LED PCB アセンブリのコストは、単一の価格ドライバーではなく、5 つの主要な価格設定要因によって形作られます。 材料とコンポーネントがベースラインを設定します。 設計の複雑さが処理の努力を決定します。 生産量はユニットの効率に影響します。 リードタイムは、スケジューリングの圧力に影響を与えます。 テストと品質管理により、検査の深さが定義されます。 これらの要素を合わせると、カスタム PCB のコストがプロジェクト間で大きく異なる理由と、外観が似ている 2 つのボードが最終的な価格を大きく異なる理由が説明されています。

これらの価格設定要因を理解することで、エンジニアや調達チームが見出しの見積もりに頼るのではなく、現実的にコストを評価することができます。 LED アプリケーションでは、コストは、単純なボード アセンブリではなく、リスク管理、プロセスの安定性、および長期的なパフォーマンス要件を反映しています。

LED PCB アセンブリのコストは何によって決まりますか?

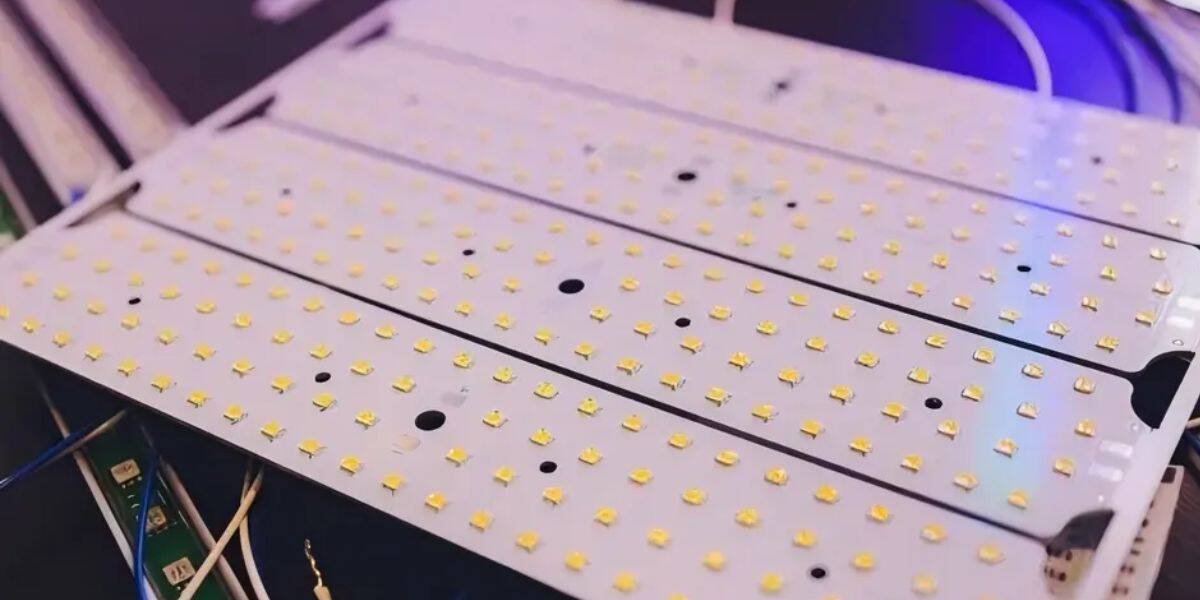

LED 基板は一度に複数の役割を果たすため、LED PCB アセンブリのコストは、標準の PCB アセンブリとは異なる動作をします。 電気接続を提供するだけでなく、ボードは、長時間の動作サイクルでの熱放散、機械的安定性、および一貫した光学性能をサポートする必要があります。

一般的な電子機器とは異なり、LED システムは、熱流量、コンポーネントの配置、および電流バランスの小さな変動に敏感です。 これらの感度は、追加の製造管理、検査手順、および材料の制約に直接影響し、これらはすべてカスタム PCB 価格に影響を与えます。

コストを分解する目的は、事前に見積もりを推定することではなく、理解することです。 なんでや 特定の設計と計画の決定により、プロジェクトのライフサイクル全体で総費用が増加または削減されます。

