En extérieur, les slips LED sont très appréciés pour leur flexibilité et leur attrait décoratif. Cependant, les éclairages à LED traditionnels sont souvent sensibles aux dégâts des eaux dans les environnements extérieurs, ce qui entraîne une diminution des performances d'éclairage ou même des dommages. Les bandes de lumière LED étanches abordent efficacement ce problème. Les bandes lumineuses LED imperméables offrent non seulement des performances imperméables supérieures, mais conservent également un éclairage stable dans diverses conditions météorologiques difficiles sans compromettre leurs effets décoratifs.

Cependant, il existe différents types de bandes LED étanches, et de nombreuses personnes peuvent ne pas être bien informées à leur sujet. Lors de leur sélection, il faut tenir compte de leur prix et évaluer leurs performances d'étanchéité, l'environnement d'utilisation prévu, la sécurité et la couleur de l'éclairage, entre autres facteurs. Ci-dessous, je fournirai une introduction détaillée aux techniques d'imperméabilisation pertinentes pour les socs LED.

Quels sont les processus d'étanchéité pour les bandes LED COB et SMD ?

Actuellement, les principaux processus d'imperméabilisation des bandes LED COB et SMD comprennent le revêtement par pulvérisation, le revêtement par goutte à goutte, le tube, le rempotage, l'extrusion et le revêtement. Chacun de ces processus a ses propres caractéristiques. Voyons les différences entre eux :

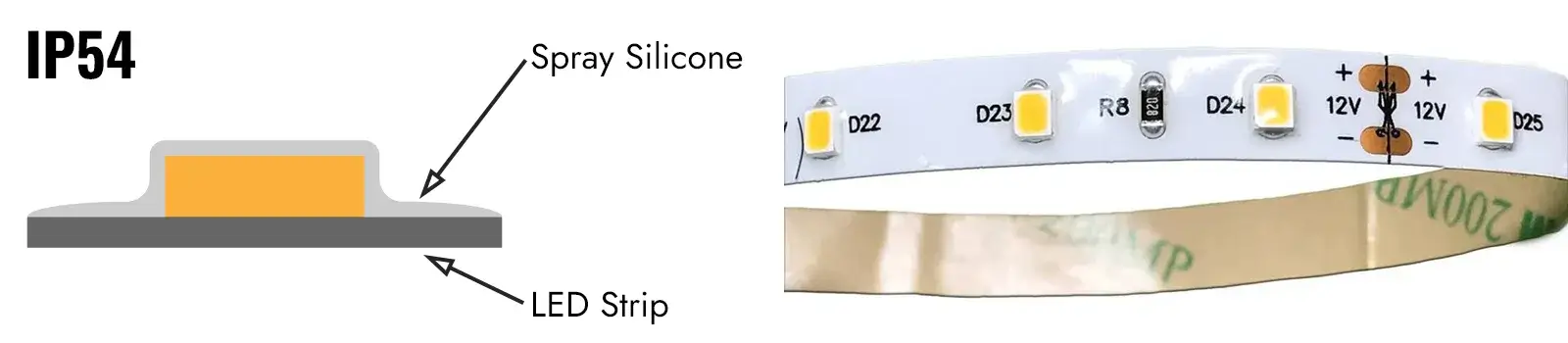

Processus de revêtement par pulvéris

Le processus d'adhésif par pulvérisation utilise principalement une machine adhésive en pulvérisation pour appliquer de l'adhésif silicone sur la surface de la bande lumineuse. L'épaisseur de la couche adhésive est généralement assez mince, généralement autour de 30 à 50 microns. En raison de la finesse de la couche adhésive, elle a un impact minimal sur les performances optiques d'origine de la bande lumineuse, telles que la luminosité, la température de couleur et l'indice de rendu des couleurs.

Les bandes LED revêtues de pulvérisation sont des produits d'éclairage LED qui combinent la technologie de collage. Ce gel offre une protection anti-éclaboussures, permettant aux produits de bandes LED revêtus de pulvériser d'atteindre une cote de protection IP54 ou supérieure, améliorant ainsi les performances de résistance à l'eau, à la poussière et à haute température de la bande LED. Ces bandes LED sont généralement installées dans les salles de bains, les cuisines, les espaces extérieurs ou les environnements résistants aux éclaboussures. Ils conviennent à la fois aux environnements secs et humides, tels que les salons, les cuisines et les salles de bains. Ils ne sont pas recommandés pour une utilisation dans les zones sujettes aux éclaboussures d'eau.

