LED sheet lighting has become a practical solution for display cabinets and shop windows because it delivers uniform illumination, requires minimal depth, adapts to flexible layouts, and allows precise brightness control. In retail environments where visual presentation directly influences customer perception, uneven lighting, visible hotspots, or bulky fixtures can undermine product impact. A properly designed LED light sheet system addresses these issues by distributing light evenly across surfaces while maintaining a slim profile that fits inside shallow cabinets and narrow window assemblies.

This article explains how LED sheet lighting improves visual merchandising performance specifically in display cabinets and shop windows. It covers the measurable benefits of uniform backlighting, strategies for layout planning in depth-constrained cabinetry, diffuser selection logic, brightness density calculation, glare control for street-facing windows, installation planning, and performance optimization. The focus remains strictly on cabinet and window applications, with technical reasoning behind each design decision.

Key Benefits of LED Sheet Lighting for Retail Displays

- Uniform Backlighting Without Hotspots

LED sheet lighting distributes diodes across a flat surface rather than along a single linear path. When paired with an appropriate LED light diffuser sheet, this layout produces even luminance across cabinet walls and window graphics. The result is reduced shadow gradients, elimination of bright nodes, and consistent visual presentation. - Ultra-Thin Integration

A Feuille de lumière LED is typically only a few millimeters thick, allowing installation inside shallow display cabinets without altering structural depth. This makes it suitable for tight cabinetry where space is limited after accounting for glass, shelving hardware, and support framing. - Energy Efficiency for Extended Retail Hours

Because LED lighting sheet panels illuminate a surface uniformly, they often require fewer overlapping light sources compared to strip-based layouts. This improves area coverage efficiency and reduces overall wattage consumption during long retail operating hours. - Improved Product Visibility

Even background illumination enhances product edges, colors, and textures. By reducing shadow buildup and uneven brightness patches, products appear more clearly defined within both cabinets and shop windows. - Lower Heat Output

The distributed diode configuration reduces localized heat concentration. Compared to fluorescent backlighting or high-intensity spotlights, sheet lights LED systems generate lower radiant heat, which is beneficial for enclosed cabinets and temperature-sensitive merchandise. - Flexible Layout Adaptation

Many LED light sheet systems are cuttable, allowing customization to fit irregular cabinet shapes or window display formats. This flexibility supports integration into curved surfaces and tight installation spaces without compromising uniformity.

Applications in Display Cabinets

Display cabinets present unique lighting challenges due to shallow depth, reflective glass surfaces, and product variety. LED sheet lighting addresses these constraints when applied strategically.

Shelf Backlighting

Shelf backlighting involves placing a LED light sheet behind a vertical rear panel to create an illuminated background. This technique enhances product silhouettes and prevents shadow buildup. For cabinets with a depth under 80 mm, diode density must be sufficient to ensure uniform brightness within a short diffuser distance.

Acrylic sheet for LED lighting is often selected in such configurations because it offers strong optical clarity and good light diffusion in shallow assemblies. Acrylic diffusers are suitable when the distance between the LED light sheet and the diffuser surface is limited to 10–20 mm.

Under-Shelf Glow

Under-shelf illumination enhances product layering and prevents shadowing from upper shelves. In this case, smaller sections of LED light panel sheet can be mounted horizontally under each shelf. A thin diffuser sheet for LED lighting softens the direct emission and prevents glare when customers view products at eye level.

Brightness density planning is important here. If diodes are spaced too widely, individual points may become visible. If too dense, energy use increases unnecessarily. In shallow under-shelf configurations, closer diode spacing ensures even light spread.

Full Cabinet Wall Illumination

Some retail concepts require the entire rear wall of a cabinet to glow uniformly. This approach is common in cosmetics, jewelry, and high-end electronics displays. A polycarbonate LED light diffuser sheet may be selected instead of acrylic in environments requiring higher impact resistance, especially in high-traffic retail settings.

Polycarbonate diffusers provide durability and slightly different light transmission characteristics. When paired with a LED light reflector sheet positioned behind the LED surface, forward light efficiency improves, reducing wasted light inside the cabinet cavity.

Highlighting Premium Product Zones

Selective brightness zoning can be achieved by varying sheet segmentation or using independent dimming channels. For example, a central premium product zone may operate at 20–30 percent higher brightness compared to surrounding areas. This method guides customer attention without using spotlights that create harsh contrasts.

