introduction

En Éclairage de bande LED Les installations, la sélection de tensions sont souvent sous-estimées, mais elles ont un impact direct sur la cohérence de la luminosité, l'efficacité énergétique et les coûts de maintenance à long terme. De nombreux installateurs ont connu des situations frustrantes : des bandes LED s'assombrissant à mi-chemin d'une course ou des alimentations électriques fréquentes nécessaires après l'installation. Dans la plupart des cas, ces problèmes sont causés par le choix du mauvais système de tension : 12 V, 24 V ou 48 V. Pour une comparaison plus approfondie entre les deux tensions les plus courantes, consultez notre guide complet : Lumières de bande LED 12V vs 24V – Comment choisir.

Le choix de la bonne tension de la bande de LED est crucial pour empêcher la chute de tension, une perte de tension qui se produit lorsque le courant électrique traverse la bande, provoquant une luminosité inégale et une énergie gaspillée. Les systèmes de tension plus élevées réduisent le courant pour la même puissance de sortie, ce qui minimise les chutes de tension et la chaleur, en particulier sur les longues courses.

Par exemple, les bandes LED 12V offrent une grande flexibilité et sont idéales pour les projets de bricolage à court terme; les bandes LED 24V établissent un excellent équilibre entre les performances et le coût pour les courses de moyenne durée; tandis que les bandes de LED 48V excellent dans les installations longue distance et les projets d'ingénierie à grande échelle. Ce guide va réduire les bases de la tension, les différences de performances et les meilleurs scénarios d'utilisation, vous permettant de choisir la tension de bande de LED adaptée à tout projet d'éclairage en toute confiance.

Comprendre la tension de la bande LED

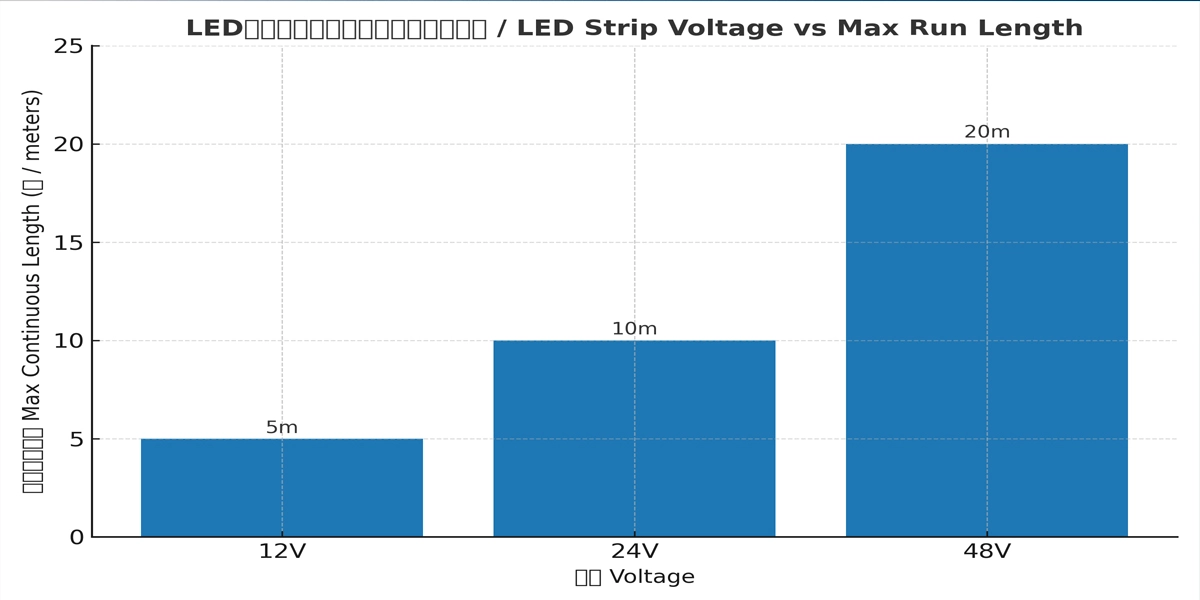

Lors de la sélection de la tension de la bande LED, il est important de comprendre la relation entre la tension et la longueur maximale de course pour les lumières de bande de LED.

