrudiert, bei der die LED-Chips vollständig von festem Silikon ummantelt werden, um eine robuste wasserdichte Struktur zu bilden. Silikonhülle mit Kunststoffhülle Das Einfädeln des vorgefertigten Lichtstreifens in eine Silikonhülse, die durch Traktion gesichert ist, um eine grundlegende Wasserdichtigkeit zu erreichen.

Diese drei Methoden unterscheiden sich in der Wasserdichtigkeit, Alterungsbeständigkeit, Wärmeableitung und Kosten. Wie sollen Kunden die richtige Auswahl treffen? Im Folgenden vergleichen wir die drei Technologien, die auf Materialeigenschaften, Herstellungsprinzipien und praktischen Anwendungen basieren, um deren technische Unterschiede und Marktpositionierung zu untersuchen.

Lesen Sie die Blog-Beiträge „Um mehr über die Techniken der LED-Streifen-Lichtdichtung zu erfahren“Welche Abdichtungsverfahren werden bei LED-Leuchten verwendet?"und"Die ultimative Anleitung für wasserdichte LED-Leuchten.”

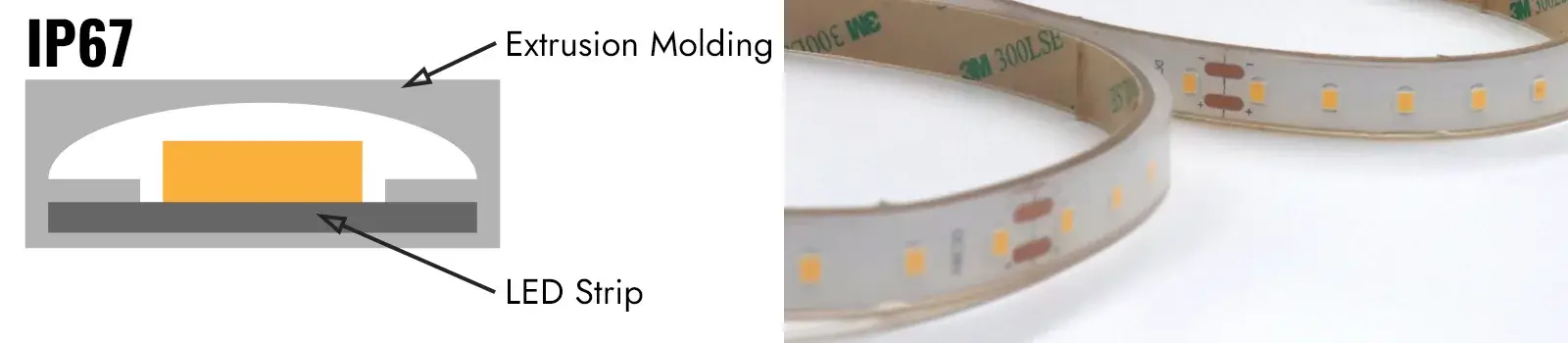

Silikon-Hohlextrusion

Wasserdichte Lichtstreifen werden typischerweise unter Verwendung von Extrusionsverfahren hergestellt, die hauptsächlich in Hohl- und Festextrusion unterteilt sind.

Hohlextrusion hinterlässt eine Lücke am Kern des extrudierten Bandes, während die feste Extrusion den gesamten Streifen als feste Struktur bildet. Die Hohlextrusion ist komplexer und erfordert spezielle Extruder und Formen, was zu höheren Produktionsschwierigkeiten und -kosten führt.

Hohlextrudierte Silikonstreifen zeichnen sich durch folgende Eigenschaften aus:

- Hohlstranggepresste Streifen haben einen inneren Lufthohlraum, was zu einer geringen Dichte führt. Das Silikon ist leicht, hochflexibel und besitzt ein gewisses Maß an Weichheit und Elastizität, so dass es sich an komplexe gekrümmte Oberflächen anpassen kann. Hochtransparentes pyrolytisches Silikon wird typischerweise für die Hohlextrusion verwendet, wobei seine hohe Fließfähigkeit den Anforderungen dünnwandiger oder komplizierter Hohlraumstrukturen entspricht.

- Der hohle Innenraum verteilt das Licht der LED-Perlen gleichmäßiger und erreicht eine überlegene Ausleuchtung. Hohlstrangstrang weisen hellere, transparentere Farben als feste Strangpressstreifen mit glatteren Kanten auf.

- Durch die Luftisolierung haben hohle Strangpressstreifen eine schlechtere Wärmeleitfähigkeit. Die Betriebstemperaturen der LED sind typischerweise 10-15°C höher als feste extrudierte Streifen.

