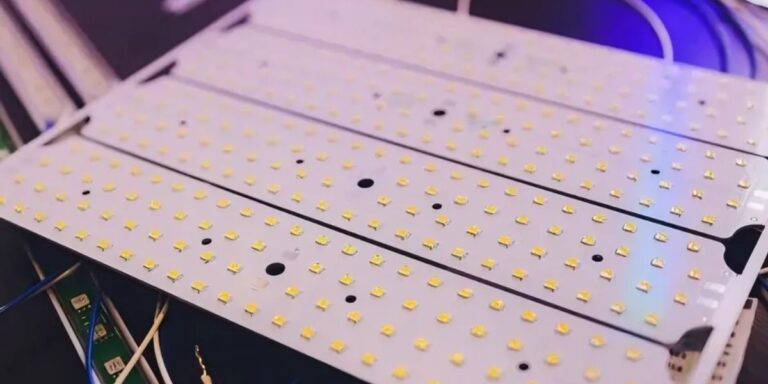

Prototipos rápidos de 3 a 5 días en el conjunto de PCB LED se refiere a producir una muestra de PCB LED funcional de cantidad limitada dentro de una ventana de fabricación comprimida. No significa saltarse pasos o apresurarse a los diseños incompletos. La velocidad de respuesta depende de la preparación del diseño, la disponibilidad de componentes confirmados y un alcance de ensamblaje claramente definido. Cuando estas condiciones se alinean, las compilaciones de prototipos acelerados se pueden lograr sin cambiar el proceso de fabricación subyacente.

Qué significa “prototipado rápido de 3 a 5 días” en el ensamblaje de PCB LED

La creación rápida de prototipos describe un atajo controlado a través de los tiempos de entrega estándar, no un atajo a través de la disciplina de ingeniería. La salida es un prototipo, no un lote listo para la producción. El objetivo es la validación, no el volumen.

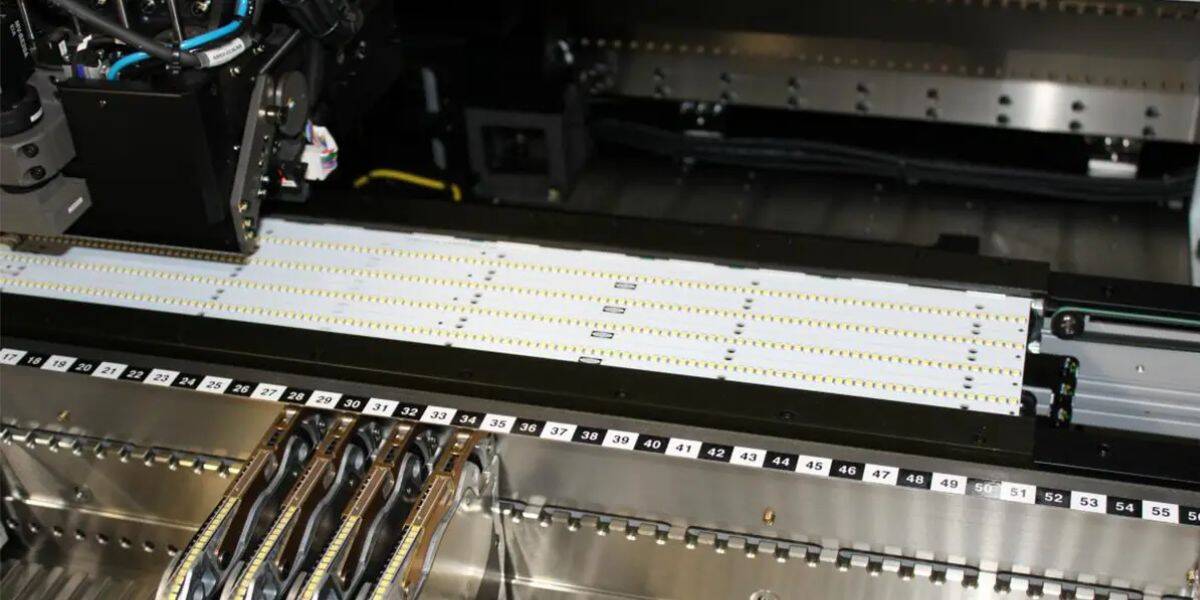

El ensamblaje de PCB LED conlleva restricciones más estrictas que muchos otros tipos de placas. Las trayectorias térmicas, la precisión de la colocación de LED y la consistencia de la corriente importan de inmediato, incluso en la etapa de prototipo. Debido a esto, la creación rápida de prototipos se enfoca en tableros que ya son fabricables, no se siguen explorando diseños.