Depth Constraints and Layout Planning

Depth directly influences diffuser selection and diode density. In cabinets with less than 50 mm available cavity depth, high-density LED sheet lighting combined with a high-diffusion acrylic sheet for LED lighting prevents dot visibility. In deeper cabinets exceeding 80 mm, lower density sheets can still achieve uniformity because light has more space to spread.

Over-spacing sheets across a large cabinet wall creates uneven brightness bands. Instead, continuous LED lighting sheet panels should be installed with minimal gaps to maintain luminance consistency.

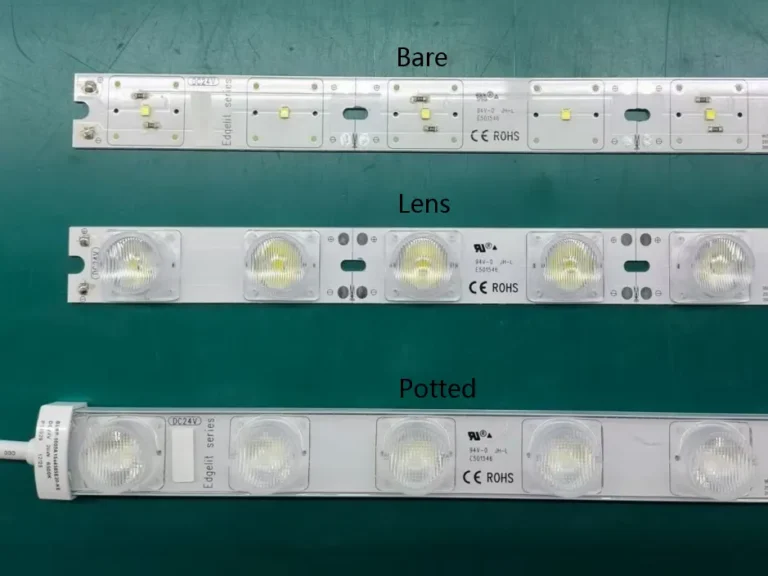

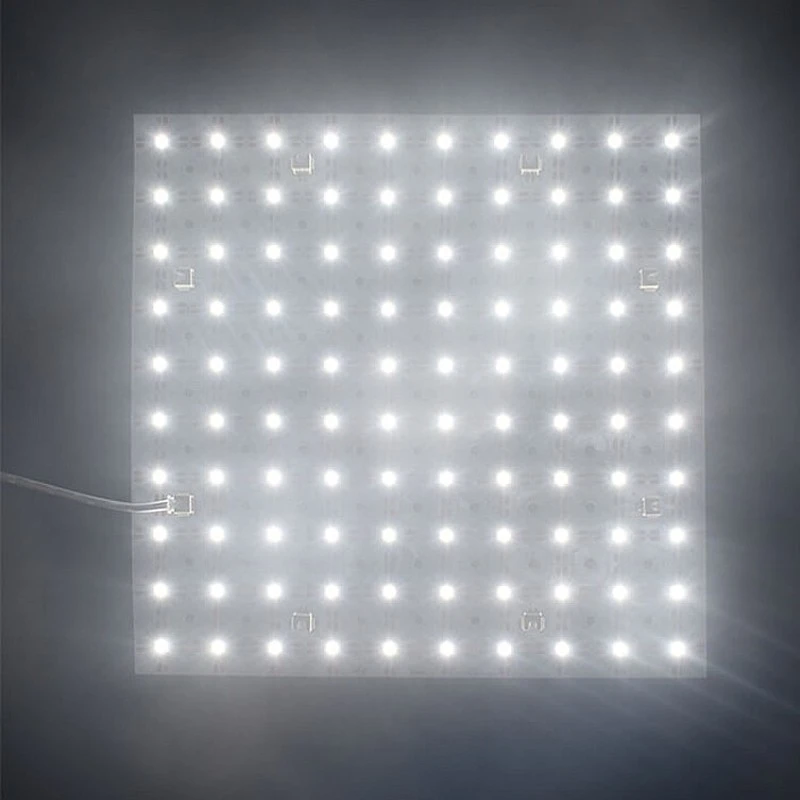

Feuilles de LED monochromes

- Taille (L x l ): 250mmx250mm/490mmx245mm

- Type de LED : 2835 SMD

- Quantité LED : 100 pièces/242pcs

- Tension de fonctionnement : DC24V

- Puissance : 12W/ 28W

- CCT : 2700K/ 3000K/4000K/6000K/6500K

- Flux lumineux : 1200lm/ 2800lm

- IRC : >80Ra

- Longueur de coupe minimale : 25mmx25mm/22.3mmx22.3mm

- Dimmable : oui

- Angle de faisceau : 120°

- Niveau imperméable : IP20 non étanche, IP54 étanche

- Garantie: 3 ans

Applications in Shop Windows

Shop windows differ from display cabinets because they compete with ambient daylight and street reflections. Illumination intensity and glare management become critical.

