Los dispositivos de protección contra sobretensiones (SPD) se clasifican como Tipo 1, Tipo 2 y Tipo 3 para reflejar dónde operan dentro de un sistema eléctrico y cómo administran la energía de sobretensión en ese lugar. Estos tipos no son intercambiables. Cada uno está diseñado para un entorno de sobretensión y una función de protección específica, y solo funcionan correctamente cuando se aplican como parte de un sistema coordinado.

Este artículo es una guía técnica comparativa. No reintroduce los fundamentos de la protección contra sobretensiones. En cambio, se centra en cómo los SPD de tipo 1, tipo 2 y tipo 3 difieren en función de la interacción de roles, capacidad y sistema, y cómo los ingenieros determinan la ubicación correcta en instalaciones eléctricas reales.

Marco de comparación: cómo se diferencian los tipos SPD

La clasificación SPD no se basa en el tamaño del producto, el precio o la robustez percibida. Se basa en la posición de instalación y la exposición de sobretensión esperada.

A medida que la energía de sobretensión viaja a través de un sistema eléctrico, sus características cambian:

- La magnitud de la corriente de sobretensión disminuye

- La forma de onda evoluciona

- La tensión residual sigue siendo peligrosa para el equipo sensible

Debido a este comportamiento, la protección contra sobretensiones se divide en zonas. Cada tipo de SPD está diseñado para operar dentro de una zona específica, donde puede manejar el estrés por sobretensión sin estar sobrecargado o bajo rendimiento.

La comparación entre los SPD de tipo 1, tipo 2 y tipo 3 siempre debe considerar:

- Ubicación de instalación

- Nivel de energía de sobretensión esperado

- Función de protección primaria

- Dependencia de otros tipos de SPD

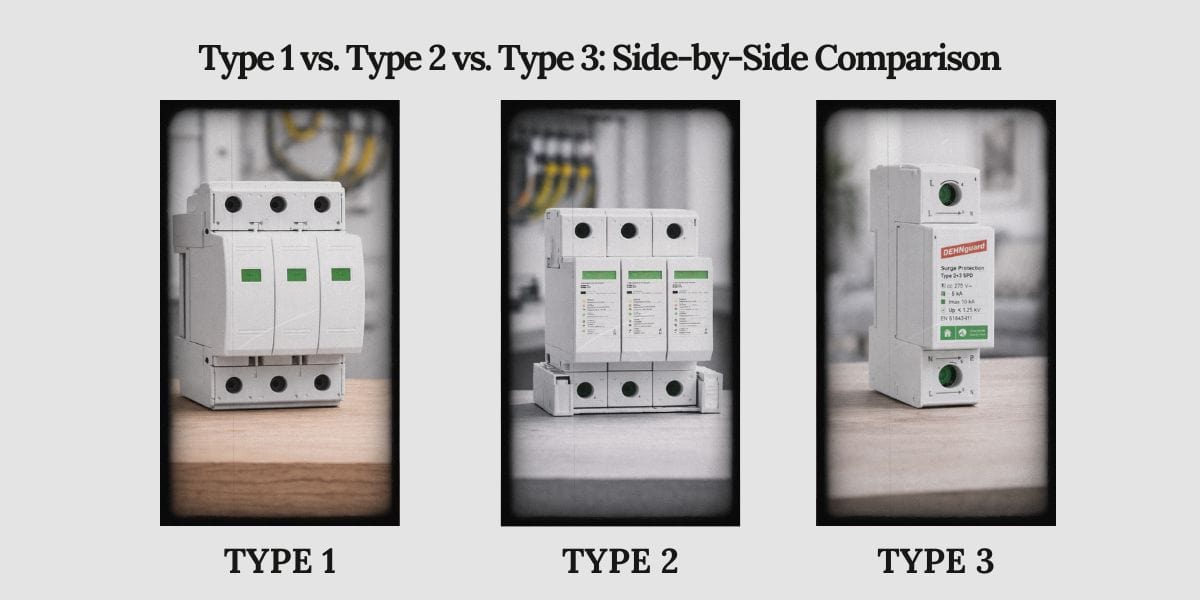

Tipo 1 frente a Tipo 2 frente a Tipo 3: Comparación lado a lado

| Parámetro | Tipo 1 SPD | Tipo 2 SPD | Tipo 3 SPD |

| Ubicación típica de instalación | Entrada de servicio, lado de línea de la desconexión principal | Paneles de distribución, lado de carga de desconexión | Equipo casi sensible |

