Nell'illuminazione commerciale e nel design per la casa, le luci lineari a LED sono ampiamente popolari per il loro design elegante e la distribuzione uniforme della luce. Tuttavia, trascurare il rating di abbagliamento unificato (UGR) può causare affaticamento visivo o persino rischi per la sicurezza. Possiamo ottenere un'esperienza confortevole di "vedere la luce senza vedere la sorgente luminosa" selezionando scientificamente l'illuminazione appropriata.

Secondo gli standard internazionali, diversi scenari hanno requisiti chiari per UGR. Gli uffici e le aule di solito richiedono UGR≤19, mentre alcune sale espositive e ospedali di fascia alta hanno requisiti più elevati per UGR, che richiedono UGR≤16. Pertanto, UGR è diventato un fattore importante che non può essere ignorato quando si acquistano luci lineari a LED.

Le luci lineari a LED possono raggiungere un UGR inferiore a 19?

Sì, Luci lineari a LED può raggiungere un UGR inferiore a 19. Il rating di bagliore unificato (UGR) è un parametro chiave per misurare l'effetto abbagliante dell'illuminazione. Ambienti di illuminazione sani come gli uffici richiedono un UGR inferiore a 19 per garantire un comfort visivo. Ad esempio, le luci lineari a LED progettate specificamente per un bagliore a basso impatto possono stabilizzare il valore UGR inferiore a 19 attraverso materiali ottici antiriflesso microstrutturati, conformi agli standard di illuminazione degli edifici.

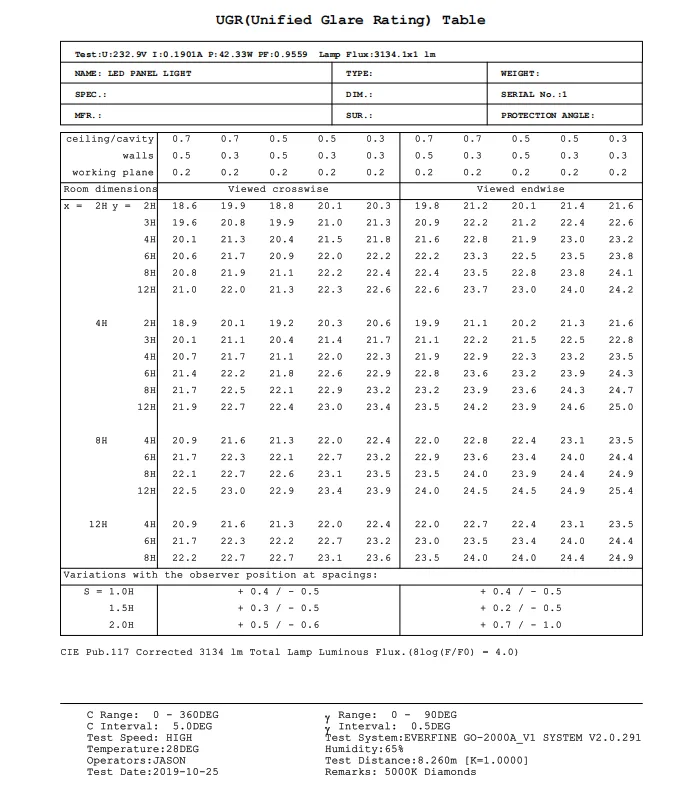

Tuttavia, come fonte di illuminazione diretta, le luci lineari possono comportare rischi di abbagliamento se progettati in modo improprio. Come mostrato nei dati di misurazione effettivi di seguito, i loro valori UGR possono raggiungere 22, superando il limite superiore raccomandato dal CIE, portando a disagio come la contrazione frequente della pupilla e il mal di testa. Pertanto, quando si selezionano i prodotti, si consiglia di dare la priorità a quelli esplicitamente etichettati come conformi ai requisiti UGR.

Perché la valutazione abbagliante (UGR) delle luci lineari dovrebbe essere inferiore a 19?

