商用照明と家庭のデザインでは、LED リニア ライトは、洗練されたデザインと均一な配光で広く人気があります。 ただし、Unified Glare Rating (UGR) を無視すると、視覚的な疲労や安全上の危険につながる可能性があります。 適切な照明を科学的に選択することで、「光源を見ずに光を見る」という快適な体験を実現できます。

国際基準によれば、さまざまなシナリオで UGR の明確な要件があります。 オフィスや教室では通常 UGR ≤19 が必要ですが、一部のハイエンドの展示ホールや病院では、UGR が 16 未満の UGR の要件が高くなります。 そのため、LED リニア ライトを購入する際に、UGR は無視できない重要な要素となっています。

LED リニア ライトは 19 未満の UGR を達成できますか?

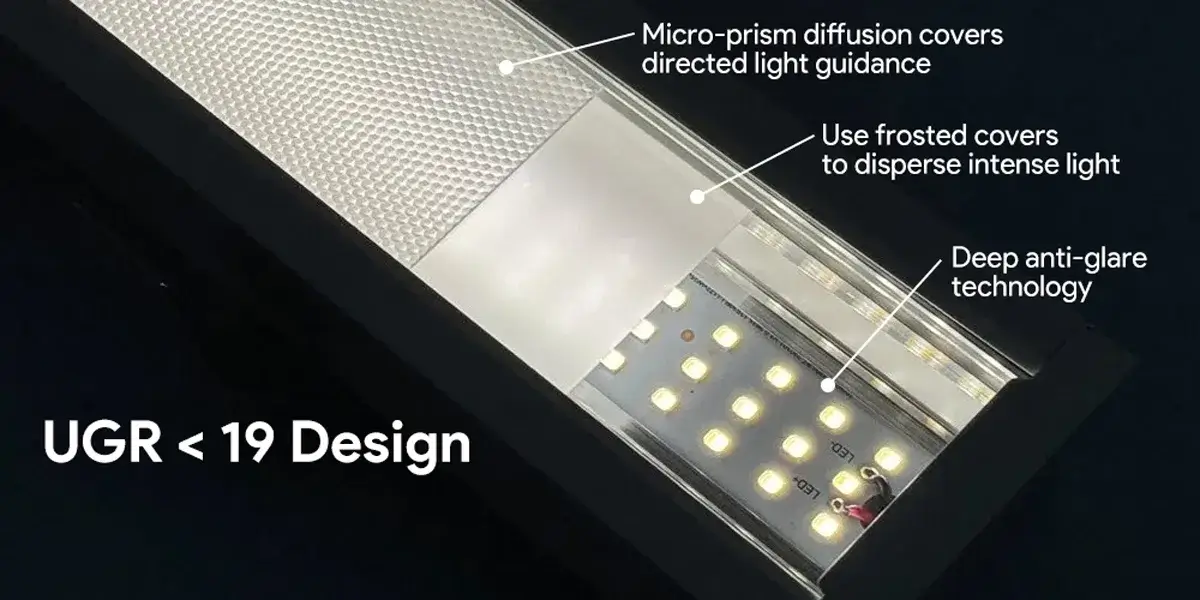

うん、 LED リニアライト 19未満のUGRを達成できます。 ユニファイド グレア レーティング (UGR) は、照明のグレア効果を測定するための重要なパラメーターです。 オフィスなどの健康的な照明環境では、視覚的な快適さを確保するために、19 未満の UGR が必要です。 たとえば、グレアが低いように特別に設計された LED リニア ライトは、建物の照明基準に準拠した微細構造の防眩光学材料により、19 未満の UGR 値を安定させることができます。