Processus de chute de colle

Le processus de collage de gouttes consiste d'abord à fixer la bande lumineuse en ligne droite, puis à utiliser une machine de distribution de haute précision pour se déplacer le long du chemin de circuit imprimé de la bande lumineuse, en injectant de la résine époxy ou de l'adhésif PU sur la surface de la bande lumineuse. En contrôlant la sortie de l'adhésif de la buse, la couche adhésive est appliquée uniformément pour recouvrir les composants et les circuits émetteurs de lumière.

L'épaisseur des gouttelettes est généralement contrôlée autour de 2 mm. Les bandes lumineuses LED produites à l'aide du processus de revêtement goutte ont atteint une valeur de protection IP67 ou supérieure tout en conservant la flexibilité et les performances de dissipation thermique. Ce processus convient aux environnements humides, fournissant efficacement une imperméabilisation de surface et peut être utilisé dans divers contextes tels que les hôtels, les maisons et les bureaux.

Les avantages des bandes de LED Drop Glue incluent une utilisation simple et des coûts inférieurs, mais la cote de protection est limitée (généralement IP54-IP65). Les inconvénients comprennent un impact potentiel sur la dissipation thermique, ainsi que certains effets sur la température de couleur et la luminosité, et la tendance à jaunir au fil du temps avec une utilisation prolongée en extérieur.

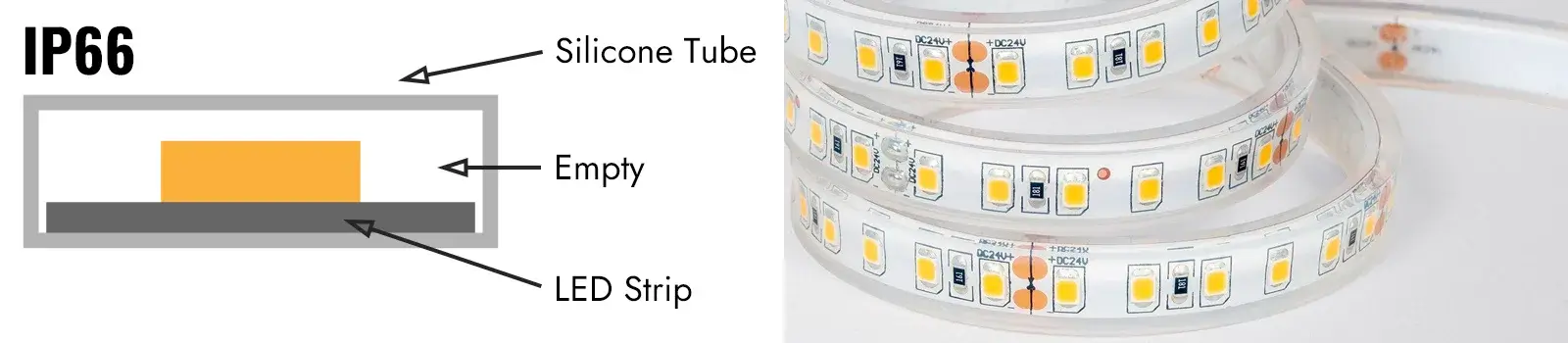

Processus de manche cr

Le processus de bande de LED de manchon est relativement simple, impliquant principalement l'insertion de la bande LED entière dans un tube de silicone/PVC, puis l'étanchéité des deux extrémités pour empêcher l'infiltration d'eau de la pluie ou d'autres sources. Ce processus permet à la bande LED d'obtenir une cote d'étanchéité d'environ IP66.

Les avantages des bandes de lumière LED à manches comprennent une bonne flexibilité, une bonne aptitude pour les installations incurvées et une résistance efficace à l'eau. Cependant, un inconvénient est que les bandes de lumière LED avec des manches ne conviennent qu'aux régions à températures plus élevées dans le sud. Dans les régions du nord plus froides, les LED à l'intérieur des manches peuvent générer de la chaleur pendant le fonctionnement. Lorsque l'environnement extérieur est froid, l'air et l'eau à l'intérieur des manchons peuvent s'oxyder, corrosionant potentiellement les LED ou oxydant le circuit imprimé. Le coût de fabrication des bandes de lumière LED tubulaires est relativement élevé et leur performance de dissipation thermique est légèrement inférieure, ce qui peut affecter leur durée de vie lorsqu'il est utilisé en continu pendant de longues périodes.