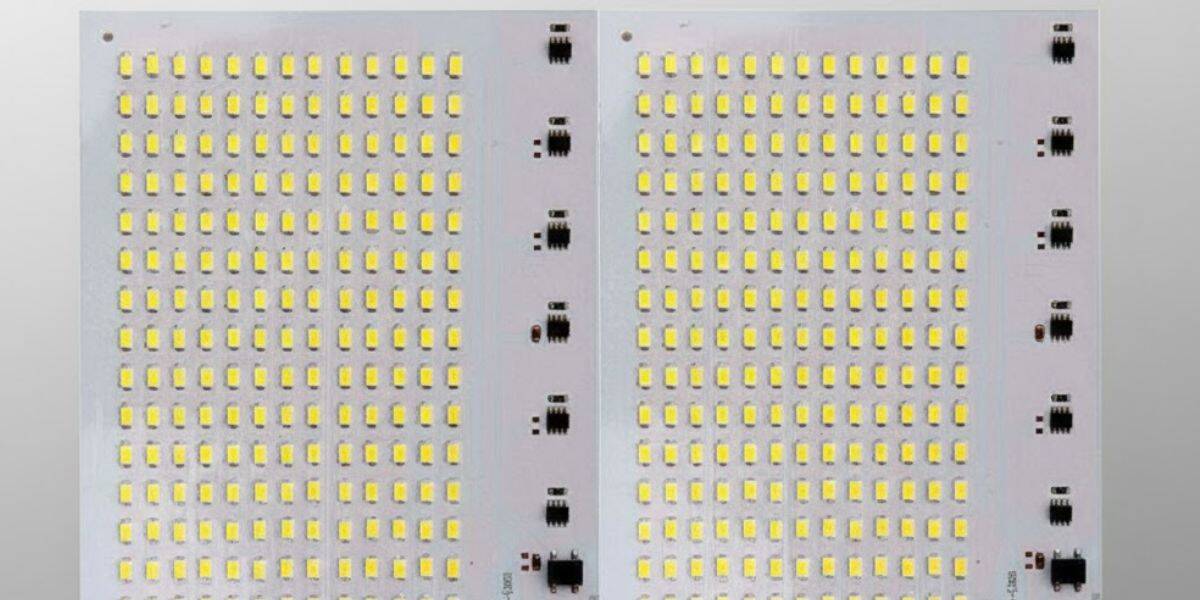

En términos prácticos, la creación rápida de prototipos de 3 a 5 días generalmente incluye la fabricación de tableros desnudos, la colocación de los componentes LED y del controlador disponibles y la verificación funcional básica. Excluye la optimización de procesos, la quemadura extendida y la optimización cosmética que pertenecen a etapas posteriores.

Flujo de trabajo típico detrás de la creación de prototipos de PCB LED rápido

La entrega rápida solo es posible cuando el flujo de trabajo sigue siendo predecible. El proceso no cambia, pero las prioridades sí.

La preparación para el diseño es la primera puerta. Los archivos deben ser finales, revisados internamente y libres de preguntas abiertas. No hay búfer de tiempo para los ciclos de aclaración.

El abastecimiento de componentes sigue a la realidad, no a la intención. Solo se pueden usar piezas que estén en stock, aprobadas y ya calificadas para el montaje. Las sustituciones lo ralentizan todo.

