2026 年、RoHS の準拠は、ポストプロダクション チェックリストではなく、LED PCB の主要な製造要件になりました。 規制の施行はより厳しく、文書化への期待は高く、サプライ チェーンの説明責任は国境を越えて拡大しています。 LED PCB は、材料の複雑さ、熱要求、および長い運用期間により、標準のボードよりも精査が見られます。これにより、コンプライアンスは信頼性、市場アクセス、および製造リスクに直接結びついています。

2026 年の LED PCB 製造における RoHS コンプライアンスの意味

2026 年の RoHS 準拠は、最終製品に制限物質が存在しないことを確認することに限定されません。 カスタム PCB の製造に携わる製造業者の場合、原材料の調達から最終的な組み立て記録まで、生産ワークフロー全体に適用されるようになりました。

実用的なレベルでは、RoHS は、材料の選択方法、プロセスの管理方法、コンプライアンスの証拠の維持方法を管理します。 LED PCB の場合、LED は電気、熱、および光の機能を 1 つのボードに組み合わせるため、この範囲は広がります。

LED PCB が標準のボードよりも影響を受けやすい理由

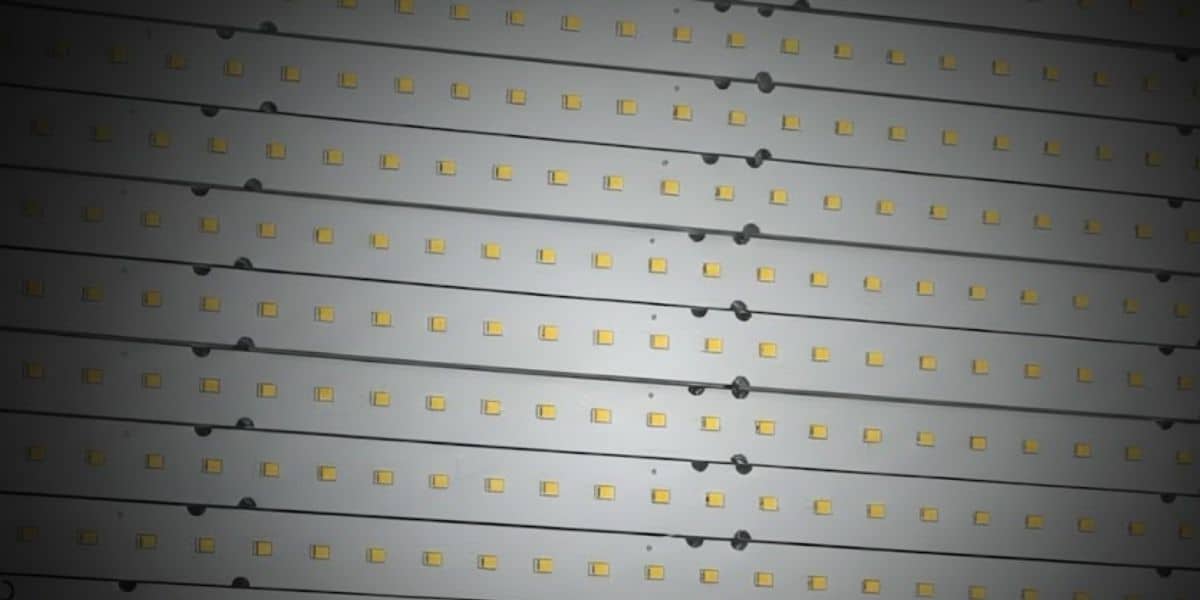

LED PCB は、従来の多くの電子機器よりも熱応力が高く、デューティ サイクルが長くなります。 これにより、RoHS の制限によって課せられる材料の変化に対する感度が高まります。 はんだ合金、表面仕上げ、または誘電体材料のわずかな偏差が、熱放散や LED の寿命に影響を与える可能性があります。

