Las tiras de luces LED UV se están convirtiendo cada vez más en una fuente de luz clave en proyectos industriales y comerciales. Son ampliamente utilizados en sistemas de curado, detección de fluorescencia, identificación antifalsificación, iluminación de escenario, iluminación de acuarios, esterilización y purificación.

Entre todas las longitudes de onda UV, 365 nm y 395 nm son las dos longitudes de onda más utilizadas. Ambos pertenecen al rango UVA (Ultravioleta de onda larga), pero muestran diferencias significativas en las características espectrales, efectos de excitación y escenarios de aplicación. Comprender las distinciones entre estas dos longitudes de onda permite a los ingenieros, al personal de adquisiciones y a los integradores de proyectos realizar selecciones más precisas para aplicaciones específicas.

Este artículo comparará sistemáticamente el rendimiento, las aplicaciones, los precios y la seguridad de las luces de tira de LED UV de 365 nm y 395 nm, lo que le ayuda a seleccionar rápidamente el producto adecuado en función de los requisitos del proyecto y recomendando soluciones adecuadas.

Luces de tira de 365 nm frente a 395 nm LED: ¿cuál es mejor?

Aunque tanto los 365 nm como los 395 nm caen dentro del espectro UVA, muestran diferencias significativas en sus características luminosas, capacidades de excitación, efectos visuales, aplicaciones adecuadas y estructuras de costos en aplicaciones prácticas.

La luz UV de 365 nm se usa más comúnmente en aplicaciones científicas e industriales debido a su mayor invisibilidad, mayor penetración y falta de interferencia con la luz visible. La luz de 395 nm tiene un espectro más cercano a la luz visible, lo que facilita la visualización del ojo humano. Si bien la longitud de onda de 395 nm también se puede usar para varias tareas, es más adecuada para aplicaciones que requieren luz visible, como curado o detección UV.

