China remains a global leader in PCB and FPCB manufacturing in 2026, making it one of the strongest sourcing regions for OEM buyers looking for reliable LED PCB boards et LED FPCB boards at scalable production capacity.

Rigid LED PCBs (such as aluminum MCPCB and FR-4) are mainly used when strong structure and heat dissipation are required, while LED FPCBs use flexible substrates like polyimide to support curved, compact, or space-limited lighting designs.

This article will explain what LED PCBs and LED FPCBs are, the key differences between rigid and flexible boards, and list the top LED PCB board manufacturers and top LED FPCB board manufacturers in China for 2026.

What is an LED PCB?

Un PCB LED is a rigid printed circuit board designed to mount and electrically connect LEDs in modules, strips, panels, and complete lighting systems. LED PCBs are engineered to support stable current paths, mechanical mounting, and thermal performance requirements for long service life.

Common LED PCB materials include:

- Aluminum MCPCB (metal core PCB) for improved heat dissipation in high-power LED applications

- FR-4 for structural circuits, control boards, and driver-related PCB designs where thermal load is lower or heat is managed separately

Top 10 LED PCB Board Manufacturers in China (2026)

Table — LED PCB Board Manufacturers

| Rank | Fabricant | Core Strength | Typical LED PCB Use Cases |

| 1 | Kinwong Electronics | Rigid and flexible PCB production | Automotive, LED & industrial |

| 2 | JLCPCB | Scalable PCB fabrication & prototyping | Single to multilayer LED PCBs |

| 3 | PCBWay | Full-feature PCB fabrication & flex/rigid support | LED prototype & production boards |

| 4 | Viasion Technology | Flexible mix of rigid + HDI PCB types | LED products + industrial PCBs |

| 5 | Wintech PCB | High-volume multilayer PCB production | LED lighting & industrial boards |

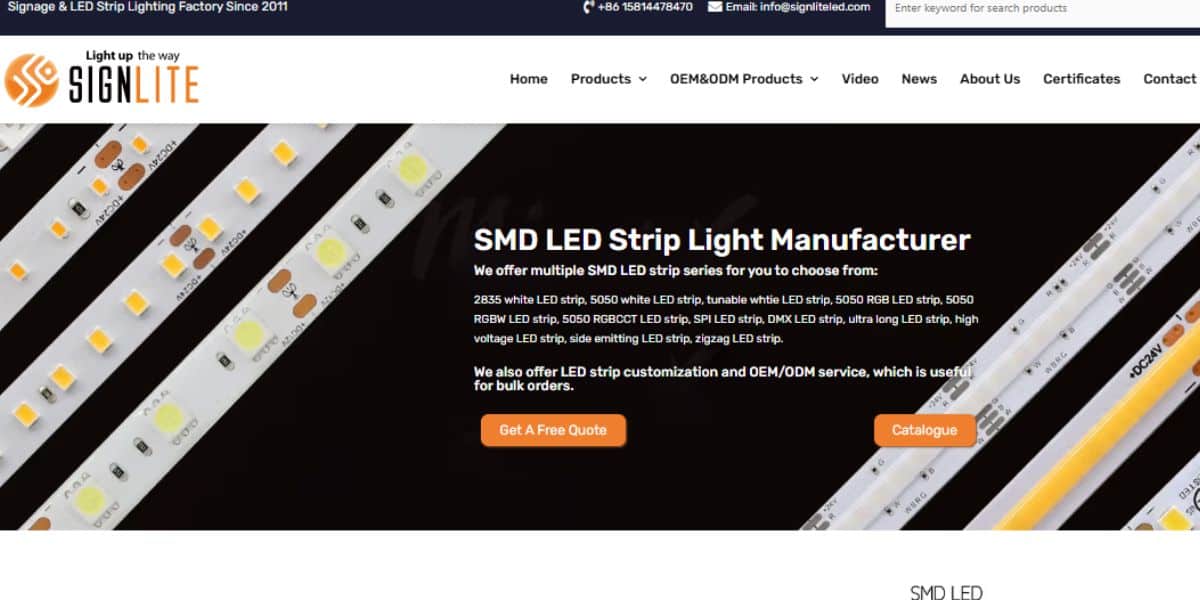

| 6 | SignliteLED | LED lighting PCB OEM/ODM | LED linear modules & custom boards |