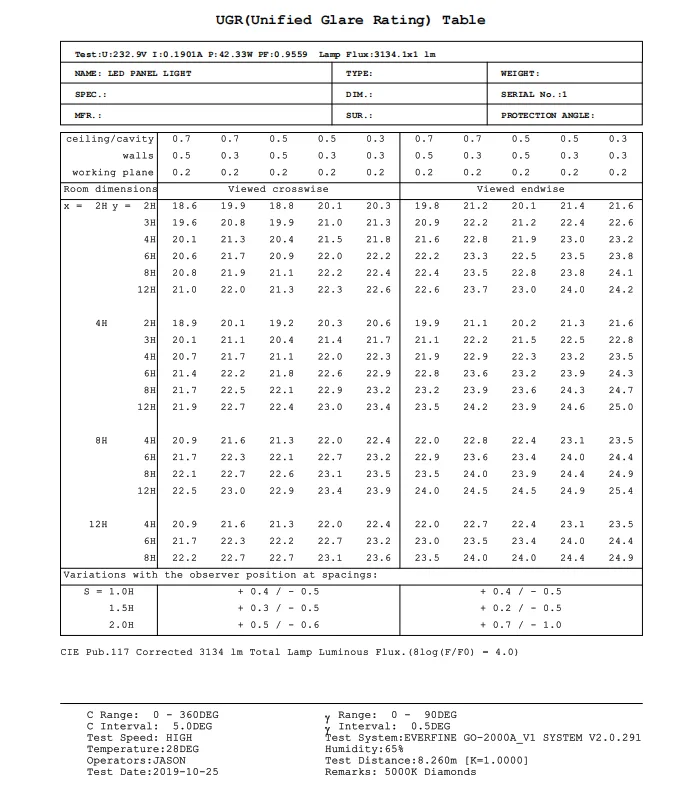

ただし、直接光源として、リニア ライトは、不適切に設計された場合、まぶしいリスクをもたらす可能性があります。 以下の実際の測定データに示されているように、UGR 値は 22 に達することがあり、CIE の推奨上限を超えて、頻繁な瞳孔収縮や頭痛などの不快感を招く可能性があります。 したがって、製品を選択するときは、UGR 要件を満たすと明示的にラベル付けされた製品に優先順位を付けることが推奨されます。

線形ライトのグレア レーティング (UGR) が 19 未満である必要があるのはなぜですか?

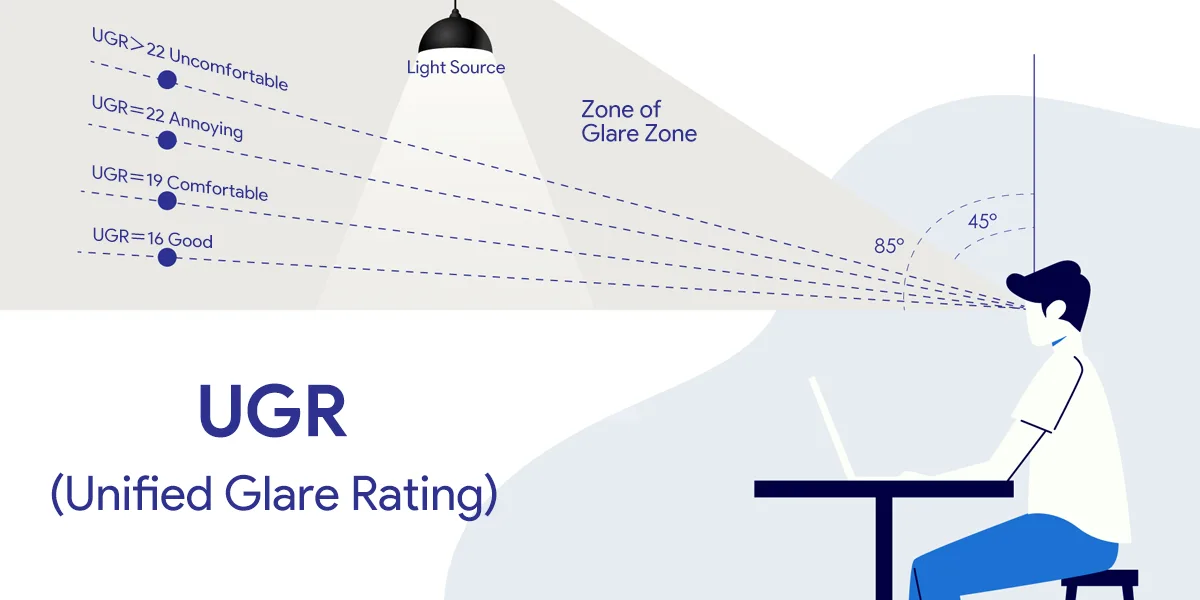

UGR (Uniform Glare Rating) は、室内の線形照明のまぶしさを評価するための国際的に認められた基準です。 UGR 値が低いほど、まぶしさが弱くなり、視覚的な快適さが高くなります。 UGR 値は、光源の明るさ、位置、および周囲の光レベルなど、複数の要因の影響を受けます。

