Para proyectos de iluminación comercial, si prioriza la fuente de alimentación estable de larga distancia, brillo constante y longevidad, entonces las tiras de LED de corriente constante son, sin duda, la opción superior. Sin embargo, si el presupuesto del proyecto es limitado, la distancia de instalación es corta y no hay requisitos estrictos para la uniformidad de brillo, entonces las tiras de LED de voltaje constante ofrecen una mejor relación calidad-precio.

Las tiras de LED de voltaje constante y de corriente constante tienen sus propias ventajas: la primera tiene un diseño de circuito simple y costos más bajos, lo que lo hace adecuado para iluminación decorativa de corta distancia; la segunda ofrece corriente estable y una vida útil más larga, lo que lo hace ideal para aplicaciones comerciales de gran o alta gama. Comprender los principios y las características de estos dos métodos Drive puede ayudarle a tomar las decisiones correctas en diferentes escenarios comerciales.

Este artículo proporcionará un análisis en profundidad de las diferencias técnicas, ventajas y desventajas, escenarios de aplicación y recomendaciones de selección de tiras de LED de corriente constante frente a voltaje constante, ofreciendo orientación para sus proyectos de iluminación comercial.

Qué Is A Cactuando CUrrent LED S¿viaje?

A Tira de LED de corriente constante Es un tipo de tira de LED que mantiene una corriente constante a través de sus LED. La corriente se ajusta y mantiene por una fuente de corriente continua.

Las tiras LED de corriente constante comunes generalmente incorporan IC de corriente constante o transistores triodos en la tira misma o tienen chips de corriente constante incorporados dentro de los LED. Su característica principal es el control de corriente preciso para lograr una iluminación estable, lo que las hace adecuadas para aplicaciones con requisitos estrictos de brillo y vida útil.

principio de funcionamiento

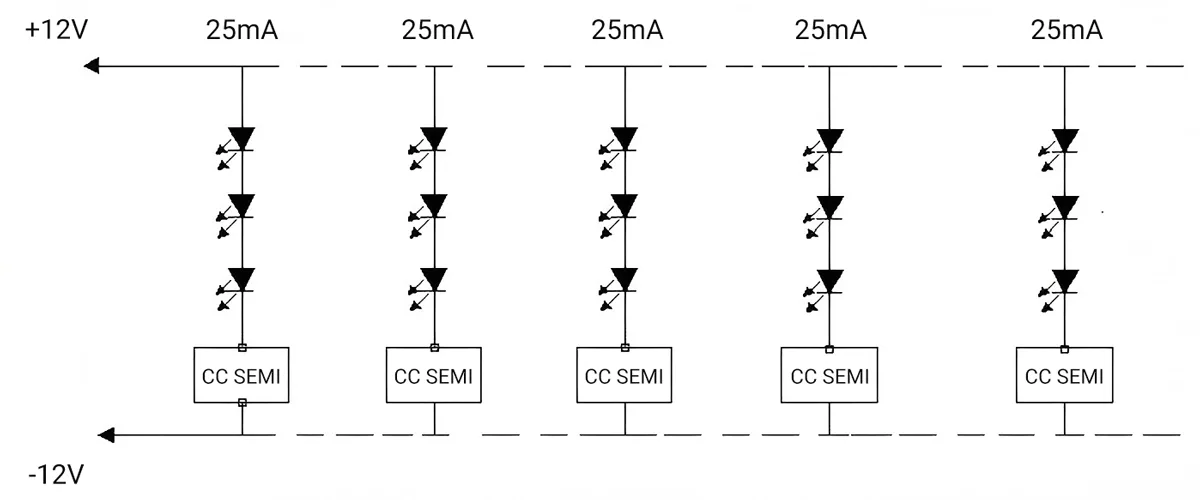

Como se muestra en la figura siguiente, cuando se encuentra en funcionamiento una tira de LED de corriente constante, el semiconductor de corriente constante (IC o transistor triode) emite una corriente constante de 25mA a través de su circuito integrado interno, mientras que el voltaje se ajusta automáticamente en función del número de LED conectados en serie. Si un solo LED tiene un voltaje de 3V, tres LED en serie requieren un voltaje de 9V. Cuando el voltaje de entrada está entre 10 y 14V, la corriente permanece en el valor preestablecido de 25mA, evitando el brillo de la potencia de entrada o la sobrecarga de LED.

Serie-Paralo Circuit Strepidación

Como se muestra en la figura siguiente, los LED de la tira de LED de corriente constante están diseñados con una configuración en serie-paralela. Cada grupo tiene una distancia de 50 mm, con un total de 3 grupos. Cada grupo está controlado de forma independiente por un transistor de triodo de corriente constante, lo que garantiza que la corriente en cada grupo sea igual y el brillo de los LED en cada segmento sea uniforme.

