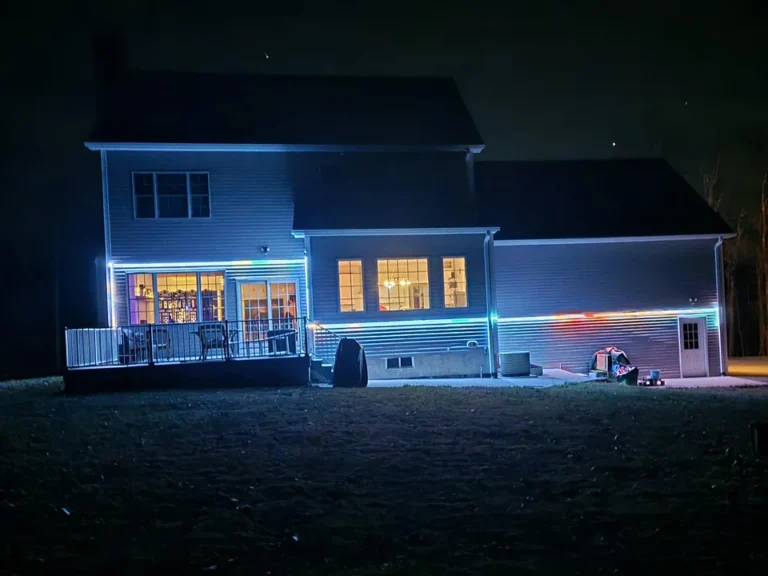

Outdoor dimmable LED tape is widely used in architectural outlines, landscape lighting, and exterior decorative applications, where both lighting performance and environmental durability are essential. Compared with indoor installations, outdoor projects place higher demands on waterproof protection, dimming stability, and overall system compatibility. Different applications may prioritize different factors depending on installation conditions, control methods, and project scale. This article outlines several key considerations when selecting dimmable LED tape for outdoor use, providing practical reference points to help buyers evaluate products and solutions more effectively for their specific applications.

Outdoor Environment and Waterproof Rating

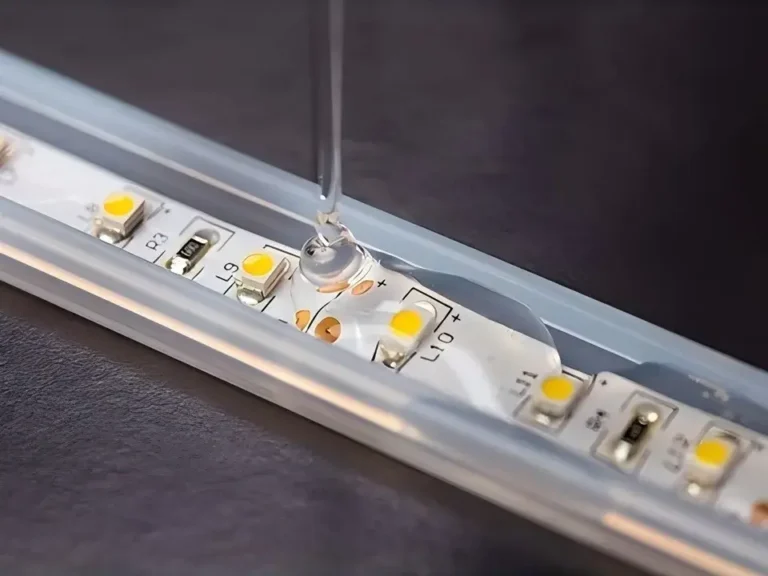

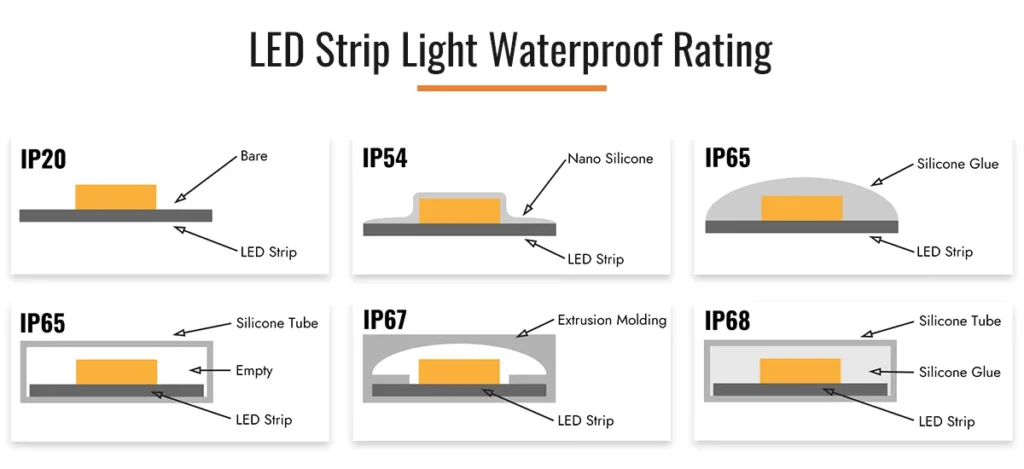

Outdoor dimmable LED tape is available in a variety of waterproof constructions, and selection should always be based on the actual installation environment. Common options include IP65 silicone coating, IP65 silicone tube, IP67 hollow extrusion, IP68 silicone filling, and IP68 silicone extrusion. Each structure offers a different balance between moisture protection, flexibility, heat dissipation, and long-term durability. There is no single “best” waterproof LED tape for all outdoor projects; the appropriate choice depends on exposure level, mounting position, and environmental conditions.

