園芸照明用の LED PCB 設計は、制御された成長環境で確実に動作する安定した長時間の照明システムの作成に重点を置いています。 一般的な照明とは異なり、園芸システムは連続光周期をサポートし、密閉された治具内で持続熱を管理し、成長サイクル全体にわたって一貫した電気性能を提供する必要があります。 LED PCB の設計方法は、実際の栽培環境での光の信頼性、均一な植物露出、長期的なシステムの安定性に直接影響します。

園芸照明における LED PCB デザインの意味

園芸照明における LED PCB 設計とは、LED が人間に焦点を当てた照明ではなく、植物成長アプリケーションで動作するように電気的および物理的にサポートされていることを指します。 設計は、LED をボードに取り付けるだけではありません。 これは、取締役会が長時間の稼働時間、環境ストレス、成長サイクル全体で一貫した生産を処理できるようにすることです。

園芸環境では、照明システムは、温度制御、湿度管理、自動化されたスケジュールを含む閉ループ設定の一部であることがよくあります。 PCB は、照明システム全体が時間の経過とともにどのように確実に機能するかに影響を与える基本的なコンポーネントになります。

園芸用の LED PCB 設計を定義する主なコンテキスト要因には、次のものがあります。

- 連続点灯サイクルは、1 日あたり何時間も途切れることなく実行されることが多い

- 制御された成長室、温室、または密閉された備品内での操作

- 使用が断続的でユーザーの快適さに重点を置いた一般的な室内照明との機能の違い

- 短時間の毎日の使用ではなく、数週間または数か月にわたる一貫性の要件

この範囲は、園芸に焦点を当てた PCB LED 設計と標準照明アプリケーションを区別するものです。

なぜ PCB 設計が園芸照明システムにとって重要なのか

植物は安定した予測可能な光への露出に依存するため、PCB の設計は園芸照明において重要です。 出力、熱処理、または電気的挙動の変動は、成長の均一性とシステムの稼働時間に影響を与える可能性があります。 PCB は、その安定性を維持する上で中心的な役割を果たします。

成長ライトは通常、生育期全体にわたって毎日繰り返される長い光周期で操作されます。 この持続的な使用は、装飾的または建築的照明とは異なる要求を PCB に課します。 ボードは、一定の負荷下で劣化、ドリフト、または故障のない信頼性の高い操作をサポートする必要があります。

園芸照明システムで PCB 設計が重要な理由は次のとおりです。

- 電気的および熱的経路にストレスを与える長い光周期操作

- 長時間のランタイムでの性能変動を避けるための熱安定性の必要性

- 設備全体で均一なプラント照明をサポートする電気的一貫性

- 複数の季節に渡る信頼性により、メンテナンスとシステムの中断を軽減

実際には、よく考えられている LED PCB デザイン 栽培環境でのキャノピーの不均一な照明や予期しないダウンタイムのリスクを軽減します。

園芸における LED PCB の設計上の考慮事項

このセクションでは、実際の園芸照明システムのパフォーマンスに直接影響を与える主要な設計要因について説明します。 これらの考慮事項は理論的ではありません。 PCB が成長室、温室、および制御された農業施設でどのように振る舞うかを反映しています。

成長環境における熱設計

熱管理は、園芸照明の LED PCB 設計の最も重要な側面の 1 つです。 成長ライトは、熱放散が制限されている密閉されたハウジング内で動作することがよくあります。 時間が経つと、管理されていない熱の蓄積が LED の性能とボードの信頼性に影響を与える可能性があります。

園芸環境では、熱の振る舞いは、ピークの明るさだけではなく、連続運転と環境条件によって形作られます。

主な熱的考慮事項には次のものがあります。

- 短いバーストではなく、長時間の稼働による熱の蓄積

- 限られた空気の流れが、固定具または密閉された環境で成長します

- PCB 温度と全体のフィクスチャ寿命との相互作用

- 電気的安定性と光の一貫性に影響を与える長期の熱応力

効果的な熱設計は安定した出力をサポートし、成長サイクル中に徐々にパフォーマンスが低下する可能性を減らします。

長時間の操作での PCB レイアウトの安定性

レイアウトの安定性は、電気経路がどのように配置され、長期間にわたって一貫した電流を供給するかに焦点を当てています。 園芸照明では、わずかな不安定性でも、植物の天蓋全体で目に見える違いにつながる可能性があります。

