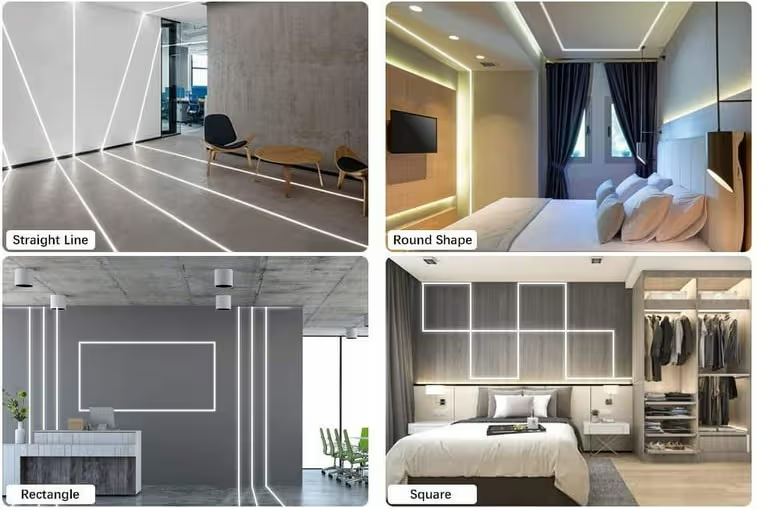

LED strip lighting has become a standard solution for architectural, commercial, and residential projects. However, even with high-quality LED strips and canaux en aluminium, many installations still suffer from visible light spots, glare, or uneven illumination. In most cases, the root cause is not the LED strip itself, but the diffuser cover.

