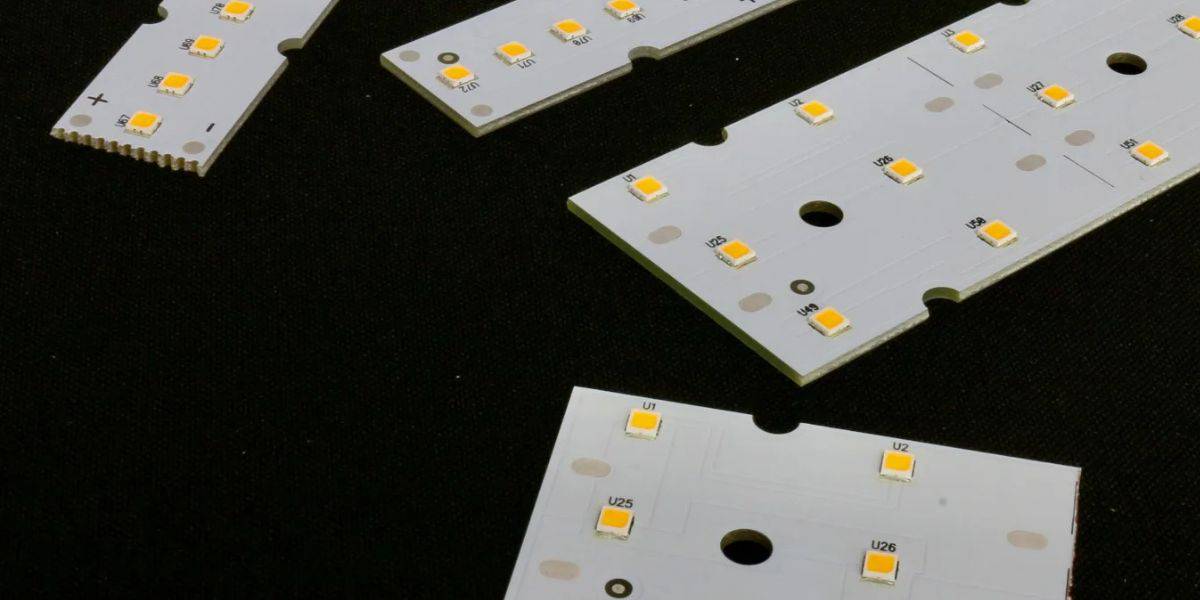

Un partner affidabile per l'assemblaggio SMT PCB LED è uno che può posizionare costantemente LED con elevata precisione, gestire il calore a livello di scheda e fornire risultati ripetibili su prototipi e cicli di produzione. L'assemblaggio del PCB LED è più complesso dell'SMT standard perché piccoli errori di posizionamento, cattiva gestione termica o variazioni dei componenti possono ridurre direttamente l'emissione di luce e la durata della vita. Affidabilità in questo contesto significa controllo del processo, qualità prevedibile e trasparenza delle decisioni piuttosto che velocità o prezzo.

Le 10 domande chiave per valutare un partner di assemblaggio SMT PCB LED

1 — Che esperienza hai con PCB LED e schede metal-core?

L'esperienza diretta con i PCB LED è importante perché gli assiemi LED si comportano in modo diverso sotto stress di calore e corrente. Un partner che ha familiarità con le schede in alluminio e altre core metalliche comprende come la disposizione, i profili di saldatura e la gestione influiscono sui percorsi termici. Senza questa esperienza, anche un produttore di PCB personalizzato capace può sottovalutare i rischi specifici dei LED, portando a guasti precoci o prestazioni ottiche incoerenti.

2 — Quale attrezzatura SMT usi per la precisione del posizionamento a LED?

L'affidabilità dei LED dipende dal posizionamento e dall'orientamento precisi, in particolare per array ad alta densità e moduli lineari. L'apparecchiatura SMT giusta assicura un allineamento costante, un controllo del volume della saldatura e una rielaborazione minima. Questa domanda ti aiuta a valutare se un produttore di PCB personalizzato può mantenere l'accuratezza del posizionamento su larga scala o se la qualità varia da un lotto all'altro, aumentando il rischio di guasto sul campo.

3 — Come gestisci le prestazioni termiche durante l'assemblaggio del PCB a LED?