| 7 | HuanyuPCB | One-stop PCB manufacturing + EMS | LED + flexible PCB support |

| 8 | PCBasic | Established PCB & PCBA manufacturer | LED lighting boards & control |

| 9 | LZJPCB | Quick-turn PCB production with more layers | Custom LED PCBs |

| 10 | High Quality PCB Co., Ltd. | Specialized in copper & high thermal PCB | LED display & high-heat boards |

This table lists leading PCB board manufacturers in China with LED board relevance and fabrication capabilities.

Describe Top 10 LED PCB Manufacturers

1) Kinwong Electronics

Kinwong Electronics is known for producing both rigid and flexible PCBs, with manufacturing capability aligned to demanding sectors like automotive and industrial electronics. For LED lighting projects, this matters because many LED systems are not just “LED boards,” but complete assemblies that include power delivery, control logic, connectors, and environmental reliability requirements. Kinwong’s broader PCB capability makes it relevant for OEMs that need consistent production quality across multiple board types used in a single LED product platform.

2) JLCPCB

JLCPCB is widely recognized for scalable PCB fabrication that supports both prototyping and volume production workflows. For LED applications, JLCPCB’s strength is helpful when engineers need fast iterations for LED module layouts, driver-support PCBs, or multilayer boards that route control signals alongside power traces. Its manufacturing model is commonly used for thin trace work, multilayer builds, and repeatable production, which can reduce development friction when LED boards move from design validation to stable supply.

3) PCBWay

PCBWay provides a full-feature PCB service model, covering prototypes through larger production runs while supporting both rigid PCB and flexible options. In LED product development, the ability to transition quickly from early test boards to refined production boards is often a key requirement, especially when optical layout, thermal pads, or mounting geometry changes during testing. PCBWay is commonly selected when buyers need a supplier that can support multiple board configurations and turnaround speeds without changing vendors mid-project.

4) Viasion Technology

Viasion Technology is a Shenzhen-based manufacturer that offers a mixed portfolio of rigid, flex, and HDI PCB types. This range can be relevant for LED product ecosystems where the lighting engine board is rigid, but supporting electronics or interconnect circuits may require different stackups. For LED drivers and industrial lighting control, HDI and specialized rigid board options can matter when space constraints increase and routing density becomes more challenging than standard single-layer LED boards.

5) Wintech PCB

Wintech PCB focuses on robust production across multilayer rigid PCB categories, which aligns with industrial-grade manufacturing expectations. In LED lighting supply chains, multilayer rigid boards are often used for control boards, interface boards, or power distribution PCBs within luminaires and lighting systems. Wintech’s high-volume orientation can be a fit for procurement teams prioritizing production stability, repeatable fabrication control, and consistent delivery for long-running LED product lines.

6) SignliteLED

SignliteLED is positioned around LED lighting PCB OEM/ODM needs, with emphasis on customization for lighting modules such as LED linear designs and application-specific board layouts. For buyers working on integrated lighting products, this can be relevant because the LED board is only one part of the system, and the supplier’s familiarity with lighting assembly requirements helps reduce design-to-production gaps. SignliteLED is also associated with LED module-oriented solutions where board layout, thermal management, and integration details matter for production readiness.

7) HuanyuPCB

HuanyuPCB offers a one-stop manufacturing approach that can include PCB fabrication and EMS-related services such as component procurement, testing, and assembly. For LED projects, this model is useful when the “LED PCB” is part of a larger electronics assembly that includes current regulation, connectors, sensing, or control components. Buyers who want fewer handoffs between vendors often consider suppliers that can manage fabrication plus assembly verification steps, especially when quality control and traceability are priorities.