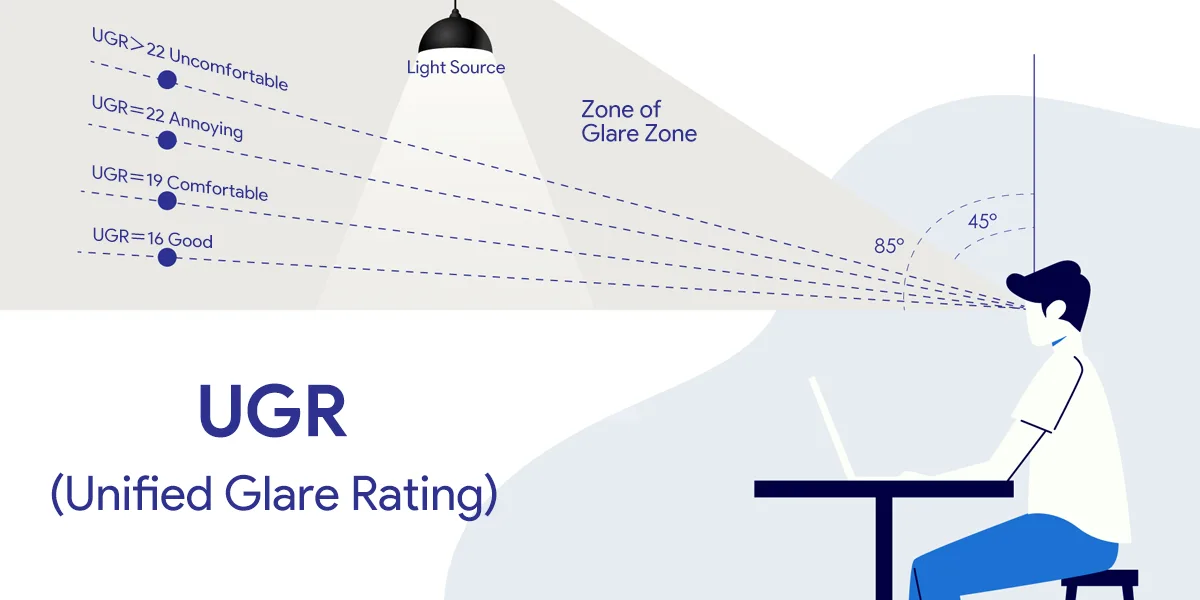

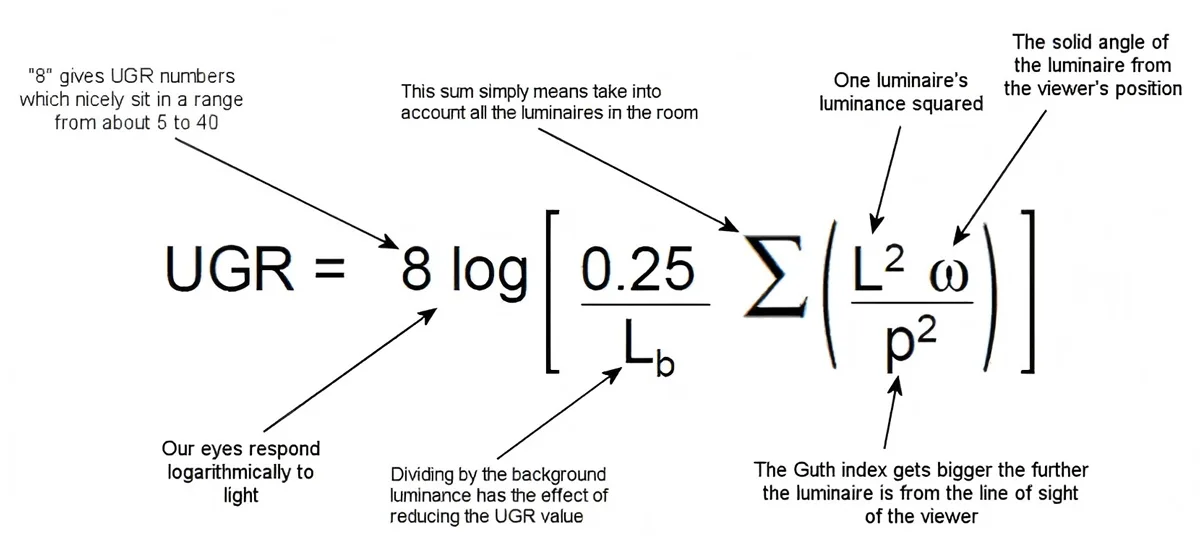

UGR (Uniform Glare Rating) è uno standard riconosciuto a livello internazionale per valutare il livello di abbagliamento dell'illuminazione lineare interna. Più basso è il valore UGR, più debole è il riverbero e maggiore è il comfort visivo. Il valore UGR è influenzato da molteplici fattori, tra cui la luminosità della sorgente luminosa, la posizione e i livelli di luce ambientale.

Quando UGR supera i 19, gli alunni si adattano frequentemente, portando all'affaticamento visivo. L'esposizione prolungata può causare danni alla retina, deterioramento della vista e un aumento del rischio di cataratta. Solo in Cina, dove oltre 60% di adolescenti soffrono di miopia, l'inquinamento dell'abbagliamento è stato identificato come uno dei principali fattori che contribuiscono.

Gli standard attuali richiedono che i valori UGR in ambienti di illuminazione sani siano inferiori a 19. Il requisito che UGR sia inferiore a 19 si basa principalmente sui seguenti motivi:

- Garantire il comfort visivo: Un valore UGR di 19 segna la soglia tra abbagliamento moderato e significativo. Quando UGR ≥ 19, la sensazione di luce abbagliante aumenta significativamente, causando potenzialmente affaticamento visivo o disagio. Tuttavia, quando UGR < 19, l'abbagliamento rimane all'interno di un intervallo accettabile, rendendolo adatto ad ambienti come uffici e aule in cui è richiesta una concentrazione prolungata.

- Adattamento ai requisiti sul posto di lavoro: In aree di ufficio e altri ambienti che richiedono precise attività visive, l'UGR ≤ 19 standard bilancia l'illuminazione e il comfort, impedendo all'abbagliamento di interferire con l'efficienza lavorativa. Ad esempio, lo standard GB50034-2013 stabilisce esplicitamente che il limite superiore UGR per le aree di ufficio generali è 19, simulando la confortevole esperienza degli ambienti di luce naturale.

