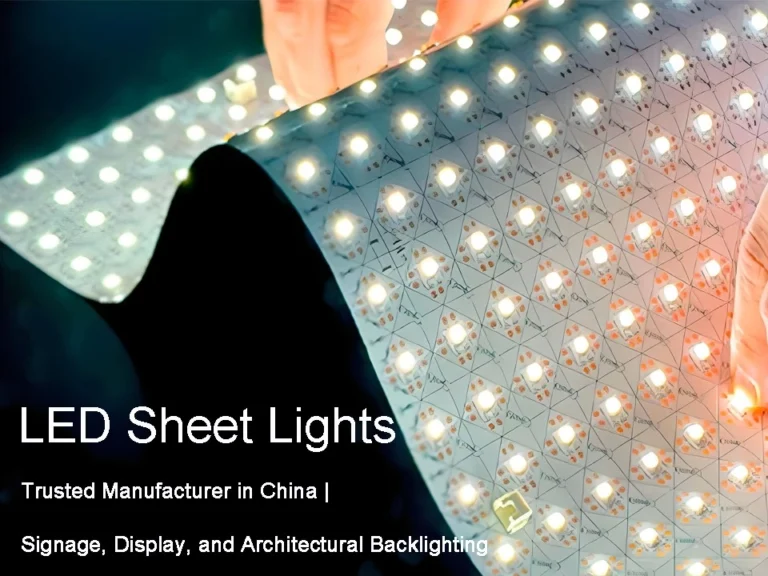

Evaluating suppliers of LED sheet lights requires a structured verification process that begins with technical sample testing and continues through supplier auditing, pilot production, and full-scale manufacturing validation. A supplier cannot be approved based on sample quality alone. The evaluation must confirm that performance, process control, and manufacturing discipline remain consistent from the first prototype to mass production.

Many buyers experience a predictable problem: initial samples perform well, but once orders scale, brightness consistency drops, thermal behavior changes, cutting tolerances drift, or adhesive performance weakens. This “quality fade” happens when the supplier’s process control cannot support volume production, even if their engineering team can produce strong early samples.

This guide outlines a step-by-step evaluation system. It does not recommend specific suppliers. Instead, it defines how procurement managers, OEM/ODM buyers, project engineers, and brand owners should verify suppliers of LED sheet lights from bench testing through full production readiness.

Stage 1: Sample Evaluation

Sample testing is not about first impressions. It is about repeatability under controlled conditions. Every LED sheet light sample must be evaluated using measurable criteria that can later be applied to production batches.

Buyers should test samples using the following verification framework:

- Optical uniformity across the LED sheet light panel

Measure brightness at multiple grid points. Variations in luminous intensity across the sheet of LED lights should stay within a defined tolerance range. Uneven diffusion or inconsistent diode spacing indicates potential scaling issues. - Brightness stability under extended runtime

For high brightness LED light sheet samples, conduct continuous operation tests for 8–24 hours. Track lumen drop, color shift, and current fluctuation. Stability under thermal load is more important than initial peak output. - Thermal performance mapping