From a practical perspective, IP ratings define protection boundaries rather than overall product quality. IP65 LED tape is suitable for environments exposed to rain or splashing water but not continuous water contact. IP67 products are designed for locations where temporary water immersion may occur, such as ground-level installations or areas prone to water accumulation. IP68 LED tape is intended for long-term or frequent immersion and is typically used in fountains, pools, or high-moisture landscape features.

The table below summarizes recommended waterproof ratings for common outdoor applications:

| Anwendungsszenario | Empfohlene IP-Be |

| Building façade outlines | IP65 |

| Eaves and canopies | IP65 |

| Balconies and terraces | IP65 / IP67 |

| Ground-level architectural lines | IP67 |

| Garden and landscape lighting | IP67 |

| Near swimming pools | IP68 |

| Water features and fountains | IP68 |

| Coastal outdoor installations | IP67 / IP68 |

In summary, waterproof rating selection should be driven by real exposure conditions rather than assumptions. For fully exposed outdoor installations, LED tape with UV-resistant materials is strongly recommended to prevent yellowing and material degradation. For coastal or high-salinity environments, products that have passed salt spray testing provide improved reliability and longer service life.

Dimming Method and System Compatibility

Several dimming methods are commonly used in outdoor LED tape projects, each suited to different control requirements and project scales. The most widely applied methods include PWM dimming, 0–10V dimming, DALI, TRIAC (phase-cut) dimming, and DMX control. While all of these methods can be implemented in outdoor environments, their performance and practicality depend largely on system design, wiring complexity, and the required level of control.

The table below compares these dimming methods from an outdoor project perspective:

| Dimmmethode | Vorteile | Beschränkungen | Typical Outdoor Applications |

| PWM | Simple, cost-effective, stable | Limited centralized control | Small to medium outdoor projects |

| 0–10v | Mature standard, good stability | Additional control wiring | Commercial façades, outdoor signage |

| Dali | Addressable, flexible control | Higher system cost | Large architectural lighting systems |

| TRIAC | Compatible with AC power | Limited low-level dimming | Retrofit outdoor lighting |

| DMX | Precise control, dynamic effects | Requires correct decoder setup | Architectural and landscape lighting |

In most outdoor applications, DC LED tape is compatible with all five dimming methods when paired with appropriate drivers or controllers. For DMX-based projects, however, selecting the correct DMX decoder is essential, as channel configuration and output type directly affect system stability. By contrast, AC LED tape is typically limited to TRIAC dimming and selected phase-cut control systems, making it more suitable for simpler outdoor installations.

Brightness and Light Uniformity

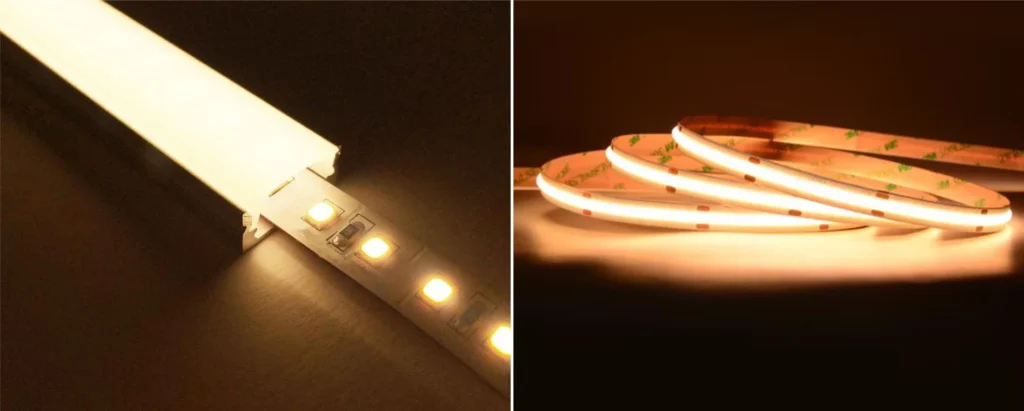

Brightness is often a primary consideration in outdoor LED tape applications, particularly for architectural outlines and functional exterior lighting. When high luminous efficacy and maximum brightness are required, SMD LED tape is generally the preferred option. High-efficiency SMD LED tape can achieve luminous efficacy above 180 lm/W, while COB LED tape typically reaches up to around 150 lm/W. For projects targeting the same brightness level, SMD LED tape usually offers better energy efficiency and lower power consumption, making it suitable for large-scale outdoor installations.