UGR が 19 を超えると、瞳孔が頻繁に適応し、視覚疲労につながります。 長時間の暴露は、網膜の損傷、視力の低下、および白内障のリスクの増加を引き起こす可能性があります。 中国だけでも、601TP3 を超える青少年が近視に苦しんでいる場合、まぶしさの汚染が主な要因の 1 つとして認識されています。

現在の基準では、健康な照明環境での UGR 値が 19 未満であることが求められています。 UGR が 19 未満であるという要件は、主に次の理由に基づいています。

- 視覚的な快適さを確保する: UGR 値が 19 の場合、中程度から重大なまぶしさの間のしきい値を示します。 UGR が 19 以上の場合、まぶしい光の感覚が大幅に増加し、視覚的な疲労や不快感を引き起こす可能性があります。 ただし、UGR が 19 歳未満の場合、グレアは許容範囲内にとどまるため、オフィスや教室などの長期的な集中が必要な環境に適しています。

- 職場の要件への適応: オフィス エリアや、正確な視覚的作業が必要なその他の環境では、UGR ≤ 19 の標準は照度と快適さのバランスを取り、まぶしさが作業効率を妨げないようにします。 たとえば、GB50034-2013 規格では、一般オフィス エリアの UGR の上限が 19 であると明示的に規定されており、自然光環境の快適な体験をシミュレートしています。

- 区別するアプリケーションのシナリオ: UGR 値の段階的な設計では、さまざまな場所の許容レベルを考慮しています。UGR < 19 は、需要の高い環境 (オフィスなど) に適していますが、UGR ≥ 19 は目立つまぶしさを引き起こす 19 は、視覚的な快適さの要件が低い産業施設または店舗にのみ推奨されます。

UGR の値はどのように評価されますか?

UGR 値の快適性評価 (Uniform Glare Rating) は、国際基準によって明確に定義されています。 具体的な快適性のしきい値と適用されるシナリオは次のとおりです。

UGR が 13 歳未満の場合、光は柔らかく、人間の目はほとんどまぶしさを認識できません。 これは、アート ギャラリーや高級住宅など、視覚的に快適な要件が非常に高いスペースに適しています。

UGR が 16 歳未満の場合、それは快適な範囲内に収まり、視覚的な作業を損なわないわずかなまぶしさがあります。 これは、正確な作業が必要な教室、読書室、およびその他の環境に推奨される基準です。 たとえば、教室の眼保護パネル ライトは、青少年の視力を保護するために、UGR ≤ 16 を制御する必要があります。

UGR の価値と人間の認識状態の評価

| UGR 範囲 | 人間の認識 | 該当するシナリオの例 |

| UGR < 13 | 目に見えるようなまぶしさはありません | 病院、高級展示ホール、特別機関 |

| 13 ≤ UGR ≤ 16 | マイルドなまぶしさ | 病院、シニア活動センター |

| 16 ≤ UGR < 19 | 中程度のまぶしさ、許容範囲ですが、疲労の原因となります | 通常のオフィス、会議室 |

| 19 ≤ UGR < 22 22 | 顕著な不快感の閾値 | 工業用工場、倉庫 |

| 22 UGR ≥ 22 | 激しいまぶしさ、頭痛の原因 | 人間の長期占有を避ける |

快適さと不快感の間の心理的限界は UGR = 19 ですが、健康な視覚環境 (学習スペースなど) は、UGR ≤ 16 を目指す必要があります。

アプリケーションシナリオの必須の基準:

- 教育施設: 教室では UGR ≤ 19 が必須です。高品質の照明ソリューションは 16 以下に最適化する必要があります。

- オフィス環境: UGR > 19 は頻繁に瞳孔収縮を引き起こし、視覚疲労につながり、適格スコアは 19 以下です。

- 工業用地: UGR ≤ 22 は許可されていますが、健康リスクを軽減するには、防眩アクセサリーを使用する必要があります。

グレア保護の実践に関する推奨事項

| 対策 | 技術原則 | UGR 削減効果 |

| マイクロプリズム拡散パネル | 高輝度光ビームを分解 | ≤16 に減少します |

| 間接照明設計 | 人間の目の周囲の 30° の干渉ゾーンを回避します | 30% 削減 |

| 低光沢材料 | 環境反射のまぶしさを軽減 | 2 ~ 3 ポイント最適化 |

注: UGR 測定には、魚眼レンズを備えた分散光度計が必要です。誤差が ±10% を超える場合は、キャリブレーションが必要です。

ヨーロッパとアメリカにおける線形照明に関する UGR 要件

ヨーロッパと米国は、LED 線形照明の UGR 要件に対する明確な評価基準を持っています。 具体的な規制と実施のポイントは次のとおりです。

必須の UGR グレーディング基準

EU コア規格: すべての室内リニア照明は、UGR ≤ 19 の最小安全閾値を満たす必要があります。 この値を超えると、CE 認証を取得できません。 特別な場所には、より厳しい要件があります。教育/オフィス エリア: 教室やオープン プランのオフィスなど、UGR が 16 以下である必要があります。アート ギャラリー/医療施設: UGR は 13 以下で、ハニカム アンチグレア構造を使用する必要があります。

北米の特別な要件: UL 1598 規格は、光生物学的危険を制御するために LED 照明器具を明示的に要求しています (波長帯域幅 4400 ~ 780 の帯域を除く)。Energy Star 認証では、商用照明器具は UGR ≤ 22 である必要があり、青色の光レベルを示す必要があります (RG0 免除レベルが優先されます)。

UGR 測定の受け入れ仕様

| 項目 | EU規格 | 北米の補足要件 |

| 観察高さ | 着席1.2m / 1.5m | CIE 117-1995 規格に準拠 |

| 測定機器 | 143° 視野 イメージング輝度計 | UL の測光校正に合格する必要があります |

| 背景の明るさ補正 | フィクスチャからの直接光干渉を排除 | ミラー反射検出アイテムを追加 |

ヨーロッパと北米の UGR 基準の比較

| インジケータ | eu | 北米 |

| 施行力 | UGR > 19 市場の流通禁止 | Energy Star 認定の自発的執行 |

| 技術的な焦点 | グレア制御 (UGR) の中心としての | 太陽光発電安全性 + エネルギー効率のデュアル制御 |

| アップグレード方向 | 2025 年までに UGR ≤ 16 を実装する | ボタン電池アクセサリの安全基準を強化する (UL4200A) |

| コアのしきい値 | UGR ≤ 19 必須のしきい値 (CE 認定の基本要件) | 連邦レベルの必須のしきい値はありません。Energy Star は ≤ 22 を推奨しています |

| 特別なシナリオ要件 | 教育/医療施設 13 ≤ 13 13 13 13 13 13 13 13 13 13 13 13 | 産業用照明が許可されている 25 UGR ≤ 25 (UL 1598 電気安全基準を満たす必要があります) |

オプティカル Pアラメーター C採取

- EU: 照明器具からの直接光による干渉を排除するために、143 度の視野画像画像輝度計を使用する必要があります。

- 北米: UL の測光校正装置に通し、ミラー反射検出を追加する必要があります。

観察参照

- EU は、目の高さに対して 1.2 m/立高 1.5 m の着座高さを均一に採用しています。

- 北米は EU 基準に沿っていますが、製造業者は独自のテストの高さを定義できます (登録が必要です)。

ヨーロッパ諸国では、2025 年から UGR ≤16 の範囲 (商業スペースを含む) のミラー天井の必須要件を実施します。: 照明器具の表面の明るさ ≤2000 cd/m²; 反射率が 60% のつや消しランプシェード。

ワイヤレス制御照明器具は、さらに準拠する必要があります。: FCC 無線周波数認証 (47 CFR パート 15)、およびボタン電池アクセサリは、UL 4200A 3 に準拠する必要があります。

トレンドアラー: EU の 2025 年の新しい規制では、光生物学的安全性 (RG0) が UGR 評価システムに組み込まれ、北米は UL 153 青色光制御基準を同時にアップグレードします。

LED リニア ライトの UGR 値を測定する方法は?

