Yes, LED sheet lights can be customized for different designs, and this flexibility is one of the main reasons they are widely used in commercial and architectural lighting projects.

In modern projects, lighting is rarely standard or rectangular. Architects design curved ceilings, illuminated walls, floating shelves, backlit stone panels, and branded feature elements that require precise light distribution. Standard fixtures often limit design freedom. In contrast, custom led sheet lighting allows lighting layouts to adapt to the design rather than forcing the design to adapt to the fixture.

LED sheet lighting systems are built around modular grids of LEDs distributed across a thin panel. Many designs allow cutting along predefined lines, electrical segmentation, and layout expansion. This makes it possible to create uniform illumination across irregular shapes, control brightness levels, and integrate lighting into custom-built elements.

This article explains how customization works in practical B2B terms. It covers physical, optical, and electrical customization, real-world applications, manufacturer-level adaptation, limitations, and a structured decision checklist to support architects, engineers, and procurement teams evaluating a sheet of led lights for commercial use.

What “Customization” Means for LED Sheet Lights

Customization in the context of LED sheet lights goes far beyond simple resizing. For B2B buyers, it refers to structured, engineering-level flexibility that supports design intent, performance requirements, and installation conditions.

In practical terms, custom led sheet lighting may involve:

- Adjusting overall panel dimensions

- Cutting along marked lines to fit irregular shapes

- Segmenting electrical circuits for large layouts

- Selecting specific brightness or density configurations

- Integrating dimming or RGBW control

Unlike fixed LED panels, which are manufactured in rigid formats such as 600×600 mm or 1200×300 mm, an led light sheet is designed to be adaptable. Instead of acting as a single enclosed luminaire, it functions as a lighting matrix that can be integrated into millwork, architectural surfaces, signage, and decorative structures.

A standard LED panel is typically self-contained. An led sheet light, by contrast, is often installed behind translucent materials such as acrylic, fabric, stone veneer, or glass to create seamless backlighting. The flexibility lies not only in size but also in layout configuration and illumination control.

For lighting engineers and OEM/ODM teams, customization means the product can be engineered around the project rather than retrofitted on-site.

Physical & Structural Customization Options

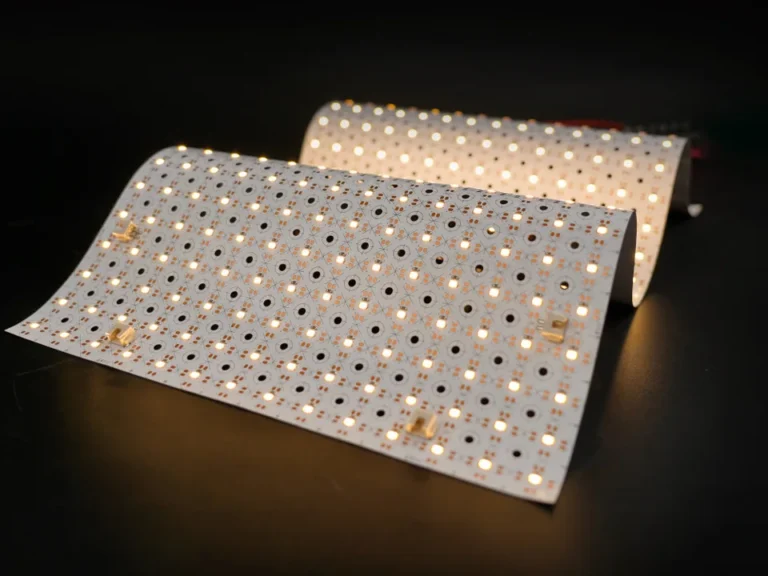

Flexible Form Factors

One of the most important advantages is the availability of a flexible led light sheet. These products are built on thin substrates that allow bending or slight contour adaptation. While not intended for extreme folding, they support curved surfaces such as:

- Cylindrical columns

- Curved reception desks

- Arched display panels

- Rounded architectural coves

This enables designers to maintain continuous illumination across surfaces that would otherwise require multiple rigid fixtures.