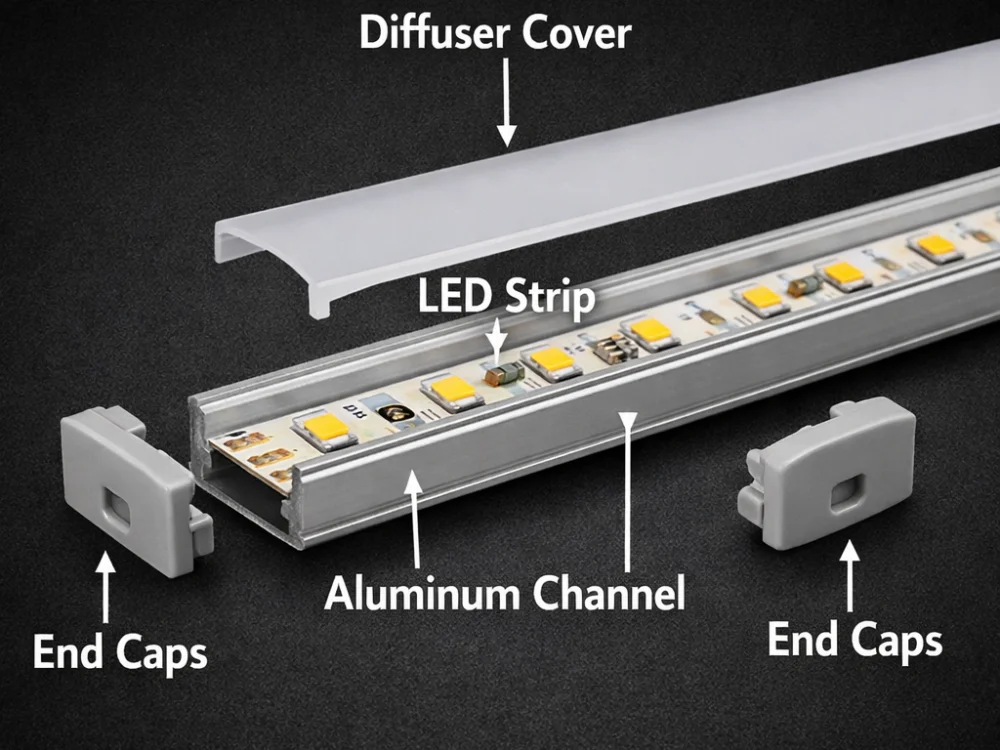

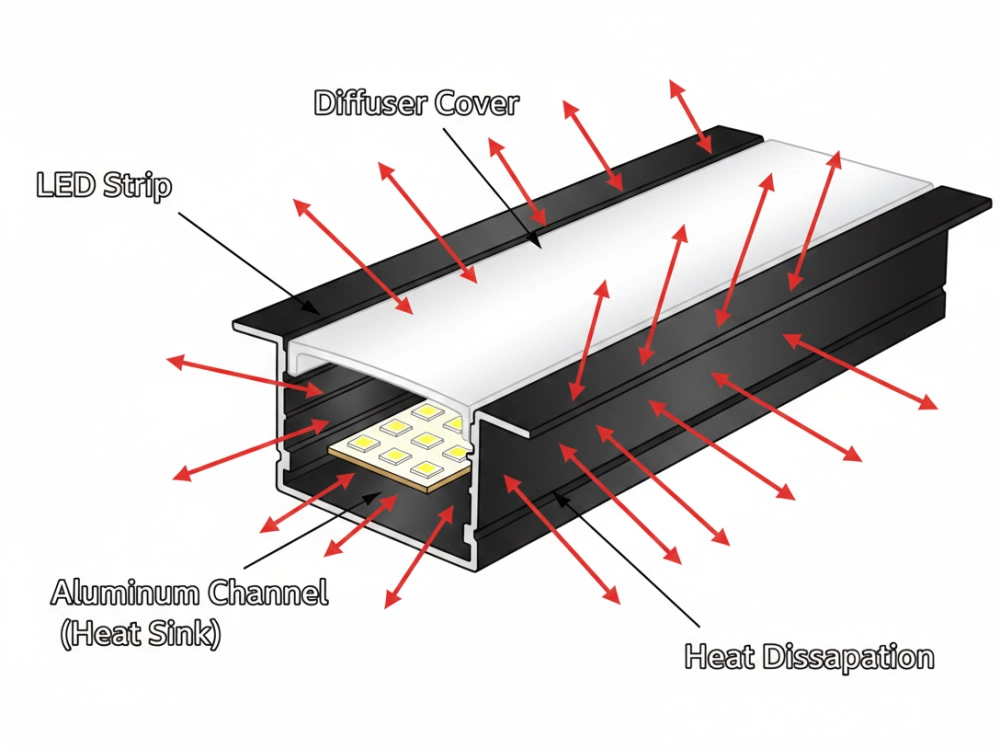

An LED diffuser cover is not merely an aesthetic accessory. It is a critical optical component that directly affects light uniformity, visual comfort, efficiency, and the overall professional appearance of a lighting system. While aluminum LED channels function primarily as heat sinks to protect LED lifespan, the diffuser determines how light is perceived.

This guide focuses on the three most common diffuser options used in LED strip channels: clear, milky, and black covers. By understanding their differences, materials, performance trade-offs, and installation considerations, you can make informed decisions that align with both technical requirements and visual expectations.

What Is an LED Channel Diffuser and Why It Matters

An LED channel diffuser (also known as a cover or lens) is the polycarbonate or PMMA component that snaps onto an aluminum LED profile. Its primary purpose is to disperse light from LED strips to eliminate hotspots, protect the LEDs from dust and physical contact, and control the beam angle for a professional finish.

In a complete LED strip channel system, the aluminum profile and the LED strip diffuser work together. The aluminum channel dissipates heat, stabilizing LED junction temperature and extending lifespan. The diffuser, on the other hand, manages light distribution and glare control. Neglecting either element often results in poor lighting quality or premature failure.

From an optical standpoint, the diffuser influences three core factors:

- Light uniformity and dot visibility

- Glare reduction and visual comfort

- Aesthetic appearance when the light is on and off

Understanding diffuser selection is therefore essential for both lighting designers and project buyers.