8) PCBasic

PCBasic is an established PCB and PCBA manufacturer with services that support both fabrication and assembly workflows. In LED lighting applications, PCBasic can be relevant for producing rigid LED boards as well as related control PCBs, particularly when buyers want a supplier that can handle both bare boards and assembled boards depending on the project stage. For procurement and engineering teams, having access to assembly support can reduce lead time and simplify supplier coordination during production ramp-up.

9) LZJPCB

LZJPCB is commonly positioned as a quick-turn PCB provider that supports multilayer builds and responsive manufacturing schedules. For LED lighting development, quick-turn capability is important when thermal testing or optical changes require PCB layout updates and new samples. LZJPCB’s relevance comes from supporting custom LED PCB designs that may need specific stackups, copper thickness selections, or revised footprints as LED modules move through validation.

10) High Quality PCB Co., Ltd.

High Quality PCB Co., Ltd. is associated with specialized thermal PCB types such as copper-based or aluminum-based constructions, which are important for high-power LED boards and heat-intensive LED display applications. Thermal performance is often a primary failure driver in LED systems, so manufacturers experienced in heat-conductive PCB structures are relevant for designs that must control junction temperature. The company is also described as having long operating history (often cited since the mid-1990s), which may appeal to buyers prioritizing manufacturing experience and process maturity.

What Is an LED FPCB?

Un LED FPCB (Flexible Printed Circuit Board) is a bendable circuit board made with flexible substrates such as polyimide (PI). Unlike rigid LED PCBs, FPCBs can be shaped, folded, or curved to fit tight product geometries.

LED FPCBs are commonly used for:

- Bandes LED flexibles and curved lighting designs

- Wearable LEDs and compact consumer devices

- Éclairage architectural where rigid boards cannot conform to surfaces

Top 10 LED FPCB Board Manufacturers in China

Table — LED FPCB Board Manufacturers

| Rank | Fabricant | Core Strength | Typical LED FPCB Use Cases |

| 1 | Asunny Circuits | Flexible PCB including automotive integrations | Flexible boards in complex assemblies |

| 2 | Flex Plus (Xiamen) | Premium FPCB specialization | Flexible LED strip & curved boards |

| 3 | MV Flex Circuit | Flexible PCB multi-layer capability | Flexible board prototypes and production |

| 4 | Xiamen Bolion Tech | Rigid-Flex + flexible PCB expert | Flexible boards for industrial LED products |

| 5 | Viasion Technology | Flexible PCB production as part of PCB suite | Flexible circuits for LED drivers |