ちらつきが見られない一般照明とは異なり、植物の照明には、時間の経過とともに均一な露出が必要です。 PCB レイアウトは、LED 間で電流が均等にどの程度分散しているかに直接影響します。

レイアウトの安定性の重要な要素には、次のものが

- 長時間の操作中の一定の電流の流れを維持する

- 連続負荷時のちらつきや不均一な出力のリスクを軽減

- 照明モジュール全体で均一な光の配信をサポート

安定したレイアウトは、すべての植物が生育地域全体で同等の光条件を確実に受けることができるようにするのに役立ちます。

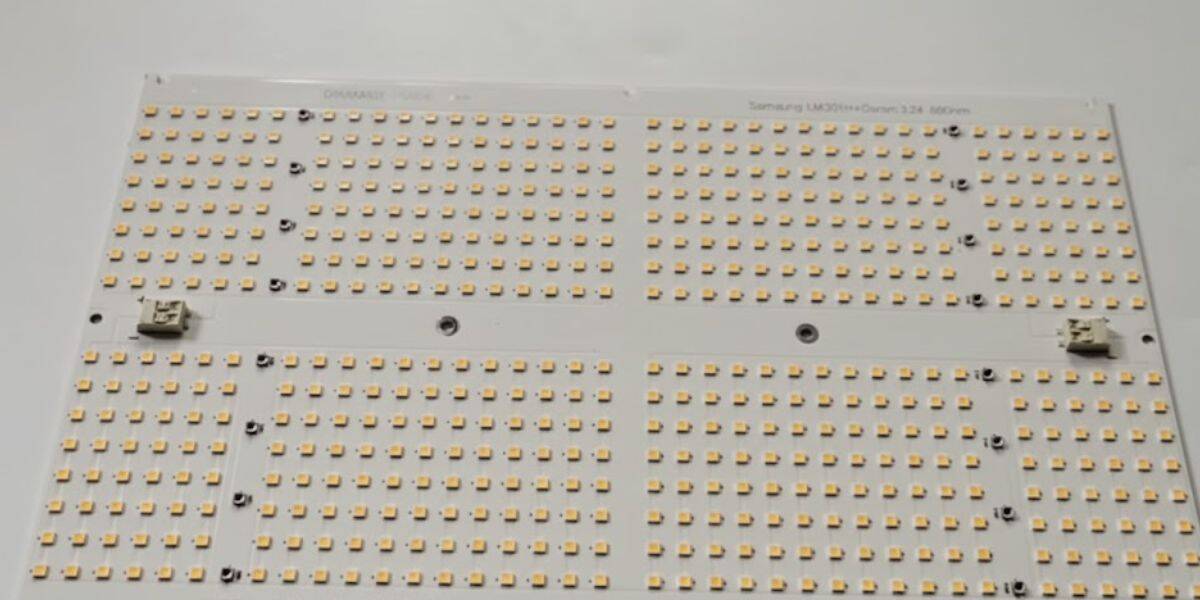

スペクトル最適化 (プラントの成長要件)

園芸照明では、LED PCB デザインは、人間の視覚的な快適さではなく、植物の光合成に合わせたスペクトル出力をサポートする必要があります。 波長が異なると、プラントの開発段階に影響を与えるため、スペクトル計画は照明設定ではなく、機能設計の考慮事項になります。

LED PCB 設計に影響を与える主なスペクトル要因には、次のものがあります。

- クロロフィル吸収ピーク

植物のクロロフィルは、主に青 (~430 ~ 450 nm) と深赤 (約 660 nm) の範囲で光を吸収します。 LED PCB レイアウトは、これらの波長に合わせた LED の安定した動作をサポートし、スペクトル ドリフトのない長い光周期全体で一貫した出力を保証する必要があります。 - 実用的な成長環境のためのフルスペクトラム バランス

