Avec la popularité croissante de la technologie d'éclairage LED, la sélection de la bonne solution de protection pour les bandes LED est devenue un facteur critique affectant la fiabilité et la portée de l'application.

Cet article se concentre sur trois solutions techniques traditionnelles : l'extrusion creuse en silicone, les gaines en silicone et les gaines en plastique, analysant systématiquement les mesures de base telles que les performances imperméables, les caractéristiques thermodynamiques et la résistance mécanique basées sur les principes de la science des matériaux et les exigences de la pratique technique.

En comparant les données expérimentales et les cas d'application de l'industrie, il fournit des bases objectives pour la sélection de la technologie dans différents scénarios, visant à aider les décideurs en ingénierie à établir un cadre de développement de produits scientifiques.

Aperçu des trois méthodes d'étanchéité

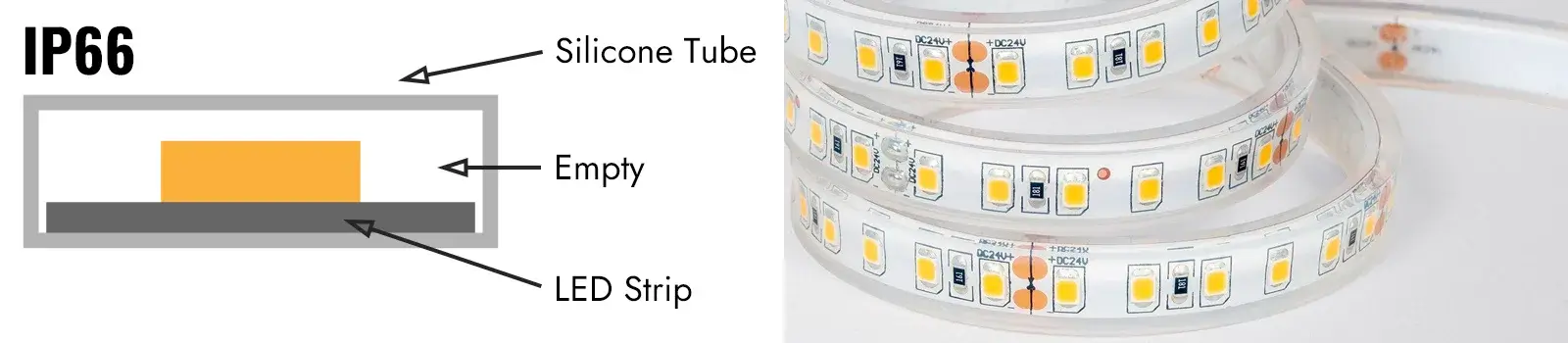

Parmi les bandes LED imperméables, trois processus sont les plus courants : extrusion creuse en silicone, manchons en silicone et manchons en plastique.

L'extrusion creuse de silicone implique la co-extrusion de la bande LED avec un manchon en silicone, où les puces LED sont entièrement encapsulées par du silicone solide pour former une structure imperméable robuste. Le manchon en silicone avec manchon en plastique consiste à enfiler la bande légère pré-fabriquée dans un manchon en silicone, sécurisée par la traction pour obtenir une imperméabilité de base.

Ces trois méthodes diffèrent par leur performance d'imperméabilisation, leur résistance au vieillissement, leur dissipation thermique et leur coût. Comment les clients doivent-ils faire le bon choix ? Ci-dessous, nous comparons les trois technologies basées sur les propriétés des matériaux, les principes de fabrication et les applications pratiques pour explorer leurs différences techniques et leur positionnement sur le marché.

Pour en savoir plus sur les techniques d'imperméabilisation des slips LED, lisez les articles du blog "Quels sont les processus d'étanchéité utilisés dans les socs de LED ?» et «Le guide ultime des slips de LED étanches.”