Ventajas técnicas de tira de LED de corriente constante

| Características | efectos |

| Consistencia de brillo | No hay caída de voltaje ni decaimiento de la luz en largas distancias (>8 metros), con variación de brillo <5% |

| Garantía de vida | Chip de compensación de temperatura negativo incorporado, reducción automática de corriente a altas temperaturas, decaimiento de la luz ≤10% durante 5 años |

| seguridad | El mecanismo de protección contra sobrecarga evita que una sola falla de LED cause que toda la tira de luz funcione mal |

| Resistencia de interferencia | La corriente permanece estable incluso con las fluctuaciones de voltaje de entrada de ±30% (las soluciones de voltaje constante con ±10% pueden causar picos de corriente de hasta 50%) |

Escenarios de aplicación

- Centro Comercial Sala de Exposiciones Sistema de atenuación: Ajuste de brillo continuo sin parpadeo; iluminación de contorno de construcción de larga distancia (como exteriores de hoteles, túneles).

- Entornos de trabajo de precisión: Iluminación sin sombras en talleres de electrónica (eliminando interferencias de parpadeo con la producción), iluminación auxiliar en quirófanos médicos.

- Casas de alta gama: Iluminación ambiental de gabinete personalizado (instalación incrustada con brillo uniforme), iluminación indirecta de techo (creando un efecto de iluminación degradado).

- Esencia técnica: Las tiras de LED de corriente constante logran un control de bucle cerrado de corriente a través de chips físicos, que se diferencian de la solución de tira de LED de voltaje constante más simple que se basa en resistencias limitadoras de corriente. Esta es la solución preferida en iluminación LED que equilibra el rendimiento y la fiabilidad.

Qué Are T¿Los principales tipos de tiras de LED de corriente constante?

1. Tiras de LED de corriente constante basadas en IC de bajo voltaje

Estas tiras de LED suelen operar a voltajes de entrada de 12V o 24V. Cada segmento de la tira está diseñado con transistores o circuitos integrados para mantener la corriente constante. Mediante el uso de transistores triodos discretos, estas tiras logran un control de corriente constante de bajo costo, lo que las hace adecuadas para aplicaciones simples.

Las soluciones de corriente constante IC se basan en chips y microcontroladores de controladores dedicados para lograr un control multicanal programable y de alta precisión. Las tiras de LED controladas a través de SPI o DMX512, como tiras de LED que cambian de color, se incluyen en la categoría de tiras de LED de corriente constante y son adecuadas para tiras de LED inteligentes de calidad comercial.

DC24V/DC48V Constante corriente LED tira de luces largas

Modelo principal: FQW10T120D

Tipo de LED: SMD2835

Cantidad de LED por metro: 120

Ancho de PCB: 10 mm/12 mm

Longitud: 10m/15m/20m/30m/40m/50m

Voltaje de entrada: DC24V/DC48V

Potencia por metro: 10W/7.2W

Temperatura de color: 2700K/3000K/4000K/5000K/6500K/customizable

Grado IP: IP20/IP54/IP65/IP67/IP68

Garantía: 3 años

Tira de luz LED direccionable RGB DC12V/24V

Modelo principal: FAA10T060C

LED CANT. por metro Opción: 60

Tipo de LED: SMD5050

Opción de ancho de PCB: 10 mm

Color: RGB

Tipo IC: WS2811/UCS1903/TM1812, CI externo

Pixel CANT: 20/10 píxeles por metro, 1 píxel 3/6 LED

Tipo de datos: Señal SPI, línea de datos única

Voltaje de entrada: DC12V/DC24V

Potencia por metro: 12 W

Opción de grado IP: IP20/IP54/IP65/IP67/IP68

Garantía: 3 años

2. Tiras rígidas LED del conductor de corriente constante

Con el motor de un driver de corriente constante, estas tiras de luz no requieren resistencias ni transistores para limitar la corriente. Tienen una alta eficiencia luminosa, con voltajes de entrada normalmente establecidos dentro del rango de 22V a 40V.

Estas tiras rígidas LED utilizan controladores de corriente constante para proporcionar una corriente continua estable. En principio, los LED están conectados en serie y luego son paralelos a los principales terminales positivos y negativos, asegurando un voltaje constante en cada sección de la tira de luz.

estas Tiras de luz rígidas de corriente constante Tienen requisitos de compatibilidad de fuente de alimentación elevados; el consumo total de corriente de la tira de luz debe coincidir con la corriente de salida de la fuente de alimentación para lograr una iluminación LED óptima. Estas tiras de luz son adecuadas para longitudes personalizadas y entornos de instalación de corta distancia.