主導権を形成する 5 つの価格設定要因 LED PCB アセンブリのコスト

1. 材料とコンポーネント

材料の選択は、最大の貢献者です。 カスタム PCB のコスト LED アセンブリで。 素材の選択だけで、コストのベースラインを大きく変えることができます。 標準の FR-4 材料は一般に安価ですが、アルミニウム ベースまたは金属コア ボードは、熱性能の要件が高まり、より複雑な処理によりコストが高くなります。

LED アセンブリは、電気負荷が短いのではなく、持続熱を管理するように設計された材料に依存することがよくあります。 この要件により、材料費が高くなり、製造公差が厳しくなります。 さらに、表面仕上げ、銅の厚さ、および熱界面に関する考慮事項は、価格設定にさらに影響します。

コンポーネントの調達も重要な役割を果たします。 LED、ドライバー、サポート コンポーネントは、可用性、ビニング要件、および電気的一貫性が大きく異なります。 コンポーネントが特定のサプライヤに厳密に指定されているか、特定のサプライヤーに限定されている場合、調達の柔軟性は低下します。 これにより、カスタム PCB 生産における調達作業、在庫リスク、および全体的なコストが増加します。

LED プロジェクトでは、材料とコンポーネントがパフォーマンスを定義するだけではありません。 それらは製造可能性を定義します。

2. 設計の複雑さとボード構造

設計の複雑さによって、製造および組み立て時に必要な処理量が決まります。 より大きなボードは、より多くの原材料を消費し、より長い取り扱いに必要です。 より高い層の数は、追加の積層、穴あけ、整列、および検査の手順を導入します。

密集した LED の密なレイアウトでは、配置速度が遅くなり、アライメント エラーに対する感度が向上します。 熱ルーティング、電流のバランス調整、および機械的制約により、さらに複雑になります。 材料を変更しなくても、これらの要因により、マシンタイム、エンジニアリングの監視、および再作業のリスクが増加するため、PCB のカスタム コストが増加します。

LED PCB アセンブリでは、外観によって複雑さは測定されません。 これは、製造時にどの程度厳密に性能公差を制御する必要があるかによって測定されます。

3. 生産量と注文規模

生産量は、単独のコスト効率に直接影響します。 少数のボードに分散するため、セットアップ、プログラミング、ステンシルの準備、および検証作業が非常に少ないため、小規模なバッチとプロトタイプ ビルドはユニットあたりのコストが高くなります。

これらの固定された取り組みは、量に応じて縮小されません。 その結果、初期のプロトタイプは、不釣り合いなほど高価に見えることがよくあります。 これは非効率性ではなく、制御された製造の現実です。

ボリュームが増加すると、プロセスが安定し、効率が向上します。 実行を大きくすると、ワークフローの最適化、予測可能な収量、および処理のばらつきを軽減できます。 これが、設計が検証段階を超えて移動すると、カスタム PCB 生産の価格設定が大幅に改善される理由です。

プロトタイプの価格設定は、生産レベルの予想コストのベンチマークとして使用されるべきではありません。

4. リードタイムとスケジューリングの優先順位

製造能力が有限であるため、リードタイムはコストに影響します。 標準のタイムラインにより、LED PCB アセンブリは他のプロジェクトと同時に効率的に流れます。 迅速な注文は、この残高を混乱させます。

圧縮されたスケジュールには、機器、労力、検査リソース、およびロジスティクスの調整の優先順位が必要です。 これにより、材料やデザインが変更されていない場合でも、コストが増加します。

LED プロジェクトでは、リードタイムのプレッシャーが品質リスクを高めることがよくあります。 急いで決定すると、代用や検査範囲の縮小が強制される可能性があり、コストが製造業から現場の故障に移行する可能性があります。 このため、リードタイムが短いほど、カスタム PCB の価格が高くなることがほとんどの場合に関連します。

ここでのコストへの影響は、速度だけではなく、スケジューリング圧力によってもたらされます。

5. テストと品質管理の要件

深度のテストは、PCB カスタム コストに直接影響します。特に、一貫性と信頼性が重要な LED アプリケーションでは特に影響を受けます。 基本的な検査ではアセンブリの精度が検証され、より深いテストでは電気的挙動、熱安定性、および長期的な性能指標が評価されます。