Extrusion creuse en silicone

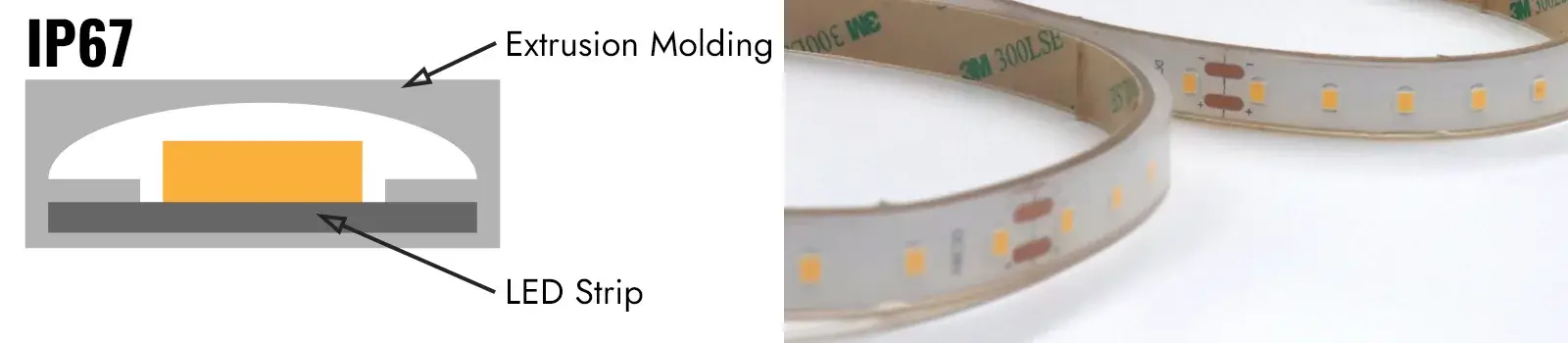

Les bandes lumineuses imperméables sont généralement fabriquées à l'aide de procédés d'extrusion, principalement classés en extrusion creuse et en extrusion solide.

L'extrusion creuse laisse un vide au cœur de la bande extrudée, tandis que l'extrusion solide forme la bande entière comme une structure solide. L'extrusion creuse est plus complexe, nécessitant des extrudeuses et des moules spécialisés, ce qui entraîne des difficultés de production et des coûts plus élevés.

Les bandes lumineuses extrudées en silicone présentent les caractéristiques suivantes :

- Les bandes creuses extrudées ont une cavité d'air interne, ce qui entraîne une faible densité. Le silicone est léger, très flexible et possède un degré de douceur et d'élasticité, lui permettant de se conformer à des surfaces courbes complexes. Le silicone pyrolytique à haute transparence est généralement utilisé pour l'extrusion creuse, avec sa grande fluidité répondant aux exigences des structures à cavité à paroi mince ou complexe.

- L'intérieur creux disperse la lumière des perles LED plus uniformément, atteignant un éclairage supérieur. Les bandes creuses extrudées présentent des couleurs plus vives et plus transparentes que les bandes extrudées solides, avec des bords plus lisses.

- En raison de l'isolation de l'air, les bandes creuses extrudées ont une conductivité thermique plus faible. Les températures de fonctionnement des LED sont généralement de 10 à 15 °C plus élevées que les bandes solides extrudées.

- Le silicone creux présente une dureté et une résistance chimique à la corrosion relativement plus faibles.

- Complexité d'installation : Les bandes creuses extrudées sont légères et peuvent être directement adhérentes, tandis que les bandes extrudées solides nécessitent un montage de support, ce qui augmente les coûts de main-d'œuvre d'environ 15%.

- En termes de coûts, les bandes extrudées creuses sont environ 20%-30% moins chères par unité que les solides, mais ont une durée de vie plus courte (généralement entre 20 000 et 30 000 heures). Les bandes extrudées solides ont des coûts initiaux plus élevés mais peuvent durer plus de 50 000 heures. Les bandes creuses extrudées peuvent être directement adhérées, tandis que les solides nécessitent un montage sur support, augmentant les coûts de main-d'œuvre d'environ 15%.

manchon en silicone

Les bandes de LED en silicone sont des bandes d'éclairage imperméables avec des ampoules LED enveloppant de matériaux en silicone flexibles.