Módulo de LED lineal de placa PCB de corriente constante

Modelo principal: SL-5.5-XX-10

Tensión: Máx. 28,5 V

Corriente de entrada: Máx. 150 mA

Vatio de entrada: Max 4.425W

Eficacia luminosa: 195lm/W

Tipos de LED: SMD2835

Temperatura de color: 2700K – 6500K

CRI: 80/90

Dimensión: 139,7 × 15,24 × 1,6 mm

Certificación: CE, RoHS

Garantía: 5 años

3. Tiras de LED de alto voltaje

Tiras LED de alto voltaje de 110 V/220 V Normalmente se utilizan tecnología de accionamiento de corriente constante. El principio central consiste en convertir el voltaje de CA 110V/220V de la fuente de alimentación en un voltaje de CC adecuado para LED mientras se mantiene una corriente estable.

Estos adaptadores de controlador suelen tener funcionalidad de salida de corriente constante. Por ejemplo, el chip PM2043 se utiliza para accionar cadenas de luces LED de alto voltaje alimentadas por electricidad de red, logrando un control de corriente constante lineal de segmentos múltiples a través de la tecnología de división armónica. Adecuado para aplicaciones de larga distancia, como iluminación de perfiles arquitectónicos y decoración al aire libre, las tiras de luz LED de alto voltaje requieren protección de aislamiento durante el uso.

Tira de luz LED de alto voltaje

Modelo principal: GQX10T120G

LED CANT. por metro Opción: 60/80/120

Metros por rollo: Máx. 100 m

Opción de ancho de PCB: 10 mm/12 mm

Opción de color: 2700K/3000K/4000K/5000K/6500K/RGB

Opción CRI: 80/90

Voltaje de entrada: AC120V/AC220V

Potencia por metro: 7W/10W

Opción de grado IP: IP67/IP68

Garantía: 3 años

Las tiras de LED de corriente constante ofrecen numerosas ventajas. Bajo la misma potencia nominal, las tiras de LED de corriente constante proporcionan un mayor brillo que las tiras de LED de voltaje constante. En comparación con las tiras LED de voltaje constante de bajo voltaje comúnmente utilizadas, experimentan una menor caída de voltaje, lo que garantiza un brillo uniforme desde el principio hasta el final de la tira.

¿Qué es una tira de LED de voltaje constante?

A Tira de LED de voltaje constante es una tira de LED basada en el control de voltaje constante, que impulsa los chips LED para emitir luz al emitir un voltaje estable desde la fuente de alimentación. Cada grupo de LEDs se conecta típicamente en serie en grupos de 3 a 6, según el voltaje requerido, para lograr el accionamiento de voltaje constante. Las tiras de LED de voltaje constante son uno de los tipos de tiras de LED más utilizados, con voltajes de funcionamiento generalmente establecidos en 12 V, 24 V, etc.

Su principio de funcionamiento se basa en la potencia de CC estable suministrada por una fuente de alimentación de voltaje constante. La estructura LED se diseña típicamente en configuraciones en paralelo o en serie, con resistencias de limitación de corriente para garantizar la compatibilidad con diferentes requisitos de carga en condiciones de voltaje constante. Si la salida de la fuente de alimentación es demasiado alta, el brillo del LED será excesivamente alto, acortando la vida útil; por el contrario, si la salida es demasiado baja, el brillo será insuficiente, afectando el rendimiento.