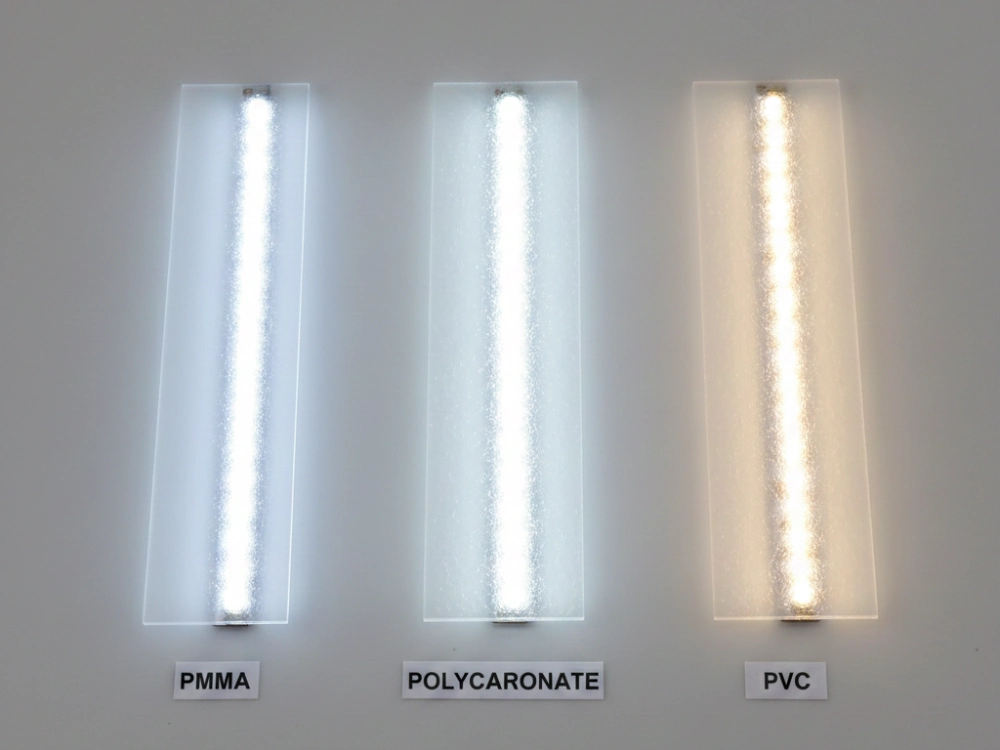

Material Matters: PMMA vs. Polycarbonate vs. PVC

The performance of an LED channel diffuser depends heavily on the material used. While many diffusers look similar at first glance, their long-term behavior can differ significantly.

Material Performance Comparison Matrix

| Material Feature | PMMA (acrylique) | Polycarbonate (PC) | PVC (Standard) |

| transmission lumineuse | High (~92%) | High (~88%) | Medium (~80%) |

| Résistance aux UV | Excellent (non-yellowing) | Good (stabilizers needed) | Poor (yellows in 1–2 yrs) |

| Impact Resistance | Moyen | extrêmement élevé | Faible |

| Meilleure application | Architectural / Retail | Public spaces / Outdoor | Budget / Temporary |

PMMA, commonly known as acrylic, is widely regarded as the best material for optical clarity. It offers excellent light transmission and strong resistance to UV-induced yellowing, making it ideal for architectural and retail lighting where visual consistency matters over time.

Polycarbonate provides superior impact resistance and is often chosen for public spaces or installations where mechanical durability is critical. However, PC typically requires UV stabilizers for outdoor use and has slightly lower optical clarity compared to PMMA.

PVC diffusers are primarily cost-driven solutions. While acceptable for temporary or low-budget projects, untreated PVC tends to degrade under UV exposure, resulting in visible yellowing and reduced light quality.

According to data from plastics industry research, PMMA can maintain optical clarity for over ten years, while untreated PVC may show significant discoloration within two years of UV exposure.

