L'industria dell'illuminazione a LED ha trasformato l'illuminazione moderna in applicazioni residenziali, commerciali, industriali e automobilistiche. I LED sono favoriti per un'elevata efficienza energetica, una lunga durata operativa e dimensioni compatte. Tuttavia, le loro prestazioni dipendono fortemente dalla progettazione PCB, dalla qualità dell'assemblaggio SMT e dall'affidabilità del giunto a saldare. Anche piccoli difetti di assemblaggio possono portare a sfarfallio, incoerenza del colore, formazione di hotspot o guasto prematuro.

Questa guida esplora

- Strategie per migliorare l'affidabilità dei LED PCB

- Concentrandosi sulle migliori pratiche SMT, sull'ottimizzazione dei giunti a saldare e sulla gestione termica.

- Aiuta i produttori a realizzare sistemi LED di alta qualità e durevoli.

Sfide di affidabilità comuni nei LED PCB

I LED sono altamente sensibili alle sollecitazioni termiche, elettriche e meccaniche. Un design o un assemblaggio scadenti possono compromettere le prestazioni e la durata della vita. Le sfide tipiche includono:

- Giunti saldati o aperti che portano a connessioni intermittenti.

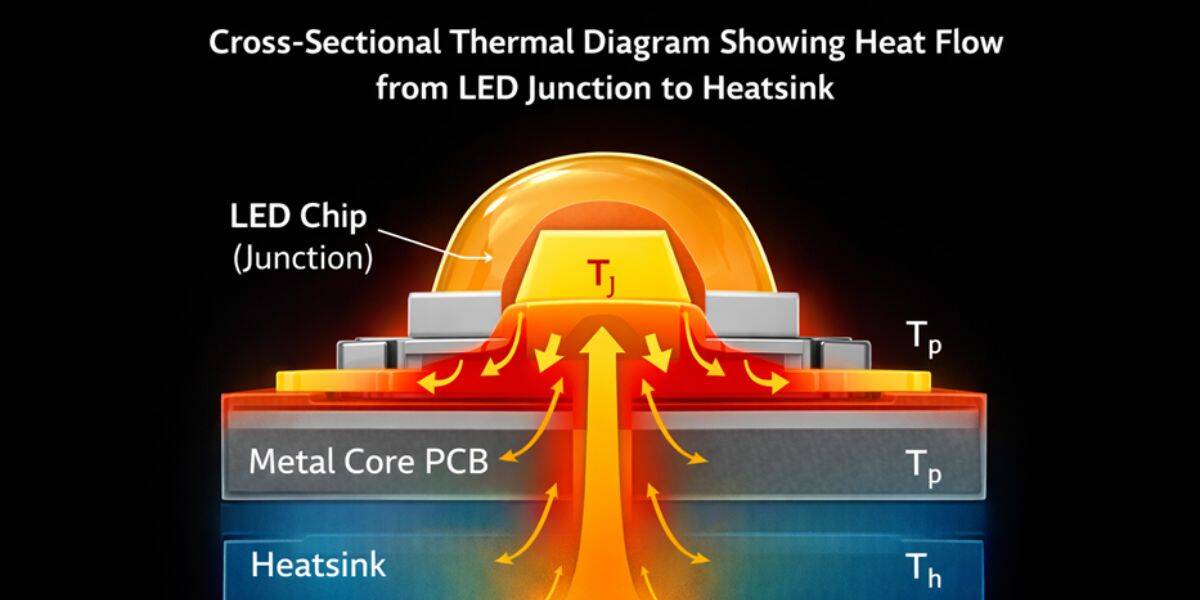

- Stress termico che causa deformazione PCB e degradazione dei componenti.

- L'elettromigrazione che danneggia le tracce di rame ad alta densità di corrente.

- Sorpresa meccanica da movimentazione, trasporto o ciclismo termico.