- Distinguimento degli scenari applicativi: Il design graduato dei valori UGR considera i livelli di tolleranza di diverse posizioni: UGR < 19 è adatto per ambienti ad alta richiesta (come gli uffici), mentre UGR ≥ 19, che causa un'abbagliamento notevole, è raccomandato solo per strutture industriali o negozi in cui i requisiti di comfort visivo sono inferiori.

Come viene valutato il valore UGR?

La classificazione del comfort del valore UGR (Uniform Glare Rating) è stata chiaramente definita da standard internazionali. Le soglie di comfort e gli scenari applicabili sono i seguenti:

Quando UGR < 13, la luce è morbida e l'occhio umano difficilmente percepisce l'abbagliamento. Questo è adatto per spazi con requisiti di comfort visivo estremamente elevati, come gallerie d'arte e residenze di fascia alta.

Quando UGR < 16, rientra nella gamma Comfort, con un leggero abbagliamento che non compromette i compiti visivi. Questo è lo standard consigliato per aule, sale di lettura e altri ambienti che richiedono un lavoro preciso. Ad esempio, le luci del pannello protettivo per gli occhi nelle aule devono controllare UGR ≤ 16 per proteggere la visione degli adolescenti.

Valore UGR e valutazione dello stato di percezione umana

| Gamma UGR | percezione umana | Esempi di scenari applicabili |

| Ugr < 13 | nessun bagliore percettibile | Ospedali, sale espositive di fascia alta, istituzioni speciali |

| 13 ≤ UGR ≤ 16 | mite bagliore | Ospedali, centri di attività per anziani |

| 16 ≤ UGR < 19 | Abbagliamento moderato, accettabile ma può causare affaticamento | Uffici ordinari, sale riunioni |

| 19 ≤ UGR < 22 | soglia per un notevole disagio | Impianti industriali, magazzini |

| UGR ≥ 22 | Abbagliamento intenso, che causa mal di testa | Evita l'occupazione umana prolungata |

La soglia psicologica tra comfort e disagio è UGR = 19, ma gli ambienti visivi sani (come gli spazi di apprendimento) dovrebbero mirare a UGR ≤ 16.