- Hohles Silikon weist eine relativ geringere Härte und chemische Korrosionsbeständigkeit auf.

- Komplexität der Installation: Hohle Strangpressstreifen sind leicht und können direkt angeklebt werden, während massive extrudierte Streifen eine Halterung erfordern, was die Arbeitskosten um etwa 151 tp3t erhöht.

- Kostenmäßig sind hohle, extrudierte Streifen pro Einheit um etwa 201 tp3t-301 TP3T billiger als feste, haben jedoch eine kürzere Lebensdauer (typischerweise 20.000-30.000 Stunden). Feste, extrudierte Streifen haben höhere Anfangskosten, können aber über 50.000 Stunden dauern. Hohle extrudierte Streifen können direkt angeklebt werden, während feste Streifen erforderlich sind, was die Arbeitskosten um etwa 151 tp3t erhöht.

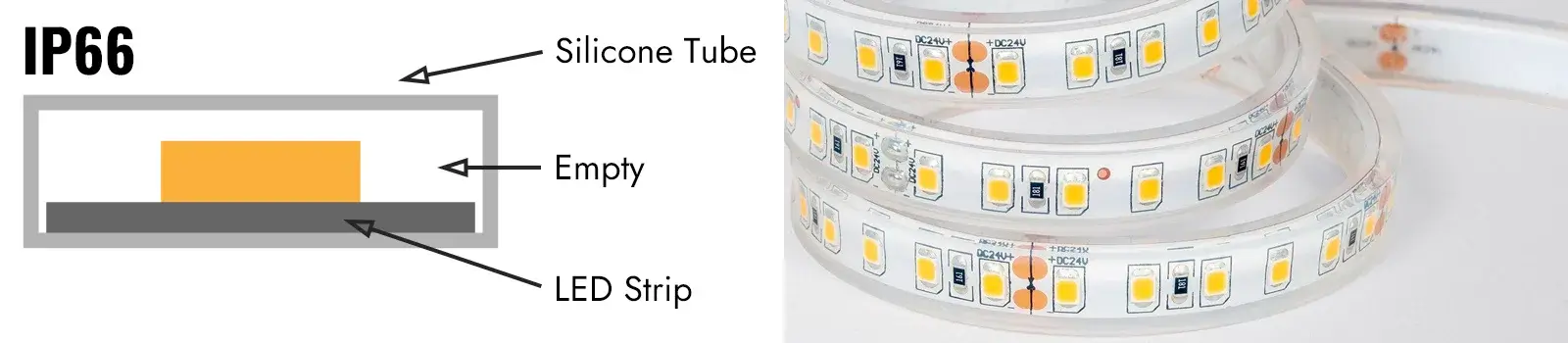

Silikonhülle

LED-Streifen aus Silikonhülle sind wasserdichte Beleuchtungsstreifen mit flexiblen LED-Lampen aus Silikonmaterial.

Der LED-Streifen wird durch die Silikonhülse gefädelt, die dann an beiden Enden versiegelt wird, um das Eindringen von Wasser durch Regen oder andere Quellen zu verhindern. Es wird häufig in architektonischen Umrissbeleuchtung, kommerziellen Dekorationen und im Freien verwendet und unterstützt das Biegen und Verformen, um sich an unregelmäßige Strukturen anzupassen.

Zu den Funktionen gehören:

- Flexibilität und Formbarkeit: Das Silikonmaterial bietet eine hervorragende Flexibilität, sodass der Streifen in verschiedene Formen gebogen werden kann. Damit eignet es sich für gebogene oder komplexe Installationen, wie z. B. kreisförmige Dekorationen, Möbelkanten oder Kunstinstallationen, um den Anforderungen der kreativen Beleuchtung gerecht zu werden.

- Wasserdichte und staubdichte Leistung: Der Silikonschlauch selbst bietet eine hohe Dichtungsintegrität und verhindert effektiv das Eindringen von Feuchtigkeit und Staub in das Bandinnenraum. Viele Produkte erreichen eine IP67-Wasserdichtigkeit, die ein kurzes Untertauchen ermöglicht. Dies macht sie besonders geeignet für feuchte Umgebungen wie Badezimmer, Küchen oder Außenbeleuchtung.

- Weich und gleichmäßig leicht: Der Silikonschlauch wirkt als Lichtdiffusor und reduziert die Blendung von LED-Lampen, um eine weichere, gleichmäßigere Beleuchtung zu erzeugen. Diese Eigenschaft passt zu Räumen, die ein komfortables Ambiente erfordern, wie Schlafzimmer, Essbereiche oder dekorative Beleuchtung in Gewerberäumen.

