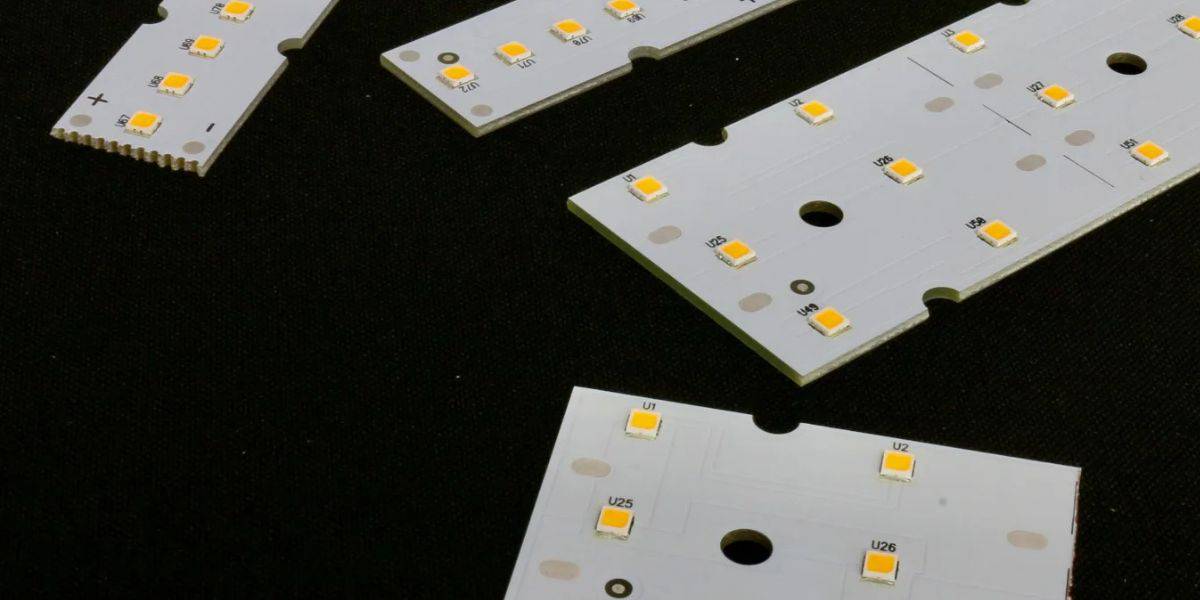

信頼できる LED PCB SMT アセンブリ パートナーは、LED を高精度で一貫して配置し、ボード レベルで熱を管理し、試作および生産の実行全体で繰り返し結果をもたらすことができるパートナーです。 LED PCB アセンブリは、標準の SMT よりも複雑です。配置エラーが小さい、熱管理が正しくない、またはコンポーネントの変動により、光の出力と寿命が直接的に減少する可能性があるためです。 このコンテキストでの信頼性とは、プロセス制御、予測可能な品質、および決定の透明性だけではなく、スピードや価格だけではありません。

LED PCB SMT アセンブリ パートナーを評価するための 10 の重要な質問

1 — LED PCB とメタルコア ボードについてどのような経験がありますか?

LED アセンブリは、熱と電流のストレス下で異なる動作をするため、LED PCB の直接的な経験は重要です。 アルミニウムやその他の金属コア ボードに精通しているパートナーは、レイアウト、はんだ付けプロファイル、およびハンドリングが熱経路にどのように影響するかを理解しています。 この経験がなければ、有能なカスタム PCB メーカーでさえ、LED 固有のリスクを過小評価し、早期の故障や一貫性のない光学性能につながる可能性があります。

2 — LED の配置精度に使用する SMT 機器は何ですか?

LED の信頼性は、特に高密度アレイとリニア モジュールの正確な配置と向きに依存します。 適切な SMT 機器は、一貫した整列、はんだ容積制御、最小限の再加工を保証します。 この質問は、カスタム PCB メーカーが配置精度を大規模に維持できるかどうか、またはバッチ間で品質が異なるかどうかを評価し、現場の故障リスクを高めるのに役立ちます。

3 — LED PCB アセンブリ中の熱性能をどのように管理していますか?