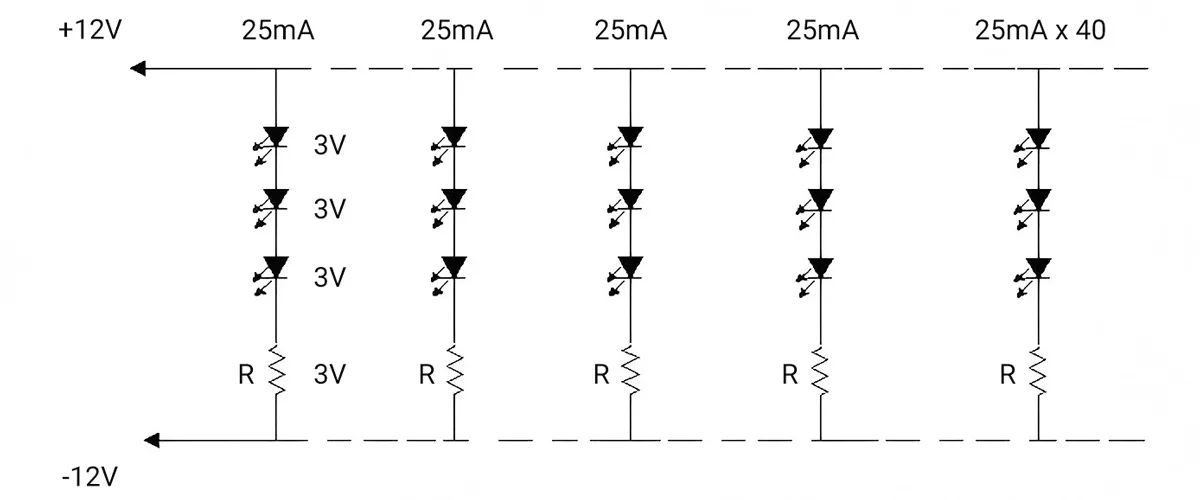

Por ejemplo, en una tira de 12 V LED, cada LED blanco tiene un voltaje de aproximadamente 3 V. Cuando se conectan tres LED en serie, el voltaje total es de 9 V. Por lo tanto, una fuente de alimentación de 12 V es adecuada para unidades compuestas por tres LED conectados en serie, con resistencias utilizadas para la división de voltaje de 3 V y la limitación de corriente. Si se requiere una potencia más alta, se pueden conectar múltiples unidades de este tipo en paralelo, siendo la corriente total la suma de las corrientes de cada unidad.

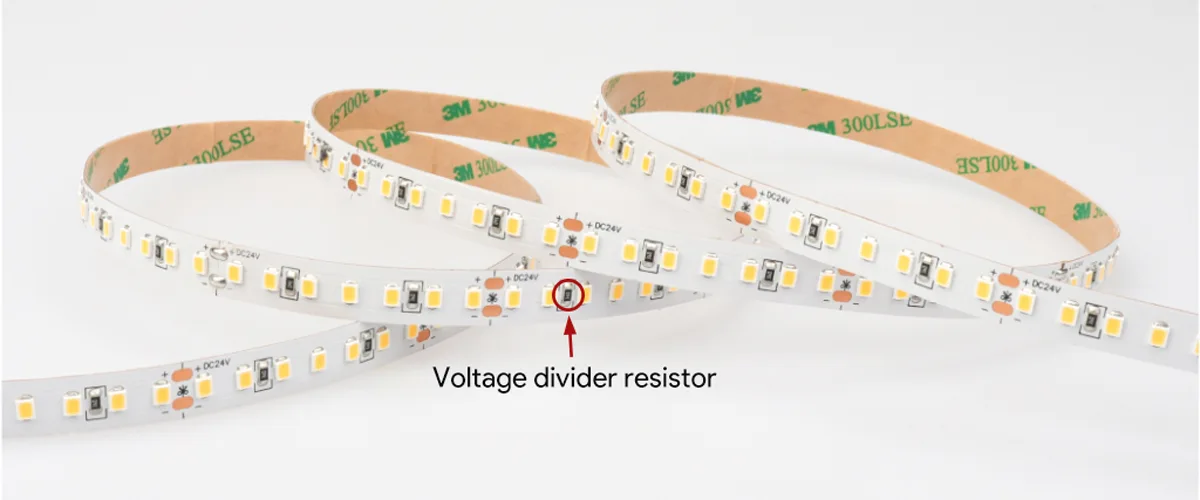

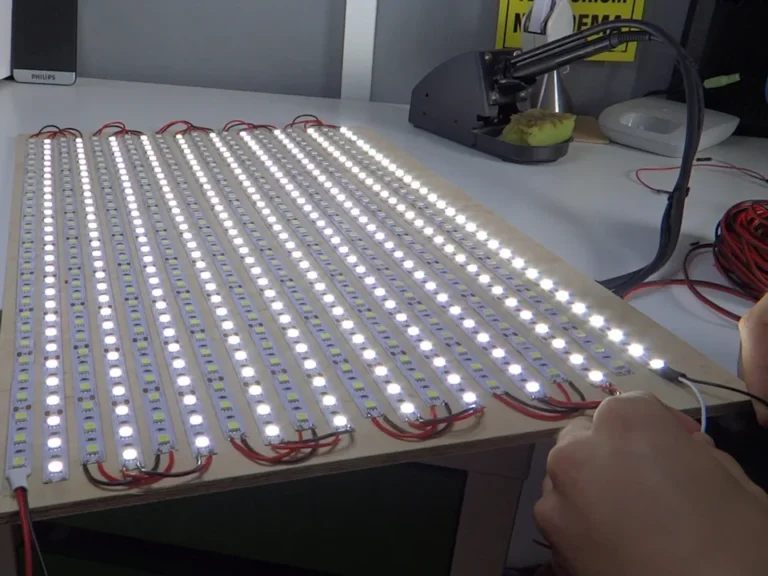

Como se muestra en la figura siguiente: Una pequeña tira de 2835 LED, con cada grupo que consta de 3 LED, cada grupo con un voltaje de 9V, es compatible con una fuente de alimentación de 12V. Una tira de 12 V de 12 V de 1 metro de largo contiene 120 LED (40 grupos × 3 LED), con cada grupo con aproximadamente 25 mA de corriente, lo que da como resultado una corriente total de 1A (40 grupos × 25mA) y una potencia total de 12W (12V × 1A).

