A indústria de iluminação LED transformou a iluminação moderna em aplicações residenciais, comerciais, industriais e automotivas. Os LEDs são favorecidos por alta eficiência energética, longa vida operacional e tamanho compacto. No entanto, seu desempenho depende muito do design do PCB, da qualidade do conjunto SMT e da confiabilidade da junta de solda. Até mesmo defeitos de montagem menores podem levar a cintilação, inconsistência de cor, formação de hotspot ou falha prematura.

Este guia explora

- Estratégias para melhorar a confiabilidade do LED de PCB

- Foco nas melhores práticas SMT, otimização de juntas de solda e gerenciamento térmico.

- Ajude os fabricantes a alcançar sistemas LED de alta qualidade e durabilidade.

Desafios comuns de confiabilidade em LEDs de PCB

Os LEDs são altamente sensíveis a tensões térmicas, elétricas e mecânicas. O design ou a montagem ruins podem comprometer o desempenho e a vida útil. Os desafios típicos incluem:

- Juntas de solda rachadas ou abertas, levando a conexões intermitentes.

- Estresse térmico causando distorção de PCB e degradação de componentes.

- Eletromigração prejudicial aos traços de cobre sob alta densidade de corrente.

- Estresse mecânico de manuseio, transporte ou ciclagem térmica.

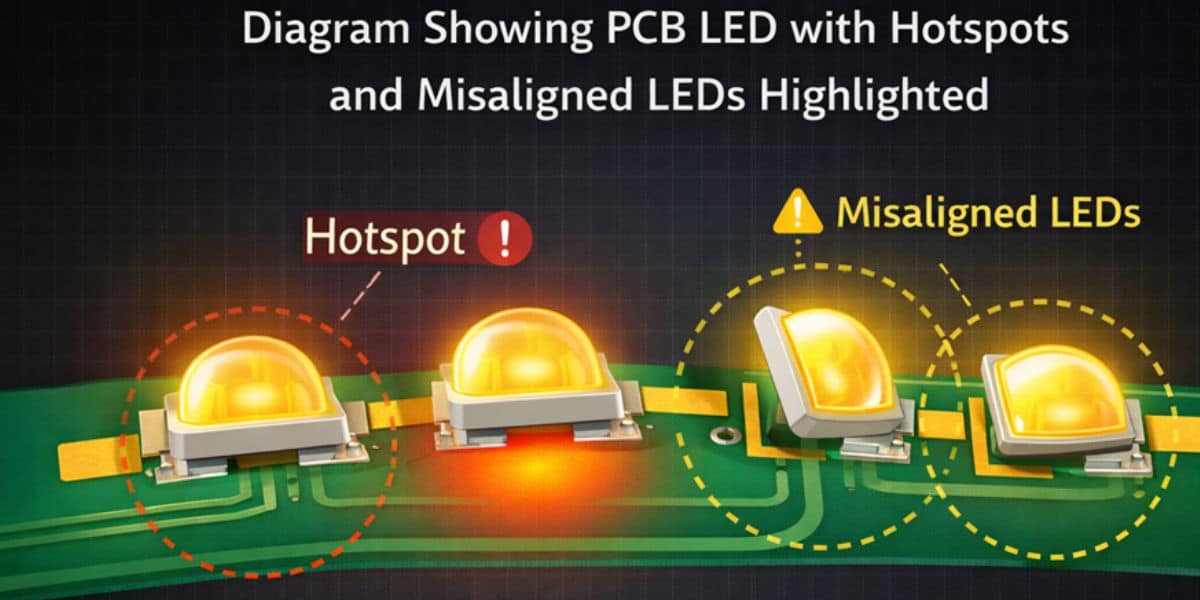

- LEDs desalinhados, resultando em uma saída de luz irregular ou pontos de acesso visíveis.

Tabela 1: Impacto dos problemas de PCB e SMT na confiabilidade do LED

| emanação | causar | Efeito no sistema de LED |

| juntas de solda rachadas | Ciclagem térmica, estresse mecânico | Circuitos abertos e cintilantes |

| LEDs desalinhados | Erros de escolha e lugar | Distribuição de luz irregular |

| pontos de acesso térmicos | Dissipação de calor ruim | Depreciação do lúmen, falha precoce |

| eletromigração | Densidade de corrente alta, traços finos | Danos de rastreamento, falhas ao longo do tempo |

| vazios de solda | Deposição de pasta inadequada | Redução da condutividade térmica/elétrica |

Considerações sobre a tecnologia de montagem em superfície (SMT)

O SMT permite um posicionamento preciso do LED, formatos menores e desempenho elétrico aprimorado. No entanto, práticas ruins de SMT reduzem a confiabilidade.