熱管理は、LED の寿命と色の安定性の中心です。 信頼できるパートナーは、はんだ付け、コンポーネントの取り付け、および組み立て後の取り扱い中の熱を考慮します。 この質問は、熱制御がシステム レベルの問題として扱われるか、後付けとして扱われるかを明らかにします。 組み立て中の熱の練習が不十分な場合、適切に設計された PCB カスタム レイアウトでさえも無効にする可能性があります。

4 — どのような検査および品質管理プロセスを適用しますか?

検査は、明らかな欠陥を検出するだけでなく、時間の経過とともに LED のパフォーマンスに影響を与える微妙な問題を検出するだけです。 一貫した品質管理により、はんだボイドや位置ずれによる潜在的な故障を防ぐことができます。 この質問は、特にミッション クリティカルな照明システムのカスタム PCB アセンブリを評価する場合に、約束ではなくプロセスの規律に基づいてパートナーを比較するのに役立ちます。

5 — LED ビニングとコンポーネントの一貫性をどのように処理しますか?

LED ビニングは、明るさ、色温度、および視覚的均一性に影響を与えます。 信頼できるパートナーには、コンポーネントの変動を管理し、単一のボード内および生産ロット全体で一貫性を維持するプロセスがあります。 この質問は、視覚的な違いが受け入れられず、一貫性のないソーシングが適切な組み立てプロセスを損なう可能性があるアプリケーションにとって不可欠です。

6 — プロトタイピングと量産の両方をサポートできますか?

パートナーを変更せずにプロトタイプからボリュームに移行できるため、リスクと通信の誤りが軽減されます。 この質問は、同じ基準とコントロールが異なる規模で適用されるかどうかを評価します。 LED プロジェクトの場合、初期のビルドと大量生産の間の矛盾は、プロトタイピングとボリュームを無関係なプロセスとして扱うパートナーにまでさかのぼることがよくあります。

7 — 典型的なリードタイムとスケジュールの信頼性は?

リードタイムの信頼性は、設置スケジュールに関連する LED PCB プロジェクトでは、公称速度よりも重要です。 この質問は、パートナーがどれだけうまく容量を計画し、変更を管理するかを理解するのに役立ちます。 スケジュールを逃した場合、経験豊富な人と一緒に仕事をする場合でも、LED のパフォーマンスに影響を与える急ぎの決定や代替を強制する可能性があります。 カスタム PCB メーカー.

8 — LED PCB プロジェクトに対して DFM フィードバックをどのように提供しますか?

レイアウトの決定が小さいと、熱の流れや配置の歩留まりに影響するため、製造可能性のフィードバックの設計は LED アセンブリで重要です。 信頼できるパートナーは、一般的なコメントではなく、リスクの軽減に焦点を当てた明確な早期のフィードバックを提供します。 この質問は、DFM が決定ツールとして使用されるか、カスタム PCB アセンブリ ワークフローで形式として扱われるかを示します。

9 — サプライ チェーンとコンポーネントの調達リスクをどのように管理していますか?

LED コンポーネントは、代替品や不足に敏感です。 信頼できるパートナーは、調達、トレーサビリティ、および変更通知のプロセスを定義しています。 この質問は、供給の混乱がどのように処理されるか、また、決定前に情報を受け取るかどうかを判断するのに役立ちます。PCB カスタム プロジェクトのパフォーマンスまたはコンプライアンスに影響を与えるかどうかを判断するのに役立ちます。

10 — どのようなコミュニケーション、ドキュメント、組み立て後のサポートを提供しますか?