Pour les bandes de LED à tension constante, une tension plus élevée signifie que moins de courant est nécessaire pour fournir la même puissance, ce qui aide à réduire la chute de tension et à maintenir une luminosité constante sur toute la longueur de la bande.

Spécifications typiques :

Bandes LED 12V: Maintenez une luminosité stable jusqu'à environ 5 mètres (16 pieds) ; au-delà de cette longueur, une gradation notable peut se produire.

Bandes LED 24V: supporte généralement des courses d'environ 10 mètres (33 pieds), avec des options de haute qualité atteignant jusqu'à 15 mètres.

Bandes LED 48V: Peut fonctionner de 15 à 20 mètres ou plus, lorsqu'il est associé à un système de bandes de LED à courant constant, des longueurs de 30 à 40 mètres (100 à 130 pieds) ou plus sont réalisables.

Un autre concept clé est la tension constante en fonction du courant constant :

Les bandes de LED à tension constante (telles que 12 V, 24 V et 48 V) utilisent une alimentation à tension fixe et sont simples à installer et à contrôler, mais sont plus sujettes aux chutes de tension sur de longues distances.

Les bandes de LED à courant constant fournissent une sortie de courant stable, assurant une luminosité et une température de couleur uniformes sur des longueurs étendues, idéales pour les projets à grande échelle nécessitant une performance et une cohérence maximales.

En comprenant ces principes, vous pouvez choisir la bonne tension de bande LED qui équilibre la longueur de l'installation, la cohérence de la luminosité, la complexité du câblage et le coût global, garantissant à la fois l'efficacité et la qualité visuelle.