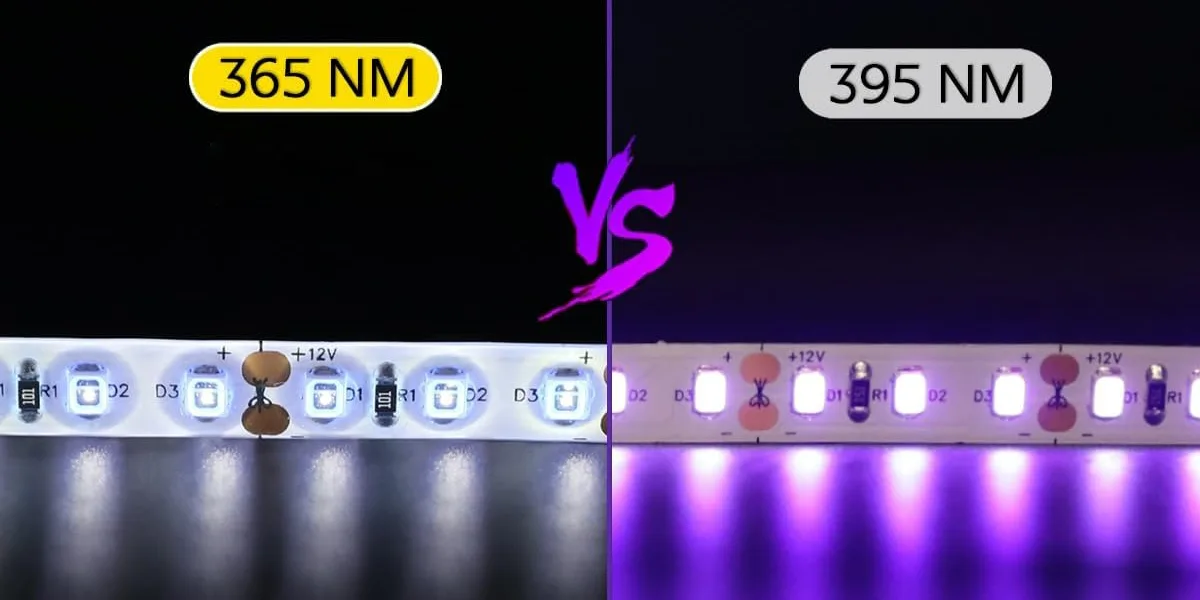

Aunque tanto de 365 nm como de 395 nm son luz UVA y producen luz negra y efectos de curado, con solo una diferencia de 30 nm, 395 nm está más cerca de la luz visible (púrpura) que de 365 nm. Por lo tanto, a simple vista, la luz UV de 395 nm aparece púrpura. 365 nm penetra más profundamente en el espectro ultravioleta invisible, contiene menos luz visible y tiene una longitud de onda más corta, por lo que a simple vista, la luz ultravioleta de 365 nm aparece como un color azul-blanco oscuro.

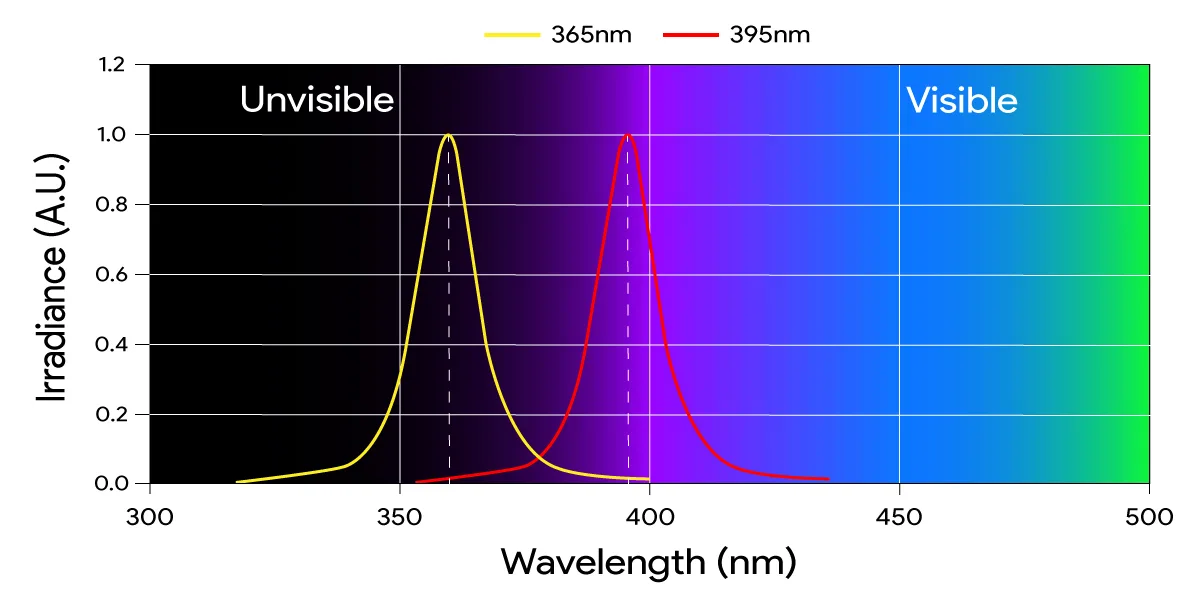

¿Por qué hay una diferencia entre 365nm y 395nm? Porque 365 nm no solo emite luz a la longitud de onda de 365 nm, y 395 nm no solo emite luz a la longitud de onda de 395 nm. Por lo tanto, al comparar luces LED ultravioleta de 365 nm y 395 nm, es esencial considerar su salida espectral y sus longitudes de onda máximas. Como se muestra en la siguiente figura:

Los LED de 365 nm y los LED de 395 nm emiten la energía máxima (es decir, longitud de onda máxima) a 365 nm y 395 nm, respectivamente, pero también emiten energía significativa en los rangos adyacentes de 350 nm a 380 nm y 390 nm a 410 nm. La energía de 365 nm y 395 nm disminuye a ambos lados de las líneas espectrales de 365 nm y 395 nm.