明確なコミュニケーションにより、プロジェクトのライフサイクル全体を通してリスクが軽減されます。 この質問は、問題の文書化方法、変更の承認方法、および組み立て後の質問の処理方法を評価します。 信頼できるパートナーは、長期的な LED システムの安定性に不可欠な、推測をせずに問題を診断するのに役立つ一貫した記録とサポートを提供します。

標準と信頼できる LED PCB SMT アセンブリ パートナーの比較

| 評価エリア | スタンダードパートナー | 信頼できるパートナー |

| LED PCB エクスペリエン | 一般的な SMT 露出 | 実績のある LED とメタルコアのフォーカス |

| 熱管理機能 | 設計から想定される | 組み立て中に積極的に管理 |

| 検査方法 | 基本的なビジュアル チェック | プロセス主導の検査戦略 |

| プロトタイピング速度 | 速いが一貫性がない | 制御され、再現可能 |

| 生産のスケーラビリティ | プロトタイピングとは別のもの | すべてのボリュームに合わせて調整 |

| DFM サポート | ジェネリックまたは遅い | 初期の LED 固有のフィードバック |

| サプライチェーンの取り扱い | 後発品の調達 | 計画的で透明性がある |

これらの質問が意思決定フレームワークとして機能する理由

これらの 10 の質問は、マーケティングの主張ではなく、運用上の現実を明らかにするように設計されています。 それぞれが、小さなプロセス ギャップが大きな下流の問題を引き起こす可能性がある LED PCB SMT アセンブリに特有のリスク領域に焦点を当てています。 回答を並べて評価すると、最初のビルドだけでなく、製品ライフサイクル全体にわたって重要な信頼性指標についてパートナーを比較することができます。

このフレームワークを使用すると、社内の利害関係者の調整にも役立ちます。 エンジニアリング チームは技術的なリスクに集中できますが、調達は予測可能性とコミュニケーションを評価できます。 その結果、主観的判断と短期的思考を減らす意思決定の共有基盤が生まれます。

避けるべきよくある評価ミス

よくある間違いの 1 つは、経験豊富な SMT プロバイダーが LED PCB に適していると仮定することです。 もう 1 つは、プロセス制御を理解せずに、見積もりのリード タイムまたは単価を優先することです。 一部のチームは、実際にツールがどのように使用されているかを尋ねずに、機器のリストを過大評価しています。 これらの罠を避けるには、規律ある質問と、意思決定が長期にわたって LED のパフォーマンスにどのように影響するかに焦点を当てる必要があります。

LED PCB と SMT の組み立てコスト構造

LED PCB SMT アセンブリのコスト評価は、主に PCB の分類、ベース材質、層数、アセンブリの複雑さ、および製造のターンアラウンド タイムに依存します。 一般的な SMT プロジェクトとは異なり、LED PCB アセンブリは、製造と組み立ての両方のコストに直接影響を与える、追加の熱および配置精度の制約を導入します。

以下の価格設定の参考は、PCB 製造プラットフォーム、オンライン価格計算機、およびサプライヤーの評価時に購入者が一般的に参照する業界ベンチマークから公開されているデータに基づいています。 すべての値は おおよその参照範囲 正式な見積もりではなく、予算編成、比較、および早期の調達計画を目的としています。

PCB 分類と典型的な製造コスト範囲

| PCB 分類 | 典型的なレイヤー数 | ベース材 | 一般的な LED アプリケーション | PCB のおおよその製造コスト (USD / ユニット、プロトタイプ ボリューム) |

| 単層基板 | 1 | fr4 | インジケータ LED、低電力照明 | $1 – $5 |

| 2 層 PCB | 2 | fr4 | リニア LED ボード、コンパクトなフィクスチャ | $3 – $10 |

| アルミニウム MCPCB | 1–2 | アルミコア | 高出力 LED 照明、熱クリティカルな設計 | $5 – $20 |

| 4層基板 | 4 | FR4 (標準または高 TG) | 高密度 LED 制御およびドライバ ボード | $10 – $25 |

| HDI PCB | 4–6+ | FR4 / ハイTG | コンパクトで高密度の LED モジュール | $30 – $60+ |

コスト範囲は、生産、特別仕上げ、または高度な電気的要件を伴わない標準仕様を反映しています。

LED PCB SMT アセンブリ コスト ドライバー

LED PCB の SMT アセンブリ コストは、製造時の機械時間、検査作業、および熱制御に影響を与えるいくつかのプロセス レベルの変数の影響を受けます。

| コストドライバー | 典型的なコスト影響 (USD / ボード、プロトタイプのボリューム) | 解説 |

| LED 配置密度 | +$1.50 – $4.00 | LED 数が増えると、配置サイクル、フィーダーの使用量、検査時間が増加します。 |

| PCB ベース材質 (MCPCB と FR4) | +$2.00 – $6.00 | アルミニウム芯板は、制御された熱プロファイルとより遅いリフロー プロセスが必要です |