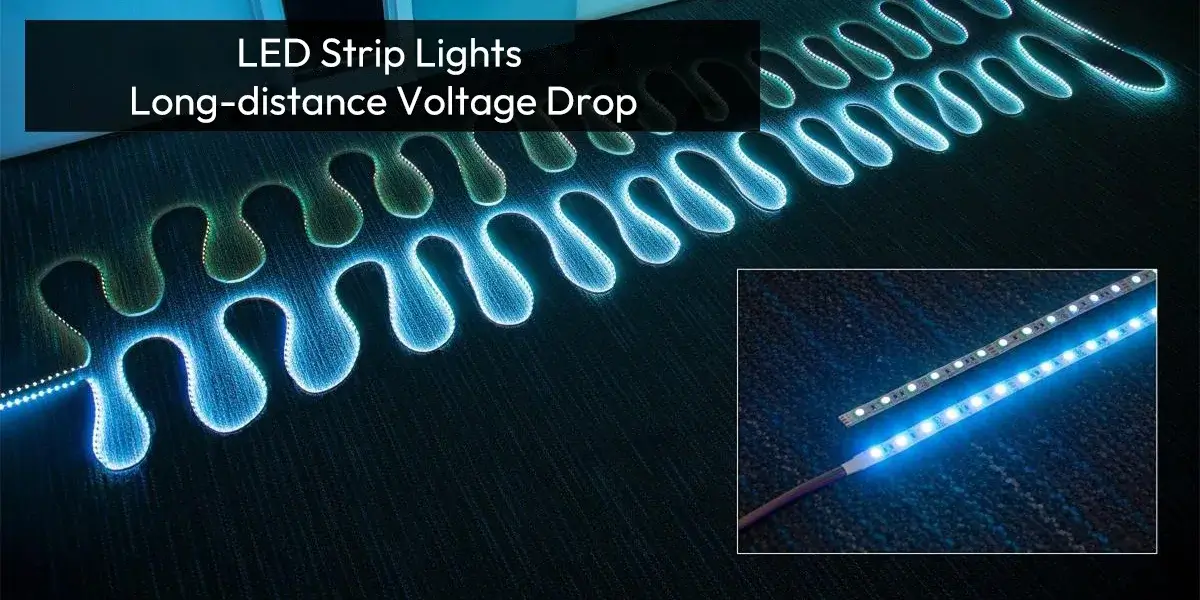

Las tiras de LED de voltaje constante son adecuadas para aplicaciones en las que el brillo y la estabilidad del color no son críticos, como la iluminación del gabinete de la cocina, la señalización o la iluminación decorativa, y admiten la tecnología de atenuación básica. Sin embargo, la longitud de la tira de LED es limitada (típicamente no más de 5 metros), y las longitudes más largas pueden dar lugar a una caída de voltaje y un brillo desigual en los extremos (la diferencia de brillo entre el principio y el final puede alcanzar 30%-50%).

En comparación con las tiras de LED de corriente constante, las tiras de LED de voltaje constante tienen una tensión de salida fija pero corriente fluctuante, lo que resulta en menores costos de instalación pero de menor uniformidad; las tiras de LED de corriente constante mantienen una corriente constante mientras el voltaje varía con la carga, lo que permite una fuente de alimentación de mayor distancia.

Tensión constante frente a corriente constante: ¿Qué tira de LED es mejor para proyectos comerciales?

Estabilidad

El inconveniente de las tiras de LED de voltaje constante es que cuando el Caídas de voltaje, la corriente puede disminuir significativamente. Cuando la longitud de la serie supera los 5 metros, el brillo de la tira de LED al principio y al final puede ser inconsistente, siendo la sección frontal más brillante y la sección trasera apareciendo más tenue.

Las tiras de LED de corriente constante mantienen una corriente constante mediante el uso de chips o transistores dedicados con adaptación de voltaje; incluso si el voltaje fluctúa dentro de un cierto rango, la corriente a través de cada LED permanece constante. Por lo tanto, la potencia permanece constante y el brillo de los LED delantero y trasero permanece constante.

La siguiente figura muestra la comparación de los datos de prueba de caída y potencia de tensión para nuestras tiras de luz LED de corriente continua y voltaje constante de CC de 24 V en distancias de 1 a 5 metros:

| Type | Classificación | 1M | 2m | 3m | 4m | 5m |

| CC LED Sviaje | Tensión | 23.84V | 23.45V | 22.83V | 22.0v | 21.02v |

| Potencia | 16.08W | 31.68W | 47.52W | 63.12W | 80.64W | |

| CV LED Sviaje | Tensión | 23.97V | 23.64V | 23.15v | 22.58V | 21.96V |

| Potencia | 16W | 31.2W | 44.44W | 55.92W | 65.4W |

A partir de los datos de comparación en la figura anterior, se puede ver que el voltaje de la tira de luz de corriente constante cae de 24V a 21V después de 5 metros, con una potencia de 80.64W. La potencia promedio por metro se calcula que es de 16W. La potencia después de 5 metros es muy cercana a la del primer medidor, lo que indica que la potencia permanece constante en todo momento.