En comparación con 365 nm, una porción más grande de la salida espectral de 395 nm se encuentra dentro de la región violeta visible, lo que brinda una experiencia visual más intensa, lo que la hace adecuada para lugares de entretenimiento o iluminación decorativa. Por el contrario, la salida espectral de 365 nm está más cerca del umbral de luz visible de 400 nm, lo que resulta en niveles de energía más bajos. Esta diferencia hace que los LED de 365 nm sean la opción preferida para la mayoría de las aplicaciones UV-A.

Aunque la longitud de onda de 365 nm es profunda dentro del espectro invisible, debido a las limitaciones en el diseño de LED o las propiedades del material, los LED de 365 nm pueden emitir una pequeña cantidad de "fuga" visible o radiación más allá de la longitud de onda de 365 nm. Estos componentes visibles pueden estar dentro del rango de espectro azul o blanco, lo que hace que la iluminación observada aparezca como un tono azul-blanco opaco en lugar de la salida UV pura deseada en la longitud de onda única de 365 nm.

Además, desde una perspectiva de costos, los LED de 365 nm suelen ser caros. Debido al complejo proceso de fabricación de los diodos LED, los chips de longitud de onda de 365 nm son ineficientes y costosos. La diferencia de precio específica depende del tipo de producto, pero los LED de 365 nm generalmente son más caros. Por lo tanto, si prefiere un haz más brillante y ancho y no necesita iluminar ninguna imperfección o mancha menor, entonces una tira de luz LED de 395 nm sería más adecuada para usted.

La siguiente es una tabla de comparación de sistemas para ayudarlo a comprender rápidamente las diferencias centrales entre los dos:

| Artículo | Luz de tira LED UV de 365 nm | Luz de tira de LED UV de 395 nm |

| Rango de longitud de onda | 360-370nm (pico a 365nm) | 390–400 nm (pico a 395 nm) |

| Características de la luz visible | azulado | morado |

| Capacidad de excitación | Extremadamente fuerte, capaz de excitar varios polvos fluorescentes, tintas UV y adhesivos UV | Fuerte, pero con efectos de excitación limitados en ciertos materiales |

| Escenarios típicos de aplicación | Adhesivo UV/Curado de tinta, Inspección de PCB, Imaging de laboratorio UV, Pasaporte/Identificación antifalsificación, Detección fluorescente industrial | Iluminación de escenario, fiestas de luz negra, iluminación de acuario, pantallas de arte fluorescente, ambiente de luz negra en lugares de entretenimiento |

| Comodidad visual humana | No es adecuado para la visualización directa a simple vista, sin sensación de fotización (alta seguridad pero no apta para exposición prolongada) | Percibe la luz ultravioleta, mínima contaminación lumínica, adecuado para fines decorativos |

| Opciones de densidad de potencia | Los sistemas comunes son de 12 V/24 V, soportan alta potencia (10–30 W/m) | Los sistemas comunes son de 12 V/24 V, con opciones de energía flexibles, que admiten un rango de 3 a 20 W/m |

| Efectos de iluminación | Enfatiza la eficiencia de excitación/penetración/reacción en lugar de atractivo visual | Enfatiza los efectos visuales y la representación atmosférica |

| Compatibilidad con tinte fluorescente | Puede excitar la mayoría de los tintes y recubrimientos fluorescentes comerciales | Puede excitar algunos tintes fluorescentes, pero con una intensidad de excitación relativamente más débil |

| Precio y disponibilidad | Mayor costo unitario (debido a los costos del controlador de chip importado de alta potencia) | Menor costo, ofreciendo una mejor rentabilidad para uso a granel |

| idoneidad para dourante aaplicaciones | Altamente adecuado, con longitud de onda precisa y fuerte energía lumínica | Generalmente no recomendado, solo adecuado para excitación de reacción leve |

| idoneidad para atmosfera doresonancia | No es adecuado, visualmente invisible | Adecuado, comúnmente utilizado para decoración comercial y efectos de escenario |

| Embalaje recomendado | 3535 Embalaje de cerámica de alta potencia / 2835, 5050 Embalaje de alta densidad | 2835 / 5050 Embalaje, adecuado para aplicaciones de tiras LED flexibles |