Veuillez regarder la vidéo suivante pour savoir comment créer une bande LED à manches creuses.

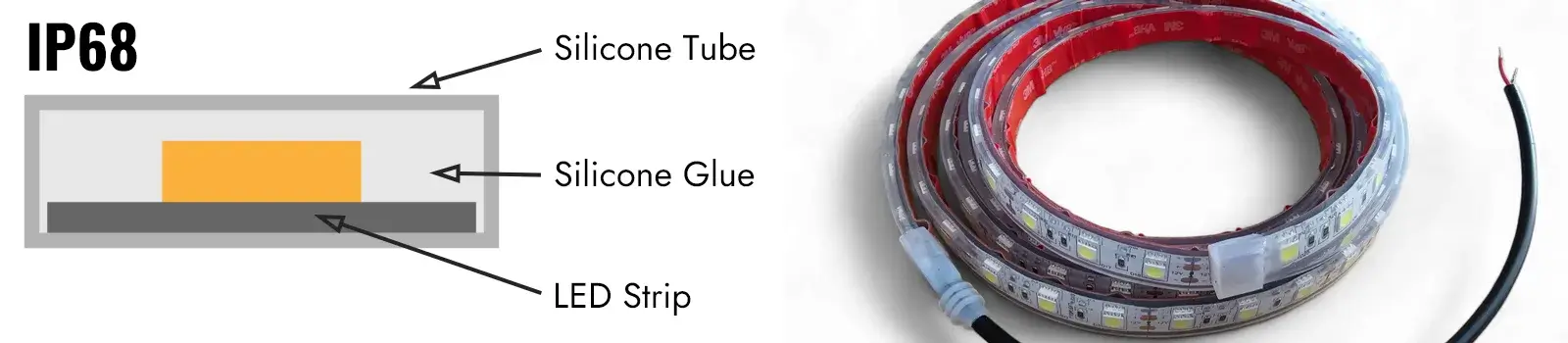

Processus de remplissage de man

Le processus de remplissage de manchons de bandes LED consiste à glisser un manchon en PVC ou silicone transparent sur la surface de la bande LED, puis à mélanger le silicone organique ou la résine époxy à deux composants dans le bon rapport pour éliminer les bulles (pour éviter les poches d'air après durcissement). Une machine d'encapsulation automatique injecte ensuite uniformément le matériau d'encapsulation dans le manchon le long de la longueur de la bande. Après durcissement, une couche scellée se forme à l'intérieur du manchon, améliorant efficacement l'imperméabilisation et les performances mécaniques.

Après le remplissage, la bande LED atteint une cote IP68 étanche, permettant une utilisation dans des environnements extérieurs ou difficiles. Les bandes LED en pot, avec leurs propriétés d'étanchéité, leur résistance aux intempéries et leur stabilité chimique, sont largement applicables dans les scénarios exigeants tels que l'éclairage extérieur, l'éclairage industriel et la décoration des véhicules, ce qui en fait un choix idéal pour les solutions d'éclairage à long terme et sans entretien.