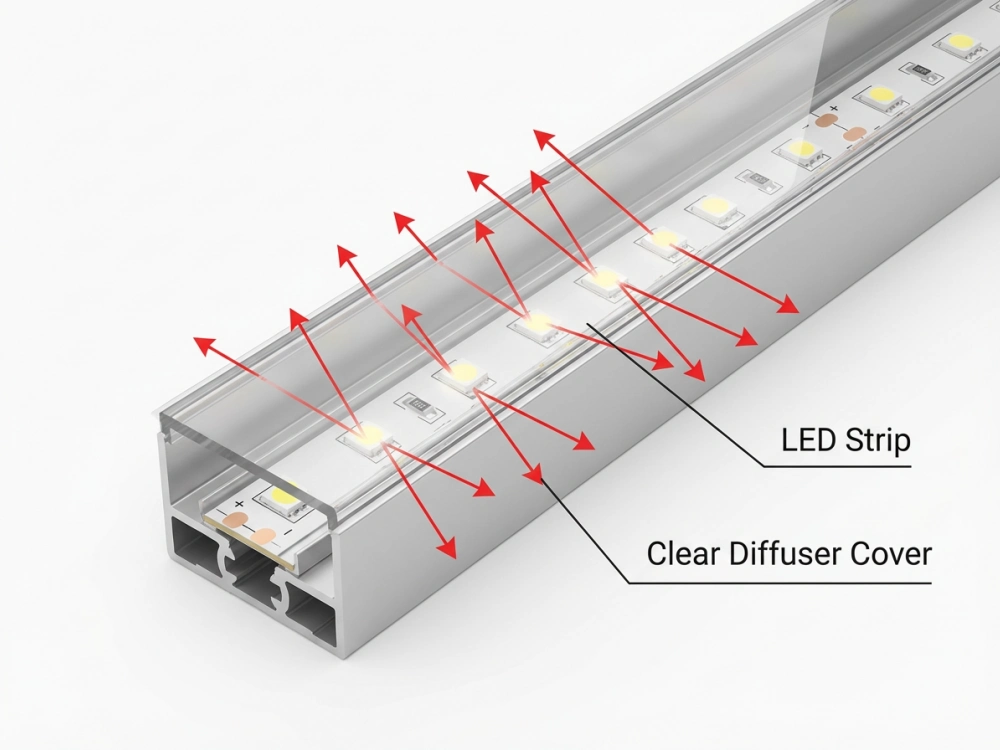

Clear Diffuser Covers: Maximum Brightness, Visible Light Points

Clear LED diffuser covers are designed to preserve as much luminous output as possible. They introduce minimal optical interference and are often selected when brightness is the primary objective.

When to Use Clear LED Bande diffuseurs

Clear diffusers are best suited for applications where light efficiency outweighs visual softness. Typical use cases include functional lighting, task lighting, and display illumination where LED points are acceptable or even desirable.

With an estimated light loss of less than ten percent, clear covers provide the highest lumen output among all diffuser types.

Pros and Cons of Clear Diffuser Covers

Advantages include high efficiency, crisp illumination, and minimal transmission loss. However, clear diffusers do little to mask individual LED points, especially when used with low-density LED strips or shallow channels. Glare may also become an issue in direct-view installations.

Lighting standards organizations emphasize that transmission loss is a critical factor in lighting design, which explains why clear diffusers are preferred when raw lumen output is prioritized.

Profilés d'angle en aluminium

Poids : 0.087KG

Épaisseur : 0,8 mm

PC color: Clear

Taille : L1000*L20*H20mm

Embouts/Clips : 1 paire/m

Couleur de l'aluminium : argent/noir

For under-cabinet task lighting where brightness is key, use a Clear Diffuser with our Corner V-Shape Channels to direct light exactly where you work.

Milky Diffuser Covers: Best Choice for Dot-Free Lighting

Milky LED strip light diffusers are the most commonly used option for LED strip channels, particularly in architectural and decorative lighting. Their primary advantage lies in their ability to scatter light and reduce visible hotspots.

Why Milky LED Diffuser Covers Are Preferred for LED Strip Channels

Milky covers balance light diffusion and efficiency. By scattering light within the channel cavity, they soften the beam and significantly reduce dot visibility. This makes them ideal for indirect lighting, coves, ceilings, and linear architectural applications.