- Haltbarkeit und Sicherheit: Silikonmaterial widersteht hohen Temperaturen und Alterung und verlängert die Lebensdauer des Streifens. Seine Isoliereigenschaften erhöhen auch die elektrische Sicherheit, indem sie das Risiko von Kurzschlüssen oder Leckagen verringern.

- Breiter Temperaturbereich: Betrieben in der Regel von -40°C bis 200°C, geeignet für Außen- und extreme Temperaturumgebungen.

- Alterungsbeständigkeit: Materialstabilität hält Öl- und Ozonbelastungen und gewährleistet eine längere Lebensdauer.

Plastikmanschette

Wasserdichte LED-Lichtstreifen aus Kunststoffhülle bestehen typischerweise aus hochwertigem PVC-Material. Sie sind wasserdicht, flexibel, biegbar und beständig gegen hohe und niedrige Temperaturen, sodass sie sowohl für den Innen- als auch für den Außenbereich geeignet sind.

Die Hülse hat eine Innenbreite von 10 mm, was das Einfügen von 8-10 mm SMD- oder COB-Lichtstreifen als Lichtquelle ermöglicht. Dies bietet ein Schutzgehäuse für den LED-Lichtstreifen, der Haltbarkeit und Langlebigkeit gewährleistet.

PVC (Polyvinylchlorid) ist aufgrund seiner ausgereiften Herstellungsverfahren und Kostenvorteile das gängige Material für Neonband- und LED-Streifenhülsen. Beispielsweise verwenden flexible Neon-Streifenkanäle häufig elastisches PVC-Material, das beim Biegen Reißen widersteht.

● Wasserdichtigkeit und Korrosionsbeständigkeit: PVC bietet eine hervorragende Wasserdichtigkeit, die Feuchtigkeitsdampf effektiv blockiert und somit für feuchte Umgebungen wie Badezimmer geeignet ist. Es zeigt auch eine gute Korrosionsbeständigkeit und eine gewisse chemische Beständigkeit, die für allgemeine Einstellungen im Innen- und Außenbereich geeignet ist.

● Einfache Installation: Seine Flexibilität ermöglicht das Biegen und Schneiden, um sich an verschiedene Formen anzupassen, während die leichte Natur den Bau erleichtert.

● Haltbarkeit: Anfällig für Alterung und Verfärbung, längere Exposition gegenüber UV-Strahlen oder hohen Temperaturen kann zu Vergilbung und Sprödigkeit führen, was die Lichtdurchlässigkeit und die Ästhetik beeinträchtigt.

● Begrenzte Temperaturtoleranz: PVC hat einen engen Temperaturbereich (-15°C bis 80°C). Längerer Gebrauch im Freien kann aufgrund von UV-Exposition zu Vergilbung und Aushärtung führen. Es emittiert beim Verbrennen reizende Gase, verformt sich bei hohen Temperaturen und kann bei niedrigen Temperaturen reißen, was seine Verwendung in extremen Außenklimaten einschränkt.

● Optische Eigenschaften: Die Lichtdurchlässigkeit beträgt nur 70%-80%, Licht erscheint tendenziell gelblich und der Farbwiedergabeindex ist niedrig (70-80), was zu einer schlechten Farbwiedergabe führt. Die Lichtgleichmäßigkeit ist den Silikon- oder Acrylmaterialien unterlegen und erzeugt möglicherweise ein körniges Aussehen.

● Umwelt- und Gesundheitsprobleme: PVC enthält Schadstoffe wie Vinylchlorid, die Schadstoffe während der Produktion und Verwendung freisetzen können und so umweltfreundlicher werden.

● Niedrige Kosten: PVC ist deutlich günstiger als Alternativen wie Silikon oder Acryl, was es für preisbeschränkte Projekte geeignet macht.

Vergleichstabelle

Silikonhohlextrusion vs Silikonhülle gegen Kunststoffhülle

| Ccharakteristisch | Silikon-Hohlextrusion | Silikonhülle | Plastikmanschette |

| Flexibilität | Hohe Flexibilität und gute Elastizität, leicht zu biegen | Hohe Flexibilität und gute Elastizität, leicht zu biegen | Hohe Härte, gute Reißfestigkeit, schlechte Rückprall, anfällig für Verformung, schlechte Biegbarkeit |

| Dauerhaftigkeit | Typisch 8-12 Jahre drinnen, 5-8 Jahre im Freien | Innen: 8-10 Jahre, Außenbereich: 5-6 Jahre | Innen: 2-3 Jahre, Außenbereich: 1-2 Jahre |