Custom Dimensions and Modular Layouts

Many led light sheets include pre-marked cut lines. These allow the installer or fabricator to trim the panel without damaging electrical pathways. For larger installations, multiple sheets can be joined to form continuous illuminated surfaces.

This modular approach supports:

- Large backlit walls

- Extended retail shelving

- Continuous ceiling features

- Full-height branding panels

Instead of relying on fixed modules, a sheet of led lights can be scaled to the required footprint.

Edge-to-Edge Lighting Concepts

Because LEDs are distributed across the full surface, an led sheet light can provide edge-to-edge coverage. This is especially important for shallow lightboxes or thin-profile architectural details where edge-lit solutions may produce shadowing or uneven distribution.

In architectural contexts, this structural flexibility allows integration behind translucent materials with minimal depth.

Optical & Lighting Customization

Physical adaptability alone is not sufficient. Optical customization is equally important in commercial environments.

Brightness Selection

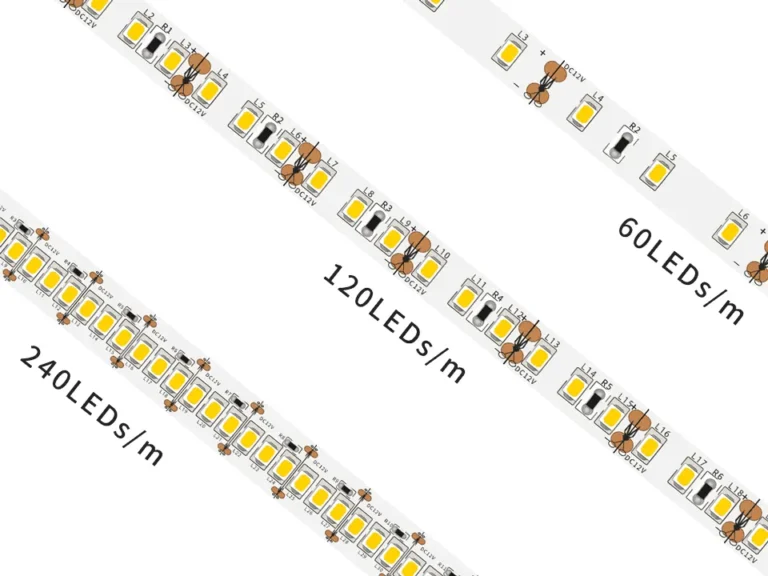

Custom led sheet lighting often allows different LED densities. Higher density configurations increase luminous output and reduce visible hotspots when placed behind diffusers.

Brightness selection depends on:

- Application type

- Viewing distance

- Diffuser thickness

- Ambient light conditions

Retail displays and signage typically require higher brightness, while decorative architectural panels may prioritize softer output.

Uniform Illumination Performance

A uniform illumination led light sheet is designed to distribute light evenly across the surface. Uniformity is critical for professional applications because uneven brightness creates visual distractions and reduces perceived quality.

Uniform illumination matters particularly in:

- Backlit onyx or stone walls

- Fabric lightboxes

- Display cases

- Branding panels

In these environments, even minor brightness inconsistencies become visible.

Dimming and Color Control

Advanced configurations include dimmable and rgbw led light sheets. These systems allow:

- Intensity control

- Ajuste da temperatura da cor

- Dynamic RGBW color changes

In hospitality, retail, and exhibition environments, dynamic control enhances mood setting and brand storytelling.

When properly engineered, dimming or RGBW functionality does not compromise uniform illumination, provided the LED density and driver compatibility are correctly specified.

Electrical & Control Customization

From a procurement and engineering perspective, electrical flexibility is a central component of customization.

Compatibilidade de regulação de fluxo luminoso

Many led sheet lights can be configured to work with common dimming systems. This allows integration into centralized lighting control environments without requiring standalone solutions.