主な理由 LED PCB がより大きな影響を与えるには、次のものがあります。

- 材料の弱点を増幅する接合温度が高くなるため

- はんだ接合部に応力がかかる高密度コンポーネント レイアウト

- 小さな欠陥が時間の経過とともに蓄積する長い耐用年数の期待

このため、LED アプリケーションでの RoHS 準拠障害は、直接的な機能障害ではなく、信頼性の問題として表面化する傾向があります。

制限物質と LED 感度

RoHS は、鉛、水銀、カドミウム、六価クロム、および特定の臭素系難燃剤などの物質を制限します。 これらの物質は、歴史的にはんだ付け性、耐久性、または耐火性を向上させるために使用されていましたが、それらの除去によって製造の挙動が変わります。

LED アセンブリは、次の理由で特に敏感です。

- 鉛フリーはんだは、より高い融点を持ち、熱暴露を増やします

- 代替の難燃剤は、熱伝導率を変えることができます

- 材料の置換は、光学的安定性または色の一貫性に影響を与える可能性があります

コンポーネントのコンプライアンスとプロセスのコンプライアンス

PCB ボードのカスタム プロダクションでよくある誤解は、準拠コンポーネントが自動的に準拠製品になると仮定することです。 2026 年には、この仮定がリスクを生み出します。

- コンポーネントのコンプライアン 各部品が物質制限を満たしていることを意味します。

- プロセスのコンプライアン 製造工程が制限物質を再導入したり、材料の完全性を損なうことはないことを意味します。

どちらも必須です。 準拠した LED パッケージは、はんだ材料、フラックス残留物、または再加工プロセスが制御されていない場合でも、RoHS の期待に失敗する可能性があります。

2026 年の LED PCB 製造に影響を与える主要な規制の更新

2026 年の規制の施行は、宣言よりも検証を重視しています。 当局は、製造業者がコンプライアンスを達成し維持する方法を示すことをますます期待しています。

EU RoHS の執行強化

EU 市場の監視は、技術文書のより深い監査に移行しています。 LED 製品を輸出するメーカーは、次のことを確認する準備をしておく必要があります。

- 明確な材料のトレーサビリティ

- 特定のバッチにリンクされたサプライヤ宣言

- 汚染を防ぐプロセス制御

ランダム サンプリングと市販後のチェックは、特に公共のインフラや商業環境で使用される照明製品でより一般的になっています。

サプライチェーンの説明責任

コンプライアンスに対する責任は、コンポーネントの調達にとどまりません。 カスタム PCB 製造に携わる製造業者は、上流の材料の起源と下流のアセンブリのリスクを理解することが期待されています。

これには以下が含まれます。

- ラミネート、はんだマスク、表面仕上げのサプライヤーの確認

- コンポーネントの配合の変化を追跡する

- 下請けプロセス全体でのコンプライアンスの管理

サプライ チェーンのどこにでもある弱点が原因で、市場へのアクセスが損なわれる可能性があります

ドキュメントとトレーサビリティの期待

2026 年には、コンプライアンス ドキュメントが構造化され、検索可能であり、最新のものになることが期待されています。 頻繁に更新される静的宣言は不十分であると見なされます。

トレーサビリティへの期待は次のとおりです。

- ロットレベルの BOM レコード

- 材料とサプライヤーの変更ログ

- 生産記録とコンプライアンス ファイルの整合

準拠していないメーカーの市場アクセスのリスク

これらの期待に応えられないと、出荷保留、強制リコール、または規制された市場からの除外につながる可能性があります。 LED PCB の場合、照明製品は安全性と環境に配慮した精査が必要になることが多いため、このリスクが増幅されます。

RoHS 準拠の LED PCB の製造要件

LED PCB 製造における RoHS 要件を満たすには、ドキュメントだけでなく、生産レベルでの変更が必要です。

材料選択制約

RoHS 制限により、ラミネート、はんだマスク、および熱界面材料の材料の選択肢が減ります。 製造業者は、特に高出力 LED 設計において、コンプライアンスとパフォーマンスのバランスを取る必要があります。