| Nivel de exposición a sobretensiones | muy alto | de medio a alto | Bajo |

| Función principal | desviar corriente de sobretensión entrante | Abrazaderas residuales y picos de conmutación | Limitación de voltaje fina |

| Manejo de corriente de sobretensión | muy alto | Moderado a alto | Bajo |

| Precisión de sujeción de voltaje | Bajo | Medio | Alta |

| Idoneidad independiente | No | limitado | No |

| Dependencia de otros SPD | Requiere Tipo 2 aguas abajo | A menudo emparejado con el Tipo 1 y el Tipo 3 | Requiere Tipo 1 o Tipo 2 Ascendente |

| Riesgo típico si se aplica incorrectamente | Protección inadecuada del equipo | Sobrecarga y reducción de la vida útil | fracaso catastrófico |

Esta comparación destaca un principio clave: Tipos de SPD se definen por la función y la ubicación, no por la clasificación de rendimiento.

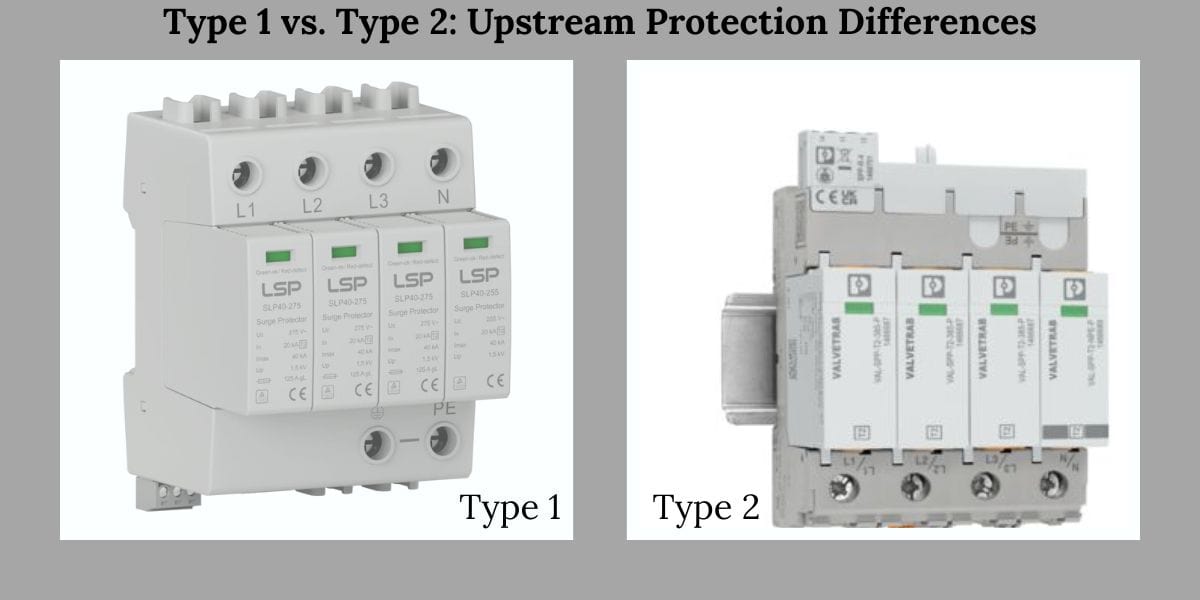

Tipo 1 vs. Tipo 2: Diferencias de protección ascendente

Contexto de instalación

Los SPD de tipo 1 se instalan en la entrada de servicio, donde la exposición de sobretensiones externa es más alta. Los SPD de tipo 2 se instalan aguas abajo, dentro del sistema de distribución interno.

Esta diferencia posicional cambia fundamentalmente lo que se espera que maneje cada dispositivo.

Perfil de energía de sobretensión

- SPD tipo 1 Encuentre impulsos de alta energía asociados con eventos relacionados con Lightning que ingresan desde la red de servicios públicos.