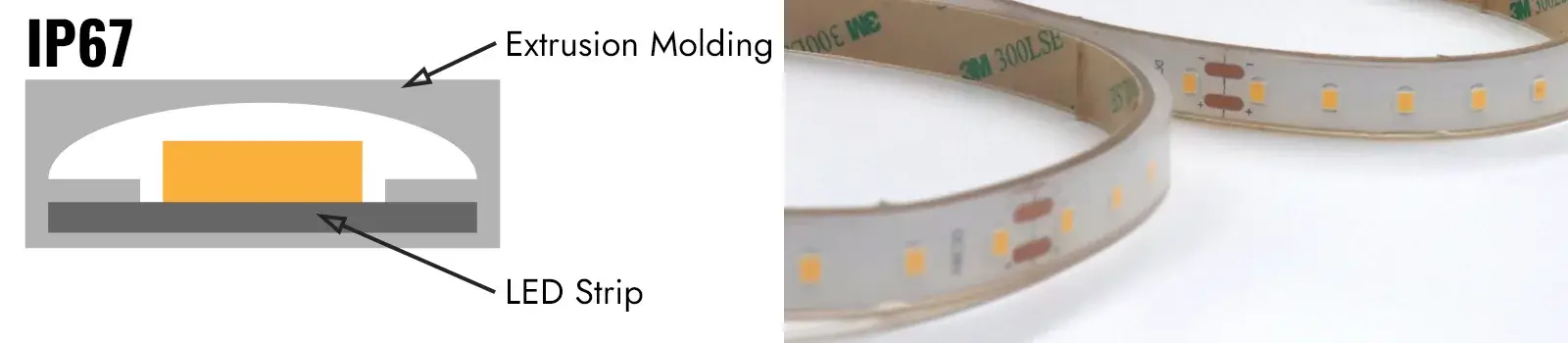

Processus d'extrusion

Le processus d'extrusion des bandes de LED flexibles consiste à chauffer et à fondre des matériaux thermoplastiques (tels que le PVC ou le silicone), puis à l'aide d'une extrudeuse à vis pour forcer le matériau dans un moule de précision, en l'extrudant en continu dans une structure en forme de bande. Les puces et les fils LED sont intégrés simultanément et une couche de protection est appliquée à l'aide de la technologie de co-extrusion. Après refroidissement et formation, la bande est enroulée sur un noyau. Ce processus garantit la flexibilité, l'imperméabilisation et l'émission de lumière uniforme des bandes lumineuses, ce qui les rend adaptées à un éclairage décoratif incurvé. Il offre également une efficacité de production élevée et des couleurs et des tailles personnalisables.

La cote imperméable des bandes lumineuses extrudées peut atteindre l'IP68, grâce à leur structure imperméable monobloc (en utilisant un processus d'extrusion qui enveloppe le noyau léger avec du silicone) et à une excellente résistance aux intempéries et à la flexibilité d'installation. Ils sont largement utilisés dans divers scénarios, particulièrement adaptés aux applications nécessitant une imperméabilisation, une durabilité ou un éclairage environnemental complexe.

Processus de nano-revêtement PECVD

Le processus de revêtement pour les bandes LED utilise principalement la technologie de revêtement imperméable à revêtement nano-pelé PeCVD, qui forme un revêtement imperméable ultra-fin et dense au niveau nanométrique à la surface des luminaires LED grâce à un dépôt en phase vapeur amélioré par plasma. L'épaisseur du revêtement peut aller de 1 à 100 μm. Lorsque l'épaisseur du revêtement est suffisante, elle atteint une imperméabilisation globale et une résistance à l'humidité (indice IP68) sans affecter la dissipation thermique des puces LED.

Le nano-revêtement de la bande LED est incolore et transparent, de sorte qu'il n'affecte pas la transmission de la lumière, assurant ainsi l'éclairage et les effets visuels du produit. L'épaisseur du revêtement est contrôlable, avec des épaisseurs de revêtement PECVD allant de 1 à 100 μm. Tout en répondant aux exigences d'imperméabilisation, l'épaisseur du revêtement peut être aussi mince que 0,1 μm, de sorte qu'elle n'affecte pas la dissipation thermique des puces LED.

Sélection de sommiers à LED étanches

alors que Sélection de la lumière de bande LED étanche, les facteurs clés suivants doivent être pris en compte en fonction des exigences actuelles des applications courantes :

1. Sélection basée sur la cote d'étanché

- Lumières de bande LED IP54: Ces lampes sont dotées d'une couche adhésive appliquée en surface, offrant une résistance aux éclaboussures mais pas une résistance à l'immersion. Ils conviennent aux environnements légèrement humides tels que les armoires de cuisine et les zones sèches des salles de bains.

- Lampes de bande LED IP65 à revêtement goutte: Fournir efficacement une imperméabilisation de surface, adaptée à divers environnements tels que les hôtels, les maisons et les bureaux.

- Bandes LED étanches à manches en silicone IP66: Obtenez une résistance à la pulvérisation à travers des tubes en silicone creux, adaptés aux réglages semi-extérieurs comme les balcons et les cours, mais peut fuir s'il est submergé pendant de longues périodes.

- IP67/IP68 Bandes LED de remplissage en silicone solides (y compris le rempotage des manches et l'extrusion solide): En utilisant un processus de silicone solide entièrement fermé, ceux-ci peuvent être directement immergés pour une utilisation (par exemple, dans des aquariums ou des piscines). Ils sont flexibles et peuvent être librement pliés en formes. Ils utilisent une conception 24 V à basse tension pour éviter le risque de choc électrique.