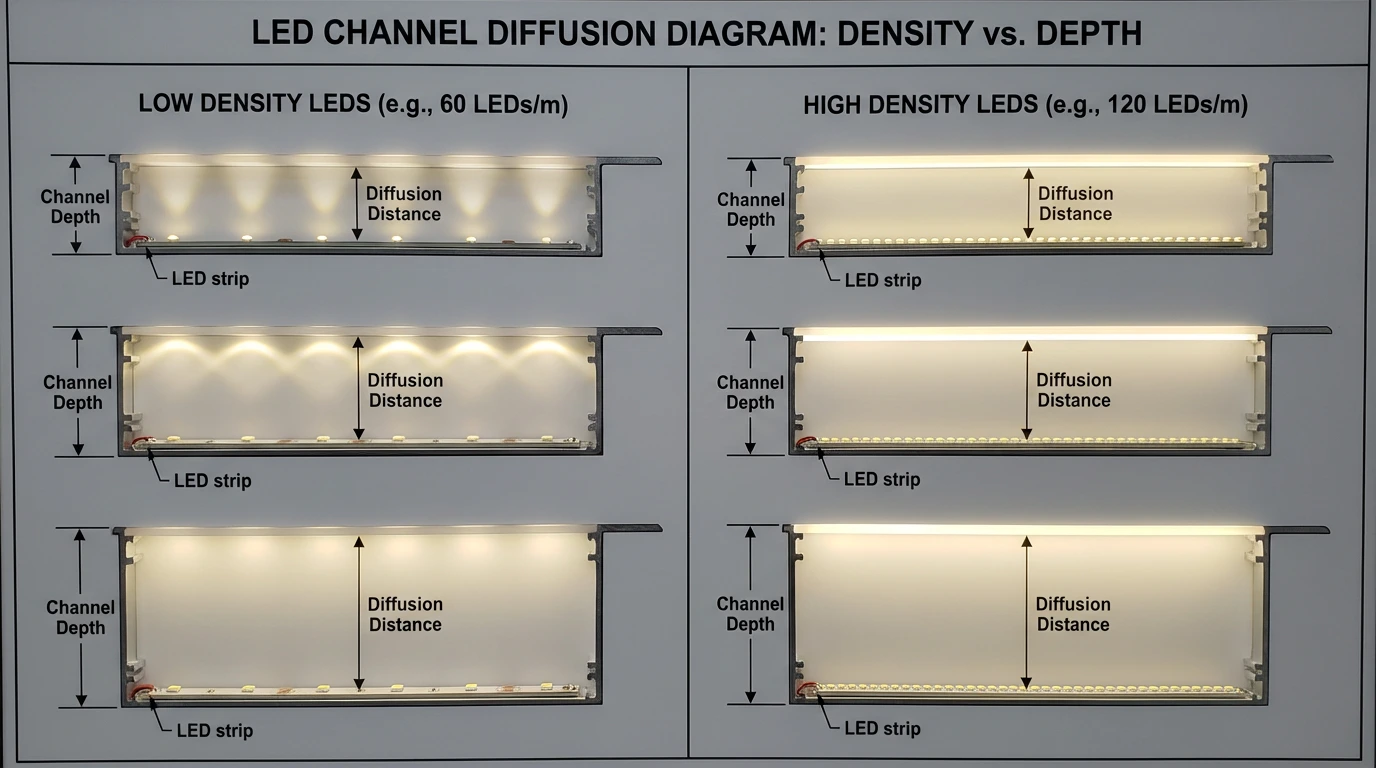

However, the diffuser alone does not guarantee a spotless appearance. Channel depth and LED density play equally important roles.

The Spotless Secret: The Ratio of Depth to LED Density

Dot-free lighting depends on the relationship between LED strip pitch and diffusion distance. The greater the distance between the LED source and the diffuser surface, the more evenly light can spread.

Spotless Distance Reference Table

| LED Strip Density | Type | Min. Channel Depth for Spotless Effect (Milky Cover) |

| 30 LED/m | Standard SMD | > 20 mm (deep recessed) |

| 60 LED/m | Standard SMD | > 12–15 mm |

| 120 LED/m | High-density SMD | > 7–10 mm |

| Bande LED COB | Chip-on-board | > 3–5 mm |

This table highlights why COB LED strips are increasingly popular in linear lighting. Their extremely high LED density allows for uniform illumination even in ultra-thin channels.

Milky Diffuser and COB LED Strips: An Ideal Combination

When paired with COB LED strips, milky diffusers can achieve a neon-like, continuous light line with minimal channel depth. This combination is widely used in high-end residential, hospitality, and commercial projects where visual comfort is critical.

Black Diffuser Covers: When Aesthetics Matter More Than Brightness

Black diffuser covers serve a different purpose altogether. Rather than maximizing light output, they focus on visual integration and atmosphere.

What Is a Black LED Lumière Diffuser Cover

Black diffusers appear dark or opaque when the light is off, allowing the channel to blend seamlessly into ceilings or walls. When illuminated, they emit a soft, controlled glow rather than a bright linear beam.

Applications of Black Diffusers in Architectural Lighting

Black covers are commonly used in hotels, luxury retail, bars, and modern residential interiors. They are ideal for mood lighting, accent lighting, and spaces where fixtures should remain visually discreet.

While light loss can reach sixty to seventy percent, this trade-off is intentional and aligns with ambient lighting objectives.