Bande LED SMD2835

Modèle principal : FQX08T120C

LED QTÉ par mètre Option : 60/72/120/128/140

Option de largeur de PCB : 6mm/8mm/10mm

Option de couleur : 2700K/3000K/4000K/5000K/6500K

Option CRI : 80/90

Tension d'entrée : DC12V/DC24V

Puissance par mètre : 6W/8W/9.6W/12W/14.4W/19.2W

Efficacité: 100-200 lumen/watt

Option de niveau IP : IP20/IP54/IP65/IP67/IP68

Garantie: 5 ans

Bande LED SMD2216

Modèle principal : FWX10T240C

LED QTÉ par mètre Option : 120/180/240/300/420

Option de largeur de PCB : 5mm/10mm

Option de couleur : 2700K/3000K/4000K/5000K/6500K

Option CRI : 80/90

Tension d'entrée : DC12V/DC24V

Puissance par mètre : 9.6W/10W/14.4W/19.2W/20W/24W

Option de niveau IP : IP20/IP54/IP65/IP67/IP68

Garantie: 5 ans

Bande lumineuse à LED à courant constant et longue durée de vie

Modèle principal : FQX10T120D

Mètre par rouleau Option : 10m/20m/30m/50m

Option de largeur de PCB : 10mm/12mm

Option de couleur : 2700K/3000K/4000K/5000K/6500K

Option CRI : 80/90

Tension d'entrée : DC24V/DC36V/DC48V

Puissance par mètre : 4,2W/7,2W/8,5W/12W

Option de niveau IP : IP20/IP54/IP65/IP67/IP68

Garantie: 5 ans

Quand choisir les bandes de LED 12V, 24V ou 48V

Lumières de bande LED 12V

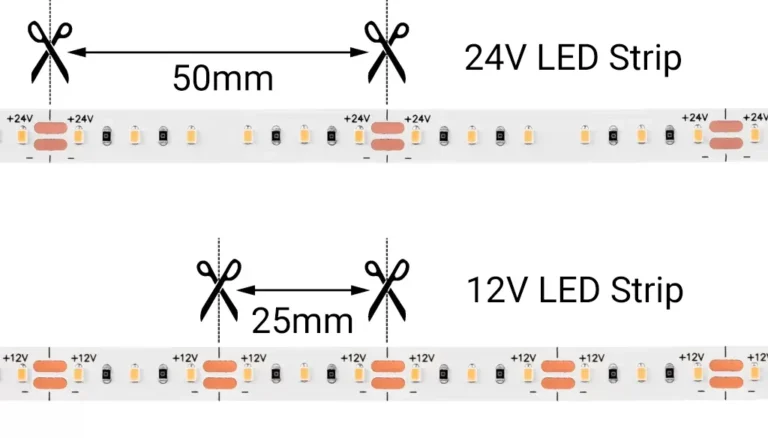

Les bandes de lumière LED 12V fonctionnent à une tension inférieure, ce qui signifie un courant plus élevé pour la même puissance. Cette conception permet des intervalles de coupe plus courts, généralement de 25 à 50 mm, ce qui les rend parfaits pour des installations détaillées telles que des étagères, des accents de meubles et des intérieurs automobiles.

Cependant, comme les systèmes à basse tension sont plus sujets à la chute de tension, il s'étend sur plus de 5 m sans injection de puissance, qui peut entraîner une perte de luminosité notable. Cela est dû à la résistance des conducteurs et du câblage de la bande, une limitation plus prononcée dans les systèmes 12V que dans les systèmes 24V ou 48V.

Idéal pour :

Courts courts jusqu'à 5 m sans perte de luminosité visible

Lampe décorative et décorative dans les meubles, les étagères et les petits espaces

Systèmes de basse tension automobiles, marins, VR et solaires

Pour :

- Faible coût initial et les pilotes et variateurs largement disponibles

- Installation flexible grâce à des intervalles de coupe courts

- Forte compatibilité avec les systèmes basés sur la batterie 12V

Cons :

- Chute de tension notable sur des courses plus longues sans injection de puissance

- Rendement inférieur par rapport aux systèmes à haute tension pour les longues distances

Lumières de bande LED 24V

Les bandes LED 24V doublent la tension des systèmes 12V, réduisant de moitié le courant pour la même puissance de sortie. Cela réduit l'accumulation de chaleur et la chute de tension, permettant des courses jusqu'à 10 m sans perte de luminosité.

La tension plus élevée signifie une meilleure efficacité et un éclairage plus stable pour des applications telles que l'éclairage de l'hôtel, les étagères de détail et l'éclairage d'accent de bureau. Alors que les intervalles de coupe sont généralement plus longs (50 à 100 mm), la réduction ultra-précise, l'équilibre global entre l'efficacité, le coût et la stabilité de la luminosité fait du 24V le choix préféré pour de nombreux projets commerciaux.

Idéal pour :

Installations de longueur moyenne autour de 10 m

Éclairage commercial dans les hôtels, les bureaux et les étagères de vente au détail

Espaces nécessitant une luminosité constante et des performances de gradation douces

Pour :

- Le courant réduit réduit la chaleur et améliore l'efficacité sur les courses moyennes

- Ratio coût-performance équilibré pour la plupart des applications commerciales

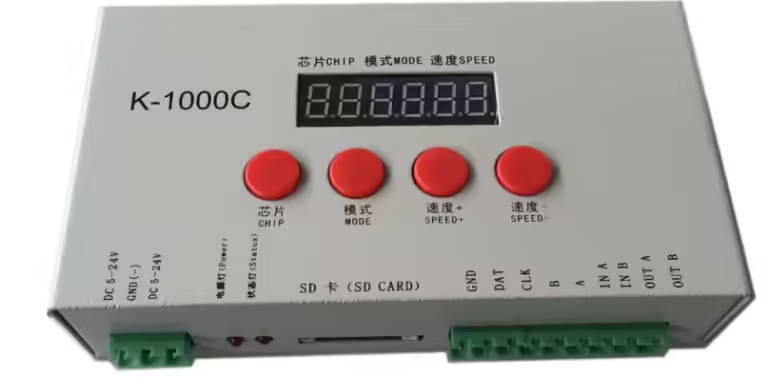

- Large compatibilité avec les pilotes de qualité professionnelle et les contrôleurs DMX/DALI

Cons :

- Des intervalles de coupe plus élevés réduisent la flexibilité dans les installations ajustées

- Coût initial légèrement supérieur à celui des systèmes 12V

Lumières de bande LED 48V

Les bandes LED 48V offrent le débit de courant le plus bas pour la même puissance, minimisant considérablement la chute de tension, même sur des distances de 15 à 20 m ou plus. Cela permet une luminosité uniforme dans les installations à grande échelle telles que les façades des bâtiments, les longues criques ou les éléments architecturaux extérieurs sans points d'injection de courant fréquents.