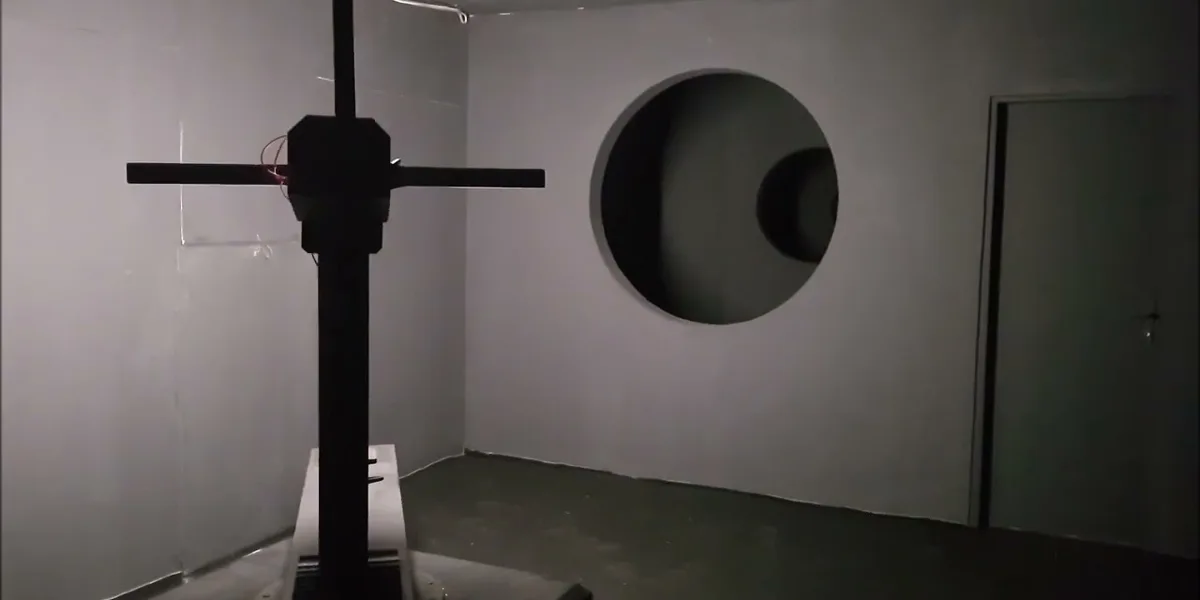

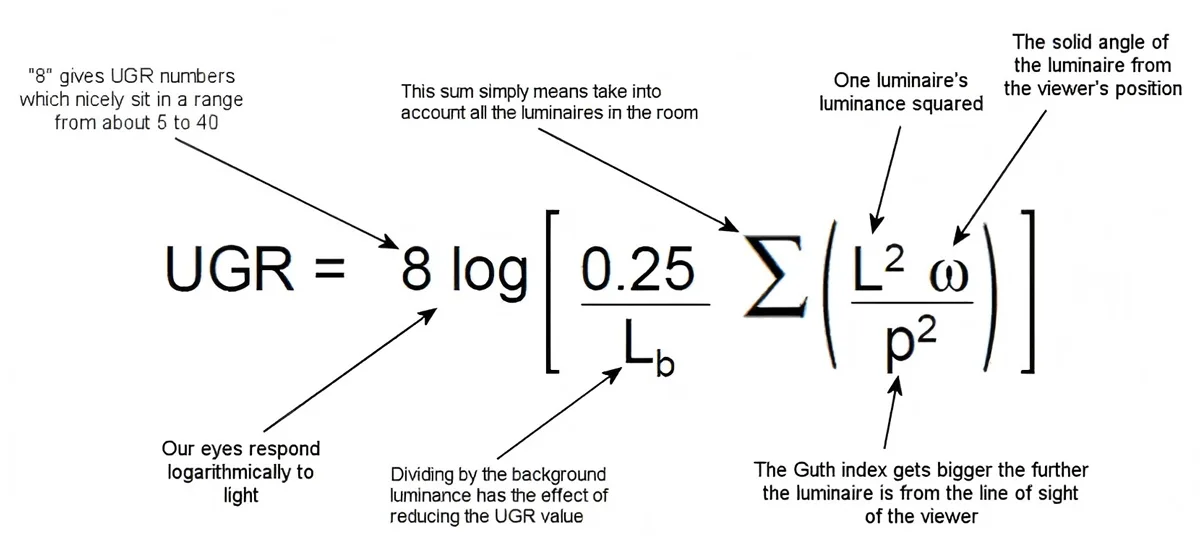

の UGR 値 LED リニアライト 通常、Goniophometer を使用して測定され、標準ソフトウェアを使用して測光データを取得し、計算をシミュレートできます。 具体的なテスト手順と重要なポイントは次のとおりです。