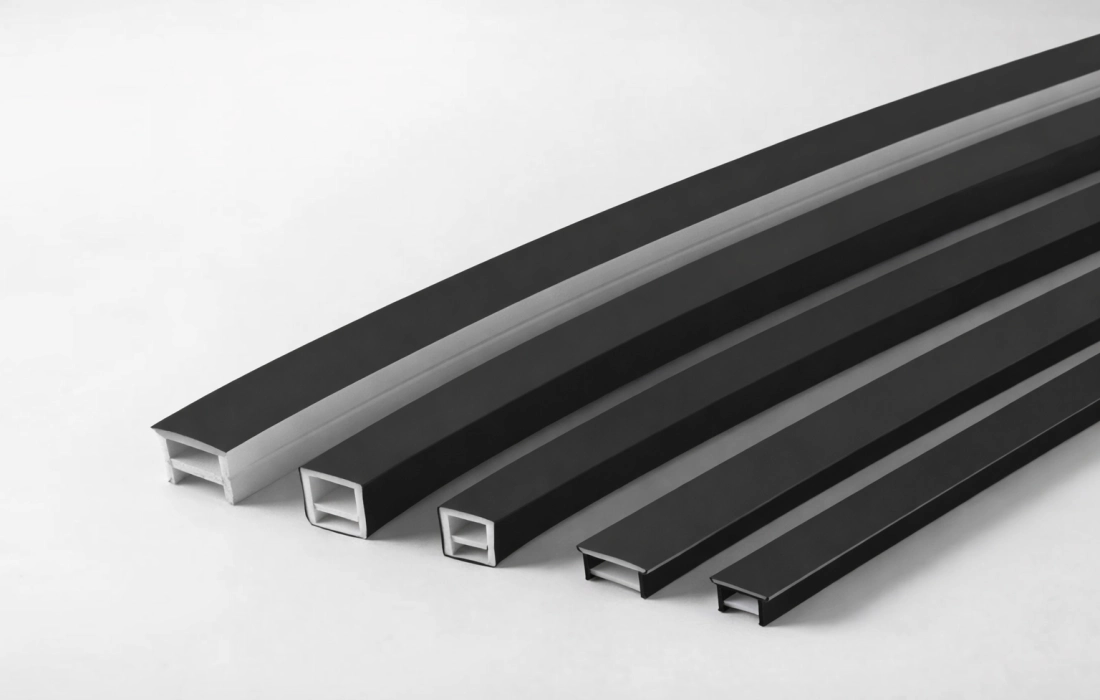

Canal encastré de bandes LED flexibles

Longueur totale : 1m/3m/5m

Direction lumineuse : Lumière frontale

Nombre de LED : 30 LED/m et plus

Couleur : Noir

Taille de la section : T1212/T1616/T2010/T2014/T2020/T2520

PCB Width: 7mm – 20mm

Angle du faisceau : 120 degrés

Matériau : Silicone

Étanchéité : IP65/IP67/IP68

Source lumineuse : SMD2835/5050, bande LED COB

For cinema rooms or dark-themed interiors, standard silver channels can be distracting. Our Black Edition Profiles disappear into the background when turned off.

Clear vs Milky vs Black Diffusers: Side-by-Side Comparison

The Ultimate Comparison Matrix

Choosing the right cover is a trade-off between lumen output (brightness) and light diffusion (smoothness). Use this table to find your balance:

| Fonctionnalité | Clear Diffuser (Transparent) | Milky Diffuser (Opal/Frosted) | Black Diffuser (Smoked) |

| transmission lumineuse | 90% – 95% | 70% – 85% | 30% – 40% |

| Dot Visibility | High (LED chips fully visible) | Low to None (Depending on depth) | Zero (Completely hidden) |

| Color Temperature Shift | None (Original CCT) | Slight Warming (-100K to -200K) | Significant Darkening |

| contrôle des reflets | minimal | Excellent (Softens light) | High (Mood lighting) |

| Aesthetics (Off State) | Visible internal strip | Clean white surface | Stealth black finish |

| Meilleure application | Under-cabinet, Cove lighting, Indirect utility | Architectural lines, Direct viewing, Office | Cinema, Bar, Dark-themed decor |

Analysis of Visual Effects

Clear Covers (The Efficiency King): Best for indirect lighting applications where the light source is hidden, such as inside a cove or above a cabinet. Since you don’t see the fixture directly, the pixelation doesn’t matter, and you get maximum lux levels.

Milky Covers (The Universal Standard): These act as a light homogenizer. By scattering the light beam, they increase the beam angle (often up to 120 degrees) and reduce eye strain. This is the standard for linear lighting fixtures where the channel is exposed.

Black Covers (The Designer’s Choice): While they reduce luminous efficacy significantly, they are unmatched for contrast and style. Perfect for “lights out” aesthetics where the channel needs to blend into dark ceilings or walls.

Installation Types: Snap-in vs Slide-in Diffusers

Before buying, you must consider where you are installing the channel. The wrong cover type can make installation impossible.

Snap-in (Click-on) Diffusers: The User-Friendly Choice

Also known as press-fit covers, these are designed to be pressed onto the aluminum channel from the front.

- Best For: Recessed installations or grooves (like in wardrobes or drywall) where the ends of the channel are blocked.