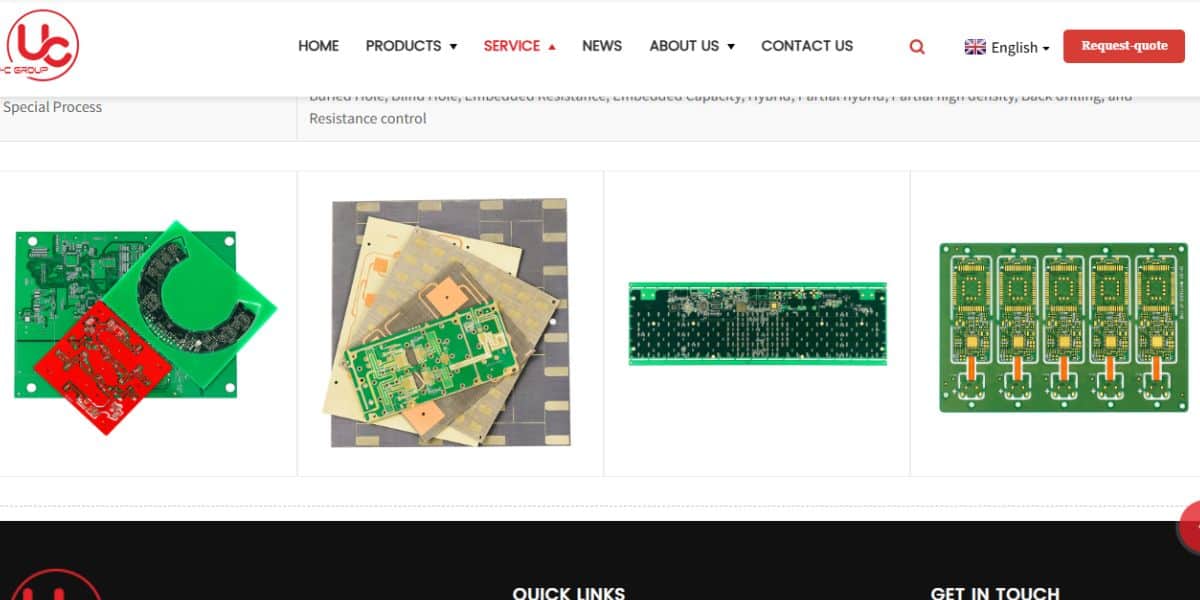

| 6 | U-C Group Limited | Known FPCB manufacture | Flexible boards across industries |

| 7 | SignliteLED | Lighting solutions + flexible board sourcing support | Flexible LED modules for lighting integration |

| 8 | Honlex | FPC (Flexible Printed Circuit) manufacturing | LED strip lighting, curved and compact flexible LED boards |

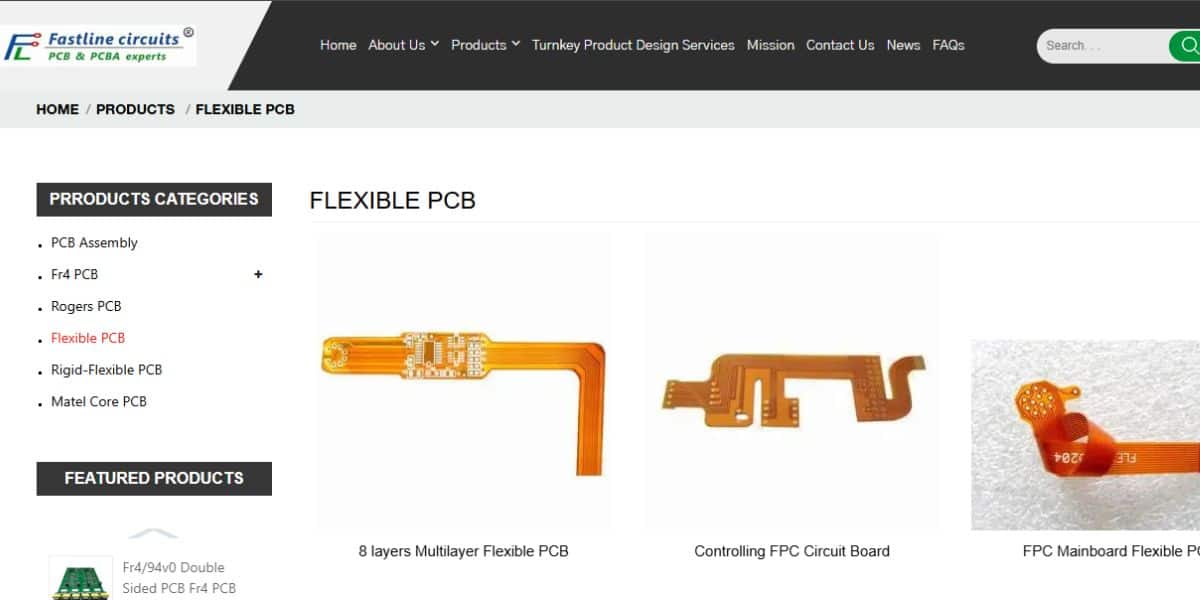

| 9 | Fastline Circuits Co., Ltd. | Flexible PCB & rigid-flex manufacture | LED lighting and prototype flex boards |

| 10 | Smart Electronics Co., Ltd | Flexible printed circuits with custom options | LED + wearables flex boards |