Light uniformity is a separate but equally important factor, especially in visible linear lighting applications. When a continuous, dot-free lighting effect is required, COB LED tape offers clear advantages due to its higher chip density and closely packed light-emitting surface, resulting in smooth illumination without dark spots. Alternatively, SMD LED tape combined with aluminum profiles and diffusers can also achieve good uniformity while improving heat dissipation and mechanical protection.

Input Voltage Selection for Outdoor Dimmable LED Tape

For outdoor projects, high-voltage LED tape is generally not recommended due to increased electric shock risk and more complex safety requirements. As a result, DC low-voltage LED tape is more commonly used, with DC12V and DC24V being the most widely applied options. However, when selecting dimmable LED tape, Spannungsabfall must be carefully considered, as it directly affects brightness uniformity and dimming consistency along the run.

With single-end power input, DC12V LED tape should typically be limited to 5 meters, while DC24V LED tape can extend up to 7 meters. When dual-end power input is used, DC12V systems can reach approximately 15 meters, and DC24V systems up to 20 meters. Exceeding these lengths may result in visible brightness reduction and uneven dimming performance.

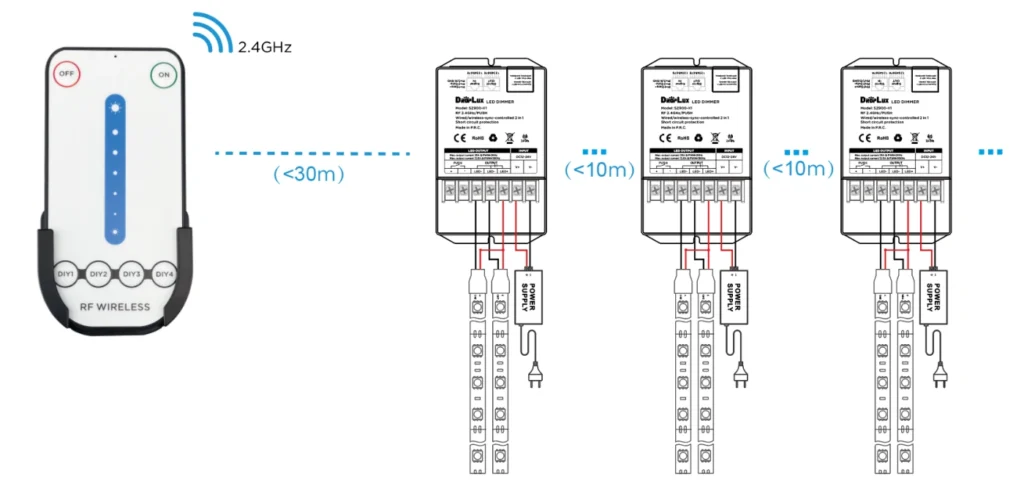

For projects requiring long continuous runs, DC48V LED tape provides a practical alternative. It supports up to 15 meters with single-end input and up to 40 meters with dual-end input, simplifying wiring and reducing voltage drop. The main limitation is the relatively smaller selection of compatible power supplies. When PWM dimming is used, dimming consistency can be further improved by adding signal amplifiers between LED tape sections or by adopting synchronous controllers, particularly in large outdoor installations.

Choosing the Right Supplier for Medium and Large Outdoor Projects

For medium to large outdoor lighting projects, supplier selection plays an important role in overall project performance. In most cases, working directly with a genuine manufacturer is preferable to sourcing through online marketplaces or trading companies. Manufacturers typically offer more competitive pricing, deeper product expertise, and stronger technical support. More importantly, they are better positioned to provide non-standard customization, which is often required in outdoor dimmable LED tape projects

When evaluating manufacturers, product compliance and testing capabilities should also be considered. Relevant certifications such as UL, CE, and RoHS demonstrate regulatory compliance, while test reports—including IES photometric data, integrating sphere tests, and salt spray testing—offer additional assurance of performance, safety, and long-term reliability in outdoor environments.

Other Important Factors to Consider

Beyond waterproof rating, dimming method, brightness, voltage selection, and supplier choice, several additional factors can influence the long-term performance of outdoor dimmable LED tape. Thermal management is particularly important, as waterproof structures can restrict heat dissipation; proper installation using aluminum profiles can significantly enhance reliability. Color consistency during dimming, especially at low brightness levels, should also be evaluated in visible architectural lighting. In addition, cable exit design, end-cap sealing, and installation details play a key role in preventing moisture ingress over time. For harsh environments, UV resistance, corrosion protection, and verified testing data provide further assurance of stable long-term operation.

With over ten years of experience in manufacturing outdoor LED tape, SignliteLED supports a wide range of exterior lighting applications. In addition to standard products, we offer customized LED tape solutions tailored to specific project requirements, including circuit design, color options, and waterproof construction. To ensure system compatibility and stable dimming performance, we also provide complete supporting solutions such as controllers, amplifiers, decoders, and power supplies. By combining product customization with practical system support, we help clients implement outdoor dimmable LED tape solutions more efficiently and reliably.