La bande LED est enfilée à travers le manchon en silicone, qui est ensuite scellé aux deux extrémités pour empêcher l'infiltration d'eau de la pluie ou d'autres sources. Généralement utilisé dans l'éclairage de contours architecturaux, la décoration commerciale et les projets de paysages extérieurs, il prend en charge la flexion et la déformation pour se conformer à des structures irrégulières.

Les fonctionnalités incluent :

- Flexibilité et formabilité: Le matériau en silicone offre une excellente flexibilité, permettant à la bande d'être pliée dans différentes formes. Cela le rend adapté aux installations courbes ou complexes, telles que la conformité à des décorations circulaires, des bords de meubles ou des installations artistiques pour répondre aux besoins d'éclairage créatifs.

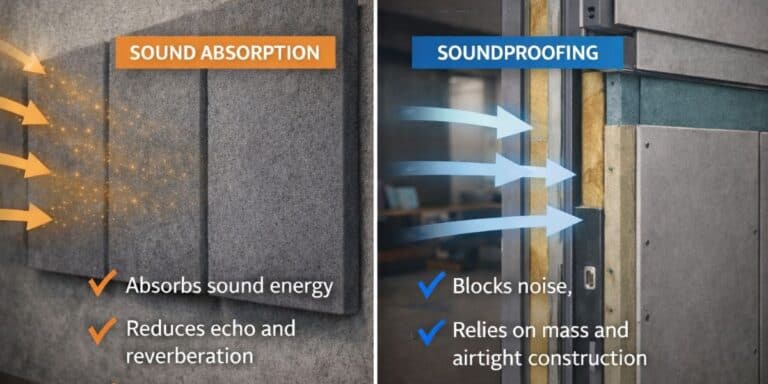

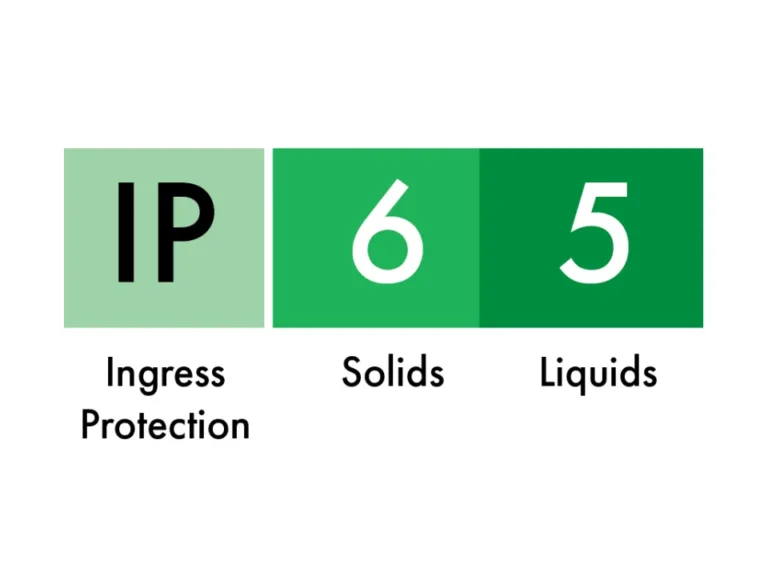

- Performance imperméable et anti-pous: Le tube en silicone lui-même offre une intégrité de scellement élevée, empêchant efficacement l'humidité et la poussière de pénétrer dans l'intérieur de la bande. De nombreux produits obtiennent une cote IP67 étanche, permettant une brève submersion. Cela les rend particulièrement adaptés aux environnements humides comme les salles de bains, les cuisines ou les éclairages extérieurs.

- Doux et uniforme: Le tube en silicone agit comme un diffuseur de lumière, réduisant l'éblouissement des ampoules LED pour produire un éclairage plus doux et plus uniforme. Cette caractéristique convient aux espaces nécessitant une ambiance confortable, comme les chambres, les salles à manger ou l'éclairage décoratif dans les espaces commerciaux.

- Durabilité et sécurité: Le matériau silicone résiste aux températures élevées et au vieillissement, prolongeant ainsi la durée de vie de la bande. Ses propriétés isolantes améliorent également la sécurité électrique en réduisant les risques de courts-circuits ou de fuites.