Standard obbligatori per gli scenari applicativi:

- Strutture educa: UGR obbligatorio ≤ 19 per le aule; le soluzioni di illuminazione di alta qualità dovrebbero essere ottimizzate a ≤ 16;

- ambienti d'ufficio: UGR > 19 provoca la contrazione frequente della pupilla che porta all'affaticamento visivo; il punteggio di qualificazione è ≤ 19;

- Siti industriali: UGR ≤ 22 è consentito, ma è necessario utilizzare accessori antiriflesso per ridurre i rischi per la salute.

Raccomandazioni sulle pratiche di protezione dall'a

| misure | Principi tecnici | Effetto di riduzione UGR |

| Pannello di diffusione microprisma | Decompone fasci di luce ad alta intensità | si riduce a ≤16 |

| Progetto di illuminazione indiretta | Evita la zona di interferenza di 30° intorno all'occhio umano | si riduce di 30% |

| Materiali a basso contenuto di lucidi | Riduce l'abbagliamento della riflessione ambientale | Ottimizza di 2-3 punti |

Nota: le misurazioni UGR richiedono un fotometro distribuito con un obiettivo fisheye, la calibrazione è necessaria se l'errore supera ±10%.

Requisiti UGR per l'illuminazione lineare in Europa e Stati Uniti

L'Europa e gli Stati Uniti hanno standard di classificazione chiari per i requisiti UGR per l'illuminazione lineare a LED. I regolamenti e i punti di attuazione specifici sono i seguenti.

Standard di valutazione UGR obbligatori

Norme di base dell'UE: Tutte le luci lineari interne devono soddisfare la soglia di sicurezza minima di UGR ≤ 19. Il superamento di questo valore comporterà il mancato ottenimento della certificazione CE. Le posizioni speciali hanno requisiti più severi: Aree di istruzione/ufficio: UGR deve essere ≤16, come aule e uffici a pianta aperta; Gallerie d'arte/Strutture mediche: UGR deve essere ≤13 e devono essere utilizzate strutture antiriflesso a nido d'ape.

Requisiti speciali del Nord America: Gli standard UL 1598 richiedono esplicitamente apparecchi di illuminazione a LED per controllare i rischi fotobiologici (esclusa la banda di lunghezza d'onda di 4400-780 nm); la certificazione Energy Star richiede apparecchi di illuminazione commerciali per avere UGR ≤ 22 e deve indicare livelli di luce blu (il livello di esenzione RG0 è prioritario).

Specifiche di accettazione della misurazione UGR

| Articolo | Norme UE | Requisiti complementari nordamericani |

| Altezza di osservazione | Seduto 1,2 m / in piedi 1,5 m | Aderisce allo standard CIE 117-1995 |

| Attrezzatura di misurazione | 143° Campo visivo Misuratore di luminanza per immagini | Deve passare la calibrazione fotometrica UL |

| Correzione della luminosità di sfondo | Elimina le interferenze dirette della luce dai dispositivi | Aggiunge l'elemento di rilevamento del riflesso speculare |