La complexité du câblage réduit et moins d'alimentations électriques réduisent les coûts d'installation et de maintenance. Cependant, les intervalles de coupe sont les plus longs (100 à 200 mm), ce qui limite l'utilisation dans les conceptions qui nécessitent un montage de précision. De plus, les pilotes et les systèmes de gradation compatibles sont moins courants que les options 12V et 24V.

Idéal pour :

Installations longue distance de 15 à 20 m ou plus

Éclairage de façade architecturale, criques de plafond et grands projets extérieurs

Projets commerciaux ou techniques visant à minimiser le câblage et les alimentations électriques

Pour :

- Courant le plus bas parmi les trois tensions, offrant la luminosité la plus stable

- Haute efficacité énergétique sur de longues distances

- Moins d'alimentations électriques requises, ce qui réduit la complexité et la maintenance du câblage

Cons :

- Disponibilité limitée des pilotes et contrôleurs compatibles par rapport à 12 V/24 V

- Les intervalles de coupe longs réduisent les options de personnalisation dans les espaces restreints

Guide de sélection de tension de bande LED

| Tension | le mieux pour | Longueur maximale de la course | Intervalle de coupe typique | Plage de puissance commune (W/m) | Pour | Cons |

| 12V | Courts-circuits ≤ 5 m; éclairage décoratif; automobile, marine, VR, systèmes solaires | ~5 m | 25–50 mm | 4,8–14,4 W/m | Faible coût, intervalles de coupe courts, compatibilité élevée avec les systèmes de batterie 12V | Chute de tension plus élevée sur les longs trajets ; efficacité réduite pour des distances étendues |

| 24V | Moyenne s'étend sur ~10 m; hôtels, bureaux, rayons de détail; gradation constante | ~10 m | 50–100 mm | 7,2–19,2 W/m | Un courant plus faible réduit la chaleur; Bon équilibre coût-performance; compatible avec les conducteurs professionnels | Des intervalles de coupe plus longs que 12 V, coût légèrement plus élevé |

| 48V | Longues courses de 15 à 20 m+, façades architecturales, grands projets extérieurs | 15 à 20 + m | 100–200 mm | 10 à 20 W/m | Courant le plus faible, chute de tension minimale ; efficacité la plus élevée sur les longues séries ; moins d’alimentations requises | Options limitées du conducteur/contrôleur ; intervalles de coupe les plus longs |

*La longueur maximale de la course est basée sur une installation standard sans injection de puissance supplémentaire.

Erreurs à éviter lors du choix de la tension de la bande LED

Le choix d'une mauvaise tension de la bande LED peut entraîner une perte de luminosité, une surchauffe ou une retouche coûteuse. Voici les erreurs les plus courantes à éviter :

Utilisation de bandes 12V pour les longues courses sans injection de puissance

Les bandes LED 12V sont idéales pour les courses courtes (≤5 m). Les utiliser pour de plus longues distances sans ajouter de puissance supplémentaire entraînera une chute de luminosité visible.

Découper la bande dans la mauvaise position

Qu'il s'agisse de 12 V, 24 V ou 48 V, toujours coupés sur les pads en cuivre désignés. La coupe ailleurs peut endommager le circuit et rendre la bande inutilisable.

Correspondance de la tension d'alimentation incorrecte

Ne connectez jamais une bande 12V à une alimentation 24V ou 48V (ou vice versa). Cela peut s'effacer instantanément des LED.

Découvrez pourquoi les tensions de correspondance peuvent endommager vos LED dans notre guide détaillé : Brancher des bandes LED 12V dans une alimentation 24V.

