LED トリプルーフ ライト (防水 LED 器具、防湿照明、防塵 LED ライト、またはバテン ライトとも呼ばれます) は、工場、倉庫、駐車場、地下鉄の駅などの厳しい環境で広く使用されています。 「Tri-Proof」という名前は、水、ほこり、腐食からの保護を指し、産業用および商業用照明に信頼できる選択肢となります。 ただし、最も耐久性のあるフィクスチャでさえ、正しくインストールされていないと失敗する可能性があります。 取り付けが不適切、配線が緩い、または防水シールが不十分であると、安全上の危険、光の効率の低下、およびコストのかかるメンテナンスにつながる可能性があります。 そのため、クリア LED トリプルーフ ライトの取り付けガイドに従うことが重要です。 この記事では、段階的なインストール手順とトラブルシューティングのヒントを説明し、安全で長持ちするエネルギー効率の高い照明システムを実現するのに役立ちます。

インストール前の準備

1. 環境チェック

をインストールする前に LED 三耐性ライト、注意深く環境を検査します。 表面が安定していて、乾燥しており、余分なほこりや油がないようにしてください。 湿度と温度レベルをチェックして、それらが器具の仕様を満たしていることを確認してください。これにより、防水および防塵性能を維持できます。

2. 材料とツールの準備

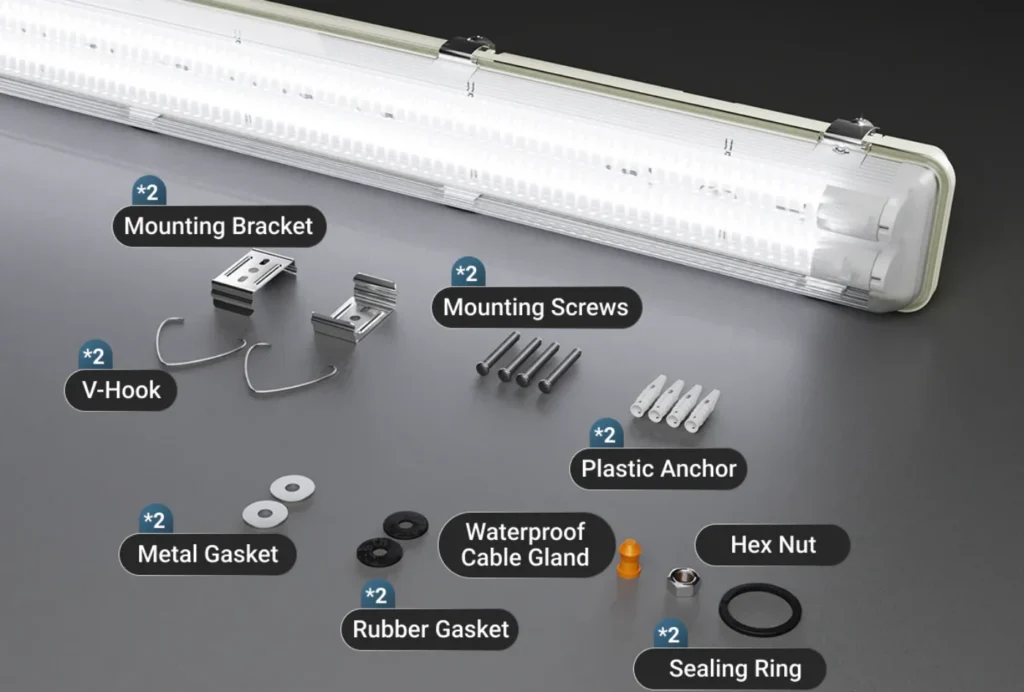

開始する前に、必要なすべてのアイテムを収集します。 これには、LED トライプルーフ ライトフィクスチャ、取り付けブラケット、ネジ、防水コネクタ、エンド キャップが含まれます。 基本的なツールには、ドリル、ドライバー、ペンチ、および絶縁テープが含まれていることがよくあります。 すべての準備が整うと、スムーズで効率的なインストール プロセスが保証されます。

3.安全上の注意

配線の前に必ず主電源を遮断してください。 事故を防ぐために、断熱工具を使用し、保護手袋を着用してください。 すべての電気接続が現地の規格に準拠していることを再確認してください。 準備段階で安全性を優先することで、信頼性が高く長持ちする LED トリプルーフ ライトの取り付けが保証されます。