1: Design de PCB para SMT

Um layout de PCB bem projetado oferece suporte à confiabilidade:

| elemento de design | Melhor prática |

| Tamanho e forma da almofada | Garanta a molhagem adequada da solda e evite a ponte |

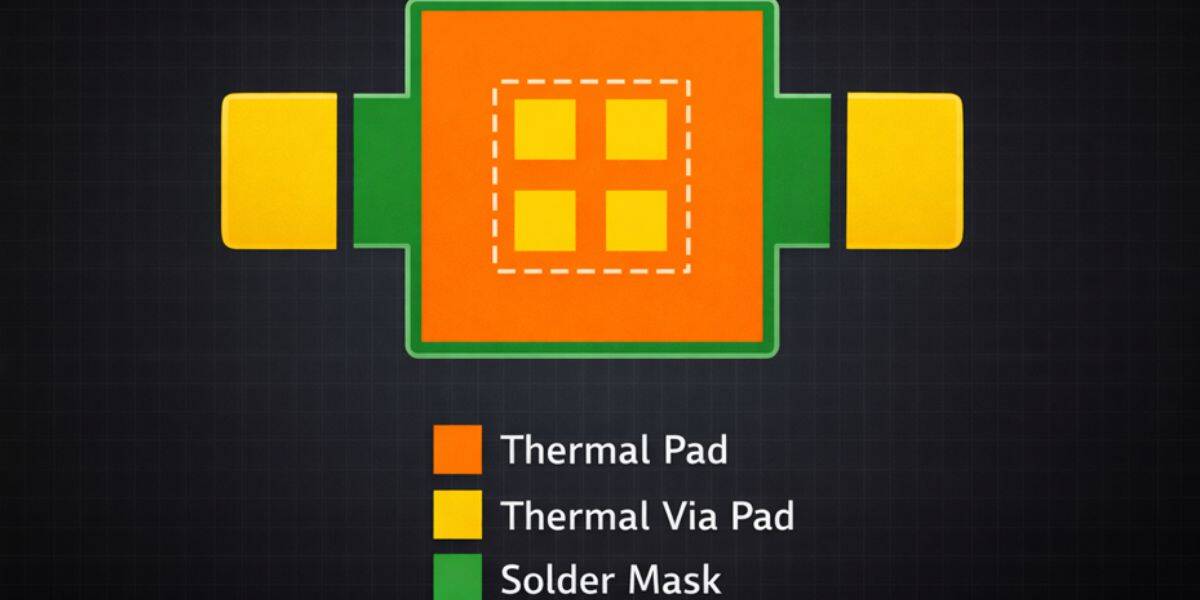

| almofadas térmicas | Melhore a dissipação de calor para LEDs de alta potência |

| design de máscara de solda | Previna o derramamento de solda e mantenha a precisão do posicionamento |

| Largura do traço e cobre | Manter baixa resistência e manusear a corrente com eficiência |

2: precisão de pick-and-place

O posicionamento adequado é fundamental para a iluminação uniforme:

- A seleção do bico, a velocidade de colocação e a pressão devem ser otimizadas.

- O desalinhamento pode criar inconsistências ópticas e estresse mecânico.

- A calibração regular reduz os erros de posicionamento e o retrabalho.

3: aplicação de pasta de solda

A qualidade da pasta de solda e a aplicação são vitais:

- A pasta de baixo vazio e de alta qualidade garante umedecimento consistente.

- Os estêncils de precisão evitam a solda excessiva ou insuficiente.

- O conteúdo de fluxo deve ser adequado para prevenir a oxidação.

Confiabilidade da junta de solda

As juntas de solda formam a conexão mecânica e elétrica entre os LEDs e os PCBs. A má soldagem é uma causa primária de falha.

1: seleção de liga de solda

- SAC305 (SNAGCU) é o padrão sem chumbo.

- As ligas de baixo derretimento reduzem o estresse térmico durante o refluxo.