ゴニオ光度計の回転マウントにリニア ライト フィクスチャを固定します。 フィクスチャまたはリフレクターを回転させることにより、360° のスペース全体で光強度分布データをキャプチャし、光束や光強度分布などのパラメーターを含む IES 形式の測光ファイルを生成します。

長い線形ライトは、通常、2 軸対称の固定具 (たとえば、長いパネル ライト) のカテゴリーに属し、2 つの対称面 (縦面 (C0-C180) と横面 (C90-C270)) の配光曲線のテストを必要とします。

データ検証

IES ファイルに完全な配光情報 (半ピークエッジ角度やビーム広がり角など) が含まれていること、および照明器具の光立体角度 ω が UGR 計算条件を満たすために 0.0003 ~ 0.1 SR の範囲内であることを確認してください。

IES ファイルをシミュレーション ソフトウェアにインポートする

Linear Light Fixture の IES ファイルを Dialux などのプロのソフトウェアにロードする場合、ファイルが完全に対称または二軸対称形式であることを確認します (非対称フィクスチャは UGR テーブルを生成できません)。 IES ファイルが自動的に適応しない場合は、補正ツールを使用して対称性を調整します。

標準シミュレーション環境をセットアップする

CIE 117-1995 規格に従って、仮想ルームを構築し、重要なパラメーターを定義します。

- スペース寸法: x=2h、4h、8h、12h に従って、長さと幅を動的に設定します (ここで、H は観察者の目から照明器具の設置高さまでの高さです)。

- 反省: 天井と壁の実際の反射係数を入力します (デフォルト値: 天井 0.7、壁 0.5)。

- 観察者の位置: 照明器具の中心点からデフォルトの距離を保ち、水平方向の視線を維持します。

- UGR テーブルの生成と修正: ソフトウェアは、1000 lm の光束での裸光源の理論値を表す「参照 UGR 照度評価表」(未補正 UGR テーブル) を出力します。

- 実際の UGR 補正式: 実際の UGR = 表値 + 10 × log (照明器具の実際の光束 / 1000)。 たとえば、照明器具の光束が 2000 lm の場合、表の値に 3 を加算します (10 × log2 ~ 3)。

- アプリケーションの制限: UGR は室内環境と両側対称照明器具にのみ適用されます。偏光設計の線形照明器具 (非対称分布壁洗浄照明器具など) は、この方法では直接評価できません。

- 測定された UGR とシミュレーション結果の違い: シミュレーション結果は標準的な環境基準値です。実際の設置は、空間寸法、反射材などに影響されます。

線形ライトの UGR 値を効果的に減らすには?

- 光学構造の最適化: グレア アングル デザインと深いアンチグレア テクノロジーを採用し、25 cm 以上のグレア角度を使用して直接光が目に届かないようにします。 工業用の設定では、3.5 m 以上の高さにライトを取り付け、それらをリフレクターと組み合わせてグレアを減らすことをお勧めします。

- 表面 T再演 T学問: ハニカムのアンチグレア メッシュを使用して、迷光反射を弱め、UGR の 30% 削減 (特に高反射環境に適しています) または、つや消し/マット ランプシェードを使用して、光の拡散を確実にし、光の拡散を 60% 未満にします。

- マイクロPリズム Dイフフュー Pアネル: 指向性の光導通により、UGR を 21 から 14 に減らします。

- インストールと Lやった Cコントロール: ランプが露出しないように設置を優先します。線形ライトは天井または壁に埋め込む必要があります (埋め込み深さ 2cm 以上)。面に取り付ける場合は、偏光レンズを使用して作業面に光を向ける必要があります。 ランプは目の高さの 30 度以内に置かないようにしてください (地上から 1.8 m 以上の高さはより安全です)。鏡面の天井は、二次反射を抑えるために、フロスト ランプシェードと組み合わせて使用する必要があります。