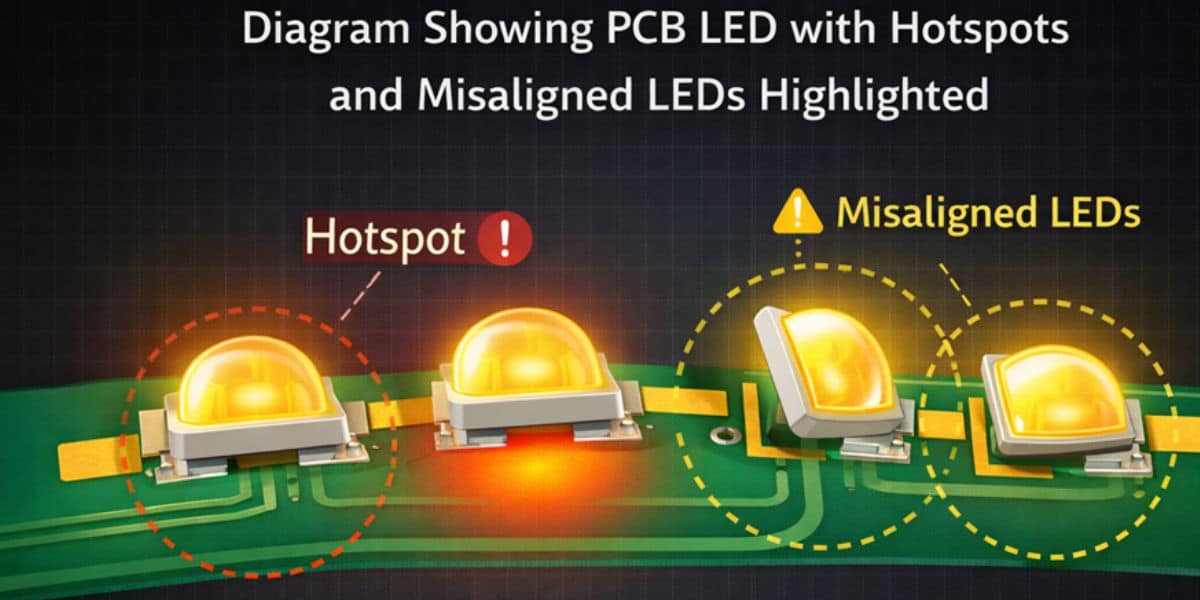

- LED disallineati che provocano un'emissione di luce irregolare o hotspot visibili.

Tabella 1: Impatto dei problemi di PCB e SMT sull'affidabilità dei LED

| emettere | causa | Effetto sul sistema LED |

| Giunti di saldatura incrinati | Ciclo termico, stress meccanico | sfarfallio, circuiti aperti |

| LED disallineati | Errori di prelievo | Distribuzione della luce irregolare |

| Hotspot termici | scarsa dissipazione del calore | Ammortamento del lume, fallimento precoce |

| elettromigrazione | Alta densità di corrente, tracce sottili | Traccia danni, guasto nel tempo |

| Vuoti di saldatura | Deposizione di pasta impropria | Conducibilità termica/elettrica ridotta |

Considerazioni sulla tecnologia a montaggio superficiale (SMT)

SMT consente un posizionamento preciso del LED, fattori di forma più piccoli e prestazioni elettriche migliorate. Tuttavia, le pratiche SMT scadenti riducono l'affidabilità.

1: design PCB per SMT

Un layout PCB ben progettato supporta l'affidabilità:

| elemento di design | migliore pratica |

| Dimensioni e forma del pad | Assicurare una corretta bagnatura della saldatura ed evitare il ponte |