Veamos ahora los datos para otra tira de voltaje constante. Después de 5 metros, la potencia es de 65,4 W, con una potencia media de aproximadamente 13 W por metro. Se puede ver que a medida que disminuye el voltaje, la potencia de la tira de voltaje constante cae significativamente después de 5 metros, con una disminución directa de aproximadamente 20%.

La disminución de potencia indica que la corriente también disminuye, lo que hace que los LED emitan menos luz que los de la parte delantera. Por lo tanto, en términos de estabilidad, las tiras de LED de corriente constante son superiores a las tiras de LED de voltaje constante.

Seguridad y fiabilidad

En tiras de LED de voltaje constante, incluso las fluctuaciones de voltaje menores pueden causar cambios significativos en la corriente. Si un LED en el circuito se corta y falla, puede hacer que el voltaje de otros LED aumente, lo que provoca un aumento en la corriente y también daña esos LED.

Los controladores de corriente constante admiten conexiones mixtas y en paralelo, y cada serie de LED recibe corriente constante independiente. Si un LED se corta, el chip del conductor ajusta automáticamente el voltaje para garantizar que otros LED continúen funcionando normalmente. Por lo tanto, incluso si falla un solo LED, los LED restantes de una tira de LED de corriente constante continúan funcionando normalmente.

Vida útil

El accionamiento de corriente constante mantiene una corriente constante mediante un control de circuito cerrado (con una precisión de ±0.3%), incluso cuando el voltaje de entrada fluctúa en ±15% o los cambios de temperatura, evitando así problemas como el sobrecalentamiento del LED, decaimiento acelerado de la luz o quemadura causada por cambios repentinos en la corriente. Los datos de laboratorio muestran que la solución de corriente constante puede controlar el decaimiento de la luz durante 5 años a ≤10%, mientras que la solución de voltaje constante puede reducir a la mitad la vida útil cuando el voltaje fluctúa.

Para obtener más información sobre la vida útil de la tira de luz LED, lea la publicación del blog "Vida útil de la tira de luz LED: ¿cuánto duran y por qué?”

Instalación y mantenimiento

Las tiras de LED de voltaje constante o de corriente constante tienen métodos de conexión de voltaje fijo y de conexión flexible, lo que permite la expansión de la energía a través de una conexión en paralelo, adecuadas para escenarios que requieren montaje flexible (por ejemplo, diseños de tiras de LED personalizadas). Para tiras de LED de voltaje constante instaladas a largas distancias (>5 metros) o tiras de LED de corriente constante instaladas a largas distancias (>8 metros), se deben tomar medidas para mitigar los efectos de la caída de voltaje en el circuito. Esto implica instalar una compensación de potencia para evitar que la caída de voltaje cause una reducción del brillo del LED y una salida de luz inestable.

Además, la potencia total de la tira de luz y la fuente de alimentación debe ser igualmente igualada. Si hay demasiadas unidades conectadas en paralelo, la corriente total puede exceder la corriente nominal de la fuente de alimentación, causando sobrecalentamiento o daño. Por ejemplo, una fuente de alimentación de 12 V con una corriente nominal de 2A puede impulsar una corriente de carga total de hasta 2A (por ejemplo, 100 grupos de 3 LED conectados en paralelo, cada grupo dibuja 20mA; sobrecargar esto causará una sobrecarga).

Las tiras LED de voltaje constante convencional pueden ver su brillo cayendo por debajo de 70% después de tres años, mientras que las tiras LED de corriente constante mantienen una tasa de retención de brillo de ≥95% después de tres años, con una reducción de 70% en la decadencia de la luz. El fallo de un solo LED no afecta el funcionamiento general, eliminando la necesidad de reemplazar toda la sección.

Coste

Las tiras de LED de voltaje constante son rentables, tienen circuitos simples y se pueden cortar libremente para adaptarse a formas curvas sin el riesgo de cambios repentinos de corriente después del corte. Adecuado para iluminación decorativa de corta distancia (≤5 metros), las tiras LED de corriente constante son relativamente más caras, tienen un circuito más complejo y tienen un costo significativamente mayor en comparación con las tiras de voltaje constante. Los precios varían ampliamente, desde $1 (corriente constante basada en transistores) hasta $7 (tiras LED que cambian de color). Se recomienda seleccionar el producto adecuado en función de los requisitos específicos (como estabilidad de brillo, entorno de instalación, etc.) y presupuesto.