- Large plage de température: Fonctionne généralement de -40 °C à 200 °C, adapté aux environnements de températures extérieures et extrêmes.

- Résistance au vieillissement: La stabilité des matériaux résiste à l'exposition à l'huile et à l'ozone, assurant une durée de vie prolongée.

manchon en plastique

Les bandes de lumière LED imperméables à manches en plastique sont généralement fabriquées à partir de PVC de haute qualité. Ils sont imperméables, flexibles, pliables et résistants aux températures élevées et basses, ce qui les rend adaptés aux applications intérieures et extérieures.

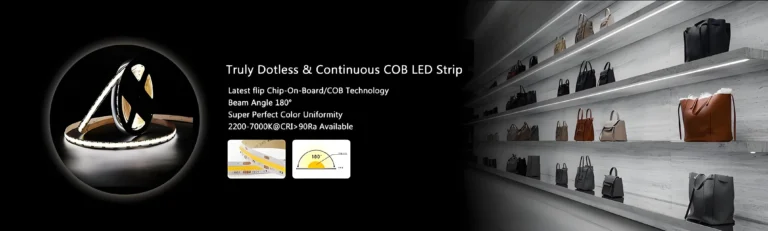

Le manchon a une largeur interne de 10 mm, permettant l'insertion de bandes lumineuses SMD ou COB de 8 à 10 mm comme source lumineuse. Cela fournit un boîtier de protection pour la bande lumineuse LED, assurant durabilité et longévité.

Le PVC (chlorure de polyvinyle) est le matériau courant des manchons de bandes de néons et de bandes LED en raison de ses processus de fabrication à maturité et de ses avantages en termes de coûts. Par exemple, les canaux de bandes de néons flexibles utilisent souvent un matériau PVC résistant qui résiste à la fissuration lorsqu'il est plié.

● Résistance à l'imperméabilisation et à la corrosion : le PVC offre une imperméabilisation supérieure, bloquant efficacement la vapeur d'eau, ce qui le rend adapté aux environnements humides comme les salles de bains. Il présente également une bonne résistance à la corrosion et une certaine résistance chimique, s'adaptant aux réglages intérieurs et extérieurs.

● Installation facile : sa flexibilité permet à la flexion et à la coupe de s'adapter à différentes formes, tandis que sa nature légère facilite la construction.

● Durabilité : sujet au vieillissement et à la décoloration ; une exposition prolongée aux rayons UV ou à des températures élevées peut provoquer un jaunissement et une fragilité, affectant la transmission de la lumière et l'esthétique.

● Tolérance de température limitée : Le PVC a une plage de température étroite (-15°C à 80°C). Une utilisation prolongée en extérieur peut entraîner un jaunissement et un durcissement dû à une exposition aux UV. Il émet des gaz irritants lorsqu'il est brûlé, se déforme à des températures élevées et peut se fissurer à basse température, limitant son utilisation dans les climats extérieurs extrêmes.

● Propriétés optiques : la transmission de la lumière est uniquement de 70%-80%, la lumière semble jaunâtre et l'indice de rendu des couleurs est faible (70-80), ce qui entraîne une mauvaise reproduction des couleurs. L'uniformité légère est inférieure aux matériaux en silicone ou acryliques, créant potentiellement un aspect granuleux.

● Problèmes environnementaux et sanitaires : Le PVC contient des substances nocives comme le chlorure de vinyle, qui peuvent éliminer les polluants pendant la production et l'utilisation, ce qui le rend moins écologique.

● Faible coût : Le PVC est nettement moins cher que les alternatives comme le silicone ou l'acrylique, ce qui le rend adapté aux projets à budget limité.