- SPD tipo 2 Encuentre energía residual de rayos y transitorios de conmutación frecuentes generados internamente.

Debido a que los dispositivos de tipo 2 no están diseñados para los impulsos de energía más altos, no pueden reemplazar la protección de tipo 1 en la entrada de servicio.

Distinción funcional

- El tipo 1 se centra en el desvío de corriente de sobretensión

- El tipo 2 se enfoca en la limitación de voltaje y el control de sobretensiones repetitivo

La instalación de protección de tipo 2 en entornos de alta exposición desplaza el estrés excesivo hacia los dispositivos que no están diseñados para ello, lo que lleva a una degradación prematura.

Tipo 2 frente a Tipo 3: Distribución frente a Protección a nivel de equipo

Proximidad de instalación

Los SPD de tipo 2 protegen las redes de distribución, mientras que los SPD de tipo 3 protegen equipos o circuitos individuales. La distancia entre el SPD y la carga protegida es un diferenciador crítico.

Control de voltaje residual

Después de la protección aguas arriba, el voltaje transitorio residual aún puede superar la capacidad de resistencia al impulso de la electrónica sensible. Los SPD de tipo 3 proporcionan un refinamiento de voltaje fino en el punto de uso.

Limitación de manejo de energía

Los SPD de tipo 3 no están diseñados para absorber la energía de sobretensión. Si se expone directamente a eventos de alta energía, pueden fallar rápidamente. Por eso nunca deben usarse sin protección upstream.

La comparación entre el Tipo 2 y el Tipo 3 no se trata de "mejor", sino de dónde reemplaza la precisión el manejo de energía.

Por qué ningún tipo SPD es suficiente

La protección contra sobretensiones no es aditiva. La instalación de varios dispositivos del mismo tipo no proporciona protección en capas.

Cada tipo SPD funciona de manera óptima solo dentro de su rango de esfuerzo previsto:

- El tipo 1 reduce la energía de sobretensión entrante

- El tipo 2 gestiona la sobretensión restante

- Tipo 3 Límites Tensión residual final

Al intentar realizar todas estas funciones con un solo dispositivo, se produce una protección comprometida, una vida útil más corta o ambas.

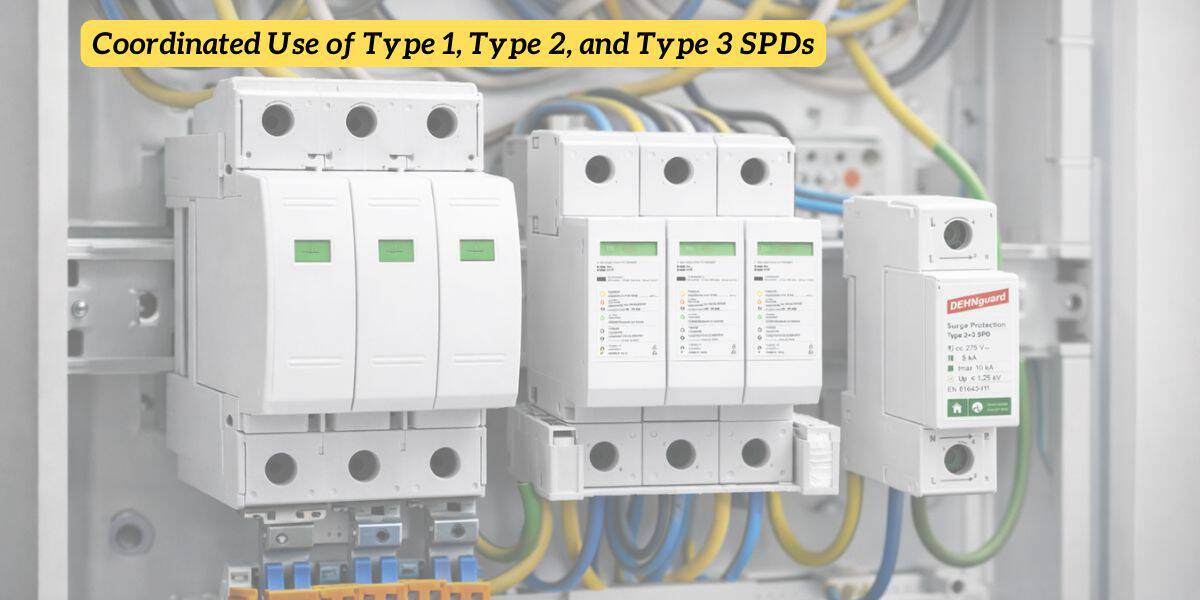

Uso coordinado de SPD de Tipo 1, Tipo 2 y Tipo 3

Cómo funciona la coordinación

Un sistema de protección contra sobretensiones coordinado refleja la forma en que se propaga la energía de sobretensión:

- Tipo 1 Desvía impulsos de alta energía al entrar en el sistema

- Tipo 2 Abrazaderas restantes sobretensiones dentro del sistema de distribución

- Tipo 3 Protege cargas sensibles de voltaje residual

Cada etapa reduce el estrés en la siguiente.

Por qué la coordinación importa más que la cantidad

La coordinación incorrecta puede causar:

- Compartir energía desigual

- Sobrecalentamiento localizado

- Comportamiento de falla impredecible

La colocación correcta y la separación de impedancia son más importantes que la instalación de dispositivos adicionales.

Escenarios de comparación basados en aplicaciones

Entrada de servicio con exposición externa

Las instalaciones con líneas de servicios públicos aéreos o infraestructura eléctrica exterior requieren protección tipo 1 en la entrada de servicio, seguida de protección de tipo 2 aguas abajo.

Sistemas de distribución comercial e industrial

Las operaciones de conmutación dominan la actividad de sobretensión. Los SPD de tipo 2 proporcionan el rol de protección principal, a menudo coordinado con dispositivos de tipo 1 ascendente.

Sistemas electrónicos sensibles

Los controladores de automatización, la instrumentación y las interfaces de comunicación requieren protección de tipo 3, pero solo cuando ya se ha reducido la energía de sobretensión ascendente.

Sistemas monofásicos frente a tres fases

una fase 3 Dispositivo de protección contra sobretensiones Debe gestionar de forma consistente los transitorios de fase a fase y de fase a tierra. La selección de tipo SPD debe alinearse con la configuración del sistema, no solo con la clasificación de voltaje.

Errores de comparación comunes que cometen los ingenieros

- Suponiendo que los dispositivos Tipo 3 pueden operar de forma independiente

- Sobredimensionar un SPD en lugar de coordinar varios tipos

- Instalación de múltiples dispositivos de tipo 2 sin considerar la impedancia

- Tratar los tipos de SPD como niveles de rendimiento en lugar de roles funcionales

Estos errores reducen la efectividad de la protección y aumentan el riesgo de mantenimiento.

Contexto de las normas

Estándares como UL 1449 e IEC 61643 definen las condiciones de prueba y los criterios de clasificación para los tipos SPD. Apoyan una comparación consistente, pero no reemplazan el juicio de ingeniería a nivel de sistema con respecto a la colocación y coordinación.

Conclusión

Los dispositivos de protección contra sobretensiones tipo 1, tipo 2 y tipo 3 cumplen funciones distintas y complementarias dentro de un sistema eléctrico. Sus diferencias se definen por la ubicación de la instalación, la exposición a la sobretensión y la función de protección, no por la clase de producto o la posición de marketing.

La protección efectiva contra sobretensiones depende de la coordinación, no de la sobredimensionamiento o de la redundancia. Cuando se aplica cada tipo SPD donde funciona mejor, la energía de sobretensión se controla progresivamente, se reduce la tensión del equipo y mejora la confiabilidad del sistema a largo plazo.

Preguntas frecuentes

prohibido . Los dispositivos de tipo 2 no están diseñados para los niveles de exposición de sobretensión más altos presentes en la entrada del sistema.

Solo indirectamente, y solo cuando la protección aguas arriba ya ha reducido la energía de sobretensión.

En entornos de baja exposición puede ser aceptable, pero el riesgo aumenta significativamente sin protección aguas arriba.

Porque la colocación incorrecta puede sobrecargar los dispositivos independientemente de la clasificación.

No siempre, pero la mayoría de las instalaciones modernas se benefician de al menos la coordinación de Tipo 1 y Tipo 2.