Tabla de decisión de selección de proyectos comerciales

| Indicadores clave | Solución de corriente constante | Solución de voltaje constante |

| Distancia de instalación | >8 metros (brillo uniforme) | ≤3 metros (se requiere prevención de caída de voltaje) |

| Rendimiento de vida útil | 5 años con decaimiento de la luz ≤10% | Las fluctuaciones de voltaje a la mitad de la vida útil |

| Costo | 30%–50% Premium (alto rendimiento a largo plazo) | Costo inicial bajo (apto para restricciones presupuestarias) |

| Riesgo central | bajo riesgo | Problemas de control de corriente debido a fluctuaciones de voltaje |

La elección de la tira de LED depende de los requisitos de aplicación específicos. SignLiteled ofrece una variedad de opciones de productos relacionados, que incluyen tiras de LED de corriente constante y tiras de LED de voltaje constante, para satisfacer sus diversas necesidades. Las tiras de LED de corriente constante son más adecuadas para aplicaciones de gran escala, mientras que las tiras de LED de voltaje constante son ideales para escenarios sensibles a costos que requieren un ajuste flexible de las cantidades de LED.

En proyectos de iluminación comercial, las tiras de luces LED de corriente constante son la solución preferida para la mayoría de los escenarios, ya que superan significativamente las soluciones de voltaje constante en términos de estabilidad de brillo, vida útil y seguridad. Las tiras de luces de tiras de corriente constante son adecuadas para iluminación industrial de alta potencia, instalaciones de larga distancia y escenarios de atenuación inteligente (como salas de exhibición de centros comerciales). Las luces de tira de voltaje constante tienen una ventaja de costo, ofrecen una instalación flexible y son adecuadas para escenarios de pequeña escala.

Cómo Identificar Cactuando Vvoltaje Power Sapps y Cactuando Current DRíos para LED Sviajes

constante Vvoltaje Power Supply: La etiqueta suele indicar “Salida: CC 12V 3A”, “24V 5A”, etc., especificando claramente los valores de voltaje y corriente. Potencia = voltaje × corriente (por ejemplo, 12 V × 3A = 36W).

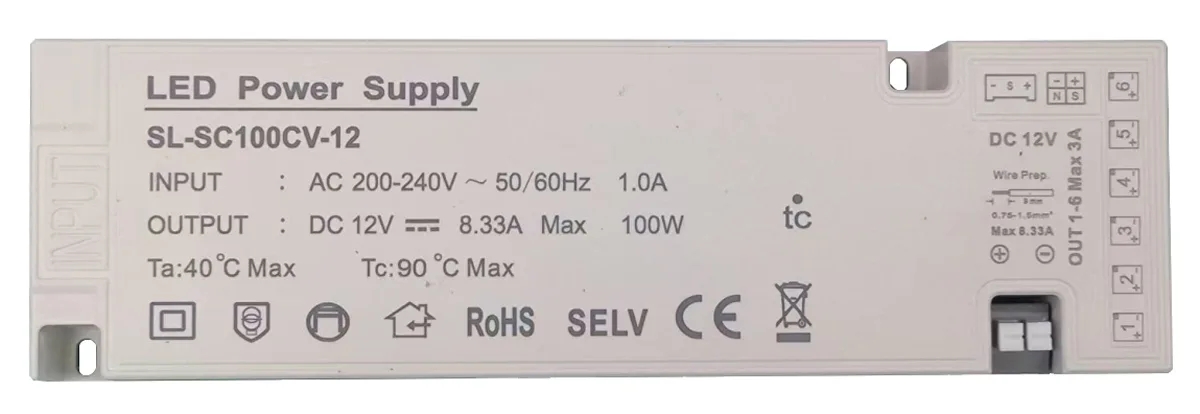

Como se muestra en la figura siguiente, este es un controlador de voltaje constante producido por SignLiteled. La etiqueta indica “Salida” como un valor fijo de “DC 12V 8.33A” (corriente de salida máxima), lo que significa que la corriente es variable, con una corriente máxima de funcionamiento de 8.33A. La potencia de potencia de la fuente de alimentación es de 100W.

Conductor de corriente constante: La etiqueta especifica “Salida: 300mA 30-100V” o “600mA 40-120V”, etc., con un valor de corriente fijo y un rango de voltaje. Potencia = voltaje máximo × corriente (por ejemplo, 100 V × 0.3A = 30W). El controlador especifica la corriente de salida como un valor fijo.

Notas importantes para reemplazar la fuente de alimentación

El voltaje debe ser estrictamente igualado y la corriente puede ser ligeramente superior a la fuente de alimentación original (por ejemplo, si la fuente de alimentación original es de 12 V/1A, puede reemplazarse con 12 V/2 A), pero no debe ser inferior a la corriente original; de lo contrario, puede causar brillo o parpadeo de la luminaria.