- Pros: Easy maintenance. If an LED strip fails, you can simply pop the cover off without removing the entire fixture.

- Mechanism: Uses small ridges to “click” securely into the profile edges.

Slide-in Diffusers: The Secure Grip

These must be inserted from the open end of the aluminum profile and slid along the entire length.

- Best For: Suspended lighting or areas with high vibration. The structure is often tighter and more resistant to popping out.

- The Catch: You need clearance space at the ends. Do not use slide-in covers for wall-to-wall recessed slots, or you will never be able to insert the lens!

How to Choose the Right Diffuser for Your LED Strip Channel

To choose the right diffuser for LED channels, follow these five steps:

- Check your LED density and strip type. High-density or COB strips pair best with milky diffusers.

- Define your visual goal. Choose clear for brightness, milky for uniformity, or black for atmosphere.

- Measure channel depth. Deeper channels improve diffusion and reduce hotspots.

- Select the right material. PMMA offers longevity, PC provides durability, and PVC should be avoided for long-term projects.

- Decide on installation type. Snap-in covers simplify maintenance, while slide-in lenses offer a cleaner finish.

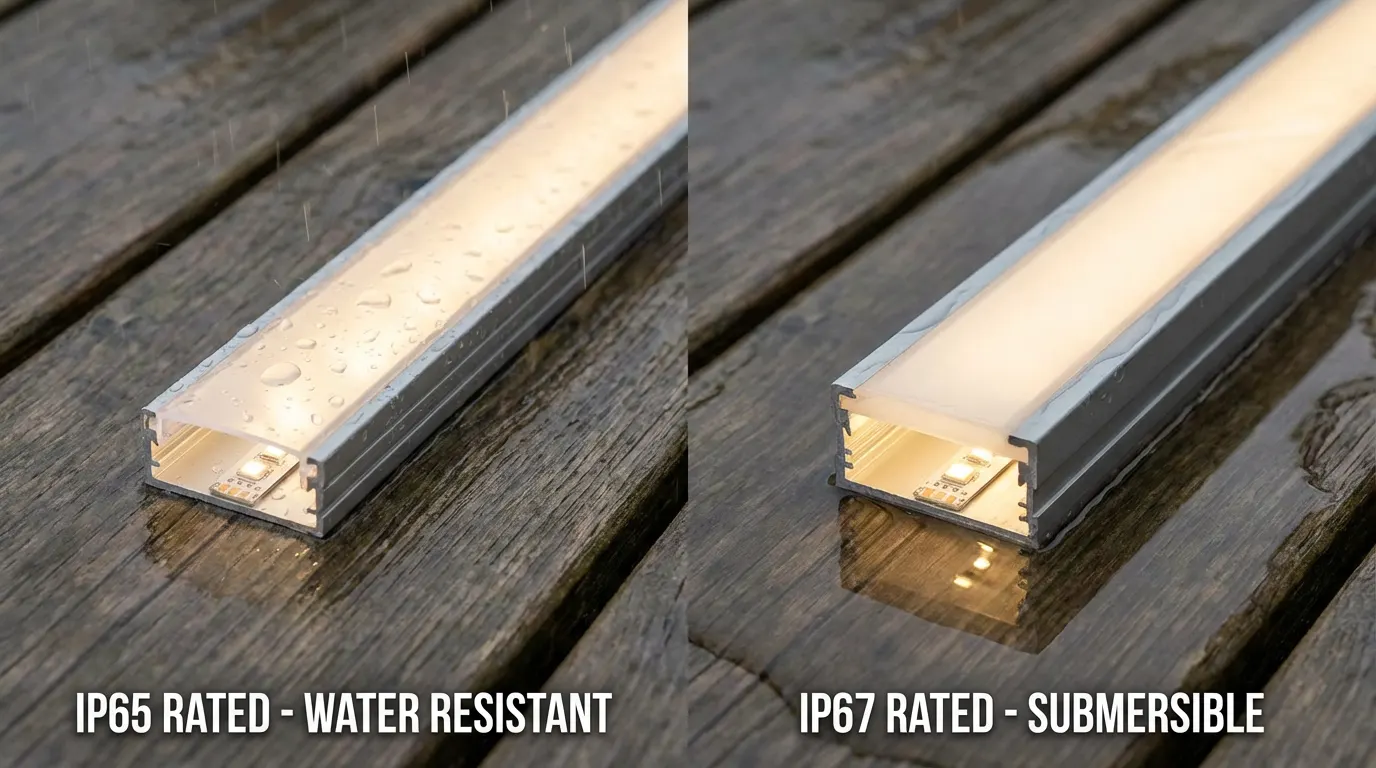

Outdoor and Waterproof Diffusers: Special Considerations

Outdoor LED strip channels require more than a diffuser with good optical properties. UV resistance, sealing structure, and ingress protection are critical.