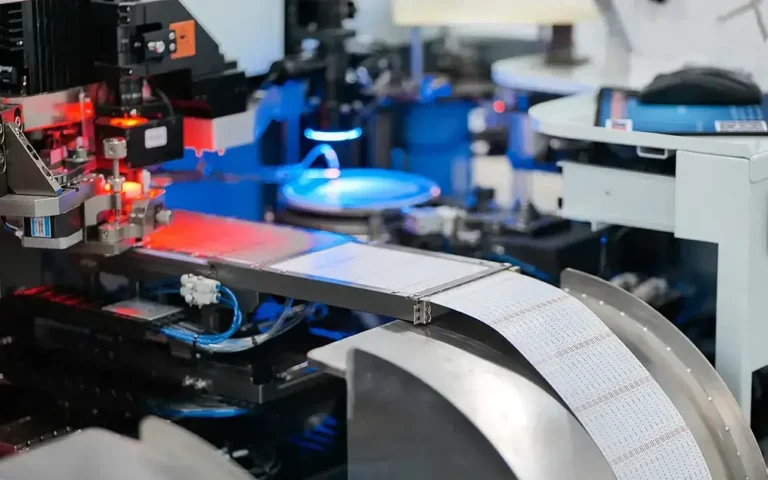

La priorización de ensamblaje ocurre en el nivel de programación. Los trabajos de prototipo se colocan en líneas existentes entre series de producción o se asignan a la capacidad de giro rápido.

El alcance de la prueba está intencionalmente limitado. El objetivo es la confirmación de que la placa funciona según lo diseñado, no la caracterización de la fiabilidad total.

La velocidad se logra reduciendo la incertidumbre, no comprimiendo la física.

Factores que permiten la respuesta de 3 a 5 días

1. Completitud del diseño y fabricación

Un diseño completo es el predictor más fuerte de entrega rápida. Los Gerbers, los datos de pick-and-place y las listas de materiales deben alinearse sin interpretación. Las placas LED que ya siguen las huellas estándar, las reglas de espaciado y las estrategias térmicas se mueven rápidamente.

- Los errores de diseño menores a menudo causan reinicios de programación completa

- La claridad de DFM es más importante que el diseño de la novedad

2. Disponibilidad de componentes para conjuntos de LED

Los componentes LED no son intercambiables en el último minuto. Las bandejas ópticas, las clases de voltaje y los tipos de paquetes limitan la flexibilidad. La creación rápida de prototipos se basa en componentes que ya están almacenados o de origen local.

- Los LED de plomo largo eliminan cualquier posibilidad de compilaciones de 3 a 5 días

- La disponibilidad de IC del conductor a menudo se convierte en el cuello de botella

3. Configuración de la línea de montaje para placas LED

No todas las líneas SMT son igualmente adecuadas para el trabajo LED. Los tableros que requieren un manejo especial, el alto peso de cobre o los pasos de la interfaz térmica disminuyen el rendimiento. Las líneas ya configuradas para la colocación de LED permiten transiciones más rápidas entre trabajos.

4. Límites de prueba e inspección

Los prototipos rápidos se someten a una inspección enfocada. Las comprobaciones eléctricas y la validación funcional básica son típicas. Se aplazan el envejecimiento prolongado, la medición fotométrica o las pruebas ambientales. Esta limitación es intencional y necesaria para proteger los plazos.

Cuando la creación de prototipos de PCB LED de 3 a 5 días es realista, y cuando no lo es

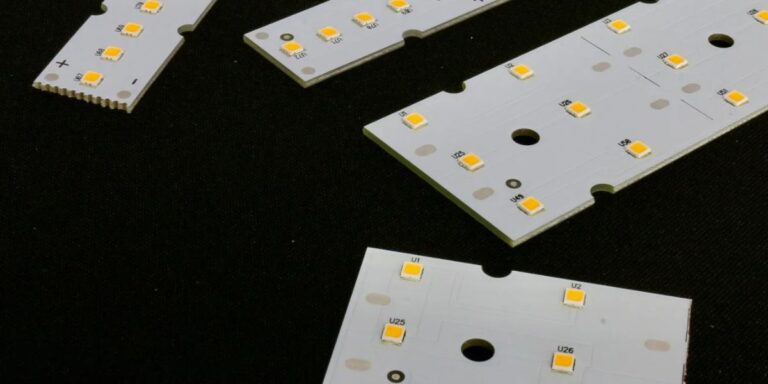

La creación rápida de prototipos es realista para diseños de PCB LED simples a moderadamente complejos que reutilizan arquitecturas conocidas. Los módulos de LED lineales, las integraciones básicas de controladores y los diseños de placa única encajan bien en los plazos acelerados.

Se vuelve poco realista cuando los diseños introducen múltiples tipos de LED, estructuras térmicas novedosas o diseños no probados. Cada variable añadida aumenta el esfuerzo y el riesgo de coordinación.

Los plazos perdidos generalmente provienen de brechas de expectativas. Los ingenieros esperan velocidad a pesar de los detalles de diseño no resueltos. La contratación espera velocidad a pesar de la oferta de componentes inciertos. La fabricación solo puede moverse tan rápido como lo permitan las entradas.