Ignorer les calculs de chute de tension

Pour les courses de plus de 5 m (12 V), 10 m (24 V) ou 20 m (48 V), calculez la chute de tension à l'avance et prévoyez des systèmes d'injection de puissance ou de tension supérieure.

Surcharge de l'alimentation

Choisissez toujours un pilote avec au moins 20 à 30% de plus de capacité que la puissance totale de vos bandes LED.

FAQ – Sélection de tension de bande LED

non . Fournir une tension plus élevée que la bande est évaluée pour survoler les LED, entraînant une surchauffe, des dommages ou une défaillance instantanée. Toujours faire correspondre la tension de bande avec la tension d'alimentation.

Pour la plupart des installations extérieures, les bandes LED 24 V ou 48 V sont préférées car elles permettent des courses plus longues avec moins de chute de tension, ce qui est important pour l'éclairage architectural ou de façade à grande échelle.

12V : jusqu'à 5 m sans injection de puissance

24V : jusqu'à 10 m sans injection de puissance

48V : jusqu'à 15 à 20 m sans injection de puissance

Les courses plus longues nécessitent des alimentations électriques supplémentaires ou un câblage parallèle.

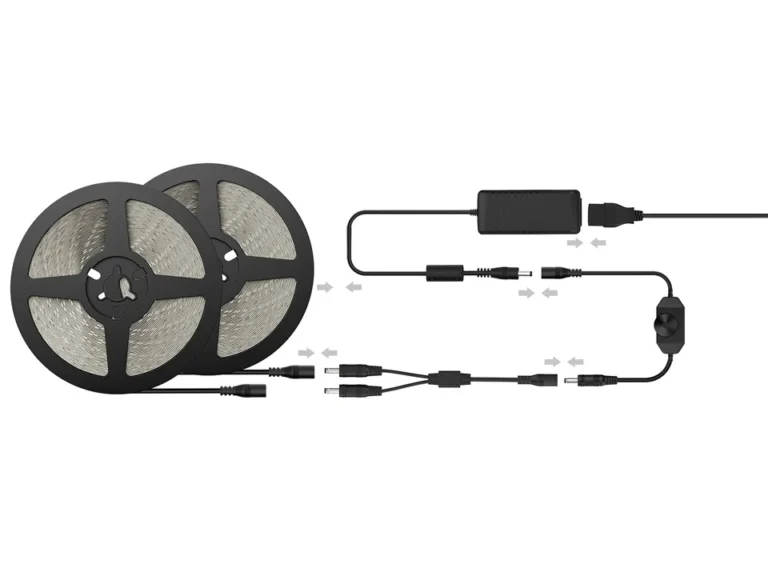

Les bandes LED 12V sont les meilleures pour les applications automobiles, marines et VR, car elles sont directement compatibles avec les systèmes de batterie 12V. Si vous envisagez de connecter plusieurs bandes LED 12 V à une alimentation, lisez notre guide étape par étape : Pouvez-vous connecter plusieurs bandes LED 12V à une alimentation électrique ?

Pas forcément. La luminosité dépend du type de LED, de la densité (LED par mètre) et de la puissance. La tension affecte principalement la longueur et l'efficacité de la course.

Conclusion

Le choix de la bonne tension de la bande LED affecte non seulement les résultats de l'installation, mais également la cohérence de la luminosité, l'efficacité énergétique et les coûts de maintenance.

Courses courtes et éclairage de précision : optez pour la 12V pour une coupe flexible et une compatibilité avec les systèmes de batteries basse tension.

Moyennes et espaces commerciaux : choisissez 24 V pour une combinaison équilibrée de performances et de coûts.

Longues courses et projets à grande échelle : optez pour le 48V pour minimiser les chutes de tension et simplifier le câblage.

Pour un résultat optimal, tenez compte de la longueur de la course, des exigences de coupe, de la disposition de puissance et de la sécurité avant de décider, cela garantit l'équilibre optimal entre les performances, le coût et la maintenance.

Pour estimer la consommation et l'efficacité énergétiques de votre projet, consultez notre guide complet : Combien d'électricité une bande de lumière LED utilise-t-elle ?