Large-Format Window Display Illumination

Large window graphics typically use a LED light sheet installed behind a printed translucent panel to create a uniformly illuminated display surface. Because the diodes are distributed across the panel area, the light output remains consistent across the entire graphic, reducing uneven patches and brightness variation.

In street-facing installations, higher brightness LED sheet lighting is often required to compete with daylight. Window displays exposed to direct sunlight must be designed with sufficient luminance to prevent the graphic from appearing faded or washed out.

Brightness planning should be based on expected ambient daylight levels. If the shop window receives strong natural light, the display luminance must exceed surrounding ambient brightness to maintain visual clarity and color definition. Proper lumen density selection, combined with a LED light reflector sheet positioned behind the lighting layer, can improve forward light efficiency without unnecessarily increasing total power consumption.

Brand Logo Illumination

Logos embedded in window displays can be illuminated using smaller segments of LED light panel sheet placed behind cut-out acrylic forms. A diffuser sheet for LED lighting ensures even logo glow without visible diode patterns.

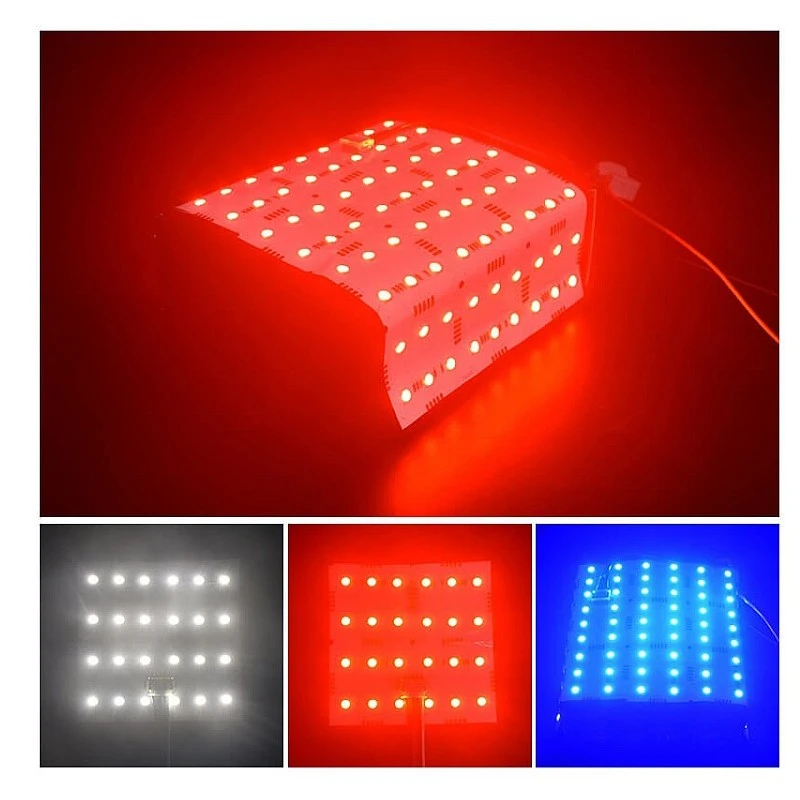

Feuilles LED RGBW

- Taille (L x L ) : 250mmx250mm/490mmx250mm

- Type de LED : 5050 RGBW 4 en 1 SMD

- Quantité LED : 150 pièces/288 pièces

- Tension de fonctionnement : DC 24V

- Puissance : 24W/ 48W

- Émettant de la couleur : RGB+3000K, RGB+4000K, RGB+6500K

- Efficacité légère : 90lm/w

- Longueur de coupe minimale : 50mmx50mm/20.4mmx122.5mm

- Angle de faisceau : 120°

- Dimmable : oui

- Niveau imperméable : IP20 non étanche, IP54 étanche

- Garantie: 3 ans

Seasonal Promotional Panels

Retail windows frequently change promotional content. Modular LED lighting sheet panels allow quick graphic replacement while maintaining consistent illumination geometry. Power connections should remain fixed while graphic layers are swapped.