Describe Top 10 LED FPCB Manufacturers

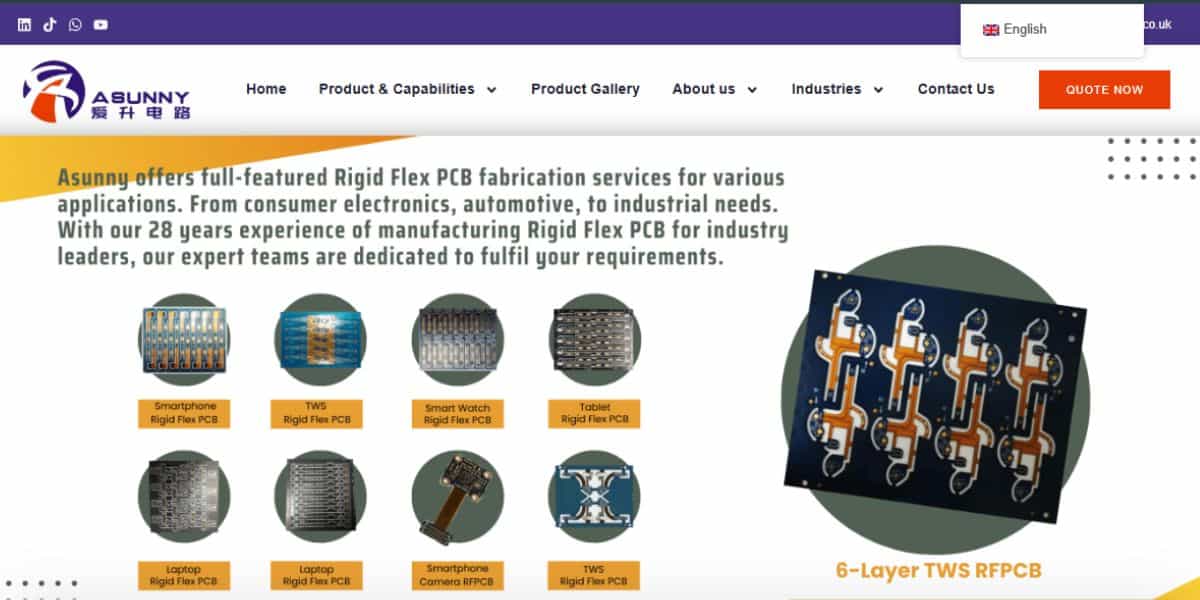

1) Asunny Circuits

Asunny Circuits has a long track record in flexible PCB manufacturing, supporting applications across multiple industries including automotive and energy-related electronics. For LED FPCB needs, this type of background is relevant because flexible boards often require tighter control of bending reliability, adhesive systems, and conductor stability than standard rigid boards. Asunny’s flex capability can be suitable for LED assemblies that integrate into compact housings or require stable performance under vibration and repeated handling.

2) Flex Plus (Xiamen)

Flex Plus (Xiamen) is positioned as a premium-focused flexible PCB manufacturer with emphasis on polyimide-based FPC fabrication and reliability-oriented production. For LED strip lighting and curved lighting modules, the material system and process control can directly affect bending endurance, solder joint stability, and long-term electrical continuity. Buyers evaluating Flex Plus typically look for consistent flex-layer builds, controlled impedance options when needed, and predictable production quality for designs that cannot tolerate cracking or delamination.

3) MV Flex Circuit

MV Flex Circuit offers flexible PCB manufacturing from prototypes to mass production, including multi-layer flexible builds. In LED applications, multi-layer flex can be useful for compact routing, improved power distribution, and mechanical packaging where rigid boards add thickness. MV Flex Circuit’s relevance for LED strip designs comes from supporting iterative product development, where mechanical constraints and LED placement often require multiple layout revisions before final production approval.