Confronto degli standard UGR tra Europa e Nord America

| Indicatore | UE | Nord America |

| Forza di applicazione | UGR > 19 vietato dalla circolazione del mercato | Certificazione Energy Star Applicazione volontaria |

| Focus tecnico | Controllo dell'abbagliamento (UGR) come focus principale | Sicurezza fotovoltaica + doppio controllo dell'efficienza energetica |

| Direzione di aggiornamento | Implementa UGR ≤ 16 entro il 2025 | Rafforzare gli standard di sicurezza per gli accessori per batterie a bottone (UL4200A) |

| Soglie fondamentali | UGR ≤ 19 Soglia obbligatoria (requisito di base per la certificazione CE) | Nessuna soglia obbligatoria a livello federale; Energy Star raccomanda ≤ 22 |

| Requisiti di scenario speciale | Strutture didattiche/mediche UGR ≤ 13 | Illuminazione industriale consentita UGR ≤ 25 (deve soddisfare gli standard di sicurezza elettrica UL 1598) |

ottico Parametro Collezione

- UE: uso obbligatorio di un misuratore di luminanza per immagini a 143° per eliminare le interferenze dalla luce diretta dall'apparecchio;

- Nord America: Deve passare l'attrezzatura di calibrazione fotometrica UL e aggiungere il rilevamento del riflesso speculare.

Riferimento di osservazione

- L'UE adotta uniformemente un'altezza seduta di 1,2 m/altezza di 1,5 m per l'altezza degli occhi;

- Il Nord America si allinea con gli standard dell'UE ma consente ai produttori di definire le proprie altezze di prova (soggetto a registrazione).

I paesi europei attueranno i requisiti obbligatori per i soffitti a specchio con copertura UGR≤16 (compresi gli spazi commerciali) a partire dal 2025.: Luminosità superficiale dell'apparecchio ≤2000 cd/m²; Paralumi satificati con riflettanza <60%.

Gli apparecchi di illuminazione a controllo wireless devono inoltre essere conformi: la certificazione FCC a radiofrequenza (47 CFR parte 15) e gli accessori per batterie a bottone devono essere conformi a UL 4200A3.

avviso di tendenza: Il nuovo regolamento dell'UE nel 2025 incorporerà la sicurezza fotobiologica (RG0) nel sistema di valutazione UGR e il Nord America aggiornerà contemporaneamente gli standard di controllo della luce blu UL 153.

Come misurare il valore UGR delle luci lineari a LED?

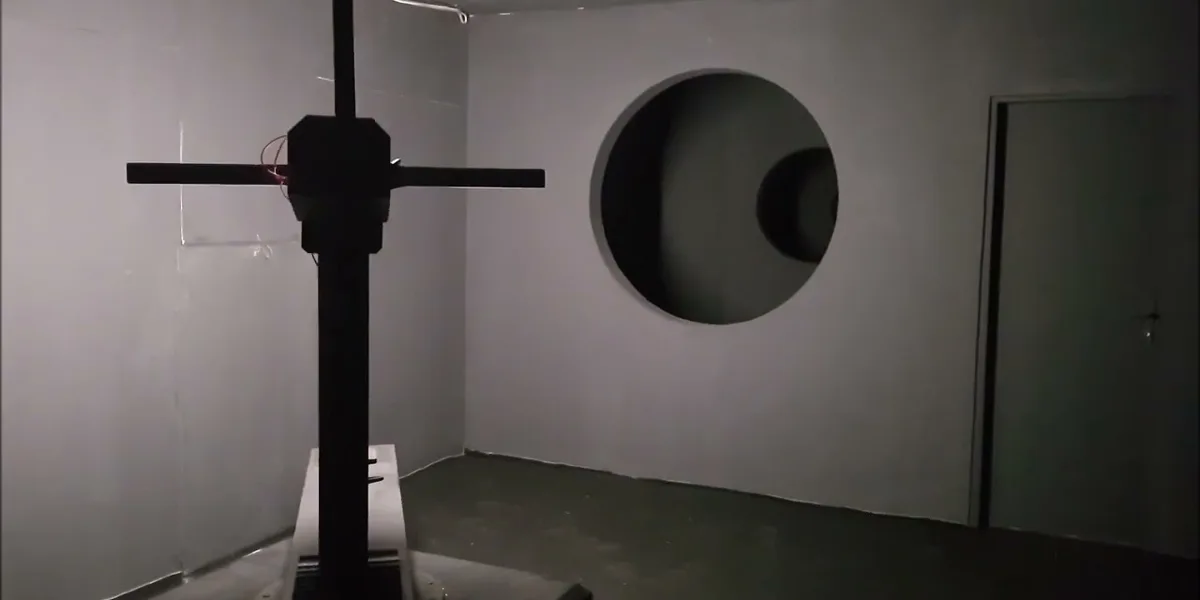

il valore UGR di Luci lineari a LED Viene comunemente misurato utilizzando un goniofotometro, che può ottenere dati fotometrici e simulare calcoli utilizzando un software standard. Di seguito sono riportate le procedure di test specifiche e i punti chiave:

Fissare la lampada lineare al supporto rotante del goniofotometro. Ruotando l'apparecchio o il riflettore, catturare i dati di distribuzione dell'intensità della luce attraverso uno spazio a 360°, generando un file fotometrico in formato IES contenente parametri come il flusso luminoso e la distribuzione dell'intensità della luce.

Le luci lineari lunghe appartengono tipicamente alla categoria degli apparecchi biassialmente simmetrici (ad esempio, lampade a pannello lunghe), che richiedono il test delle curve di distribuzione della luce per due piani simmetrici: il piano longitudinale (C0-C180) e il piano trasversale (C90-C270).

Convalida dei dati

Assicurarsi che il file IES contenga informazioni complete sulla distribuzione della luce (come l'angolo di spigolo a metà picco e l'angolo di diffusione del fascio) e che l'angolo solido luminoso Ω dell'apparecchio sia compreso tra 0,0003 e 0,1 SR per soddisfare le condizioni di calcolo UGR.

Importazione del file IES nel software di simulazione

Quando si carica il file IES di un apparecchio lineare in software professionale come Dialux, verificare che il file sia in un formato completamente simmetrico o biassialmente (le apparecchiature asimmetriche non possono generare tabelle UGR). Se il file IES non si adatta automaticamente, regolare la simmetria utilizzando uno strumento di correzione.

Impostare l'ambiente di simulazione standard

Secondo gli standard CIE 117-1995, costruire una stanza virtuale e definire i parametri chiave:

- Dimensioni dello spazio: impostare la lunghezza e la larghezza dinamicamente secondo X=2H, 4H, 8H, 12H (dove H è l'altezza dagli occhi dell'osservatore all'altezza di installazione dell'apparecchio);

- riflesso: immettere i coefficienti di riflettanza effettivi per il soffitto e le pareti (valori predefiniti: soffitto 0,7, pareti 0,5);

- Posizione dell'osservatore: Mantenere una linea di vista orizzontale, con una distanza predefinita dal punto centrale dell'apparecchio.

- Generazione della tabella UGR e correzione: Il software emette la “Tabella di valutazione dell'illuminamento UGR di riferimento” (tabella UGR non corretta), che rappresenta i valori teorici per la sorgente luminosa nuda a un flusso luminoso di 1000 lm.

- Formula di correzione UGR effettiva: UGR effettivo = valore della tabella + 10 × log (flusso di luce effettivo dell'apparecchio / 1000). Ad esempio, quando il flusso di luce dell'apparecchio è di 2000 lm, aggiungere 3 al valore della tabella (10 × log₂ ≈ 3).

- Limitazioni dell'applicazione: UGR è applicabile solo agli ambienti interni e agli apparecchi bilateralmente simmetrici; gli apparecchi lineari con disegni polarizzati (come gli apparecchi di lavaggio a parete a distribuzione non simmetrici) non possono essere valutati direttamente con questo metodo.

- Differenze tra UGR misurati e risultati di simulazione: I risultati della simulazione sono valori di riferimento ambientali standard; le installazioni effettive sono influenzate da dimensioni spaziali, materiali riflettenti, ecc.

Come ridurre efficacemente il valore UGR delle luci lineari?