段階的な取り付け方法

表面実装インストール

- LED トライプルーフ ライトの長さを測定し、天井または壁のドリル位置をマークします。

- マークされた点に穴を開け、深さが拡張プラグと一致するようにします。

- ドリルで穴に拡張プラグを挿入します。

- 金属製の取り付けブラケットをネジで固定し、しっかりと締めて動きを避けます。

- 取り付けられたブラケットに照明器具を合わせます。

- 固定具をしっかりとカチッと音がするまでブラケットにそっと押し込みます。

- 配線図に従って防水電源ケーブルを接続します。

- 次のステップに進む前に、安定性と整列を再確認してください。

中断されたインストール

- 天井に 2 つのサスペンション ポイントを印を付け、治具の長さに合わせます。

- 穴を開けて、マークされた位置に拡張プラグを挿入します。

- サスペンション フックをねじ込むか、スチール ワイヤー アンカーをしっかりと取り付けます。

- 吊り下げチェーンまたはスチール ケーブルの長さを、希望の取り付け高さに調整します。

- サスペンション キットの両端を治具の取り付けクリップに取り付けます。

- 揺れやバランスの不均一を防ぐために、ライトを固定してください。

- 電源を入れる前に、フィクスチャを静かに引っ張って安定性をテストします。

- シールリングが正しく締め付けられていることを確認して、防水配線を慎重に接続してください。

インストールのヒント

設置中は、照明が均一になるように、フィクスチャを水平に保ちます。

ハウジングの損傷を防ぐために、ネジまたはブラケットを締めすぎると締めすぎないようにしてください。

IP66 以上の定格でない限り、しっかりとしたウォーター ジェットの下に器具を直接置かないでください。

防水保護を維持するために、すべてのコネクタとシールが完全にロックされていることを常に確認してください。

| インストールの種類 | 主な手順 | 代表的なアプリケーション |

| 表面実装 | ドリル → ブラケットを修正 → スナップインライト → 配線を接続 | 駐車場、廊下 |

| サスペンド | ドリル → フックを取り付ける → チェーンを調整する → フィクスチャを吊るす → 配線を接続する | 倉庫、工場、ホール |

配線と防水接続

配線方法

LED トライプルーフ ライトを取り付ける場合、プロジェクトの要件に応じて、シングルエンド入力またはダブルエンド入力を介して配線できます。 シングルエンド入力は小規模な設置では一般的ですが、長時間の実行やデイジーチェーン接続には、ダブルエンド入力が適しています。 電源の不一致を避けるために、AC220V、AC277V、または AC347V または AC480V などのより高い産業規格のいずれであっても、フィクスチャの定格電圧を常に確認してください。

防水接続

IP65 または IP66 の保護を維持する上で重要な要素は、コネクターにあります。 高品質の防水ケーブル グランドを使用し、シーリング リングが正しく締め付けられるようにします。 脆弱な領域に絶縁テープまたはシリコン リングを適用すると、二次保護が得られます。 電気の安全性と安定性を確保するためにも、適切な接地が必要です。

一般的な配線に関する懸念

接続が緩んでいることが、ちらつき、短絡、さらには水の侵入などの障害の最も一般的な原因です。 これらの問題を防ぐために、ワイヤーが正しい長さに剥がされ、完全に挿入され、しっかりと固定されていることを常に再確認してください。 この段階で細心の注意を払うことで、信頼性が高く長持ちする LED トリプルーフ ライトの取り付けが保証されます。

チェックとテストとトラブルシューティング

チェック

電源を入れる前に、安全で安全な設置を確認するために、慎重に検査してください。 電線がすべてしっかりと接続されていること、および断熱材が正しく適用されていることを確認して、短絡を防ぎます。 LED トライプルーフ ライトがブラケットまたはサスペンション キットにしっかりと固定されていることを確認し、フィッティングが緩んでいないことを確認します。 吊り下げ設置の場合は、吊り下げの高さが均一な照明を維持するようにすることを確認してください。 最後に、PC ディフューザー カバーが完全にロックされていることを確認して、防水性と防塵性能を保証します。

テスト

検査後、電源を入れてフィクスチャをテストします。 LED トライプルーフ ライトがすぐに点灯し、輝度が一定であることを確認します。 ドライバーからのちらつき、調光、または異常な音がないか注意してください。 この手順により、ライトが日常的に使用される前に、電気的接続と機械的接続が正しく行われるようになります。

トラブルシューティング

テスト中に問題が発生した場合は、次の一般的なケースを考慮してください。

点灯しない → 配線が正しく接続されているか、電源に問題があるかどうかを確認します。

ちらつきの問題 → ドライバーが LED ボードとの接触不良を確認するか、ドライバーの出力電圧が LED モジュールの要件に合っているかどうかを確認します。

内部の結露または湿気 → ディフューザー カバーがしっかりとロックされ、ケーブル エントリーが防水コネクタで完全に密閉されていることを確認します。

適切なチェック、テスト、およびトラブルシューティングにより、LED トリプルーフ ライトの設置の安全性と寿命を最大限に引き上げることができます。

結論

適切な設置、慎重な配線、徹底的なテストが、LED トリプルーフ ライトが要求の厳しい環境で信頼できる性能を発揮するための鍵です。 推奨される手順に従い、必要に応じてトラブルシューティング方法を適用することで、ユーザーは、ちらつき、停電、水の侵入などの一般的な問題を回避できます。 十分にインストールされたシステムは、安全性を高めるだけでなく、長期的なメンテナンス コストを削減します。

SignLiteLed では、当社が製造するすべてのトライプルーフ ライトは、電源障害や防水の問題がないことを確認するための厳格な検査とテストを受けます。 当社の製品は柔軟性を考慮して設計されています。大規模なプロジェクトでのデイジーチェーン接続をサポートし、安全性を高めるために非常用電源ソリューションと組み合わせることもできます。 工場、倉庫、駐車場の耐久性のある備品が必要な場合でも、SignLiteLED は、プロジェクトの要件を満たすプロフェッショナルで信頼性の高い LED トリプルーティング照明を提供します。 プライベート トライプルーフ ライトをお持ちの場合は、カスタマイズすることもできます。 LED リニア モジュール 当社から、大量供給とカスタマイズされたテクニカル サポートについて、今すぐお問い合わせください。