Daylight Competition Strategies

Sunlight introduces glare and reflection. Positioning a LED light reflector sheet behind the LED surface increases forward output and reduces backward light loss. This increases effective luminance without raising power consumption excessively.

Reflection and Glare Management

Glass reflections can distort perceived brightness. Diffuser thickness and surface finish should be chosen carefully. Matte-finish polycarbonate LED light diffuser sheets can reduce glare reflection compared to high-gloss surfaces.

When customers approach from different angles, uniform luminance reduces eye strain and enhances graphic clarity.

Diffusion & Optical Layer Strategy

The LED light diffuser sheet plays a central role in achieving uniform illumination. Without proper diffusion, individual diode points become visible, especially at short distances.

Role of Diffusers

Diffusers scatter emitted light to create a continuous luminous surface. The amount of scattering depends on material composition and thickness. A diffuser sheet for LED lighting must balance transmission efficiency and opacity.

Acrylic vs Polycarbonate

An acrylic sheet for LED lighting typically offers higher light transmission and good optical clarity. It works well in controlled indoor cabinets where impact resistance is not a major concern.

A polycarbonate LED light diffuser sheet offers greater mechanical strength and higher temperature resistance. It is often chosen for shop windows where durability and public exposure are factors.

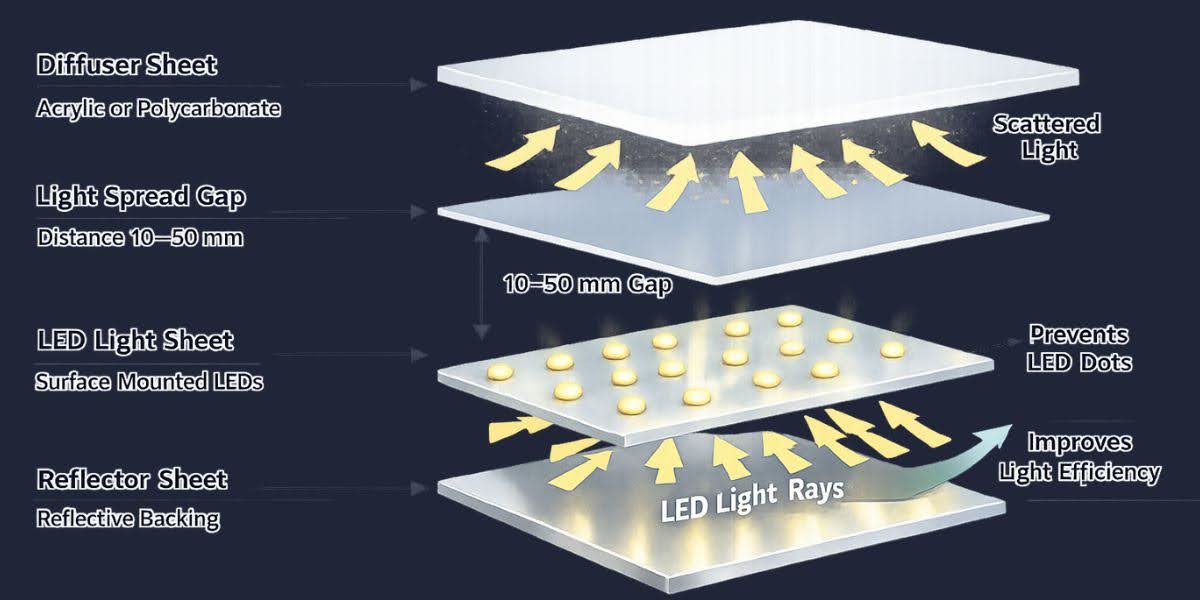

Light Spread Distance

The gap between the LED light sheet and the diffuser affects uniformity. A smaller gap requires higher diode density to avoid hotspots. Larger gaps allow light to spread naturally but require deeper cabinet space.

Preventing LED Dot Visibility

Dot visibility occurs when diode spacing exceeds diffusion capacity. Increasing diffuser thickness or reducing spacing between LEDs resolves this issue. Uniformity must be visually tested at typical viewing distances.