| LED パッケージ サイズ (小さな SMD 形式) | +$1.00 – $3.00 | パッケージが小さいほど、より厳密な配置公差と検証手順が求められます |

| LED ビニング制御 | +$0.50 – $2.00 | ロットの分離、追跡、および処理により、プロセスのオーバーヘッドが増えます |

| 検査レベル(AOI および手動チェック) | +$1.00 – $3.00 | 追加の検査段階により、人件費と設備の利用率が向上します |

アセンブリ コストへの影響は、一般的に公開されている SMT 価格設定モデルから得られた、ボードごとの参考資料です。

LED PCB プロジェクトへのターンアラウンド タイムとコストへの影響

製造リードタイムの選択は、特に厳密な熱制御と配置制御が必要なプロジェクトの場合、総 LED PCB SMT アセンブリ コストに測定可能な影響を与えます。

| 製造のターンアラウンド タイム | 典型的なコストの増加 | よくある使用例 |

| 標準 (10 ~ 15 営業日) | ベースライン | 計画的な生産ビルドと資格認定の実行 |

| 加速 (5 ~ 7 営業日) | +20% から +40% | パイロット生産とスケジュール駆動型のプログラム |

| エクスプレス (24 ~ 72 時間) | +50% ~ +100% | 緊急の代替またはタイム クリティカルな展開 |

調達およびエンジニアリング チームのコストの解釈

これらのコスト参照により、調達およびエンジニアリング チームは、現実的な分類ベースの価格予想を使用して、LED PCB SMT アセンブリ パートナーを評価できます。 PCB タイプ、材料の選択、組み立ての複雑さ、およびリード タイムが総コストにどのように影響するかを理解することで、購入者は、長期的な信頼性と生産の安定性を考慮せずに、見出しの価格設定のみに基づいて、より多くの情報に基づいた意思決定を行い、選択を回避できます。

結論

信頼できる LED PCB SMT アセンブリ パートナーを選択することは、購入作業ではなく、リスク管理の決定です。 このガイドの 10 の質問は、製造理論や販売の主張にドリフトすることなく、経験、プロセス制御、および一貫性を評価するための構造化された方法を提供します。 意思決定者は、LED 固有のリスク、通信品質、および長期的な安定性に注目することで、照明製品の全ライフサイクル全体にわたって予測可能なパフォーマンスをサポートするパートナーを選択できます。

よくある質問

LED は熱、配置精度、およびコンポーネントの変動に敏感であるため、LED PCB SMT アセンブリは異なります。 小さなアセンブリの問題で、光出力や寿命が短縮され、多くの標準の SMT アプリケーションよりもプロセス制御がより重要になります。

主なリスクには、早期 LED の故障、一貫性のない明るさ、色の変化、および再作業の遅延が含まれます。 これらの問題は、インストール後に発生することが多く、修正費用が高く、評判への影響が大きい場合に発生します。

熱処理は、LED の信頼性の中心です。 PCB 設計自体が健全であっても、アセンブリに関連する熱ストレスが LED を損傷したり、熱経路を弱めたりする可能性があります。

はい。 小さな配置エラー、はんだ欠陥、または制御されていない熱暴露により、LED の寿命が大幅に短縮され、時間の経過に伴うシステムの安定性が低下する可能性があります。

品質の問題が繰り返される場合、コミュニケーションの透明性が欠けている場合、または設計変更がないにもかかわらず、生産結果が実行によって異なる場合は、パートナーの変更を検討する必要があります。