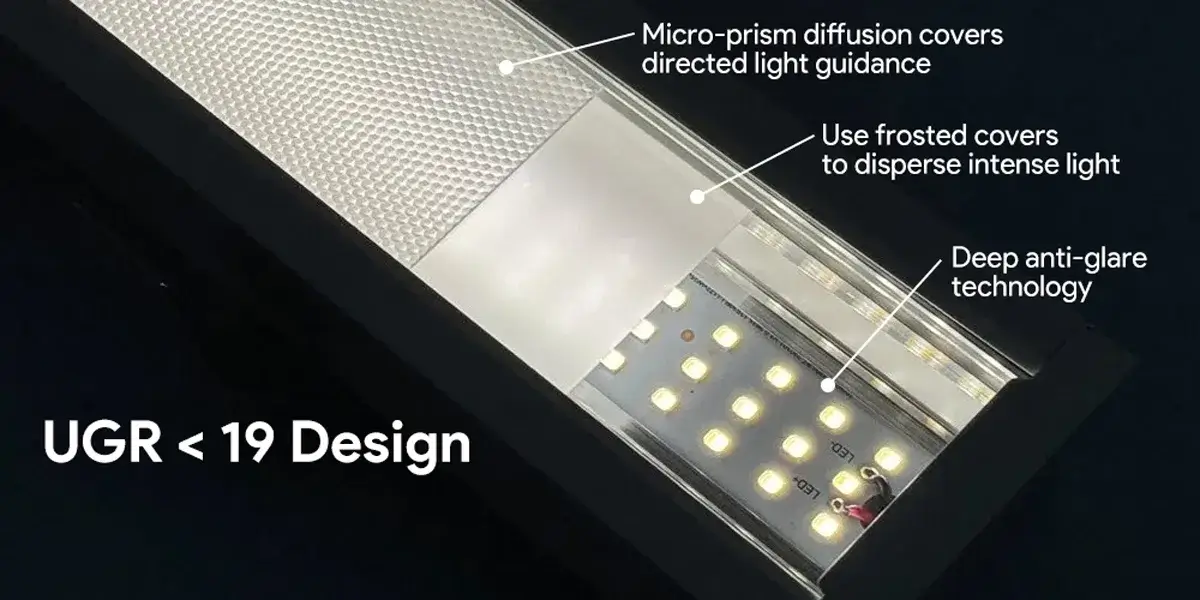

- Ottimizzazione della struttura ottica: Adotta un design dell'angolo di abbagliamento e una tecnologia antiriflesso profonda, con un angolo di bagliore di ≥25 cm per impedire alla luce diretta di raggiungere gli occhi. Per le impostazioni industriali si consiglia di installare le luci ad un'altezza di ≥3,5 m e combinarle con riflettori per ridurre l'abbagliamento.

- superficie Tritrattiatura Tenologia: utilizzare una rete antiriflesso a nido d'ape per indebolire i riflessi randagi, ottenendo una riduzione di 30% in UGR (particolarmente adatta per ambienti ad alta riflettività); in alternativa, utilizzare paralumi sati/opachi per disperdere la luce intensa, garantendo una diffusione uniforme della luce, con una riflettanza superficiale <60%;

- micro-Prisma Difffusione Panie: Guida leggera diretta, riducendo UGR da 21 a 14.

- installazione e Layout Controllo: Dare priorità all'installazione da incasso per evitare lampade a vista; le luci lineari devono essere incorporate in soffitti o pareti (profondità incorporata ≥2 cm); quando le lenti polarizzate montate in superficie devono essere utilizzate per dirigere la luce verso il piano di lavoro. Le lampade non devono essere posizionate entro 30° dal livello degli occhi (un'altezza di ≥1,8 m dal suolo è più sicura); i soffitti a specchio devono essere abbinati a paralumi smerigliati per sopprimere i riflessi secondari.

- Controllo del materiale della parete: Utilizzare vernice opaca (riflesso <60%), evitando materiali ad alta riflessione come pareti bianche o piastrelle; installare fessure di luce riflettente curva per convertire la luce diretta in luce diffusa (UGR misurato ridotto da 21 a 13).

- RG0-Level Blue Lluce Controllo: utilizzare sorgenti luminose a spettro completo per ridurre la stimolazione fotobiologica;

- svelto Dimming Ssistema: Ridurre dinamicamente il contrasto nelle aree ad alta luminosità (deve essere certificato FCC/CE).