- 壁の材料管理: マット ペイント (反射率 <60%) を使用し、白い壁やタイルなどの高反射素材を避け、湾曲した反射光スロットを取り付けて、直接光を拡散光に変換します (UGR を 21 から 13 に減らした測定)。

- rg0-Lレベル Bルーエ Lちょうど Cコントロール: フルスペクトル光源を使用して、光生物学的刺激を減らします。

- 頭がいい Dイミング Sシステム: 高輝度領域のコントラストを動的に減らします (FCC/CE 認定を受けている必要があります)。

- 注意事項: 透明な LED 電球は光源であり、激しいまぶしさを引き起こす可能性があります。ランプの間隔が 1.5 倍以上の高電力密な配置を避け、照明器具の投影角度から、ミラー家具、机、スクリーンなどの反射面をオフセットする必要があります。

- 効果 Vエラー化: 143° 視野の画像輝度計を使用して補正された UGR 値を測定して、19 (オフィス) または 13 (医療/教育) を確実にします。

さらに、UGR ≤19 を満たすために、照明プロジェクトは 3 倍の技術制御を採用する必要があります。

- オプティカル Dデザイン: 微細構造の光拡散板を使用して表面の明るさを下げます。

- 作戦: 人間の目の干渉ゾーンを避けてください (30° 上向きの視野内)。

- 素材 S選挙: 光沢の低い素材を使用して、反射のまぶしさを軽減します。 たとえば、教室の照明には UGR ≤ 19 (国家標準 GB7793-2010) が義務付けられていますが、ハイエンドの備品 (街路灯など) はさらに UGR ≤ 16 に最適化されています。

- 光学最適化: マイクロ プリズム拡散パネルの取り付け: UGR は 21 から 14 にまで減らすことができます; 偏光レンズを使用: 産業用設定では UGR ≤ 25 を許容しますが、反射率が 60% 以下の壁とペアにする必要があります。

- インストールのタブー: 人間の目の 30 度の水平視野に裸のランプを置くことを固く禁じます。地上から 1.8 メートルの高さはより安全です。鏡面天井の設定では、フロスト ランプシェードを使用する必要があります。

SignLiteLED LED リニア ライトの 4 つのコア メリット

優れた光学性能: UGR が 19 のグレア低減設計を特徴とする光は、プリズム拡散パネルを介して均一に拡散し、光スポット境界のシャープネスを効果的に制御する高精度の光学レンズ システムによって補完され、美術館のグレード抑制基準を実現します。

工業用構造設計: 航空宇宙グレードのアルミニウム合金プロファイルとナノコーティング技術で構築されており、-30°C から 60°C の極端な環境に耐えることができる IP66 保護定格を誇っています。 革新的なモジュール式のアセンブリ構造は、0° から 90° までの多次元調整をサポートし、湾曲したスペースや不規則な空間での設置に対応します。

頭がいい E体系 私統合: DALI/PWM デュアル プロトコル ドライバーが組み込まれており、主流のスマート コントロール システムと互換性があります。 グラフェン熱放散技術は、93% 以上のエネルギー効率変換を達成し、50,000 時間以上の寿命を合わせ、従来の照明器具と比較して 40% エネルギーを節約します。

分化した Vアルレ: この製品は CE と RoHS の認定を受けており、5 年間の保証を提供します。 カスタマイズされたサービス システムは、商業スペース、アート ギャラリー、およびその他のシナリオの特別な色温度 (2700K から 6500K まで調整可能) および演色指数 (RA ≥ 95) の要件に対応できます。

優れた光学性能、耐久性のある工業用グレード構造、スマート コントロールの互換性、高度にカスタマイズされたサービスを備えた SignLiteLed の LED リニアライト 近代的な建築照明や高級商業空間に最適な選択肢となっています。 新しい建設プロジェクトであろうと照明のアップグレードであろうと、SignLiteLED はより効率的でスマートで、よりデザイン指向の照明ソリューションを提供します。