For exterior installations, channels rated IP65 or IP67 according to IEC 60529 standards are recommended. These ratings ensure protection against dust and water jets, reducing the risk of premature failure.

Material choice is equally important. PMMA and UV-stabilized polycarbonate outperform PVC in outdoor environments, maintaining clarity and structural integrity over time.

Common Mistakes When Choosing LED Diffuser Covers

Mistake #1: The “Hotspot” Trap (Shallow Depth + Low Density)

Using a shallow surface profile (e.g., 6mm height) with a standard 60 LEDs/m strip will guarantee visible dots, even with a milky cover.

Fix: Use COB LED strips or a deep profile (min. 15mm depth) to ensure the light beams overlap before hitting the lens.

Mistake #2: Ignoring UV Degradation (The “Yellowing” Effect)

Buying the cheapest diffuser usually means it’s made of generic plastic without UV stabilizers. Indoors near windows or outdoors, these will turn brittle and yellow within months.

Fix: Always specify UV-stabilized PMMA (Acrylic) or Polycarbonate covers for longevity.

Mistake #3: Forgetting End Cap Tolerances

Diffusers can expand and contract with heat (thermal expansion). Cutting the diffuser to the exact same length as the aluminum channel can sometimes cause buckling.

Fix: Leave a 1-2mm gap or ensure the end caps are designed to hold the diffuser specifically.

Custom Diffuser Options for Aluminum LED Strip Channels

Standard 1-meter or 2-meter lengths aren’t always enough for professional projects. This is where partnering with a specialized manufacturer like SignliteLED adds value.

We offer bespoke solutions for commercial and architectural lighting needs:

- Custom Lengths: Need a continuous run of 3 meters or more without seams? SignliteLED can extrude custom lengths to minimize light leaks and connection points.

- Tailored Opacity: For OEM projects, we can adjust the diffusion mixture of our PMMA covers—creating the perfect balance between hiding the LED dots and maximizing light transmission for your specific LED strip.

- Material Selection: Choose between high-impact Polycarbonate (PC) for public walkways or optical-grade PMMA for museum-quality clarity.

- Complete System Matching: Don’t guess if the cover fits. SignliteLED provides fully integrated systems, ensuring the aluminum heatsink, diffuser lens, and mounting accessories work in perfect harmony.

FAQ

An LED channel diffuser is a cover or lens, typically made of PMMA or polycarbonate, that snaps onto an aluminum LED strip channel. Its primary function is to soften and evenly distribute light from LED strips, reduce visible hotspots, protect the LEDs from dust and contact, and improve the overall appearance of linear lighting installations.

The main difference between clear and milky LED diffusers is light diffusion. A clear diffuser offers maximum brightness with minimal light loss but may show visible LED dots. A milky diffuser scatters light more effectively, creating a smooth, dot-free glow, though it typically reduces total light output by 30–50% depending on thickness and channel depth.

An LED strip diffuser usually refers to any material used to soften light directly above an LED strip, while an LED channel diffuser is specifically designed to work with an aluminum LED channel system. Channel diffusers are engineered for precise fit, better heat management, cleaner installation, and consistent optical performance compared to standalone diffuser solutions.

In most professional lighting applications, a diffuser is strongly recommended for LED strip lights. Without a diffuser, LED strips often produce harsh glare and visible hotspots. Using an LED channel diffuser improves visual comfort, protects the LED strip, and creates a more polished, architectural lighting effect, especially in residential, retail, and commercial environments.

To reduce LED hotspots while maintaining brightness, use a milky LED diffuser combined with sufficient channel depth or higher-density LED strips. Increasing the distance between the LED strip and the diffuser improves light blending. COB LED strips are especially effective, as they produce uniform light even with shallow channels and minimal brightness loss.

Réflexions finales

Diffuser selection is one of the most underestimated aspects of LED strip lighting design. By understanding the differences between clear, milky, and black covers, along with material science, channel depth, and installation methods, you can achieve lighting results that are both visually refined and technically sound.

A well-chosen diffuser transforms an LED strip channel from a simple housing into a professional lighting solution that meets modern architectural standards.