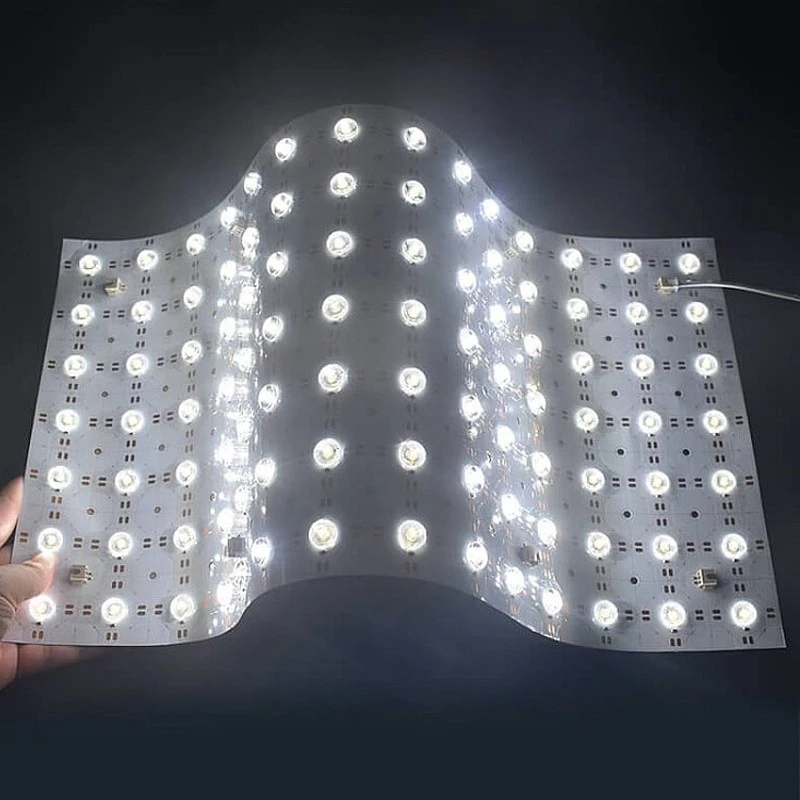

Use thermal imaging to record hotspot distribution. Compare center vs edge temperature rise. Excessive heat concentration often predicts long-term degradation when scaling production. - Mechanical integrity of flexible and rigid formats

For flexible LED light sheet formats, perform bending cycle tests. For rigid formats, apply mild torsion stress to confirm solder joint durability. Mechanical stability must be repeatable across multiple samples. - Cutting tolerance and electrical continuity

If the LED sheet light allows field cutting, test multiple cut points. Confirm that electrical continuity remains stable and no edge dimming occurs. Inconsistent copper trace routing becomes visible here. - Adhesive performance and substrate bonding

Evaluate peel strength and adhesion stability under heat exposure. Weak adhesive systems often degrade during large-scale production because of material substitutions.

The key principle is replication. Buyers should test multiple samples from different production dates if possible. If performance varies between units, the supplier likely lacks process consistency.

Stage 2: Supplier Background & Capability Audit

Strong samples do not guarantee a capable manufacturer. Many suppliers outsource partial production or rely on small engineering batches for evaluation units. A background audit determines whether the supplier can consistently produce LEDシートライト at volume.

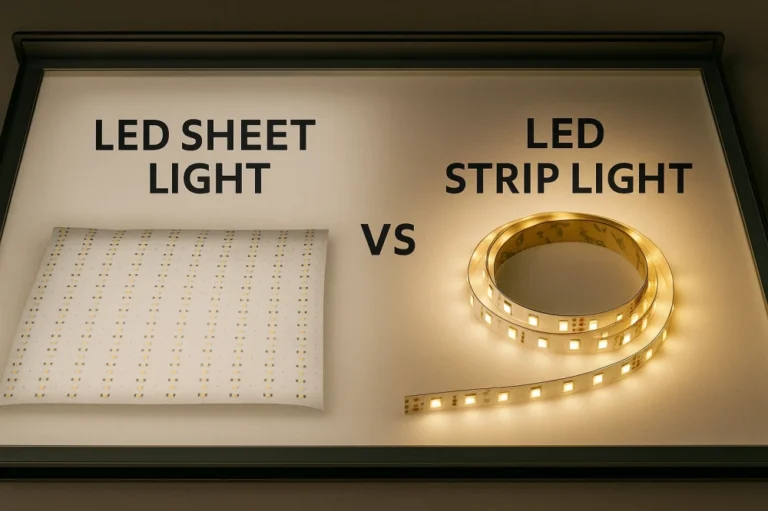

Start by examining specialization. A factory that primarily produces generic LED strips may not have deep experience in high brightness LED light sheet panel manufacturing. Production lines, SMT configuration, and optical diffusion control differ significantly between formats.

Next, assess engineering depth. Custom LED sheet lighting projects require layout optimization, current balancing, and thermal modeling. Suppliers should demonstrate the ability to modify PCB architecture, not simply adjust brightness levels. Review prior project documentation and engineering change workflows.

Production history also matters. A supplier with limited production cycles may lack structured yield monitoring. Consistent large-batch history reduces scaling risk.

Finally, evaluate quality system maturity. The focus should not be on certificate displays. Instead, verify whether:

- There are defined in-process inspection checkpoints.

- Process parameters are documented and locked.

- Engineering changes require structured approval.

- Root cause analysis is recorded and traceable.

A capable supplier shows operational discipline, not marketing documentation.

Stage 3: Compliance & Process Verification

Compliance validation is not about listing standards. It is about confirming that the supplier can prove test traceability and regulatory conformity with documented evidence.

First, verify whether safety testing corresponds to the actual LED sheet light configuration being purchased. Documentation must match wattage, substrate type, and driver compatibility. Generic certificates that do not reference specific build configurations present risk.

Second, confirm internal quality checkpoints. Ask how solder paste inspection is verified. Review how LED bin selection is recorded. Examine how current calibration is performed for high brightness LED light sheet variants.

Third, review batch traceability. Each sheet of LED lights should be traceable to LED bin codes, PCB lot numbers, and assembly shift records. Without traceability, field failure investigations become impossible.