- Bandes LED nano-enduites de IP65-IP68: Les performances imperméables de ce processus sont flexibles, permettant de personnaliser l'épaisseur du revêtement en fonction des exigences d'imperméabilisation. Par exemple, dans un environnement IP65, l'épaisseur du revêtement peut être de 0,1 à 0,3 microns, dans un environnement IP68, l'épaisseur du revêtement doit être de 1 à 2 microns.

Pour plus d'informations sur les cotes IP, veuillez lire le blog : Guide d'étanchéité des bandes lumineuses à LED (indice IP).

2. Correspondance en fonction des scénarios d'utilisation

- Environnements sous-marins/extrêmement humides: Les bandes LED solides en silicone IP68 sont obligatoires, comme pour les murs de piscine ou l'éclairage d'aquarium.

- Bâtiments extérieurs/Cours de canop: Les bandes LED avec IP65 ou plus sont recommandées, nécessitant une installation professionnelle pour éviter les chocs électriques.

- Armoires de miroir de salle de bain/fonds d'armoire: Les bandes LED en pot basse tension IP65 sont plus sûres, résistantes à l'humidité et émettent une lumière douce.

- Tunnels/Éclairage de construction: Les bandes lumineuses imperméables à haute luminosité avec des options encapsulées ou enduites sont préférées et doivent être utilisées avec des boîtiers de protection.

3. Sécurité de la tension

- Des bandes lumineuses basse tension 24 V doivent être utilisées dans les zones où le contact humain est probable (p. ex. plinthes, meubles)

- Les bandes lumineuses haute tension ne doivent être installées que par des professionnels dans des endroits élevés ou cachés.

4. Efficacité et qualité lumineuses

- Si un indice de rendu des couleurs (IRC) ≥90ra (de préférence ≥95ra) est requis pour garantir la précision des couleurs, les bandes lumineuses imperméables COB doivent être priorisées.

- Si une consistance de lumière élevée est requise, Bandes lumineuses LED Avec plus de 120 LED par mètre ou Bandes de lumière COB Avec plus de 320 LED par mètre, il faut sélectionner pour éviter un aspect granuleux.

- Si la précision de la température de couleur élevée et le contrôle de la température sont nécessaires, choisissez des bandes LED revêtues de pulvérisation ou revêtues. Ces types de bandes LED ont un revêtement plus fin, de sorte que la température de couleur ne dérivait pas et ils ont de meilleures performances de dissipation thermique.

5. Contrôle de chute de tension

- Les bandes de LED 24V doivent être de ≤20 mètres par bande et les bandes de 12 V LED doivent être de ≤ 5 mètres par bande. Pour des longueurs plus longues, une alimentation parallèle est nécessaire pour éviter la gradation aux extrémités.

6. Conseils d'installation et d'entretien

- Masquage de transformateur: Planifiez à l'avance les emplacements des alimentations électriques (par exemple, ouvertures de maintenance du climatiseur, trous de lumière encastrées) ;

- Flexibilité de coupe: Préférez les modèles où chaque LED peut être coupée pour obtenir des dimensions précises.

- Durabilité des matériaux: Le matériau en silicone a une meilleure résistance au vieillissement que le tube en PVC, prolongeant la durée de vie extérieure de plus de 30%.

Résumé: Confirmez d'abord les exigences d'étanchéité (Numéro IP) → correspondre à la tension de la scène → Vérifiez les paramètres d'efficacité de la lumière (CRI/Numéro de LED/Température de couleur) → Planifier le schéma d'installation (emplacement du transformateur + manipulation des chutes de tension). Exemple : Pour les armoires de salle de bain, choisissez une bande de LED en silicone IP68 24 V (3 000 000, 120 LED/mètre) associée à un transformateur caché installé dans le plafond.