- A liga deve ser compatível com os acabamentos de PCB (ENIG, HASL, OSP).

2 : otimização do perfil de refluxo

A temperatura de refluxo deve ser controlada:

- O pré-aquecimento, o molho e as temperaturas máximas devem corresponder às recomendações do fabricante.

- Evite o superaquecimento de LEDs ou almofadas para evitar choque térmico.

- O resfriamento controlado reduz os riscos de fissuras.

3: geometria da junta de solda

A forma adequada da articulação melhora a resistência e a condutividade:

- A altura do filete deve cobrir a almofada sem excesso de solda.

- Filetes lisos e côncavos reduzem a formação de vazios.

- A coplanaridade garante um contato elétrico estável.

4: inspeção e controle de qualidade

- A Inspeção Óptica Automatizada (AOI) detecta defeitos visíveis.

- A inspeção por raios X identifica os vazios ocultos em almofadas térmicas.

- As auditorias regulares de processos mantêm uma qualidade consistente.

Tabela 2: Especificações de filete de solda recomendadas para LEDs

| Tipo de LED | Altura do filete (mm) | ângulo de junta | notas |

| 0,2–0,5 w LEDs | 0,2–0,3 | 45–60° | LED de montagem em superfície padrão |

| LEDs de 1 a 3 W | 0,3–0,5 | 45–70° | LEDs de alta potência requerem suporte térmico |

| > LEDs de 5 W | 0,4–0,6 | 60–75° | Use vias térmicas e PCB de metal-core |

Gerenciamento térmico de LEDs SMT

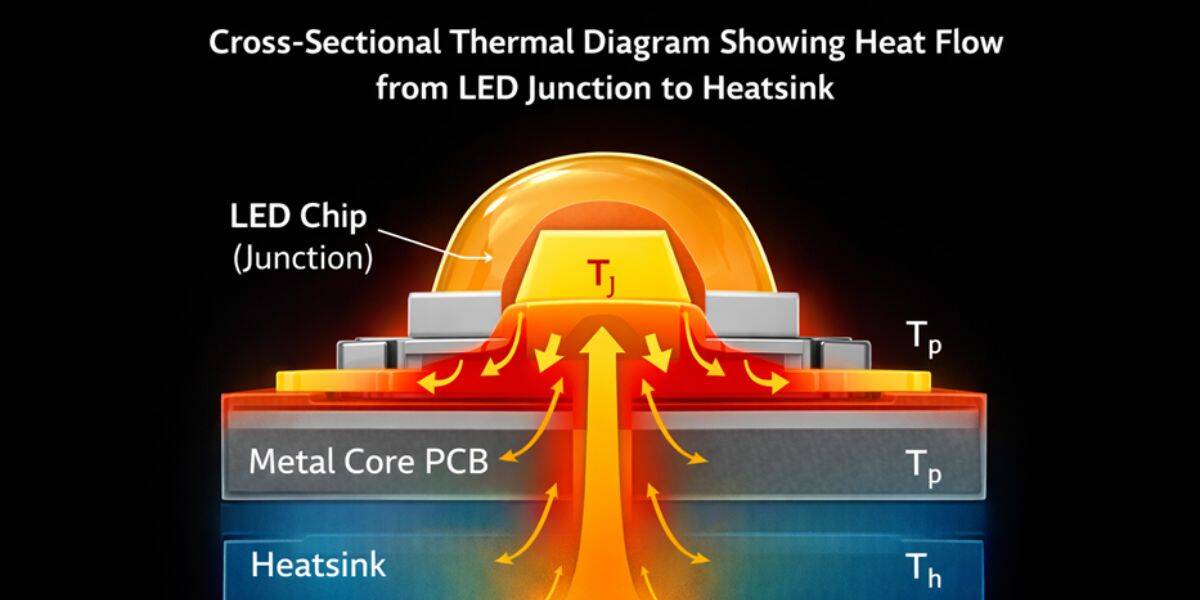

O calor é o mais Fator crítico para confiabilidade de LED. Altas temperaturas aceleram a depreciação do lúmen e reduzem a vida útil.

Estratégias chave:

- Os PCBs de núcleo de alumínio melhoram a dissipação de calor.

- As vias térmicas sob LEDs transferem o calor para planos de cobre maiores.