Unverifiable documentation signals potential instability. If a supplier cannot explain how a test result was generated or which batch it represents, production reliability cannot be guaranteed.

Stage 4: Pilot Run & Pre-Production Validation

Sample approval should always be followed by a controlled pilot run. This is the stage where real manufacturing stress is introduced.

Buyers should evaluate pilot production using these criteria:

- Small-batch replication of production settings

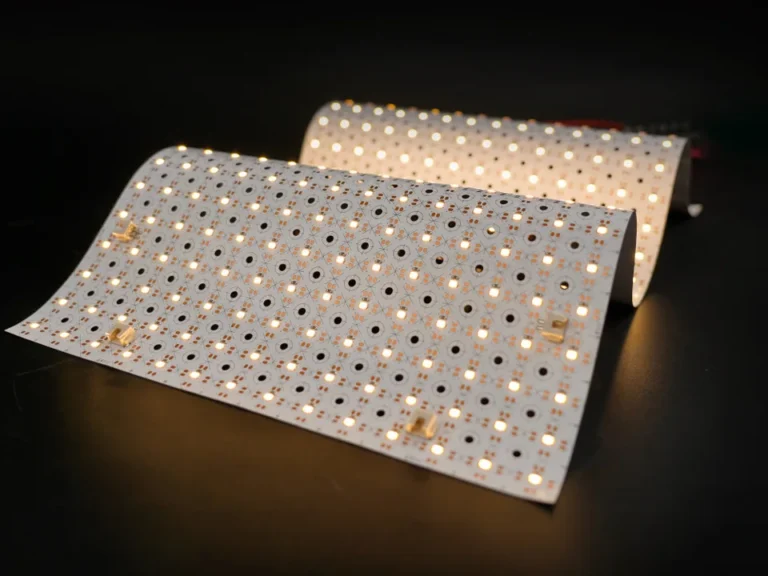

The pilot should use actual mass-production tooling and materials, not prototype components. - Consistency across multiple LED light sheet panels

Measure brightness, color temperature, and power draw across at least 20–50 units. Variability reveals process stability. - Thermal stability under grouped installation conditions

Test multiple panels installed together to simulate real application heat accumulation. - Yield and defect rate tracking

Request data on production yield percentage. Early yield instability indicates future scale problems. - Packaging and handling durability

Shipping vibration tests reveal weak solder joints or adhesive flaws.

Pilot runs expose issues that single samples cannot reveal. Minor variations in solder reflow temperature or LED bin mixing often appear only when batch size increases.

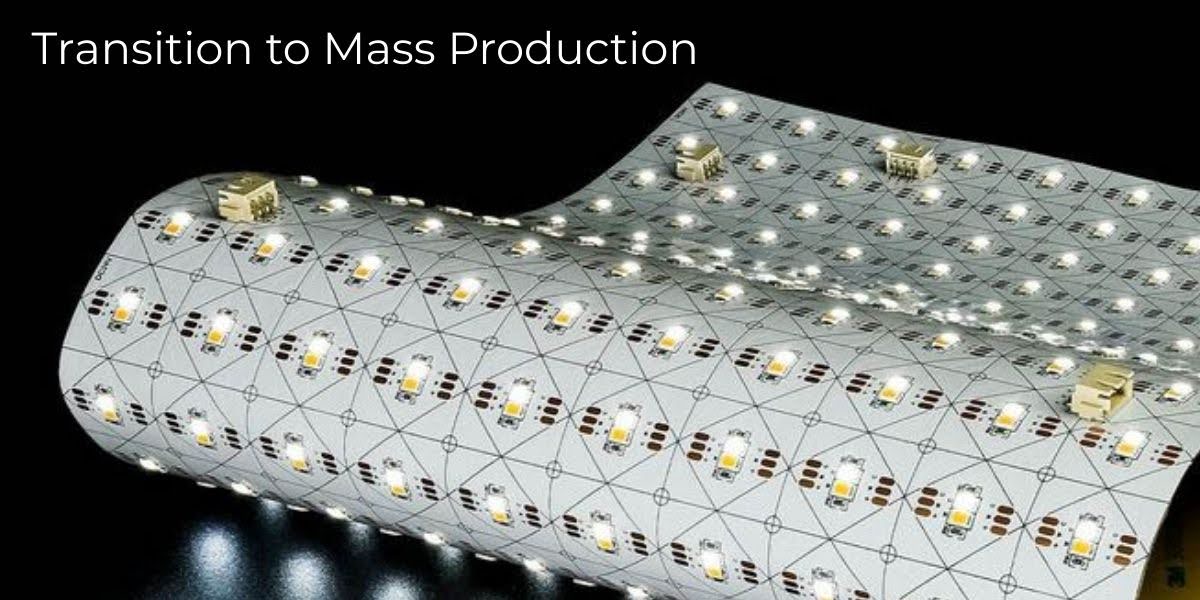

Stage 5: Transition to Mass Production

The transition from pilot to mass production is where quality fade most commonly occurs. Even well-performing flexible LED light sheet products can degrade when volume pressures increase.