Dimming supports:

- Energy management

- Atmosphere adjustment

- Time-based programming

RGBW and Tunable Configurations

Dimmable and rgbw led light sheets allow independent control of red, green, blue, and white channels. This is valuable in environments where color plays a strategic role, such as branded interiors or experiential retail spaces.

Tunable white versions enable adjustment between warm and cool tones. This flexibility supports:

- Day-to-night transitions

- Product highlighting

- Visual comfort optimization

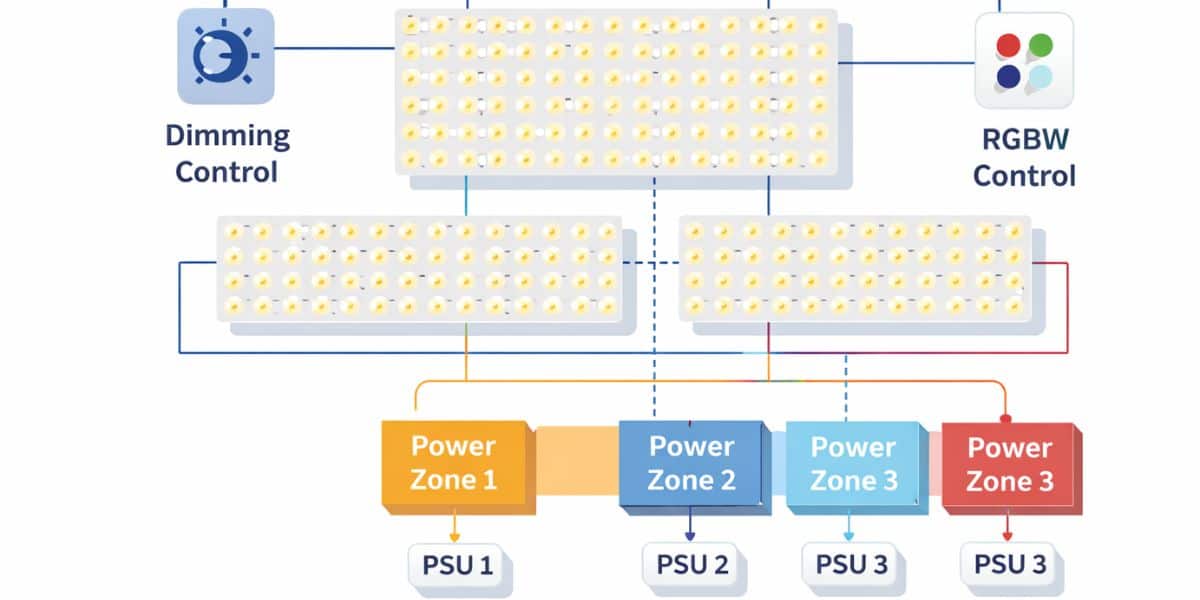

Power Segmentation for Large Installations

For large illuminated surfaces, electrical segmentation becomes important. Instead of powering an entire wall from a single feed, multiple zones can be divided for:

- Load balancing

- Maintenance flexibility

- Zonal lighting control

This structured segmentation should be defined during product specification, particularly for large-scale installations. In professional projects, modular layouts and circuit segmentation are typically determined at the manufacturing level to ensure stable performance and long-term reliability.