一般的な考慮事項は次のとおりです。

- 難燃剤を含むラミネートの選択

- はんだマスクがより高い鉛フリーリフロー温度に耐えられるようにする

- サーマル パッドと接着剤が物質の制限を満たしていることを確認する

材料の代替には、プロセスの再認定が必要になることがよくあります。

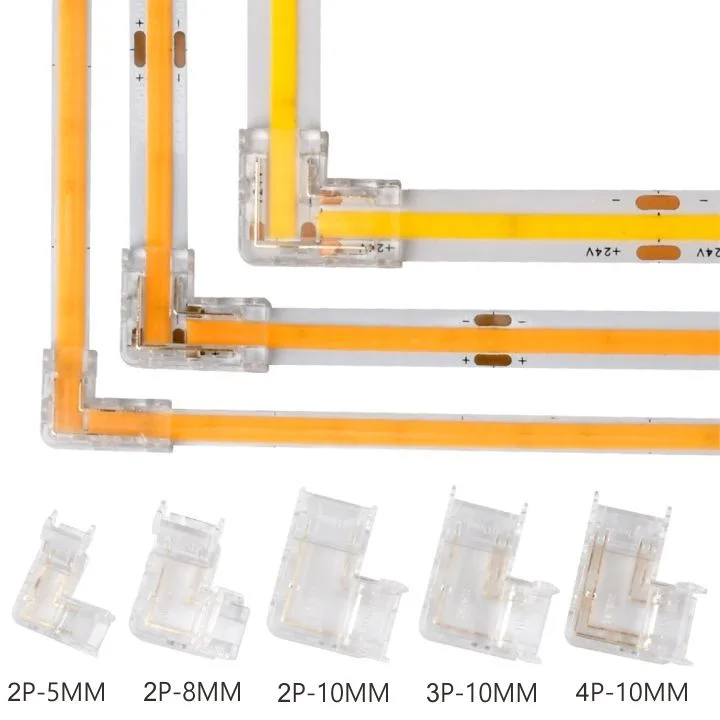

はんだ付けと表面仕上げの影響

鉛のないはんだ付けは、アセンブリの信頼性と熱暴露の両方に影響を与えます。 リフロー温度が高くなると、LED や PCB 材料にストレスがかかる可能性があります。

ENIG、浸漬シルバー、OSP などの表面仕上げの選択肢は、次の条件で評価する必要があります。

- LED パッケージとの互換性

- サーマル サイクルでの長期安定性

- 準拠のはんだ合金との相互作用

これらの決定は、収量と現場の信頼性に直接影響します。

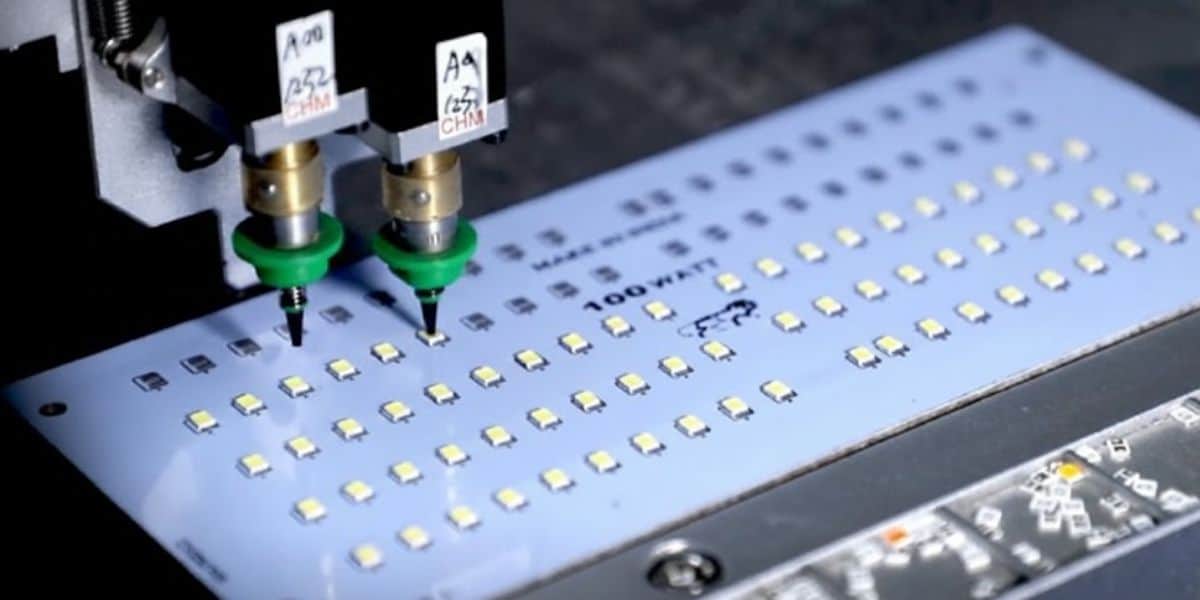

プロセス制御の期待

プロセスのばらつきにより、コンプライアンス リスクが高まります 2026 年には、製造業者は次の点について一貫して制御を行うことが期待されています。

- リフロー プロファイル

- クリーニングプロセス

- やり直しと修理方法

制御されていない再作業は、汚染や不遵守の原因となることがよくあります。

サプライヤーの資格の重要

サプライヤーの資格は、価格と容量を超えています。 製造業者は、サプライヤーが安定した準拠の処方を維持し、変更を通知することを確認する必要があります。

これは、特定の熱または機械的要件に合わせて材料を調整できるカスタム PCB ボード プロジェクトでは特に重要です。

LED PCB 特有の材料とプロセスの課題

LED PCB は、標準的な電子機器では通常見られない課題を組み合わせ、RoHS のコンプライアンスをより複雑にします。

熱材料と RoHS の制限

高出力 LED は、効率的な熱伝達に依存しています。 歴史的に有効な熱材料の中には、制限物質が含まれていました。 準拠した代替品は、異なる機械的または老化特性を有する場合があります。

メーカーは次のことを検証する必要があり

- 長期の熱安定性

- 熱サイクル下での接着

- はんだ接合部との相互作用