El valor de corriente debe coincidir, y el rango de voltaje debe incluir el voltaje total de los LED originales. Por ejemplo, si el dispositivo original utiliza 30 LED blancos en serie (tensión total de 90 V), seleccione una fuente de alimentación con la misma corriente y un rango de voltaje que incluya 90 V (por ejemplo, 600 mA 40-120 V).

Ya sea que utilice un modo de voltaje constante o un modo de corriente constante con ajuste de voltaje dinámico, el objetivo principal es garantizar que los LED funcionen dentro de los límites de voltaje y corriente seguros.

Como usuario, simplemente recuerde los siguientes puntos clave: Compruebe los parámetros de entrada/salida especificados en el producto, asegúrese de que la fuente de alimentación del conductor coincida con las especificaciones del dispositivo y evite el cableado directo o las dispares de parámetros. Al comprender y operar correctamente el sistema, puede aprovechar completamente las ventajas energéticamente eficientes de la iluminación LED al mismo tiempo que garantiza un uso seguro.

Conclusión

En los proyectos de iluminación comercial, las tiras de LED de corriente constante se han convertido en la opción preferida para la gran mayoría de los proyectos de mediana y gran escala debido a su control de corriente estable, su excelente consistencia de brillo, una mayor vida útil y mayor seguridad. Son especialmente adecuados para centros comerciales, fachadas de hoteles, iluminación industrial y escenarios que requieren cableado de larga distancia.

En contraste, las tiras de luces LED de voltaje constante sobresalen en términos de circuitos simples, menores costos y de instalación flexible, haciéndolos más adecuados para espacios reducidos, iluminación decorativa o proyectos sensibles al presupuesto.

Por lo tanto, al seleccionar una solución, debe sopesar los factores como la escala del proyecto, la distancia de instalación, el presupuesto y los requisitos para el rendimiento de la iluminación. Si la operación estable a largo plazo y la salida de luz de alta calidad son prioridades, se debe preferir la solución de corriente constante, mientras que las soluciones de voltaje constante son suficientes para la iluminación de acento a pequeña escala.

Además, en aplicaciones de ingeniería reales, la selección y la combinación de la fuente de alimentación adecuada del conductor y la estrictamente cumplimiento de los estándares de instalación son esenciales para aprovechar al máximo las ventajas de las tiras de LED.

Como proveedor profesional de iluminación de tiras LED, SignLiteleted ofrece una variedad de Soluciones de tira de LED de voltaje constante y de corriente constante Para ayudarle a equilibrar el control de costos y el rendimiento de la iluminación en proyectos comerciales, logrando el mejor retorno de la inversión.

PREGUNTAS FRECUENTES

un: Las tiras de LED de corriente constante mantienen una corriente constante, y las fluctuaciones en el voltaje de entrada de hasta 15% no afectan la corriente constante, lo que permite que los LED funcionen de manera más estable. En comparación con las tiras de LED de voltaje constante, tienen una vida útil más larga.

un: Estas tiras son tiras de alto voltaje que integran una fuente de alimentación del controlador en miniatura en la parte delantera, convirtiendo 220 V CA a CC adecuadas para LED. Aunque no se ven componentes del controlador externo, todavía confían en la fuente de alimentación del conductor para funcionar.

un: prohibido Ambos deben cumplir con los mismos requisitos de corriente y cubrir el rango de voltaje total del LED. Por ejemplo, no se puede utilizar una fuente de alimentación de 300 mA con una fuente de alimentación de 600 mA. El primero puede resultar en un brillo insuficiente del LED debido a una corriente insuficiente, mientras que el segundo puede dañar los LED debido a una corriente excesiva.

un: Iluminación de larga distancia de más de 5 metros, como iluminación de fachada de edificios; requisitos de atenuación precisos, como vitrinas de museo, iluminación médica, proyectos al aire libre y entornos industriales.

un: Sí. Esto se debe a que cuando se instalan tiras de LED de corriente constante de bajo voltaje (por ejemplo, 24 V) en distancias superiores a 5 metros, la caída de voltaje en el circuito supera los 10%. Para distancias superiores a 5 metros, se requiere una fuente de alimentación segmentada o puntos de inyección de energía adicionales al final del circuito.

Alguien esencialmente echa una mano para hacer publicaciones significativas. Podría decir que es la primera vez que frecuentaba su página web y hasta ahora me sorprendió con la investigación que hizo para crear este lugar en particular.

Su escritura es un verdadero testimonio de su experiencia y dedicación a su oficio. Estoy continuamente impresionado por la profundidad de su conocimiento y la claridad de sus explicaciones. ¡Sigan con el trabajo fenomenal!