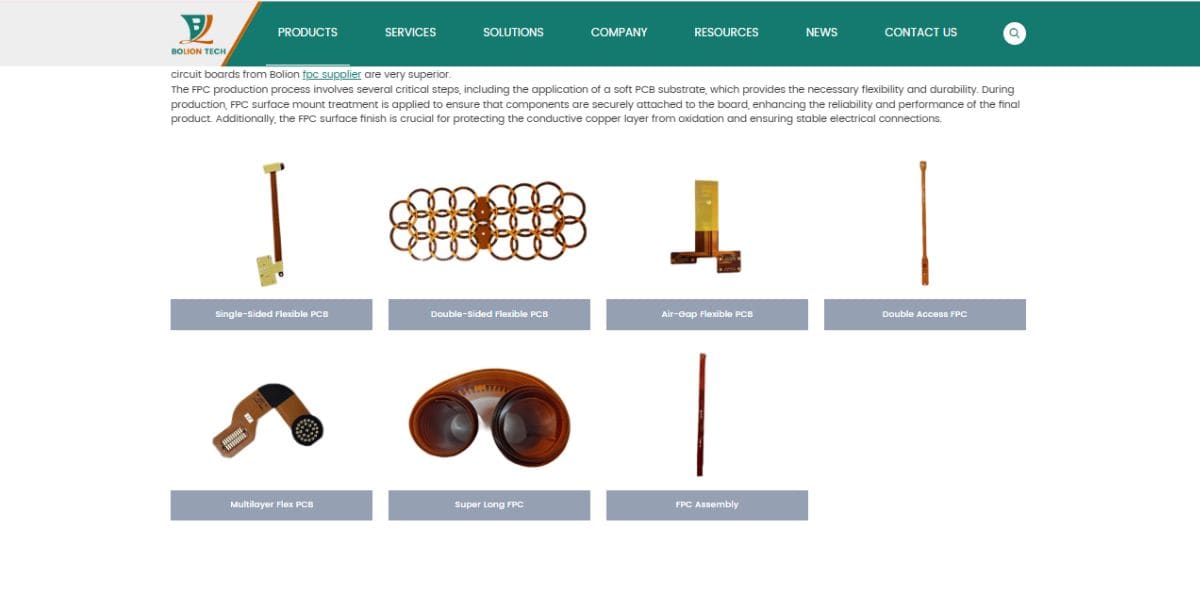

4) Xiamen Bolion Tech

Xiamen Bolion Tech is known for rigid-flex and flexible PCB capability, which fits LED products that combine a rigid LED mounting section with flexible interconnect routing. Rigid-flex structures can reduce connectors and simplify assembly in compact luminaires, automotive lighting modules, or industrial LED products where space and vibration are concerns. For OEM buyers, Bolion’s rigid-flex support can help reduce wiring complexity and improve repeatability in assembly processes.

5) Viasion Technology

Viasion Technology appears in both lists because it supports flexible PCB production as part of a broader PCB manufacturing suite. For LED FPCB projects, this is useful when the product requires both rigid and flexible circuits sourced under one supplier relationship. Flexible circuits used for LED drivers, compact interconnects, or shaped lighting modules benefit from stable process control and documentation consistency, especially when the FPCB must match rigid board tolerances during final assembly.

6) U-C Group Limited

U-C Group Limited is a known flexible PCB supplier with focus on FPC manufacturing for a range of electronics applications. For LED use cases, the supplier’s value often depends on consistent flexible copper patterning, stable coverlay application, and quality inspection suitable for repeated bending environments. Buyers selecting U-C Group for LED FPCBs typically evaluate bend radius requirements, stiffener integration options, and whether the supplier can support production documentation needed for OEM supply chains.

7) SignliteLED

SignliteLED is relevant to the LED FPCB category through lighting-oriented solutions and flexible board sourcing support for OEM lighting integration. For many LED products, especially linear lighting systems, flexible circuits may be used in specific zones for routing, connectors, or space-limited sections while rigid boards handle the main LED mounting. SignliteLED’s positioning can be helpful when procurement teams want a lighting-focused supplier that understands how flexible boards integrate into LED modules, optical constraints, and installation form factors.

8) Honlex

Honlex is a China-based manufacturer with an established focus on FPC (Flexible Printed Circuits), making it a relevant option for LED strip lighting and other flexible lighting applications where boards must bend or fit compact spaces. For LED FPCB projects, supplier capability in flexible material handling, coverlay application, and stable copper trace formation can directly affect soldering reliability and long-term durability. Buyers typically evaluate Honlex for flexible circuit consistency, support for different FPC structures, and production stability when designing curved or space-limited LED lighting assemblies.