Several factors contribute to this risk:

Material substitution is common at scale. Suppliers may switch adhesive brands, PCB copper thickness, or LED batches to meet cost targets. Each substitution affects optical and thermal stability.

Tooling drift can occur when stencil wear changes solder volume deposition. Over time, this affects brightness uniformity across the LED sheet light panel.

Thermal load behavior also shifts at scale. In high brightness LED light sheet production, minor current imbalance becomes amplified across large quantities. Heat dissipation variance may lead to premature lumen depreciation.

Process locking is critical. Once pilot approval is complete, suppliers should freeze component specifications, SMT parameters, and inspection thresholds. Any change must trigger a documented engineering review.

Buyers should request confirmation of:

- Component locking procedures

- Approved vendor lists for raw materials

- Change notification protocols

- Ongoing performance monitoring methods

Mass production readiness is defined by control, not capacity.

Stage 6: Ongoing Quality Control During Mass Production

Quality assurance does not end at purchase order issuance. Continuous verification is required to maintain performance stability in LEDシートライト.

Incoming material inspection ensures LED bins match approved specifications. PCB substrates must meet defined copper thickness and insulation resistance criteria.

In-process inspection should monitor solder paste deposition, LED placement accuracy, and current calibration. Automated optical inspection can detect alignment drift before defects multiply.

Final inspection logic should verify:

- Electrical continuity across cut points

- Uniform brightness distribution

- Power consumption within tolerance

- Adhesive bonding integrity

Factories with disciplined process control outperform larger but loosely managed operations. Consistency is determined by process discipline, not production volume.

Supplier Evaluation Comparison Table

| Evaluation Stage | What Buyer Should Verify | Why It Matters at Scale | Risk If Skipped |

| Sample Testing | Optical uniformity, thermal stability, repeatability | Detects early design weaknesses | Hidden defects appear in production |

| Supplier Audit | Engineering depth, process discipline, production history | Confirms ability to scale reliably | Strong samples from weak factories |

| Compliance Check | Traceable documentation, batch records | Enables defect tracking | Uncontrolled regulatory risk |

| Pilot Run | Batch consistency metrics, yield rate | Simulates production stress | Quality fade after order confirmation |

| Mass Production Lock | Material control, tooling stability | Prevents drift over time | Performance decline across batches |

Common Buyer Mistakes

Many procurement teams approve suppliers based only on initial sample performance. This ignores process capability and scaling discipline.

Skipping pilot runs is another common mistake. Without batch replication, hidden yield issues remain undetected.

Buyers often assume that flexible LED light sheet products behave identically at volume as they do in small test batches. In reality, soldering tolerance, copper trace stress, and heat distribution change with production scale.

Another mistake is overlooking internal traceability. When failure occurs in field installations, lack of batch documentation prevents root cause analysis.

Supplier evaluation must move beyond price comparisons and aesthetic inspection. It requires structured verification from first sample through ongoing production monitoring.

結論

Evaluating suppliers of LED sheet lights is a process-driven exercise that moves step by step from sample validation to mass production discipline. Strong samples are necessary but insufficient. True supplier capability is proven through repeatability, traceability, pilot replication, and process locking.

Quality fade between sample and scale is preventable when buyers apply structured verification at each stage. Procurement decisions should be based on process control strength, not initial pricing or first impressions.

From bench testing to volume stability, supplier evaluation is a system. When applied rigorously, it protects performance, reliability, and long-term product integrity.

よくある質問

Because small-batch engineering builds often use tighter control than standard production lines. Scaling exposes process instability.

At least multiple units from different production batches should be tested to confirm repeatability.

Whenever order volume exceeds prototype scale or when custom LED sheet lighting specifications are involved.

Measure luminous intensity across multiple grid points and compare variance against defined tolerances.

Locked materials, controlled SMT parameters, documented inspection points, and proven pilot batch stability.

They often require tighter solder and substrate control because bending stress magnifies minor assembly flaws.

Uncontrolled material substitutions and tooling drift.

By linking each LED light sheet panel to LED bin codes, PCB lot numbers, and assembly batch records.