En resumen, la elección entre 365 nm y 395 nm depende de la aplicación específica y la preferencia personal. Cada longitud de onda tiene sus propias ventajas, por lo que es esencial tener en cuenta las ventajas de cada longitud de onda al determinar qué luz UV es más adecuada para sus necesidades. Además, si bien 395 nm es más rentable, no puede reemplazar a 365 nm para el curado UV de grado industrial o la detección precisa. Por el contrario, 365nm, debido a sus características de luz invisible, a menudo no logra los efectos visuales deseados cuando se usa para iluminación comercial.

Para obtener más información sobre las luces de tiras LED UV, lea el blog: Guía de luces LED UV.

Recomendaciones de productos: tiras LED UV de 365 nm y 395 nm de alto rendimiento

Para satisfacer las diversas necesidades de tiras de luz UV en diferentes bandas de longitud de onda en aplicaciones de curado industrial e iluminación comercial, SignLiteled ha seleccionado y lanzado cuidadosamente los siguientes dos productos insignia, cada uno de los cuales se enfoca en el curado UV de alta precisión y la iluminación de ambiente negro. Estos productos admiten la personalización de OEM a gran escala, el envío internacional y la integración con los contratistas de proyectos.

FAU10T60A-365NM—DC12V 365nm LED UV de curado Tira Luz (grado industrial)

Esta tira de luz LED UV de 365 nm está diseñada específicamente para aplicaciones de iluminación de adhesivo UV, detección de fluorescente e iluminación de precisión, utilizando fuentes de luz UV SMD5050/SMD2835 de alta intensidad con una eficiencia de excitación excepcional y estabilidad estructural.

Modelo principal: FAU10T60A-365NM

Tipo de LED: UV SMD5050/SMD2835

Cantidad de LED por metro: 60/120

Ancho de PCB: 10 mm

Longitud de onda: 365-370nm

Voltaje de entrada: DC12V

Potencia por metro: 14W

Grado IP: IP20/IP65/IP67

Garantía: 5 años

Por encima de la función admite la personalización.

FAU10T60A-395NM—DC12V 395nm Tira LED UV de luz negra Luz (Decoración Visual)

Diseñado específicamente para crear atmósferas comerciales y mejorar los efectos visuales, la longitud de onda de 395 nm emite luz violeta visible. Cuando se combina con recubrimientos fluorescentes o materiales reflectantes, puede crear ricas experiencias interactivas e impacto visual.

Modelo principal: FAU10T60A-395NM

Tipo de LED: UV SMD5050/SMD2835

Cantidad de LED por metro: 60/120

Ancho de PCB: 10 mm

Longitud de onda: 395-400nm

Voltaje de entrada: DC12V

Potencia por metro: 14W

Grado IP: IP20/IP65/IP67

Garantía: 5 años

Por encima de la función admite la personalización.

¿Por qué 365nm y 395nm son las longitudes de onda convencionales para la iluminación LED UV?

365 nm y 395 nm se refieren a longitudes de onda en el espectro ultravioleta. Estas longitudes de onda se encuentran dentro del rango de UVA y se las conoce comúnmente como "luz negra" porque pueden hacer que ciertos materiales emitan fluorescencia o luz visible.

El rango de longitud de onda de las fuentes de luz UVA disponibles comercialmente generalmente abarca de 365 nm a 405 nm, siendo 365 nm y 395 nm las opciones más comúnmente elegidas. En las aplicaciones de detección de fluorescencia y luz negra UV, seleccionar entre 365 nm y 395 nm es una consideración común.