La gestione termica è centrale per la durata della vita e la stabilità del colore dei LED. Un partner affidabile considera il calore durante la saldatura, l'attacco dei componenti e la gestione post-assemblaggio. Questa domanda rivela se il controllo termico viene trattato come una preoccupazione a livello di sistema o un ripensamento. Le pratiche termiche scadenti durante l'assemblaggio possono annullare anche un layout personalizzato PCB ben progettato.

4 — Quali processi di ispezione e controllo qualità applichi?

L'ispezione non riguarda solo il rilevamento di difetti evidenti, ma la cattura di problemi sottili che influenzano le prestazioni dei LED nel tempo. Il controllo di qualità costante aiuta a prevenire i guasti latenti causati da vuoti di saldatura o disallineamento. Questa domanda ti aiuta a confrontare i partner in base alla disciplina del processo piuttosto che alle promesse, in particolare quando si valuta l'assemblaggio di PCB personalizzato per i sistemi di illuminazione mission-critical.

5 — Come gestisci la binning e la coerenza dei componenti?

Il binning a LED influisce sulla luminosità, sulla temperatura del colore e sull'uniformità visiva. Un partner affidabile dispone di processi per gestire le variazioni dei componenti e mantenere la coerenza all'interno di una singola scheda e in tutti i lotti di produzione. Questa domanda è essenziale per le applicazioni in cui le differenze visive sono inaccettabili e dove l'approvvigionamento incoerente può minare un processo di assemblaggio altrimenti sano.

6 — Puoi supportare sia la prototipazione che la produzione in volume?

La possibilità di passare dal prototipo al volume senza cambiare partner riduce i rischi e la cattiva comunicazione. Questa domanda valuta se gli stessi standard e controlli si applicano a scale diverse. Per i progetti a LED, le incongruenze tra le prime build e la produzione di massa spesso risalgono a partner che trattano la prototipazione e il volume come processi non correlati.

7 — Qual è il tipico lead time e l'affidabilità della pianificazione?

L'affidabilità dei tempi di consegna conta più della velocità nominale nei progetti PCB a LED legati ai programmi di installazione. Questa domanda ti aiuta a capire quanto bene un partner pianifica la capacità e gestisce il cambiamento. I programmi mancati possono forzare decisioni o sostituzioni affrettate che influiscono sulle prestazioni dei LED, anche quando si lavora con un esperto Produttore di PCB personalizzato.

8 — Come si fornisce un feedback DFM per i progetti PCB LED?

Il feedback di progettazione per la producibilità è fondamentale negli assiemi LED perché le piccole decisioni di layout influenzano il flusso di calore e la resa del posizionamento. Un partner affidabile offre un feedback chiaro e precoce incentrato sulla riduzione del rischio piuttosto che sui commenti generici. Questa domanda mostra se DFM viene utilizzato come strumento decisionale o trattato come una formalità nei flussi di lavoro di assemblaggio di PCB personalizzati.

9 — Come gestisci i rischi di approvvigionamento della catena di approvvigionamento e dei componenti?

I componenti LED sono sensibili alle sostituzioni e alle carenze. Un partner affidabile ha definito processi per l'approvvigionamento, la tracciabilità e la notifica di modifica. Questa domanda ti aiuta a valutare come vengono gestite le interruzioni dell'offerta e se sarai informato prima che le decisioni influiscano sulle prestazioni o sulla conformità nei progetti personalizzati PCB.

10 — Che tipo di supporto per la comunicazione, la documentazione e il post-assemblaggio offrite?

Una comunicazione chiara riduce il rischio durante tutto il ciclo di vita del progetto. Questa domanda valuta come vengono documentati i problemi, come vengono approvate le modifiche e come vengono gestite le domande post-assemblaggio. Partner affidabili forniscono record e supporto coerenti che ti aiutano a diagnosticare i problemi senza congetture, il che è fondamentale per la stabilità del sistema a lungo termine.