Design Applications That Require Custom LED Sheet Lighting

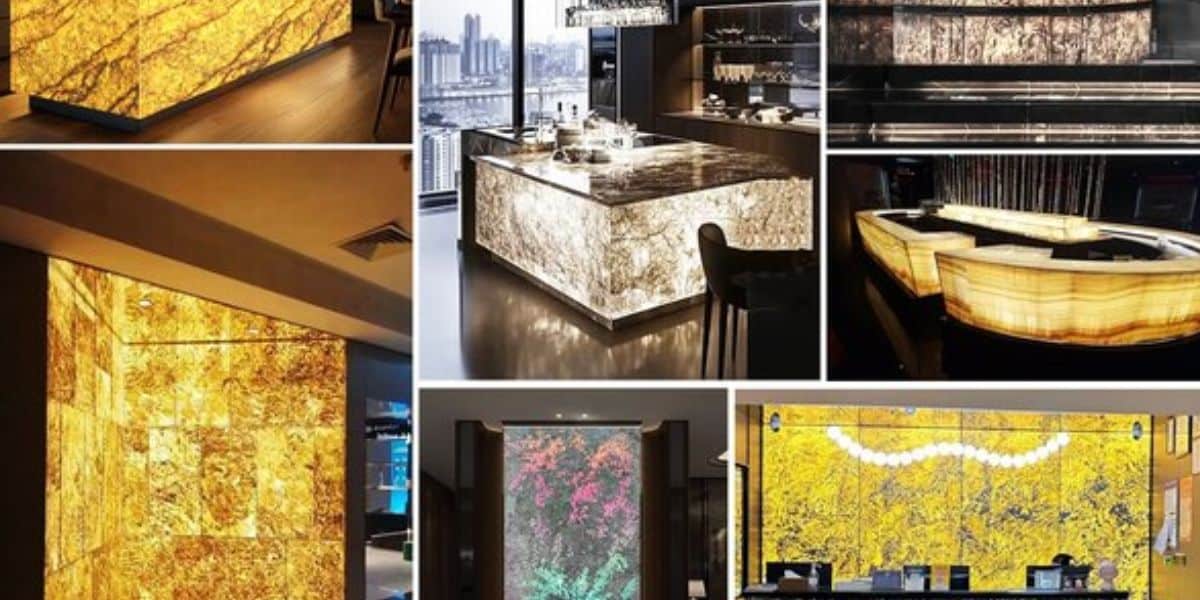

Iluminação arquitetônica

Architectural backlighting often involves irregular surfaces such as stone panels, textured glass, or stretched fabric. Standard luminaires cannot match these shapes effectively.

Custom led sheet lighting allows designers to create evenly lit vertical and horizontal surfaces that enhance material characteristics while maintaining visual consistency.

In architectural backlighting projects, visual consistency and structural flexibility are critical. The example below demonstrates how an led sheet light can be integrated behind stone panels to achieve uniform illumination across the surface.

Retail Displays and Shopfitting

Retail fixtures require precise illumination behind shelves, logos, and feature panels. An led light sheet can be cut and adapted to match cabinetry dimensions without visible gaps.

Because lighting is integrated into millwork, customization ensures seamless integration.

Signage and Branding Panels

Branding elements frequently involve logos, typography, or asymmetrical forms. A flexible led light sheet can be shaped behind acrylic or fabric to ensure even brightness across all sections.

Inconsistent lighting would compromise brand presentation, making uniformity critical.

Cabinets, Showcases, and Feature Walls

Showcases often have limited depth. A thin sheet of led lights enables shallow installation while still delivering sufficient brightness.

Feature walls, particularly in hospitality and corporate environments, benefit from clean, shadow-free illumination across wide surfaces.

Manufacturer-Level Customization vs On-Site Modification

Understanding where customization should occur is essential for procurement teams.