Estas dos bandas de longitud de onda se han convertido en estándares de la industria principalmente porque logran un equilibrio óptimo entre rendimiento y rentabilidad en términos de eficiencia de excitación, compatibilidad de materiales, seguridad de uso y control de costos. El siguiente análisis explora por qué estas dos bandas de longitud de onda dominan el mercado desde cuatro perspectivas clave:

1. Fuerte capacidad de excitación espectral, adecuada para diversas aplicaciones

Tanto 365 nm como 395 nm están ubicados en la región ultravioleta de longitud de onda larga (315-400 nm) de UVA, que exhibe excelentes capacidades de excitación de fluorescencia y es capaz de activar una amplia gama de materiales reactivos con ultravioleta.

365Nuevo Méjico: Longitud de onda UV casi invisible, excita eficazmente polvos fluorescentes, tintas UV, adhesivos UV, etc., ampliamente utilizado en aplicaciones de alta demanda como curado, inspección industrial e iluminación de laboratorio.

395nm: Presenta un ligero tono púrpura, que ofrece efectos visuales más notables, lo que lo hace ideal para aplicaciones decorativas o interactivas, como efectos de iluminación de escenario, pantallas de arte e iluminación de acuario.

Ya sea para aplicaciones técnicas (por ejemplo, inspección de fluorescencia de PCB) o aplicaciones orientadas a la experiencia visual (por ejemplo, iluminación de fiestas negras), se pueden encontrar soluciones adecuadas dentro de estas dos bandas de longitud de onda.

2 Calificación de seguridad moderada, adecuada para uso comercial/industrial a largo plazo

En comparación con las bandas UVB (280–315nm) y UVC (100–280 nm), las bandas de 365 nm y 395 nm representan un menor riesgo potencial para la salud humana. Su energía de radiación tiene un impacto mínimo en los operadores y el personal circundante cuando no se expone directamente a los ojos o a la piel, haciéndolos ampliamente utilizados en áreas públicas y en ambientes abiertos.

- Cajas de luz de exhibición interior

- Iluminación de taller de inspección

- Equipos educativos/laboratorios

- Iluminación funcional UV inteligente para el hogar

Para los desarrolladores de proyectos, esto significa menos restricciones de seguridad, mayor cumplimiento del proyecto y mayor flexibilidad en la aplicación.

3. Cadena de suministro madura, fácil de integrar a granel

Ya sea de 365 nm o 395 nm, sus chips LED, empaques ópticos y soluciones de controladores han logrado una producción a gran escala a nivel mundial, con una buena madurez técnica y estabilidad de canal.

- Marcas de chips: Cree, Osram, LG, Seúl, Sanan, etc., todos proporcionan un suministro estable.

- Formatos de embalaje: Los formatos de empaquetado convencionales como 2835, 3535 y 5050 son todos personalizables.

- Soporte de voltaje: Diseño de voltaje constante de 12 V/24 V, compatible con sistemas de controladores de tiras LED convencionales

Esto mejora significativamente la eficiencia de integración de productos y la controlabilidad posventa para fabricantes de OEM, contratistas de proyectos de ingeniería y compradores internacionales.

4. Eficaz, adecuado para varios niveles presupuestarios

- Las tiras de LED de 395 nm, debido a su estructura simple y bajos costos de material, se usan comúnmente en aplicaciones de media a baja potencia y son la opción preferida para proyectos sensibles al presupuesto.

- Las tiras de LED de 365 nm, con sus efectos de excitación más fuertes y su valor añadido técnico, ofrecen una mayor rentabilidad en proyectos de prueba/curado de calidad profesional, a pesar de su precio unitario ligeramente más alto.

Los clientes pueden elegir entre los dos de forma flexible según el presupuesto del proyecto y los requisitos funcionales para lograr el equilibrio óptimo entre rendimiento y costo.

En resumen, las bandas de longitud de onda de 365 nm y 395 nm no solo son técnicamente maduras, seguras, estables y ampliamente disponibles, sino que también cubren una amplia gama de escenarios de aplicación, desde la fabricación industrial hasta las pantallas comerciales. Como resultado, se han convertido en el "dual núcleo" del mercado de tiras de luces LED UV y seguirán liderando las tendencias de aplicación en los años venideros.