Comprender estos límites evita la frustración en todos los lados.

Función de las consideraciones de ensamblaje específicas de LED

El ensamblaje del LED de PCB introduce restricciones que afectan la velocidad incluso en la etapa del prototipo. La precisión de la colocación de LED afecta directamente el rendimiento óptico y no se puede tratar de manera casual. El retrabajo es limitado una vez que se montan los LED.

Los caminos térmicos deben ser continuos e intencionales. Las interfaces térmicas deficientes se revelan rápidamente durante el encendido inicial, a menudo deteniendo las pruebas adicionales.

El comportamiento a nivel del sistema importa temprano. Incluso los prototipos deben manejar la propagación del calor, el equilibrio actual y la alineación mecánica. Estas realidades explican por qué el prototipo rápido de recompensas recompensa los diseños maduros y penaliza a los exploratorios.

Qué tan rápido la creación de prototipos admite las decisiones de ensamblaje de PCB personalizadas

Existen prototipos rápidos para reducir la incertidumbre antes del compromiso. Los ingenieros los usan para verificar las suposiciones de diseño, confirmar el comportamiento eléctrico y observar la respuesta térmica en condiciones reales.

Desde el punto de vista de la decisión, Ensamble de PCB personalizado La planificación se beneficia de las primeras señales. Un prototipo puede confirmar que un diseño está listo para escalar o revelar que se requiere una revisión antes de la inversión en volumen.

Los equipos de adquisiciones también se benefician. Las primeras compilaciones exponen los riesgos de abastecimiento y ayudan a validar si los componentes planificados admiten cronogramas realistas.

La creación rápida de prototipos no se trata solo de velocidad. Se trata de la toma de decisiones informadas.

Qué tan rápido encaja la creación de prototipos en las tuberías de fabricación de PCB personalizadas

La creación rápida de prototipos ocupa una posición estrecha pero crítica en el flujo de fabricación de PCB personalizado más amplio.

| plataforma | Propósito | expectativa de velocidad |

| prototipo | Validación funcional | Alcance rápido y limitado |

| vigencia | Refinamiento de diseño | estándar |

| modificación | Corrección de emisión | cambiable |

| gama | producción estable | Plazos de entrega planificados |

La creación rápida de prototipos termina una vez que se establece la confianza en el diseño. La fabricación estándar comienza cuando la consistencia, el rendimiento y la repetibilidad se convierten en prioridades.

Tratar de estirar los métodos de giro rápido a la producción crea riesgos de calidad y de programación.

Malentendidos comunes sobre el prototipo rápido de PCB

Una creencia común es que rápido significa baja calidad. En realidad, la calidad depende de la disciplina de diseño, no de la duración del horario. Los prototipos rápidos cumplen con los controles definidos pero evitan los innecesarios.

Otro malentendido es que cada diseño califica. La entrega rápida favorece los diseños que ya son estables. Los conceptos de etapa inicial rara vez encajan.

Una tercera suposición es que los prototipos representan el producto final. Los prototipos responden preguntas. No definen la preparación de la producción por su cuenta.

Aclarar estos puntos evita las expectativas desalineadas.

Conclusión

Prototipos rápidos de 3 a 5 días en el ensamblaje de PCB LED significa producir un prototipo de PCB LED funcional dentro de un marco de tiempo comprimido pero controlado. Depende de la preparación del diseño, la disponibilidad de componentes y el alcance de ensamblaje limitado. No es una promesa de velocidad para cada proyecto, ni un sustituto de los procesos de producción estándar. Cuando se usa correctamente, Fast Prototyping proporciona una visión técnica temprana y respalda mejores decisiones de producción de PCB personalizadas.

Preguntas frecuentes

Fast Prototyping es la producción acelerada de una muestra de PCB LED de cantidad limitada enfocada en la validación funcional en lugar de la calificación completa.

prohibido . Solo los diseños que son completos, fabricables y compatibles con componentes disponibles se ajustan a este período de tiempo.

Los componentes de plomo no disponible o de larga duración extienden inmediatamente los plazos, independientemente de la capacidad de fabricación.

prohibido . Reduce el alcance de las pruebas, no la precisión del ensamblaje o la integridad funcional básica.

La fabricación estándar de PCB personalizada es apropiada una vez que se valida el diseño y la producción repetible se convierte en el objetivo.