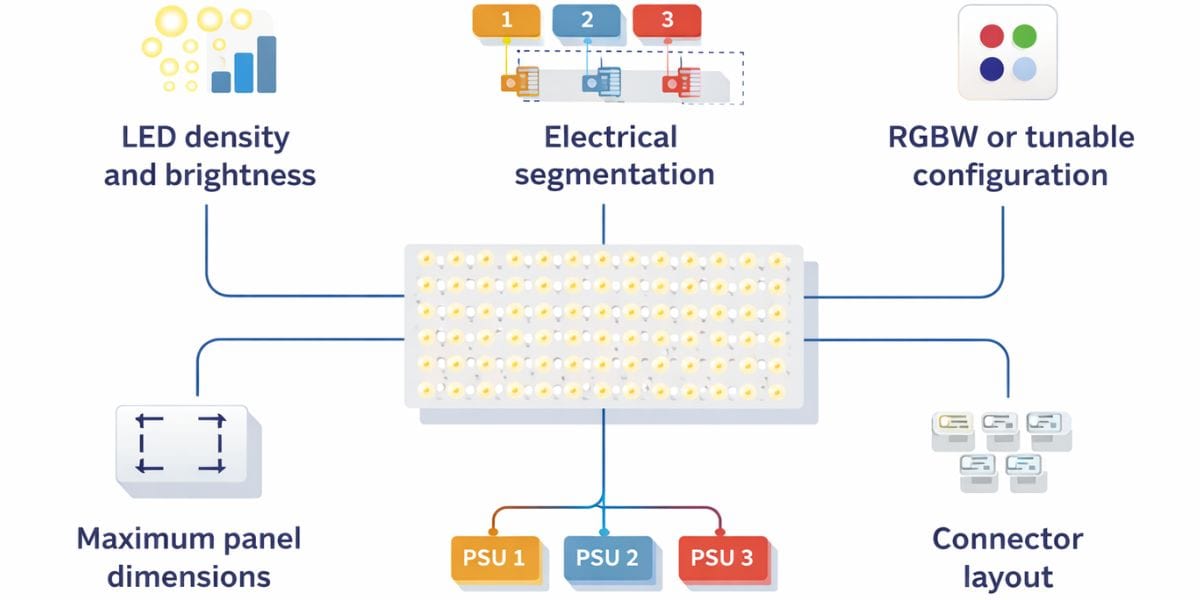

Manufacturer-Level Customization

The following elements should ideally be defined at the factory level:

- LED density and brightness

- Electrical segmentation

- RGBW or tunable configuration

- Maximum panel dimensions

- Connector layout

Factory-defined customization ensures quality control, electrical reliability, and consistent illumination performance.

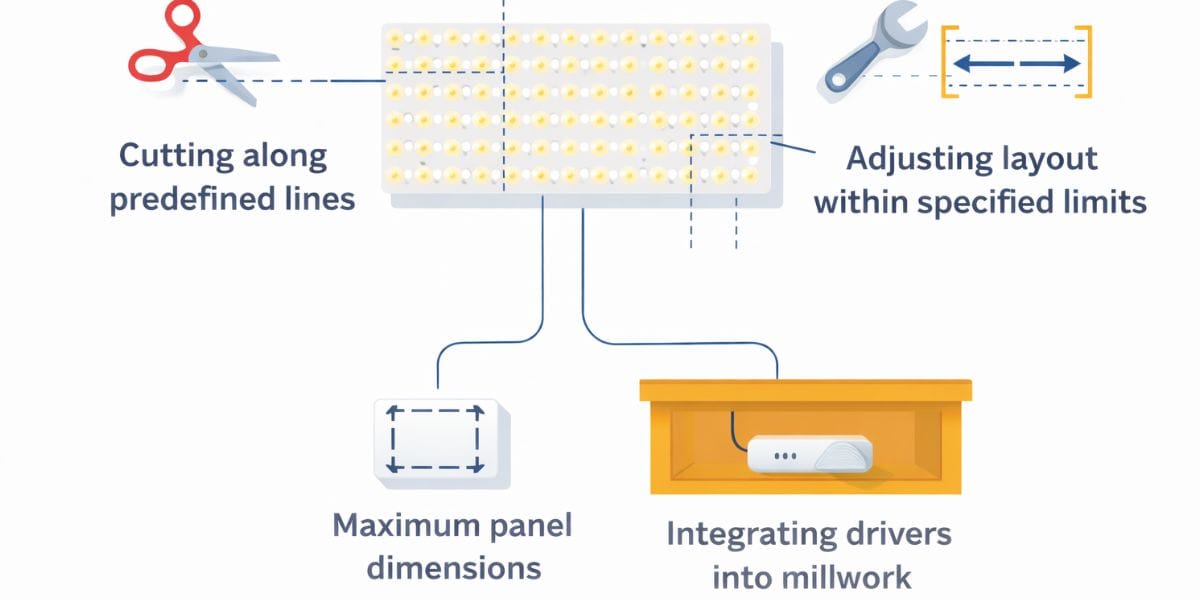

On-Site Modification

On-site modification may include:

- Cutting along predefined lines

- Adjusting layout within specified limits

- Integrating drivers into millwork

However, altering electrical pathways beyond designed cut points can compromise performance and safety.