9) Fastline Circuits Co., Ltd.

Fastline Circuits Co., Ltd. provides flexible PCB and rigid-flex manufacturing capability, which can suit prototype LED projects as well as scaled production needs. LED development teams often need fast sample cycles to validate mechanical fit, light distribution, and electrical behavior, and flex boards frequently require tuning of stiffeners or bend zones. Fastline’s relevance comes from offering both flex and rigid-flex options that can match the evolving design constraints typical of LED lighting engineering.

10) Smart Electronics Co., Ltd

Smart Electronics Co., Ltd. is associated with flexible printed circuits and custom configuration support, which can be useful for wearable LED designs, compact lighting modules, and products with unique mechanical constraints. LED FPCBs often require careful balance between flexibility and structural reinforcement, achieved through stiffeners, selective thickness, and controlled bending areas. For OEM buyers, a flexible PCB supplier that can support customization is valuable when standard FPCB templates do not match the product’s assembly or durability requirements.

How to Choose the Right LED PCB / LED FPCB Manufacturer

Use this checklist to evaluate an LED PCB Board Manufacturer ou LED FPCB Board Manufacturer for OEM purchasing:

- Rigid vs flexible board needs

- Rigid PCB for stable mounting and structure

- FPCB for curved, folded, or space-limited layouts

- Rigid PCB for stable mounting and structure

- Thermal requirements for LEDs

- Aluminum MCPCB or high-thermal materials for high-power LEDs

- Copper thickness and thermal path design considerations

- Aluminum MCPCB or high-thermal materials for high-power LEDs

- Layer count & material quality

- Single-layer vs multilayer routing requirements

- FR-4 grade, polyimide quality, and stackup control

- Single-layer vs multilayer routing requirements

- Assembly & testing capabilities

- PCBA support if needed (SMT, inspection, functional testing)

- Optical alignment considerations for LED module builds

- PCBA support if needed (SMT, inspection, functional testing)

- Lead time & sample support

- Prototype speed for design validation

- Stable lead times for volume orders

- Prototype speed for design validation

- Technical responsiveness

- DFM feedback quality (pad design, thermal relief, bend zones)

- Clear documentation and revision control for engineering changes

- DFM feedback quality (pad design, thermal relief, bend zones)

Conclusion

This article provided two distinct Top 10 lists: one for LED PCB board manufacturers in China and one for LED FPCB board manufacturers in China, reflecting the different technical requirements between rigid and flexible LED circuit designs.

China remains a strong manufacturing base for printed circuit boards in 2026 due to production scale, engineering depth, and supplier availability across rigid PCB, aluminum MCPCB, and flexible FPCB categories.

For OEM buyers, the manufacturer choice directly impacts LED product performance, thermal stability, assembly yield, and long-term integration reliability, especially when designs move from prototype validation into volume supply.

FAQ

Use rigid PCB (including aluminum MCPCB) when you need strong mounting, stable geometry, and thermal handling. Use FPCB when the LED circuit must bend, curve, or fit into tight packaging such as flexible strips, curved channels, or compact housings.

No. Many PCB manufacturers focus mainly on rigid boards. FPCB production requires different materials and processes, so buyers should confirm the supplier’s flex capability (and rigid-flex capability if needed) before placing orders.

High-power LEDs generate heat at the junction. Aluminum-core MCPCB helps transfer heat away from the LED package into the fixture or heat sink, improving stability, reducing thermal stress, and supporting longer operating life.

It depends on complexity, layer count, and materials. Many manufacturers can provide prototype samples within days to a few weeks, while rigid-flex and specialty thermal boards may require longer processing and validation.

Yes. Many suppliers offer PCBA services (SMT assembly, testing, inspection) in addition to bare board fabrication. This can simplify procurement and reduce coordination issues, especially for LED modules that require consistent assembly quality.