表面仕上げとコンプライアンスバランス

一部の仕上げは電気的には良好に機能しますが、適切に制御されていないと、腐食や移動のリスクが生じる可能性があります。 LED アプリケーションでは、これらのリスクは、ルーメンの段階的な減価償却または色の変化として現れる可能性があります。

コンプライアンスとパフォーマンスのバランスを取るためには、デフォルトの材料選択ではなく、慎重なプロセスの調整が必要です。

コンプライアンスが誤った場合の LED 信頼性のリスク

コンプライアンスの不適切な処理は、次の原因になる可能性があります。

- 初期のはんだ接合部疲労

- 熱応力による剥離

- 材料相互作用による光学的劣化

これらの障害は、多くの場合、展開後数か月または数年後に発生し、保証と評判上のリスクが高まります。

ショートカットが長期的な失敗を引き起こす理由

文書化されていない材料の置換や不完全なクリーニングなどのショートカットが、すぐに欠陥を引き起こすことはありません。 ただし、連続熱負荷の下では、小さな不整合が蓄積します。

何万時間も稼働すると予想される LED システムでは、これらのショートカットが直接寿命を縮めます。

ドキュメント、トレーサビリティ、コンプライアンス検証

2026 年には、文書化は製造プロセス自体の一部として扱われます。

2026 年のドキュメントが重要な理由

文書化は、コンプライアンスが偶発的ではなく体系的であることを示す主要な証拠です。 メーカーにとって、それは外部からの証拠と同じくらい内部統制を提供します。

優れたドキュメントは次のとおりです。

- 失敗の根本原因を特定する

- サプライヤーの変更を管理

- 監査に迅速に対応

BOM トレーサビリティ

各 BOM エントリは、準拠したサプライヤー宣言までトレース可能である必要があります。 これには、取るに足らないように見えるかもしれないが、RoHS の範囲に該当する受動部品、コネクタ、および材料が含まれます。

サプライヤーの宣言

宣言は最新かつ具体的でなければなりません。 材料識別子のない一般的なステートメントは、監査中にますます疑問視されています。

監査準備

監査準備とは、本番環境を中断することなくコンプライアンスを実証できることを意味します。 これには、エンジニアリング、調達、および製造記録を調整する必要があります。