多くの園芸システムは、赤と青の LED と緑または白のチャネルを組み合わせて、植物のバランスの取れた成長をサポートし、生産者による目視検査を可能にします。 PCB 設計は、電気的不均衡やチャネル間での老化のない混合 LED 集団に対応する必要があります。 - LED ビニングとスペクトルの一貫性

スペクトルの均一性は、制御された LED ビニングと前方電圧のマッチングに依存します。 一定の電流分布をサポートする PCB レイアウトは、パネル全体で均一な光出力を維持し、延長された動作サイクル中の長期スペクトル変動を低減します。

PCB 設計の決定にスペクトル要件を統合することにより、園芸照明システムは、より予測可能な植物応答と、完全な成長サイクルでの安定した性能を実現します。

状況における材料と構造に関する考慮事項

園芸 LED PCB の材料的および構造的な選択は、マーケティングの違いではなく、運用上の状況によって左右されます。 目標は、一定の使用、熱暴露、および環境ストレス下での信頼性をサポートすることです。

構造設計は、基板が固定具、取り付け面、および冷却要素とどのように相互作用するかに影響します。 材料の選択は重要ですが、それは常に単独ではなく、実際の動作環境内で考慮する必要があります。

システム レベルでは、構造的整合性が維持されます。

- 繰り返し熱サイクルでの機械的安定性

- 安定した位置決めをサポートする安全な取り付け

- 変形や応力関連の故障のない長期耐久性

これらの要因は、栽培期間全体にわたって、信頼できる照明性能をまとめてサポートします。

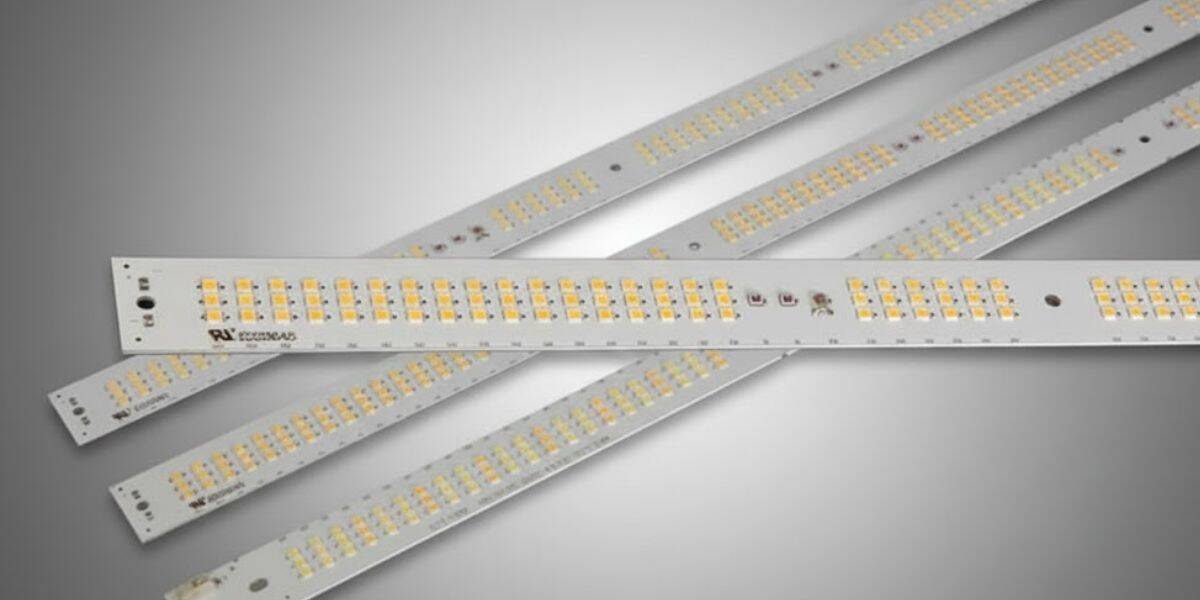

園芸照明における LED リニア PCB ボードの役割

リニア PCB フォーマットは、植物の配置方法や、成長する地域全体での光の供給方法によく一致するため、園芸照明で広く使用されています。 リニア LED PCB ボードは、プラント キャノピー全体での均一な配分をサポートし、行やラック全体で照明システムを簡単にスケーリングできます。