PREGUNTAS FRECUENTES

un: No recomendamos usar tiras de LED de 395 nm para aplicaciones de curado industrial. Aunque cae 395 nm dentro del espectro UVA, su eficiencia de excitación es significativamente menor que la de 365 nm, lo que hace que no pueda cumplir con los requisitos de resistencia de curado de la mayoría de los adhesivos y tintas UV. Para aplicaciones que involucran la unión, la impresión, la encapsulación y otras tareas de curado industrial, recomendamos priorizar 365nm.

un: Sí. SignLiteled admite la personalización para múltiples voltajes de entrada, incluidos DC12V, DC24V y DC36V, para adaptarse a los diferentes requisitos de integración de circuitos y distribución de energía en diferentes proyectos. La versión de 24 V es más adecuada para instalaciones de gran superficie o de larga distancia para minimizar los efectos de caída de voltaje.

un: Absolutamente. Ofrecemos servicios integrales de personalización OEM/ODM, que incluyen:

1. Tipo de chip LED (2835/5050/3535, etc.)

2 Ancho de tira de LED (8 mm/10 mm / 12 mm)

3. Cantidad de LED (30 LEDs/m a 240 LED/m)

4. Rango de potencia (5 W/m a 30 W/m)

5. Material de PCB, longitud de segmento, conectores, respaldo adhesivo y otros detalles

6. Envíe sus dibujos o especificaciones, y podemos proporcionar servicios de producción de muestra.

un:

1. Modelos estándar en stock: envío dentro de 3 a 5 días;

2. Modelos personalizados para muestreo: aproximadamente 7-10 días laborables;

3. Pedidos a granel: el ciclo de producción es de 10 a 15 días, dependiendo de la complejidad del pedido;

4. Métodos de envío: soporta fletes aéreos de DHL, FedEx y UPS; también se puede organizar carga marítima terrestre.

Tenemos una amplia experiencia en el manejo de pedidos internacionales y de apoyo a las exportaciones a múltiples países y regiones, incluidos Europa, Oriente Medio, Sudeste Asiático y Australia.

un: Sí. Nuestras tiras de luz LED UV son compatibles con la mayoría de los dimmers PWM de voltaje constante, sistemas de iluminación inteligente, sensores de infrarrojos/microondas y otros módulos de control disponibles en el mercado. Si se requiere soporte para protocolos de grado industrial como DMX, 0–10V o DALI, también podemos proporcionar las soluciones correspondientes.

un: prohibido .365nm cabe dentro del rango de longitud de onda ultravioleta pura, que es prácticamente invisible para el ojo humano, pero de hecho funciona. Puede verificar su funcionalidad brillándola sobre papel blanco o materiales fluorescentes o usando una tarjeta de detección UV. Si los chips LED no muestran puntos ni calor, póngase en contacto con el soporte técnico para obtener más confirmación.

Conclusión

Los avances e innovaciones en el campo LED UV han hecho que la mayoría de las aplicaciones sean más seguras y efectivas. Las longitudes de onda y las fuentes de luz UV-A son las más efectivas, como 365nm y 395 nm. Sin embargo, la longitud de onda específica y la fuente de luz dependen en última instancia de los requisitos del usuario.

En el mercado de iluminación LED UV altamente competitivo de hoy, elegir el proveedor adecuado es más importante que elegir el producto adecuado. Signliteled, como profesional Fabricante de iluminación de tiras LED y proveedor de soluciones, se ha ganado la confianza de numerosos clientes mayoristas globales a través de su excepcional rendimiento de productos y su sistema de servicio integral.

Ya sea que sea un fabricante de marcas de tiras LED, una empresa de ingeniería de iluminación o un distribuidor global, Signliteleted puede ser su socio de iluminación LED UV de confianza. ¡Contáctenos para solicitar muestras, cotizaciones de proyectos o soluciones personalizadas, y emprenda su viaje de actualización de iluminación UV!