Confronto di un partner di assemblaggio SMT PCB LED affidabile e affidabile

| Area di valutazione | socio | Partner affidabile |

| Esperienza PCB LED | Esposizione generale SMT | Messa a fuoco LED e metal-core comprovata |

| Capacità di gestione termica | assunto dal design | gestito attivamente durante l'assemblaggio |

| Metodi di ispe | Controlli visivi di base | Strategia di ispezione basata sui processi |

| Velocità di prototipazione | Veloce ma incoerente | controllato e ripetibile |

| scalabilità di produzione | separato dalla prototipazione | allineato su tutti i volumi |

| Supporto DFM | generico o in ritardo | Feedback specifico dei LED |

| Gestione della catena di approvvigio | Sourcing reattivo | pianificato e trasparente |

Perché queste domande funzionano come un quadro decisionale

Queste dieci domande sono progettate per far emergere la realtà operativa piuttosto che le affermazioni di marketing. Ognuno si concentra su un'area di rischio specifica per l'assemblaggio SMT PCB LED, in cui piccole lacune di processo possono causare grandi problemi a valle. La valutazione delle risposte fianco a fianco consente di confrontare i partner su indicatori di affidabilità che contano durante l'intero ciclo di vita del prodotto, non solo durante le build iniziali.

L'utilizzo di questo quadro aiuta anche ad allineare le parti interessate interne. I team di ingegneri possono concentrarsi sul rischio tecnico, mentre gli appalti possono valutare la prevedibilità e la comunicazione. Il risultato è una base condivisa per il processo decisionale che riduce il giudizio soggettivo e il pensiero a breve termine.

Errori di valutazione comuni da evitare

Un errore comune è supponendo che qualsiasi provider SMT esperto sia adatto per PCB LED. Un altro è dare priorità al lead time o al costo unitario citato senza comprendere il controllo del processo. Alcuni team sopravvalutano anche gli elenchi delle apparecchiature senza chiedere come vengono utilizzati questi strumenti nella pratica. Evitare queste trappole richiede domande disciplinate e concentrarsi su come le decisioni influenzano le prestazioni guidate nel tempo.

Struttura dei costi di assemblaggio PCB e SMT

La valutazione dei costi per l'assemblaggio SMT PCB LED dipende principalmente dalla classificazione del PCB, dal materiale di base, dal conteggio degli strati, dalla complessità dell'assemblaggio e dai tempi di consegna della produzione. A differenza dei progetti SMT generali, gli assiemi PCB a LED introducono ulteriori vincoli di precisione termica e di posizionamento che influenzano direttamente sia i costi di fabbricazione che di assemblaggio.

I seguenti riferimenti ai prezzi si basano sui dati pubblicamente disponibili da piattaforme di produzione di PCB, calcolatori di prezzi online e benchmark del settore comunemente citati dagli acquirenti durante la valutazione dei fornitori. Tutti i valori lo sono Gamme di riferimento approssimative Destinato al budget, al confronto e alla pianificazione degli appalti anticipati, non alle quotazioni formali.

Classificazione PCB e intervalli di costi di fabbricazione tipici

| Classificazione PCB | Conteggio tipico degli strati | materiale di base | Applicazioni a LED comuni | Costo approssimativo di fabbricazione PCB (USD/unità, volumi prototipo) |

| PCB a strato singolo | 1 | FR4 | LED indicatori, illuminazione a bassa potenza | $1 – $5 |

| PCB a doppio strato | 2 | FR4 | Schede LED lineari, apparecchi compatti | $3 – $10 |

| MCPCB in alluminio | 1–2 | anima in alluminio | Illuminazione a LED ad alta potenza, design termocritico | $5 – $20 |

| PCB a 4 strati | 4 | FR4 (standard o alto TG) | Controllo LED e schede di guida dense | $10 – $25 |

| PCB HDI | 4–6+ | FR4 / Alto TG | Moduli LED compatti ad alta densità | $30 – $60+ |

Le gamme di costo riflettono le specifiche standard senza produzione accelerata, finiture speciali o requisiti elettrici avanzati.