L'impact de différents processus sur la température de couleur dans les bandes LED imperméables

Ceux qui connaissent les bandes de LED imperméables savent que l'ajout de différents matériaux, tels que le silicone, le PVC et l'adhésif PU, provoque des changements de couleur lorsque la lumière traverse ces matériaux. Par conséquent, différents processus de fabrication entraînent des changements variables de température de couleur. Comme le montre le tableau ci-dessous, il s'agit d'un résumé de la température de couleur correspondant à différents processus de fabrication, compilé par SaiNai Optoélectronique, basé sur des années d'expérience dans la production de bandes LED étanches, pour référence :

| Type de processus | Évaluation imperméable | Capacité de protection | Changement de température de couleur |

| pulvérisation superficielle | IP54/IP65 | Anti-éclaboussures, anti-poussière | Pas de changement significatif |

| Surface anti-chute | IP65/IP67 | Anti-éclaboussures, anti-poussière | Augmentation d'environ 10% |

| manche creux | IP66/IP67 | Haute pression étanche, anti-poussière | Augmentation d'environ 10% |

| Empotage des manches | IP67/IP68 | Immersion à court terme (1 mètre/30 minutes) | Augmentation de 25%-280% |

| Extrusion | IP67/IP68 | Immersion à court terme/long terme | Augmentation de 15-150% |

| nano-revêtement | IP65/IP68 | Immersion à long terme (profondeur/temps personnalisable) | Peu ou pas de changement |

En nous référant au tableau ci-dessus, lors de la conception de bandes LED, nous devons ajuster la température de couleur en fonction des changements causés par le processus d'imperméabilisation. Par exemple, si vous avez besoin d'une bande LED COB enduite de silicone imperméable avec une température de couleur de 3 000 000 000 k, la sélection d'une bande de LED de température de couleur de 3 000 K pour le revêtement en silicone est incorrecte, car la température de couleur résultante sera d'environ 3 300 000. Au lieu de cela, vous devez choisir une bande LED COB avec une température de couleur de 2 700 000 pour le revêtement de silicone, car la température de couleur augmentera de 10% après le processus, ce qui entraînera la température de couleur souhaitée à 3 000 000.

Données de test sur l'impact des processus d'étanchéité sur la température de couleur : veuillez vous référer à l'autre article de l'auteur : Quels sont les types de bandes LED ?

Comparaison des coûts de différents processus pour les bandes LED étanches

Parmi les bandes de LED étanches, le procédé de revêtement par pulvérisation a le coût le plus bas, avec un équipement simple adapté au revêtement de précision de petites surfaces; le processus de revêtement par goutte à goutte a des coûts d'équipement modérés mais une efficacité de production élevée, convient à la production de volume moyen; et les processus de moulage et d'extrusion par injection nécessitent l'investissement d'équipement le plus élevé, mais atteignent une utilisation de 95% et une augmentation de 3 à 5 fois en termes de production, adaptée à une production continue à grande échelle. Le processus de revêtement a le coût global le plus élevé, avec un équipement coûtant 1 à 3 millions de yuans, nécessitant un environnement de vide et une consommation d'énergie élevée. Cependant, il peut atteindre des couches minces à l'échelle nanométrique et le coût par unité diminue considérablement avec le volume de production accru.

| Type de processus | Avantages de base | Coût de traitement/mètre (USD) |

| pulvérisation superficielle | Émission légère uniforme, structure légère | 0.29 |

| Surface anti-chute | Processus simple et économique | 0.34 |

| manche creux | Faible coût des matériaux, coût de main-d'œuvre élevé pour l'encapsulation | 0.53 |

| Pottage des manches | Coût élevé des matériaux, mauvaise dissipation thermique | 0.76 |

| Extrusion | Coût élevé, cote de protection élevée | 0.65 |

| nano-revêtement | Imperméable, bonne dissipation thermique, épaisseur contrôlable (nanomètre) | 0.61 |

Résumé

En résumé, la sélection des processus de production des bandes LED étanches devrait tenir compte de l'environnement d'utilisation (humidité, température), de la cote de protection, des exigences de dissipation thermique et du budget des coûts.

Si les exigences d'imperméabilisation ne sont pas strictes, le processus de pulvérisation peut être choisi pour sa rentabilité ; si les exigences d'imperméabilisation sont élevées, le processus d'extrusion peut être sélectionné, bien qu'il soit plus coûteux. Si la température de couleur et les exigences de dissipation thermique sont élevées, le processus de nano-revêtement est recommandé. La technologie de revêtement imperméable à revêtement nano-rétractable offre des solutions innovantes aux défis de l'imperméabilisation et de la dissipation thermique pour les luminaires à bande LED avec ses avantages uniques.

Avec des progrès technologiques continus et de nouvelles réductions de coûts, l'avenir offre des perspectives prometteuses pour Éclairage de bande LED Technologie d'imperméabilisation et de dissipation thermique, motivée par l'émergence de nouveaux matériaux et processus.