For large commercial projects, B2B buyers typically prefer factory-defined customization because it reduces installation risk and ensures predictable outcomes.

Customization Limitations (Realistic & Honest)

While led sheet lights are highly adaptable, they are not universally suitable.

Design Constraints

Extreme three-dimensional folding or tight bending radii may exceed the flexibility limits of a flexible led light sheet.

Electrical Limits

Large installations require careful load calculation. Overextending a circuit beyond its rated capacity can lead to voltage drop and uneven brightness.

Thermal Considerations

High-density configurations in enclosed spaces must consider heat management.

When LED Sheet Lights May Not Be Ideal

They may not be the best solution for:

- Direct-view decorative lighting

- Outdoor environments without appropriate protection

- Applications requiring deep directional beam control

Recognizing these limits ensures appropriate specification and long-term reliability.

folhas de led de cor única

- tamanho ( l x w ): 250mm x 250 mm/ 490 mm x 245 mm

- Tipo de LED: 2835 SMD

- Quantidade do LED: 100 peças/242 pcs

- Tensão de funcionamento: CC 24 V

- Potência: 12W/28W

- CCT: 2700K/3000K/4000K/6000K/6500K

- Fluxo luminoso: 1200lm/2800lm

- IRC: >80ra

- Comprimento mínimo de corte: 25mmx25mm/22.3mmx22.3mm

- Regulável: sim

- Ângulo do feixe: 120°

- Nível impermeável: IP20 não à prova d'água, IP54 à prova d'água

- Garantia: 3 anos

Custom LED Sheet Lighting: Decision Checklist

| Customization Area | What Can Be Customized | Porque é que é importante |

| Size & Shape | Custom panel dimensions and cut lines | Enables integration into unique architectural forms |

| Brilho | LED density and output level | Ensures correct illumination for retail, signage, or décor |

| Cor | White, RGBW, dimming capability | Supports mood control and branding needs |

| traçado | Modular segmentation and expansion | Allows scaling for large installations |

| Illumination | Even light distribution across surface | Delivers professional, uniform finish |

This structured evaluation helps procurement teams align technical specifications with design objectives.

Common Buyer Mistakes to Avoid

One common mistake is confusing Tiras de LED with led sheet lights. Strips provide linear lighting, while sheets provide surface-based illumination. They are not interchangeable.

Another frequent issue is assuming all products provide uniform illumination. Not all led light sheets are engineered for consistent distribution, especially at lower densities.

Some buyers also overlook manufacturer customization capabilities. Without confirming segmentation, density, or control compatibility in advance, projects may face installation challenges.

Clear specification at the beginning prevents redesign or costly adjustments later.

Conclusão

LED sheet lights can be customized for different designs, and this flexibility makes them highly suitable for commercial and architectural projects.

From shape and size adaptation to brightness control and RGBW configuration, custom led sheet lighting enables designers and engineers to integrate illumination seamlessly into modern structures. When properly specified, an led light sheet provides uniform illumination, scalable layouts, and adaptable control options that support a wide range of applications.

For B2B buyers, the key is defining customization at the correct stage, understanding technical boundaries, and aligning optical and electrical specifications with design goals.

FAQs

Yes. Many led sheet lights include predefined cut lines that allow trimming to fit custom dimensions without damaging circuitry.

A flexible led light sheet can adapt to gentle curves and cylindrical forms, making it suitable for many architectural features.

When properly engineered, dimmable and rgbw led light sheets maintain uniform illumination across the surface.

Customization influences driver placement, power segmentation, and layout configuration. Early coordination ensures smoother installation

Architectural backlighting, retail displays, signage panels, showcases, and feature walls benefit significantly from tailored led sheet lighting solutions.

Yes. Signage and branding panels require even brightness to maintain professional visual quality and consistent brand presentation.