LED PCB は、軽微な欠陥が明るさの均一性、色の一貫性、または寿命に影響を与える可能性があるため、より厳格な品質管理を必要とすることがよくあります。 追加の検査手順により、取り扱い時間と文書化の労力が増加し、コストが増加します。

ただし、このコストは、過剰なプロセスではなく、リスクの軽減を表しています。 LED システムでは、品質管理は、早期の劣化と保証の露出に対する財務の保護となります。

コスト ドライバーと LED PCB アセンブリへの実際の影響

| コストファクター | コストの原因は何か | 価格への実際的な影響 |

| 材料とコンポーネント | 基板の選択と部品の入手可能性 | ベースラインのコスト レベルを設定します |

| デザインの複雑さ | ボードのサイズ、レイヤー、レイアウトの密度 | 処理と検査の労力を増やす |

| 生産量 | 注文サイズと設定配布 | 低容量でのより高い単価 |

| リードタイム | スケジューリング圧力と優先処理 | 厳しいタイムラインでコストを引き上げる |

| テストと品質管理 | 検査の深さと信頼性の要件 | コストを追加して、パフォーマンス リスクを軽減します |

これらのコスト要因が実際のプロジェクトでどのように相互作用するか

これらの価格設定要因は、独立して機能しません。 複雑な設計により、マテリアル ハンドリングの労力が増幅されます。 リードタイムが厳しいため、検査要件のコストへの影響が大きくなります。 少量と高度な基板を組み合わせると、ユニットあたりの価格設定が不均衡になります。

調達チームにとって、これはコストの最適化をシステムとして評価する必要があることを意味します。 ある分野のコストを削減すると、他の場所での圧力が高まることがよくあります。 これらのやり取りを理解することで、より現実的な期待と、エンジニアリングと購入の決定の間のより良い調整が実現します。

LED PCB アセンブリのコストに関するよくある誤解

コストが高くても、不必要な複雑さを示すものではありません。 多くの場合、長期的なパフォーマンスを保護する材料または検査要件を反映しています。

最低の見積もりは、常に最低の総費用を表すとは限りません。 テストの削減やスケジュールの縮小により、費用は、それを排除するのではなく、将来の失敗に移行することがよくあります。

プロトタイプの価格設定を生産価格と直接比較してはなりません。 初期のビルドでは、大規模に消えるセットアップと検証の費用がかかります。

コスト削減は、サプライヤーの変更によるものではありません。 多くの場合、設計、ボリューム、リードタイムの決定をより効果的に調整することが原因です。

より多くの支払いでプロジェクトの総費用が削減される場合

LED PCB アセンブリでは、前払いコストが高くなれば、再作業率を下げ、製品の寿命を延ばし、メンテナンスや保証の露出を減らすことで、プロジェクト全体の費用を削減できます。 材料、テスト、または現実的なリードタイムにより多くの費用をかけると、多くの場合、管理がはるかに困難なダウンストリーム コストが回避されます。

この観点は、現場の故障が運用上および評判上のリスクを伴う長寿命照明アプリケーションにとって特に重要です。

結論

LED PCB アセンブリのコストは、材料とコンポーネント、設計の複雑さ、生産量、リード タイム、およびテストと品質管理という 5 つの主要な価格設定要因によって形作られます。 それぞれの要因は、任意の価格設定行動ではなく、実際の製造作業を反映しています。

これらの要因を理解することで、エンジニアや調達チームはトレードオフを明確に評価し、プロジェクトを現実的に計画し、目に見える最小の数を追跡するのではなく、透明性をもってカスタム PCB コストを管理できます。

よくある質問

LED ボードには、長時間の動作サイクルと熱感受性により、特殊な材料、より厳密な熱制御、より厳密な検査が必要です。

プロトタイプ ビルドには、セットアップ、プログラミング、および検証作業が含まれ、ごくわずかなユニットにまたがります。

リードタイムが短くなると、スケジューリングの圧力が高まり、生産の柔軟性が低下し、コストが増加します。

はい、ただし、パフォーマンスと信頼性のリスクが軽減され、多くの場合、総ライフサイクル コストが低下します。

はい。 レイアウト、レイヤーの縮小、またはボード サイズの調整を簡素化すると、処理の労力とコストが削減されます。