Role of Reflector Sheets

A LED light reflector sheet installed behind the LED surface improves forward efficiency by reflecting backward-emitted light. This increases perceived brightness without increasing wattage. Reflector materials should have high reflectance and minimal absorption.

Installation Strategy for Cabinets & Windows

- Ensure mounting surfaces are clean, flat, and free of dust to prevent uneven adhesion and light distortion.

- Maintain proper spacing between the LED light sheet and the LED light diffuser sheet based on diode density and cabinet depth.

- Position power supplies outside enclosed cabinet cavities when possible to reduce internal heat accumulation.

- Route cables along concealed edges of cabinetry to avoid shadow lines or visible wiring through glass panels.

- Provide minimal but effective ventilation in enclosed cabinets to prevent heat buildup, especially in high-brightness window applications.

- Confirm dimmer compatibility with the specific driver type to avoid flicker or uneven brightness transitions.

Design Optimization for Visual Merchandising

- Use layered lighting by combining background Éclairage de feuille LED with focused accent lighting to create visual hierarchy.

- Integrate a LED light panel sheet behind branding graphics while adding subtle edge accents to frame the display area.

- Control contrast ratios so highlighted products appear brighter than surrounding elements without causing glare.

- Apply dynamic dimming in shop windows to adapt brightness from daytime to evening conditions.

- Match luminance levels to product type, using softer illumination for reflective items and higher brightness for opaque merchandise.

Performance Comparison Table

| Facteur | LED Sheet Lighting | Bandes LED traditionnelles | Fluorescent Backlighting |

| épaisseur | Very thin, typically a few mm | Moderate, requires channel | Bulky fixture depth |

| Uniformité | High with diffuser | Often uneven, hotspot risk | Moderate, tube shadowing |

| Efficacité énergétique | High area efficiency | Modéré | Lower compared to LED |

| Puissance calorifique | Low distributed heat | Localized heat points | Higher heat generation |

| Visual Quality | Smooth luminous surface | Visible strip lines possible | Flicker and uneven aging |

| Flexibilité d'intégration | Cuttable, shape adaptable | Linear only | Fixed tube length |

Common Mistakes in Retail LED Sheet Installations

One frequent mistake is insufficient lumen density planning. Installing a low-density LED sheet lighting system in a shallow cabinet often results in visible diode patterns. Brightness must align with diffuser spacing and viewing distance.

Poor diffuser selection also affects performance. Using a thin diffuser in a short-depth cabinet may not adequately scatter light, while overly opaque materials can reduce brightness excessively.

Ignoring daylight conditions in shop windows leads to underpowered displays. Street-facing installations require brightness calculations based on ambient lux levels.

Over-spacing sheets across large panels creates brightness gradients. Continuous coverage ensures uniform luminance.

Finally, neglecting dimming integration prevents adaptive brightness control. Retail environments benefit from adjusting luminance based on time of day and seasonal changes.

Conclusion

LED sheet lighting significantly improves presentation quality in display cabinets and shop windows by delivering uniform illumination, minimizing structural depth, and enabling flexible layout integration. Its distributed diode configuration supports smooth backlighting without hotspots, while controlled brightness and reflector integration enhance efficiency.

Successful implementation depends on selecting the appropriate diffuser material, calculating brightness density based on cabinet depth and daylight exposure, and applying proper installation logic. When these technical factors are addressed carefully,LED sheet lighting enhances visual clarity, product focus, and energy efficiency within retail environments.

FAQ

Brightness depends on product type and ambient lighting. Enclosed cabinets typically require moderate luminance, while glass-front cabinets exposed to ambient retail lighting may require higher output.

Spacing varies with diode density. Shallow cabinets may require high-density sheets with minimal spacing, while deeper cabinets allow greater diffusion distance.

Heat output is low compared to fluorescent systems, but enclosed cabinets should still allow minimal airflow for temperature stability.

Most systems operate for tens of thousands of hours, depending on driver quality and operating temperature.

Yes. Dimmable drivers enable brightness reduction during nighttime hours to conserve energy and reduce glare.

It is recommended when maximizing forward light output is necessary, particularly in shallow cabinets or daylight-exposed windows.

Uniformity can be achieved in shallow depths with proper diode density and diffuser selection. Deeper cabinets offer more flexibility.

Higher daylight levels require increased luminance to maintain visibility. Brightness planning must consider sun direction and reflection.