- Dissipadores de calor e TIMS são essenciais para aplicações de alta potência.

- O espaçamento correto do LED previne os pontos de acesso e garante uma distribuição uniforme da temperatura.

Problemas comuns de SMT e solda

| emanação | causar | Solução |

| Tombstone | Tensão superficial irregular durante o refluxo | Ajuste o volume e o perfil da pasta de solda |

| ponte de solda | Solda em excesso, almofadas desalinhadas | Reduza a deposição de pasta, melhore o estêncil |

| juntas de solda fria | Molhamento ruim, baixa temperatura | Otimize o perfil de refluxo e o tipo de solda |

| mixórdia | ar preso ou fluxo | Use pasta de baixo vazio, refluxo adequado |

Práticas recomendadas para um conjunto de LED PCB confiável

Design para manufaturabilidade (DFM): Alinhe os pads, traços e caminhos térmicos com recursos SMT.

- Use pasta de solda de alta qualidade: Liga de baixo vazio e consistente com fluxo adequado.

- Perfil de refluxo controlado: Evite o superaquecimento e o resfriamento rápido.

- inspeção: AOI, raios X e verificações manuais.

- Manuseio: Minimize o estresse mecânico durante o transporte e montagem.

- Projeto térmico: PCBs de núcleo de metal, vias térmicas e dissipadores de calor.

- Processos padronizados: A documentação garante repetibilidade.

Estudo de caso: módulo LED de alta potência

Um módulo de LED industrial de alta baía teve falhas frequentes nas juntas de solda devido ao ciclagem térmica.

Melhorias implementadas:

- Mudados para PCBs de núcleo de alumínio.

- Deposição de pasta de solda otimizada.

- Perfis de refluxo controlados.

- Adicionadas vias térmicas sob LEDs.

Resultados:

- 30% Redução de defeitos de juntas de solda.

- Melhora na manutenção do lúmen após 5.000 horas de funcionamento.

Tendências emergentes no conjunto de LED de PCB

- Ligas de solda de baixa temperatura reduzem o estresse térmico.

- A solda sem chumbo garante a conformidade regulatória sem reduzir a confiabilidade.

- A inspeção assistida por IA detecta defeitos mais rapidamente do que os métodos tradicionais.

- Os materiais avançados de PCB com alta condutividade térmica melhoram a dissipação de calor.

- As simulações térmicas 3D predizem os hotspots antes da produção.

Dicas adicionais para fabricantes

- Use o software de design de estêncil para uma deposição precisa de pasta de solda.

- Realize simulações térmicas para evitar pontos de acesso antes da produção.

- Calibre regularmente as máquinas de coleta e lugar.

- Manter a umidade e a temperatura controladas nas áreas de montagem.

- Use revestimentos protetores para ambientes de alta umidade.

Conclusão

A confiabilidade do LED PCB depende da qualidade do conjunto SMT, da integridade da junta da solda e do gerenciamento térmico. O design adequado, a solda e o controle de processos evitam falhas, aprimoram o desempenho e prolongam a vida útil do LED. Os fabricantes que implementam layouts otimizados, soldagem de alta qualidade e estratégias térmicas avançadas obtêm sistemas LED confiáveis e duradouros com saída de luz consistente.

Para soluções de LED de alto desempenho e durabilidade, a confiança sinalizada para conjuntos de LED PCB com engenharia especializada. Nós nos concentramos na otimização SMT, soldagem precisa e gerenciamento térmico avançado para fornecer iluminação confiável.

Contato Signliteled hoje Para melhorar a qualidade do seu produto, reduzir falhas e garantir um desempenho superior do LED.

FAQs

SMT (Tecnologia de montagem em superfície) permite um posicionamento preciso do LED, reduz o tamanho e melhora o desempenho elétrico e térmico.

As juntas de solda fornecem suporte mecânico e conexão elétrica; as juntas ruins podem causar falhas ou tremeluzir.

Defeitos típicos incluem atolamento, ponte de solda, juntas frias e vazios, reduzindo o desempenho e a vida útil.

Dissipação de calor eficiente por meio de vias térmicas, PCBs de núcleo de alumínio e dissipadores de calor evita o superaquecimento e prolonga a vida útil.

A inspeção óptica automatizada (AOI), a inspeção por raios X e as verificações manuais detectam defeitos como desalinhamento, vazios e pontes.