成長部屋と垂直農業のセットアップでは、リニア ボードを使用すると、設計者は栽培エリア全体で光源を均等に配置できます。 これにより、ポイントベースの照明フォーマットで発生する可能性のあるホットスポットとシャドウイングが減少します。

園芸におけるリニア PCB 設計の主な利点は次のとおりです。

- 植物のキャノピー レイアウトに合わせた幅広い範囲

- 成長室の拡張または再構成のためのモジュラー スケーラビリティ

- フィクスチャとゾーン全体で一貫した配光

均一なカバレッジをサポートすることで、線形設計は、成長するスペース全体で一貫した植物の露出を維持するのに役立ちます。

園芸 LED PCB プロジェクトでよくある設計ミス

園芸 LED PCB プロジェクトの間違いは、成長に特化した要求を考慮せずに、デザインが一般照明から直接適応される場合によく発生します。 これらの問題はすぐには見えないかもしれませんが、時間の経過とともにパフォーマンスに影響を与える可能性があります。

多くの場合、問題は、熱、持続時間、および環境要因が混在している場合にのみ、長時間の操作の後にのみ発生します。

よくある間違いは次のとおりです。

- グロー ライトを標準の室内照明のように扱い、日常の使用を制限します。

- 密閉された器具と高密度の設置による熱的影響を無視する

- 長さと安定性を見落としながら、主に明るさを重視する設計

これらの落とし穴を回避するには、実際の環境で園芸照明がどのように機能するかを明確に理解する必要があります。

LED PCB デザインがどのように現代の園芸操作をサポートするか

現代の園芸は、自動化されたシステム、スケジュールされた照明サイクル、およびスケーラブルなインフラストラクチャにますます依存しています。 LED PCB Design は、予測可能な照明動作の安定した基盤を提供することで、これらの操作をサポートします。

適切に設計された PCB は、タイマー、制御システム、自動化された成長セットアップとスムーズに統合されます。 照明が灌漑、気候制御、成長計画と同期している場合、信頼性は特に重要になります。

システム レベルでは、効果的な LED PCB ライト設計により、次のことが可能になります。

- 自動照明スケジュールとの信頼性の高い統合

- 制御された成長システムでの予期しないダウンタイムのリスクの軽減

- 運用の進化に合わせて、照明レイアウトをアップグレードまたは再構成する柔軟性

このコンテキストでは、PCB LED ソリューションはスタンドアロン コンポーネントではありません。 それらは、一貫性と信頼性が重要な、より広範な運用エコシステムの一部です。

園芸照明における設計要因と実用的な影響

| デザイン面 | 実用的な影響 |

| 熱安定性 | 長サイクルでの一貫した植物の露出をサポート |

| レイアウトの均一性 | 成長地域全体で天蓋照明も促進します |

| 構造的信頼性 | メンテナンスの必要性とダウンタイムを削減 |

この表は、コア デザインの選択が実際の園芸の結果にどのように直接影響するかを示しています。

結論

園芸照明の LED PCB 設計は、電気、熱、および構造の動作を植物の成長環境の現実に合わせることによって機能します。 一般照明とは異なり、園芸システムは、長期間安定性、一貫した出力、および成長サイクル全体にわたる信頼できる動作を要求します。 設計上の決定が短期的なパフォーマンスよりも信頼性に重点を置いている場合、その結果、均一な植物の開発と予測可能な栽培の結果をサポートする照明が実現します。

よくある質問

成長ライトは長期間動作するため、PCB 設計は信頼性、熱管理、プラントへの一貫した光の供給に直接影響します。

標準の PCB は機能しますが、長時間の光周期、密閉環境、または持続熱負荷には最適化されていない場合があります。

熱安定性は、時間の経過とともに一貫した出力を維持するのに役立ち、植物の成長に影響を与える可能性のある変動を減らします。

リニア デザインは、キャノピーのカバレッジも提供し、成長部屋やラック全体で簡単にスケールできます。

レイアウトが不安定になると、長時間の動作サイクルで、配光が不均一、ちらつき、または徐々にパフォーマンスにドリフトする可能性があります。

はい。 信頼性の高い PCB 動作は、予測可能な照明スケジュールをサポートし、自動化された園芸操作の混乱を減らします。