| Lichtdurchlässigkeit | Hervorragende Lichtdurchlässigkeit > 90% | Gute Lichtdurchlässigkeit, 90%-95% | Lichtdurchlässigkeit, ca. 60%-85% |

| Temperaturbeständigkeit | Hält extremen Temperaturen stand, geeignet für -40°C bis 230°C, kein Vergilben bei Langzeitanwendung | Hält extremen Temperaturen stand, geeignet für -40°C bis 230°C | Schlechte Temperaturbeständigkeit, spröde unter -10°C, Obergrenze 70°C, vergilbt bei längerer Sonneneinstrahlung |

| Sicherheit | Umweltverschmutzung während der Produktion und Nutzung | Umweltverschmutzung während der Produktion und Nutzung | Schlechte Umweltleistung; löst bei hohen Temperaturen schädliche Gase aus |

| Abdichtung und Korrosionsbeständigkeit | beständig gegen Säuren/Alkalien und Korrosion; ungeeignet für längeres Unterwassertauchen | beständig gegen Säuren/Alkalien und Korrosion; ungeeignet für längeres Unterwassertauchen | Überlegene Wasserdichtigkeit und Korrosionsbeständigkeit; ungeeignet für direkte Sonneneinstrahlung; schlechte Säure- / Alkalibeständigkeit |

| Installation und Wartung | Mittelgewicht, direkt verklebt werden, langer Wartungszyklus | Leicht, direkt verklebt, biegbar, langer Wartungszyklus | Einfache Installation, aber häufige Wartung erforderlich; Außeneinsatz muss alle 1-2 Jahre ausgetauscht werden |

| Kosten | Teuer | Relativ hoch | Relativ niedrig |

| Anwendungsszenarien | Langzeitnutzung im Freien, Umgebungen mit hoher Luftfeuchtigkeit und Temperatur, Einstellungen für medizinische / Lebensmittel, Langzeitbeleuchtung in Wohnräumen, Schränken usw. | Langzeitbeleuchtung in Wohnzimmern, Schränken usw. | Kurzzeitdekoration, preiswerte Innenbeleuchtung |

Zusammenfassend sind die Materialien, die in Hohlextrusions- und Silikonhülsenverfahren verwendet werden, im Wesentlichen gleich, mit nur bestimmten Unterschieden in den Herstellungsverfahren. Die Extrusion beinhaltet eine direkte Maschinenbearbeitung, während der Hülsenprozess mehr manuelle Arbeit erfordert.

Beim Vergleich von LED-Streifen mit hohlen Silikon-Strangpressrohren, Silikonhüllen und PVC-Hülsen hat jede ihre eigenen Eigenschaften und ist für verschiedene Szenarien geeignet. Um die Wirksamkeit von LED-Lichtstreifen in verschiedenen Anwendungen zu maximieren, ist die Auswahl des geeigneten Prozesses und der Eigenschaften unerlässlich.

Für preisbewusste Projekte in milden Umgebungen können Kunststoffhüllen in Betracht gezogen werden, obwohl die Austauschhäufigkeit beachtet werden sollte. Ausgleichende Gesamtleistung und langfristige Kosten, Silikonhohlextrusion oder Silikonhüllen bieten eine hervorragende Auswahl, insbesondere hervorragend in der Wasserdichtigkeit, Temperaturbeständigkeit und Flexibilität.

Szenarien & Auswahlhandbuch

Silikon-Hohlextrusion

Ideal für Deckenleuchten, Unterschrankbeleuchtung, Treppengeländer und ähnliche Anwendungen, bietet es sowohl funktionale Beleuchtung als auch ästhetische Anziehungskraft. Sein sanfter Glanz eignet sich besonders für die Schaffung von Ambiente in Schlafzimmern oder Wohnräumen.

Dank ihrer wasserdichten Eigenschaften können die LED-Streifen aus Silikon-Hohlextrusion für die dekorative Beleuchtung in Gärten, Poolkanten oder Gebäudeaußenbereichen verwendet werden. Sie halten auch in regnerischen oder staubigen Umgebungen einen stabilen Betrieb.

Silikonhülle

In Geschäften, Bars oder Messehallen machen sie die Flexibilität und Formbarkeit von Silikon-Hülsen-Lichtstreifen eine ideale Wahl für dekorative Beleuchtung. Sie können beispielsweise die Konturen von Vitrinen umreißen oder einzigartige künstlerische Lichtinstallationen erstellen.