Driver di costo dell'assemblaggio SMT PCB LED

Il costo di assemblaggio SMT per i PCB LED è influenzato da diverse variabili a livello di processo che influiscono sul tempo della macchina, sullo sforzo di ispezione e sul controllo termico durante la produzione.

| autista di costo | Tipico impatto sui costi (USD / scheda, volumi prototipo) | spiegazione |

| Densità di posizionamento a LED | +$1.50 – $4.00 | Conteggi LED più elevati aumentano i cicli di posizionamento, l'utilizzo dell'alimentatore e il tempo di ispezione |

| Materiale di base PCB (MCPCB vs FR4) | +$2.00 – $6.00 | Le schede di nucleo in alluminio richiedono profili termici controllati e processi di riflusso più lenti |

| Dimensioni del pacchetto LED (formati SMD piccoli) | +$1.00 – $3.00 | Pacchetti più piccoli richiedono tolleranze di posizionamento più strette e fasi di verifica |

| Controllo binning LED | +$0.50 – $2.00 | La separazione, il monitoraggio e la gestione dei lotti introducono un sovraccarico di processo aggiuntivo |

| Livello di ispezione (AOI e controlli manuali) | +$1.00 – $3.00 | Fasi di ispezione aggiuntive aumentano l'utilizzo di manodopera e attrezzature |

Gli impatti sui costi di assemblaggio sono riferimenti indicativi per scheda derivati da modelli di determinazione dei prezzi SMT comunemente pubblicati.

Tempi di consegna e impatto sui costi sui progetti PCB a LED

La selezione dei tempi di produzione ha un impatto misurabile sul costo totale dell'assemblaggio del PCB LED PCB, in particolare per i progetti che richiedono un controllo rigoroso del sistema termico e del posizionamento.

| Tempi di consegna della produzione | Tipico aumento dei costi | Caso d'uso comune |

| Standard (10–15 giorni lavorativi) | linea di base | Costruzioni di produzione pianificate e corse di qualificazione |

| Accelerato (5–7 giorni lavorativi) | +20% a +40% | Produzione pilota e programmi guidati dal programma |

| espresso (24–72 ore) | +50% a +100% | sostituzioni urgenti o distribuzioni critiche nel tempo |

Interpretazione dei costi per gli appalti e i team di ingegneri

Questi riferimenti sui costi consentono ai team di approvvigionamento e di ingegneria di valutare i partner di assemblaggio SMT PCB LED utilizzando aspettative di prezzo realistiche basate sulla classificazione. Comprendendo come il tipo di PCB, la scelta del materiale, la complessità dell'assemblaggio e i tempi di consegna influiscono sul costo totale, gli acquirenti possono prendere decisioni più informate ed evitare le selezioni basate esclusivamente sui prezzi dei titoli senza tenere conto dell'affidabilità a lungo termine e della stabilità della produzione.

Conclusione

La scelta di un partner affidabile per l'assemblaggio SMT PCB LED è una decisione di gestione del rischio piuttosto che un'attività di acquisto. Le dieci domande in questa guida forniscono un modo strutturato per valutare l'esperienza, il controllo dei processi e la coerenza senza passare alla teoria della produzione o alle affermazioni di vendita. Concentrandosi sui rischi specifici dei LED, sulla qualità della comunicazione e sulla stabilità a lungo termine, i decisori possono selezionare partner che supportano le prestazioni prevedibili durante l'intero ciclo di vita dei loro prodotti di illuminazione.

Domande frequenti

L'assemblaggio SMT PCB LED è diverso perché i LED sono sensibili al calore, all'accuratezza del posizionamento e alla variazione dei componenti. I piccoli problemi di assemblaggio possono ridurre l'emissione di luce o la durata della vita, rendendo il controllo del processo più critico rispetto a molte applicazioni SMT standard.

I rischi principali includono guasto prematuro del LED, luminosità incoerente, variazione del colore e ritardi di rilavorazione. Questi problemi si verificano spesso dopo l'installazione, quando le correzioni sono costose e l'impatto sulla reputazione è elevato.

La gestione termica è fondamentale per l'affidabilità del LED. Lo stress termico relativo all'assemblaggio può danneggiare i LED o indebolire i percorsi termici, anche se il design del PCB stesso è sano.

si. Piccoli errori di posizionamento, difetti di saldatura o esposizione incontrollata al calore possono ridurre significativamente la durata dei LED e ridurre la stabilità del sistema nel tempo.

Dovresti considerare di cambiare i partner quando i problemi di qualità si ripetono, la comunicazione manca di trasparenza o i risultati della produzione variano tra le esecuzioni nonostante i progetti invariati.