LED PCB 製造における一般的な RoHS コンプライアンスのリスク

一般的なリスクを理解することで、費用のかかる修正を防ぐことができます。

コンプライアンスの部分的な誤解

ある段階でのコンプライアンスがプロセス全体をカバーすると仮定すると、ギャップが生じます。 コンプライアンスは、材料の受領から最終出荷まで継続していなければなりません。

コンポーネントの代替リスク

土壇場での代替は、同等の部品であっても、非準拠の材料やテストされていない相互作用を導入する可能性があります。

不完全なドキュメント

物理的な製品が準拠していても、レコードの欠落または古い記録により、コンプライアンスの主張が弱まります。

製造プロセスのギャップ

制御されていない洗浄剤、リワーク ハンダ、または共有機器は、制限物質を再導入する可能性があります。

コンプライアンスがリードタイム、コスト、計画に与える影響

RoHS コンプライアンスは、製造業の経済に直接影響します。

コンプライアンスがタイムラインに影響を与える理由

追加の検証、サプライヤ チェック、およびドキュメントにより、準備段階が拡張されます。 のため カスタム PCB 製造 プロジェクトでは、これは早期に説明する必要があります。

コストとリスクのトレードオフ

準拠した材料と管理されたプロセスは、単価を上げることができますが、再作業、リコール、および市場アクセスの問題のリスクを軽減します。

2026 年製造業の計画変更

製造業者は、計画モデルを調整して、例外ではなく標準変数としてコンプライアンス リード タイムを含めるようにしています。

2026 年のコンプライアンス標準に向けて LED PCB 製造を準備する

準備とは、レジリエンスを構築することであり、監査に反応することではありません。

プロセスの準備

プロセスは、事後にそれを検出するのではなく、コンプライアンス違反を防ぐように設計する必要があります。

コンプライアンスに合わせたデザインの考え方

エンジニアは、設計中のコンプライアンスの制約をますます考慮し、ダウンストリームの調整を減らしています。

サプライヤーの調整

緊密な調整により、変更が早期に伝達され、適切に検証されるようになります。

長期の製造安定性

安定した準拠のプロセスは、一貫した品質と予測可能な配信をサポートします。これらは、長期的なサービスを期待する LED アプリケーションで重要です。

LED PCB 製造に対する RoHS コンプライアンスへの影響

| コンプライアンス分野 | 製造への影響 | 無視するとリスクがあります |

| 素材の選択 | ラミネート、はんだ、仕上げオプションを制限します | 熱障害、監査拒否 |

| はんだ付けプロセス | リフロー温度が高く、より厳密な制御 | 関節の疲労、LED の損傷 |

| サプライヤーの管理 | 検証済みの宣言と変更の追跡が必要 | 非表示の非準拠 |

| ドキュメン | 継続的な記録保守 | 市場アクセスの制限 |

| プロセスのトレーサビリティ | ロットレベルの追跡と監査 | リコールと責任のエクスポージャー |

結論

LED PCB 製造における RoHS 準拠は、書類作成の練習ではなく、規律ある生産アプローチです。 2026 年、コンプライアンスは材料の選択、プロセス制御、ドキュメンテーション、長期的な信頼性に影響を与えます。 コンプライアンスを統合された製造機能として扱うメーカーは、リスクを管理し、市場へのアクセスを維持し、長期にわたるライフサイクルにわたって安定した LED パフォーマンスを提供するのに適しています。

よくある質問

LED PCB は連続熱応力下で動作するため、コンプライアンス エラーが小さいと、長期的な信頼性の障害が発生する可能性があります。

間接的に、そうです。 コンプライアンスに必要な材料とプロセスの変更は、熱管理とはんだ接合の信頼性に影響を与える可能性があります。

部分的なコンプライアンスだけでは十分ではありません。 コンポーネントと製造プロセスの両方が、RoHS 要件を満たす必要があります。

コンプライアンスは、検証と文書化の手順を追加します。これらは、生産スケジュールに計画する必要があります。

製造業者は、規制された市場への出荷の遅延、リコール、またはアクセスの喪失に直面する可能性があります。