Während das Silikonmaterial hitzebeständig ist, kann ein längerer Betrieb mit hoher Helligkeit immer noch zu Wärmebildung führen, was die Lebensdauer der LED beeinträchtigt. Vermeiden Sie einen kontinuierlichen Volllastbetrieb in geschlossenen oder schlecht belüfteten Umgebungen.

Plastikmanschette

Geeignet für Außenbeleuchtungsprojekte, sind PVC-Hülsen-Lichtstreifen ideal für kurzfristige Dekorationen, preisbeschränkte Projekte oder nicht extreme Umgebungen (z. B. temporäre Ausstellungen, Umgebungsbeleuchtung mit niedriger Helligkeit). Für den langfristigen Einsatz oder anspruchsvolle Szenarien (z. B. Außeneinstellungen, hohe Anforderungen an die Farbwiedergabe) wird Silikonmaterial empfohlen.

Beachten Sie außerdem, dass die oben genannten LED-Streifen für wärmere Klimazonen besser geeignet sind. In kälteren Bereichen können LEDs innerhalb der Hülse während des Betriebs Wärme erzeugen.

Bei niedrigen Außentemperaturen können Luft und Feuchtigkeit in der Hülse oxidieren, möglicherweise LEDs oder Leiterplatten korrodieren oder einen dunstigen Nebel erzeugen, der die Lichtleistung beeinflusst. Für höhere Beleuchtungsanforderungen können feste, extrudierte Optionen bevorzugt werden.

Kosten- und Wartungsüberlegungen

Silikonhohle extrudierte LED-Streifen: Höhere Materialkosten durch einteiliges Silikonformverfahren. Niedrige Wartungskosten. Die wasserdichte IP68-Bewertung minimiert feuchtigkeitsbedingte Ausfälle. Langzeitgebrauch ohne häufigen Ersatz. Vermeiden Sie übermäßiges Biegen während der Installation, um einen internen Stromkreisbruch zu vermeiden. Geeignet für raue Umgebungen wie Außeneinstellungen und Wasserspiele, erfordert jedoch eine angemessene Wärmeableitung, um eine beschleunigte Alterung durch hohe Temperaturen zu verhindern.

LED-Streifen aus Silikonhülle: Breite Preisklasse; transparente oder zweifarbige Designs beeinflussen die Kosten. Gemäßigte Wartung ist erforderlich - Überprüfen Sie regelmäßig die Passung von Hülse zu Streifen, um das Eindringen von Wasser zu verhindern. Passen Sie die Hülsengröße während der Installation an den Streifen an, um eine schlechte Wärmeableitung durch Dichtheit oder eine beeinträchtigte Wasserdichtigkeit durch Lockerheit zu vermeiden. Temperaturbereich: -60°C bis 200°C, obwohl eine längere hohe Hitze das Gelbfärben von Silikon beschleunigen kann.

LED-Streifen aus Kunststoff: Niedrigste Kosten, geeignet für budgeteinschränkte Szenarien. Höhere Wartungskosten; PVC-Material altert leicht und erfordert einen regelmäßigen Ärmelwechsel. Nur für trockene Umgebungen geeignet, imprägnierungen sind schwächer als Silikonlösungen (niedrigere IP-Bewertung). Kontakt mit chemischen Lösungsmitteln vermeiden, um die Sprödigkeit der Hülse und Risse zu verhindern.

Umfassende Vergleichstabelle:

| Typ | Stückpreisspanne (USD/m) | Wartungsfrequenz | geeignete Umgebung |

| Silikonhohle extrudiert | $3.67-4.9 | Niedrig | Outdoor-/Wasser-Funktionen |

| Silikonhülle | $0.22-3.78 | Mittel | Innen-/Halb-Outdoor |

| Plastikmanschette | $0.02-1.33 | Hoch | Innen trocknen |

Empfehlung: Priorisieren Sie hohles, extrudiertes Silikon für hohe Feuchtigkeit oder Außeneinstellungen, die Wasserdichtigkeit und Haltbarkeit ausgleichen. Für preisbeschränkte Projekte in stabilen Umgebungen können Kunststoffhülsen verwendet werden, erfordern jedoch kürzere Wartungszyklen.

Abschluss

Dieser Artikel bietet technischen Entscheidungsträgern eine wissenschaftliche Grundlage für die technische Auswahl, indem sie die Materialeigenschaften, die wasserdichte Leistung und die Wärmeableitung von drei Arten von wasserdichten LED-Streifen systematisch analysieren.

Signlited ist spezialisiert auf die Fertigung Wasserdichte LED-Streifen mit verschiedenen Produktionstechniken. Bei Fragen zu Ihren Projekt- oder Bewerbungsvoraussetzungen kontaktieren Sie uns bitte für weitere Unterstützung!