Tableau de comparaison

Extrusion creuse en silicone VS manche en silicone VS manche en plastique

| Carithmé-rique | Extrusion creuse en silicone | manchon en silicone | manchon en plastique |

| Flexibilité | Grande flexibilité et bonne élasticité, facile à plier | Grande flexibilité et bonne élasticité, facile à plier | Dureté élevée, bonne résistance à la déchirure, rebond médiocre, sujet à la déformation, à la flexion |

| Durabilité | Généralement 8 à 12 ans à l'intérieur, 5 à 8 ans à l'extérieur | Intérieur : 8-10 ans, extérieur : 5-6 ans | Intérieur : 2-3 ans, extérieur : 1-2 ans |

| transmission lumineuse | Excellente transmission lumineuse, >90% | Bonne transmission de la lumière, 90%-95% | Transmission de faible luminosité, env.60%-85% |

| Résistance à la température | Résiste aux températures extrêmes, convient de -40°C à 230°C, sans jaunissement avec une utilisation à long terme | Résiste aux températures extrêmes, convient de -40°C à 230°C | Mauvaise résistance à la température, fragile en dessous de -10°C, limite supérieure à 70°C, sujette au jaunissement avec une exposition prolongée au soleil |

| Sécurité | Non polluant pendant la production et l'utilisation | Non polluant pendant la production et l'utilisation | Mauvaise performance environnementale; libère des gaz nocifs à haute température |

| Résistance à l'imperméabilisation et | Résistant aux acides/alcalis et à la corrosion ; inadapté à une immersion prolongée sous-marine | Résistant aux acides/alcalis et à la corrosion ; inadapté à une immersion prolongée sous-marine | Imperméabilisation et résistance à la corrosion supérieures; non adaptés à l'exposition directe au soleil; mauvaise résistance aux acides/alcalis |

| Installation et maintenance | Poids moyen, peut être directement collé, long cycle d'entretien | Léger, peut être directement collé, facilement pliable, long cycle d'entretien | Installation simple mais entretien fréquent requis; utilisation en extérieur nécessite un remplacement tous les 1 à 2 ans |

| Coût | Coûteux | relativement élevé | relativement faible |

| Scénarios d'application | Utilisation à l'extérieur à long terme, environnements à haute humidité/température, paramètres médicaux/de qualité alimentaire, éclairage à long terme dans les salons, les armoires, etc. | Éclairage à long terme dans les salons, les armoires, etc. | Décoration à court terme, éclairage intérieur à faible coût |

En résumé, les matériaux utilisés dans les procédés d'extrusion de silicone creux et de manchon en silicone sont essentiellement les mêmes, avec seulement certaines différences dans les méthodes de fabrication. L'extrusion implique un traitement direct de la machine, tandis que le processus de manchon nécessite plus de travail manuel.

Lorsque vous comparez des bandes LED avec des tubes extrudés en silicone creux, des manchons en silicone et des manchons en PVC, chacun a ses propres caractéristiques et convient à différents scénarios. Pour maximiser l'efficacité des bandes de lumière LED dans diverses applications, il est essentiel de sélectionner le processus et les caractéristiques appropriés.

Pour les projets soucieux de leur budget dans des environnements doux, des manchons en plastique peuvent être envisagés, bien qu'il convient de noter la fréquence de remplacement. Équilibrant la performance globale et le coût à long terme, les gaines en silicone creuses ou en silicone offrent des choix supérieurs, notamment en matière d'imperméabilisation, de résistance à la température et de flexibilité.

Scénarios et guide de sélection

Extrusion creuse en silicone

Idéal pour les criques de plafond, l'éclairage sous l'armoire, les garde-corps d'escalier et des applications similaires, il offre à la fois un éclairage fonctionnel et un attrait esthétique. Sa douce lueur est particulièrement adaptée pour créer une ambiance dans les chambres ou les salons.

Grâce à leurs propriétés imperméables, les bandes LED à extrusion creuse en silicone peuvent être utilisées pour l'éclairage décoratif dans les jardins, les bords de la piscine ou les extérieurs des bâtiments. Ils maintiennent un fonctionnement stable même dans les environnements pluvieux ou poussiéreux.

manchon en silicone

Dans les magasins, les bars ou les salles d'exposition, la flexibilité et la malléabilité des bandes de lumière en silicone en font un choix idéal pour l'éclairage décoratif. Par exemple, ils peuvent décrire les contours des vitrines ou créer des installations de lumière artistiques uniques.