- banconote: le lampadine a LED trasparenti sono sorgenti luminose a vista e possono causare un forte riflesso; evitare disposizioni ad alta potenza, con spaziatura della lampada ≥ 1,5 volte la larghezza dell'apparecchio; superfici riflettenti come mobili a specchio, scrivanie e schermi dovrebbero essere sfalsati dall'angolo di proiezione dell'apparecchio.

- Effetto Verificazione: Misurare il valore UGR corretto utilizzando un misuratore di luminanza per immagini a 143° per garantire ≤19 (ufficio) o ≤13 (medico/educativo).

Inoltre, per soddisfare UGR ≤19, i progetti di illuminazione devono utilizzare il controllo della tripla tecnologia:

- ottico Ddesign: Utilizzare piastre di diffusione della luce microstrutturate per ridurre la luminosità superficiale;

- strategia: evitare la zona di interferenza dell'occhio umano (entro un campo visivo verso l'alto di 30°);

- Materiale Selezione: Utilizzare materiali a basso colore per ridurre l'abbagliamento riflettente. Ad esempio, l'illuminazione in classe ha il compito di avere UGR ≤ 19 (standard nazionale GB7793-2010), mentre gli apparecchi di fascia alta (come i lampioni) sono ulteriormente ottimizzati per UGR ≤ 16.

- Ottimizzazione ottica: Installare i pannelli di diffusione a microprisma: UGR può essere ridotto da 21 a 14; utilizzare lenti polarizzate: le impostazioni industriali consentono UGR ≤ 25, ma devono essere abbinate a pareti aventi una riflettanza ≤ 60%.

- Tabù di installazione: vietare severicamente di posizionare lampade nude all'interno del campo visivo orizzontale di 30° dell'occhio umano; un'altezza di 1,8 metri dal suolo è più sicura; in ambienti a soffitto a specchio, devono essere utilizzati paralumi smerigliati.

I quattro principali vantaggi di SIGNLITELED LED LINEAR

Prestazioni ottiche eccezionali: Caratterizzato da un design a riduzioni di abbagliamento con UGR < 19, la luce viene equamente diffusa attraverso un pannello di diffusione prismatico, completato da un sistema di lenti ottiche ad alta precisione che controlla efficacemente la nitidezza del confine del punto luminoso, raggiungendo standard di soppressione dell'abbagliamento di livello museale.

Progettazione strutturale di livello industriale: Costruito con profili in lega di alluminio di grado aerospaziale e tecnologia di nano-rivestimento, vanta un grado di protezione IP66, in grado di resistere a ambienti estremi da -30°C a 60°C. La sua innovativa struttura di montaggio modulare supporta la regolazione multidimensionale da 0° a 90°, adattando l'installazione in spazi curvi o irregolari.

svelto Ecosistema IOintegrazione: Driver a doppio protocollo DALI/PWM integrato, compatibile con i sistemi di controllo intelligenti tradizionali. La tecnologia di dissipazione del calore al grafene raggiunge la conversione di efficienza energetica oltre 93%, combinata con una durata di oltre 50.000 ore, risparmiando oltre 40% di energia rispetto ai tradizionali apparecchi di illuminazione.

diversificato Vallusione: Il prodotto è certificato da CE e RoHS, offrendo una garanzia di 5 anni. I sistemi di servizio personalizzati possono soddisfare i requisiti speciali di temperatura del colore (regolabili da 2700K a 6500K) e indici di resa cromatica (RA ≥ 95) per spazi commerciali, gallerie d'arte e altri scenari.

Con le loro eccezionali prestazioni ottiche, la struttura durevole di livello industriale, la compatibilità con il controllo intelligente e i servizi altamente personalizzati, SIGNIFERWER Luci lineari a LED sono diventati la scelta ideale per l'illuminazione architettonica moderna e gli spazi commerciali di fascia alta. Che tu stia intraprendendo un nuovo progetto di costruzione o un aggiornamento dell'illuminazione, SignLiteled ti offre soluzioni di illuminazione più efficienti, più intelligenti e più orientate al design.