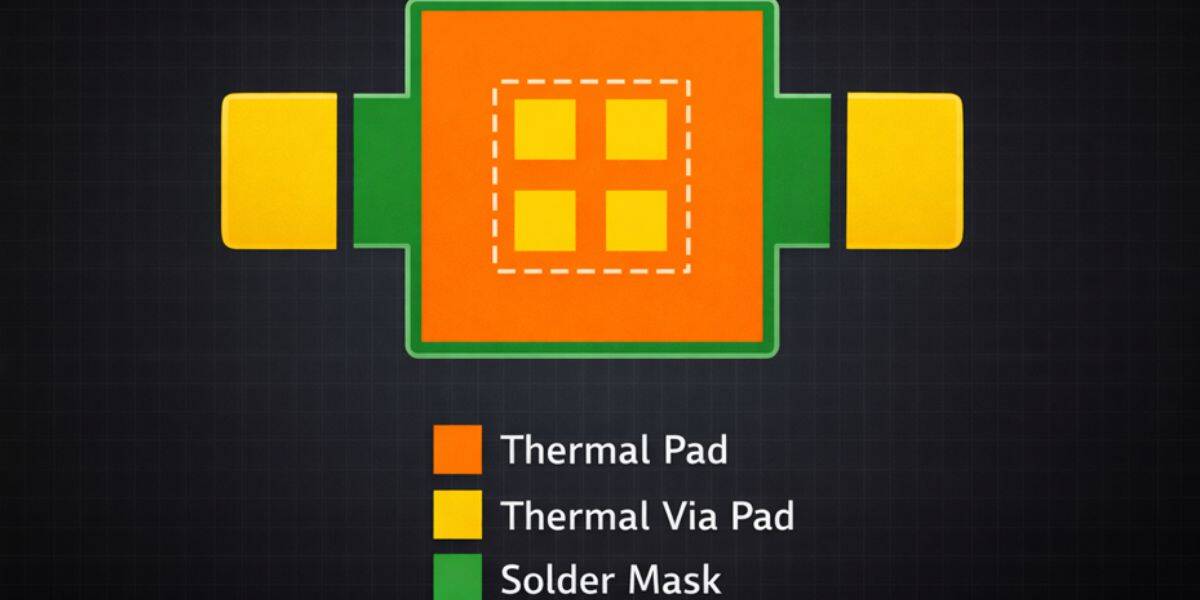

| Pad Termici | Migliora la dissipazione del calore per i LED ad alta potenza |

| Disegno di maschera per saldatura | Prevenire la fuoriuscita di saldatura e mantenere la precisione del posizionamento |

| Traccia larghezza e rame | Mantieni la bassa resistenza e gestisci la corrente in modo efficiente |

2: Precisione di pick-and-place

Il corretto posizionamento è fondamentale per l'illuminazione uniforme:

- La selezione degli ugelli, la velocità di posizionamento e la pressione devono essere ottimizzati.

- Il disallineamento può creare incongruenze ottiche e sollecitazioni meccaniche.

- La calibrazione regolare riduce gli errori di posizionamento e la rielaborazione.

3: Applicazione di pasta saldante

La qualità e l'applicazione della pasta saldante sono vitali:

- La pasta a basso vuoto e di alta qualità garantisce una bagnatura costante.

- Gli stencil di precisione impediscono una saldatura insufficiente o eccessiva.

- Il contenuto di flusso deve essere adatto per prevenire l'ossidazione.

Affidabilità del giunto a saldare

I giunti saldanti formano il collegamento meccanico ed elettrico tra LED e PCB. Una cattiva saldatura è una causa di errore primaria.

1: Selezione della lega di saldatura

- SAC305 (SNAGCU) è lo standard privo di piombo.

- Le leghe a bassa fusione riducono lo stress termico durante il riflusso.

- La lega deve essere compatibile con le finiture PCB (Enig, HASL, OSP).

2 : Ottimizzazione del profilo di riflusso

La temperatura di riflusso deve essere controllata:

- Le temperature di preriscaldamento, ammollo e di picco devono corrispondere alle raccomandazioni del produttore.

- Evitare i LED o i pad di surriscaldamento per prevenire gli shock termici.

- Il raffreddamento controllato riduce i rischi di cracking.

3: geometria del giunto a saldare

La corretta forma articolare migliora la resistenza e la conduttività:

- L'altezza del filetto dovrebbe coprire il tampone senza saldare in eccesso.

- Filetti lisci e concavi riducono la formazione di vuoti.

- La complanarità garantisce un contatto elettrico stabile.

4: ispezione e controllo di qualità

- L'ispezione ottica automatizzata (AOI) rileva difetti visibili.

- L'ispezione a raggi X identifica i vuoti nascosti nei pad termici.

- Gli audit di processo regolari mantengono una qualità costante.

Tabella 2: Specifiche consigliate per filetto di saldatura per LED

| Tipo di LED | Altezza filetto (mm) | angolo di giunzione | banconote |

| 0,2–0,5 W LED | 0,2–0,3 | 45–60° | LED standard per montaggio superficiale |

| LED da 1–3 W | 0,3–0,5 | 45–70° | I LED ad alta potenza richiedono supporto termico |

| >5 W LED | 0,4–0,6 | 60–75° | Utilizzare VIA termici e PCB di metallo-core |

Gestione termica per LED SMT

Il calore è il massimo Fattore critico per l'affidabilità dei LED. Le alte temperature accelerano l'ammortamento del lume e riducono la durata della vita.

Strategie chiave:

- I PCB con nucleo in alluminio migliorano la dissipazione del calore.

- Via termiche sotto LED trasferiscono il calore su piani di rame più grandi.

- Dissipatori di calore e TIMS sono essenziali per applicazioni ad alta potenza.

- La corretta spaziatura dei LED previene gli hotspot e garantisce una distribuzione uniforme della temperatura.