Alors que le silicone est résistant à la chaleur, une luminosité prolongée peut encore provoquer une accumulation de chaleur, ce qui affecte la durée de vie des LED. Évitez le fonctionnement continu à pleine charge dans des environnements fermés ou mal ventilés.

manchon en plastique

Convient pour les projets d'éclairage extérieur, les bandes lumineuses à manchon en PVC sont idéales pour les décorations à court terme, les projets à petit budget ou les environnements non extrêmes (par exemple, expositions temporaires, éclairage ambiant à faible luminosité). Pour une utilisation à long terme ou des scénarios exigeants (par exemple, les paramètres extérieurs, les exigences de rendu des couleurs élevées), le matériau en silicone est recommandé.

Notez également que les bandes LED susmentionnées sont plus adaptées aux climats plus chauds. Dans les régions plus froides, les LED dans le manchon peuvent générer de la chaleur pendant le fonctionnement.

Lorsque les températures externes sont basses, l'air et l'humidité à l'intérieur du manchon peuvent s'oxyder, ce qui peut corroder les LED ou les circuits imprimés ou produire un brouillard brumeux qui affecte la production de lumière. Pour des exigences d'éclairage plus performantes, des options extrudées solides peuvent être préférables.

Considérations relatives aux coûts et à l'entretien

Lumières de bande LED extrudées creuses en silicone: Coûts de matériaux plus élevés grâce au processus de moulage en une seule pièce. Faibles frais d'entretien. Le classement étanche IP68 minimise les défaillances liées à l'humidité. Utilisation à long terme sans remplacements fréquents. Évitez les plis excessifs lors de l'installation pour éviter la rupture du circuit interne. Convient aux environnements difficiles comme les paramètres extérieurs et les éléments d'eau, mais nécessite une conception appropriée de la dissipation thermique pour éviter un vieillissement accéléré par des températures élevées.

Lumières de bande de LED de manchon en silicone: Large gamme de prix, les conceptions transparentes ou bicolores affectent le coût. Un entretien modéré est requis : inspectez régulièrement le moule à bande pour éviter la pénétration d'eau. Faites correspondre la taille des manches à dénuder lors de l'installation pour éviter une mauvaise dissipation thermique due à l'étanchéité ou à une imperméabilité compromise due à l'enlèvement. Plage de température : -60°C à 200°C, bien que la chaleur élevée prolongée puisse accélérer le jaunissement du silicone.

Lumières de bande de LED en plastique: Coût le plus bas, adapté aux scénarios à budget limité. Coûts d'entretien plus élevés; Le matériau PVC vieillit facilement, ce qui nécessite un remplacement régulier des manchons. Uniquement adapté aux environnements secs; l'imperméabilisation est plus faible que les solutions en silicone (cote IP inférieure). Évitez le contact avec les solvants chimiques pour éviter la fragilité et la fissuration des manches.

Tableau de comparaison complet :

| Type | Gamme de prix unitaire (USD/m) | Fréquence de maintenance | Environnement convenable |

| Silicone creux extrudé | $3.67-4.9 | Faible | Caractéristiques extérieures/eau |

| manchon en silicone | $0.22-3.78 | Moyen | Intérieur/Semi-extérieur |

| manchon en plastique | $0.02-1.33 | Haut | Sécher à l' |

Recommandation : Priorisez le silicone creux extrudé pour des réglages à haute humidité ou en extérieur, en équilibrant l'étanchéité et la durabilité. Pour les projets limités par le budget dans des environnements stables, des manchons en plastique peuvent être utilisés mais nécessitent des cycles d'entretien plus courts.

Conclusion

Cet article fournit aux décideurs techniques une base scientifique pour la sélection technique en analysant systématiquement les propriétés des matériaux, les performances d'étanchéité et les capacités de dissipation thermique de trois types de bandes LED imperméables.

Signiteled est spécialisé dans la fabrication Bandes LED imperméables en utilisant diverses techniques de production. Si vous avez des questions sur votre projet ou vos exigences, veuillez nous contacter pour un soutien supplémentaire !