Problemi comuni di SMT e saldatura

| emettere | causa | Soluzione |

| lapide | Tensione superficiale irregolare durante il riflusso | Regola il volume e il profilo della pasta di saldatura |

| ponte di saldatura | Saldatura in eccesso, pastiglie disallineate | Riduci la deposizione di pasta, migliora lo stencil |

| Giunti a saldare a freddo | Bagnatura scarsa, bassa temperatura | Ottimizza il profilo di riflusso e il tipo di saldatura |

| vuoto | aria o flusso intrappolato | Usa pasta a basso vuoto, corretto riflusso |

Migliori pratiche per un assemblaggio LED PCB affidabile

Design for Manufacturability (DFM): allinea pad, tracce e percorsi termici con funzionalità SMT.

- Usa pasta saldante di alta qualità: Lega a basso vuoto e coerente con flusso adeguato.

- Profilo di riflusso controllato: Prevenire il surriscaldamento e il raffreddamento rapido.

- Ispezione: AOI, radiografie e controlli manuali.

- Gestione: Ridurre al minimo lo stress meccanico durante il trasporto e l'assemblaggio.

- Disegno termico: PCB di nucleo metallico, vie termiche e dissipatori di calore.

- Processi standardizzati: La documentazione garantisce la ripetibilità.

Caso di studio: modulo LED ad alta potenza

Un modulo LED industriale ad alta asta subita ha subito frequenti guasti ai giunti di saldatura dovuti al ciclo termico.

Miglioramenti implementati:

- Passato a PCB con nucleo in alluminio.

- Deposizione di pasta saldante ottimizzata.

- Profili di riflusso controllati.

- Aggiunti via termici sotto LED.

Risultati:

- 30% Riduzione dei difetti di giunzione di saldatura.

- Manutenzione del lume migliorata dopo 5.000 ore di funzionamento.

Tendenze emergenti nell'assemblaggio LED PCB

- Le leghe di saldatura a bassa temperatura riducono lo stress termico.

- La saldatura senza piombo garantisce la conformità normativa senza ridurre l'affidabilità.

- L'ispezione assistita da IA rileva i difetti più velocemente dei metodi tradizionali.

- I materiali PCB avanzati con elevata conduttività termica migliorano la dissipazione del calore.

- Le simulazioni termiche 3D prevedono gli hotspot prima della produzione.

Ulteriori suggerimenti per i produttori

- Utilizzare il software di progettazione stencil per una precisa deposizione di pasta saldante.

- Condurre simulazioni termiche per prevenire gli hotspot prima della produzione.

- Calibrare regolarmente le macchine pick-and-place.

- Mantenere l'umidità e la temperatura controllate nelle aree di assemblaggio.

- Utilizzare rivestimenti protettivi per ambienti ad alta umidità.

Conclusione

L'affidabilità del LED PCB dipende dalla qualità dell'assemblaggio SMT, dall'integrità del giunto a saldare e dalla gestione termica. La progettazione, la saldatura e il controllo di processo adeguati prevengono i guasti, migliorano le prestazioni e prolungano la durata della vita dei LED. I produttori che implementano layout ottimizzati, saldature di alta qualità e strategie termiche avanzate ottengono sistemi LED affidabili e di lunga durata con un'emissione luminosa costante.

Per soluzioni LED ad alte prestazioni e durevoli, Trust SignLiteled per gruppi LED PCB sapientemente progettati. Ci concentriamo sull'ottimizzazione SMT, sulla saldatura precisa e sulla gestione termica avanzata per fornire un'illuminazione affidabile.

Contatta SignLiteled oggi Per migliorare la qualità del tuo prodotto, ridurre i guasti e garantire prestazioni LED superiori.

Domande frequenti

SMT (Surface-Mount Technology) consente un posizionamento preciso dei LED, riduce le dimensioni e migliora le prestazioni elettriche e termiche.

I giunti saldanti forniscono supporto meccanico e collegamento elettrico; i giunti scadenti possono causare guasti o sfarfallio.

I difetti tipici includono lapidi, ponticelli per saldatura, giunti freddi e vuoti, tutti riducendo le prestazioni e la durata della vita.

L'efficiente dissipazione del calore attraverso vie termiche, PCB con nucleo in alluminio e dissipatori di calore previene il surriscaldamento e prolunga la durata della vita.

L'ispezione ottica automatizzata (AOI), l'ispezione a raggi X e i controlli manuali rilevano difetti come disallineamento, vuoti e ponte.