ด้วยการพัฒนาอย่างต่อเนื่องและความก้าวหน้าของเทคโนโลยีการบรรจุ LED แถบ LED ได้รับการปรับให้เหมาะสมอย่างต่อเนื่องในแง่ของประสิทธิภาพการส่องสว่าง ความสม่ำเสมอ ความยืดหยุ่น และประสิทธิภาพการกระจายความร้อน ทำให้เกิดโครงสร้างแถบใหม่ที่หลากหลาย ในบรรดาสิ่งเหล่านี้ COB (ชิปบนกระดาน) ได้กลายเป็นวิธีการบรรจุภัณฑ์หลักสำหรับแถบ LED ที่มีความหนาแน่นสูง ซึ่งใช้กันอย่างแพร่หลายในการใช้งานระดับมืออาชีพ เช่น ไฟเชิงพาณิชย์ ไฟคอนทัวร์สถาปัตยกรรม และไฟตกแต่งแบบกำหนดเอง ในขณะเดียวกัน CSP (แพ็คเกจเครื่องชั่งชิป), SCob (ชิปสเตอริโอสโคปบนบอร์ด) และ SOB เป็นวิธีการบรรจุภัณฑ์แถบ LED ล่าสุดที่สร้างการอภิปรายที่สำคัญในปี 2567-2568

ไม่ว่าคุณจะทำโครงการเชิงพาณิชย์ วางแผนการติดตั้งไฟกลางแจ้ง หรืออัพเกรดไฟบ้าน การเลือกประเภทของไฟ LED ที่เหมาะสมจะส่งผลต่อประสิทธิภาพของแสงและส่งผลกระทบโดยตรงต่อต้นทุนของโครงการ ประสิทธิภาพการบำรุงรักษาหลังการติดตั้ง และประสบการณ์แสงขั้นสุดท้าย อย่างไรก็ตาม เนื่องจากความแตกต่างในโครงสร้างบรรจุภัณฑ์ ลักษณะการปล่อยแสง วิธีการกระจายความร้อน และความเข้ากันได้ของการใช้งานระหว่าง COB, CSP, SCob และ SOB ผู้ใช้หลายคนมักพบว่ามันสับสนเมื่อเลือกตัวเลือกที่เหมาะสม

บทความนี้จะดำเนินการเปรียบเทียบเชิงลึกของหลักการโครงสร้าง พารามิเตอร์ประสิทธิภาพ สถานการณ์การใช้งาน และข้อดีและข้อเสียของแถบไฟ LED ทั้งสี่ประเภทนี้ ช่วยให้คุณตัดสินใจเลือกอย่างมีข้อมูลมากขึ้นจากมุมมองของการจัดซื้อจัดจ้างอย่างมืออาชีพ

ทำความเข้าใจกับไฟ COB, CSP, SCob และ SOB LED Strip

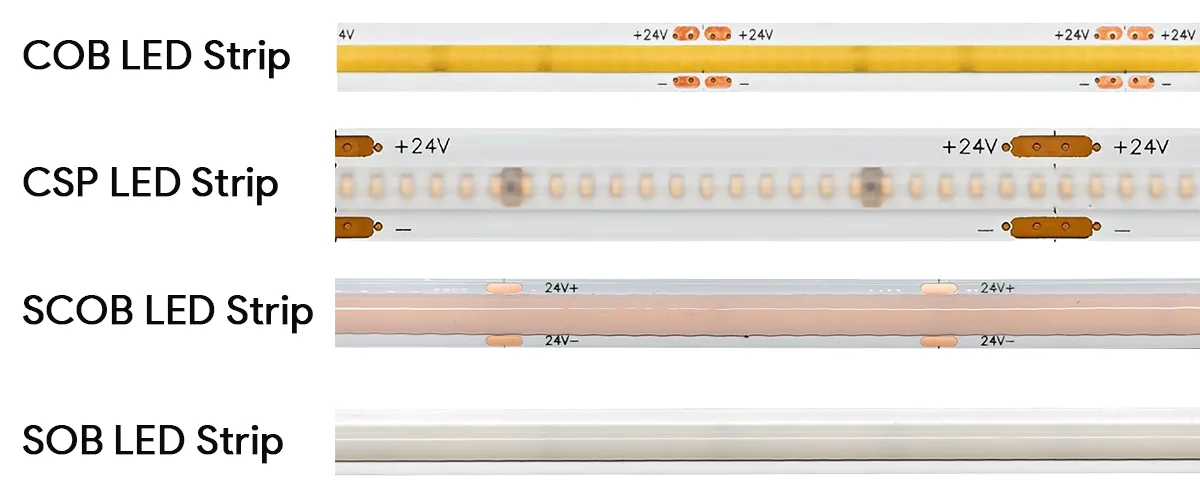

เมื่อเลือกไฟแถบ LED การทำความเข้าใจวิธีการบรรจุหีบห่อเป็นขั้นตอนแรกในการประเมินประสิทธิภาพ แม้ว่า COB, CSP, SCOB และ SOB ทั้งหมดจะจัดอยู่ในหมวดหมู่ของบรรจุภัณฑ์ไฟ LED แถบความหนาแน่นสูง แต่ก็แตกต่างกันอย่างมากในแง่ของการออกแบบโครงสร้าง เอฟเฟกต์แสง และความสามารถในการปรับการติดตั้ง

ไฟ LED แบบ COB (ชิปบนบอร์ด) คืออะไร?

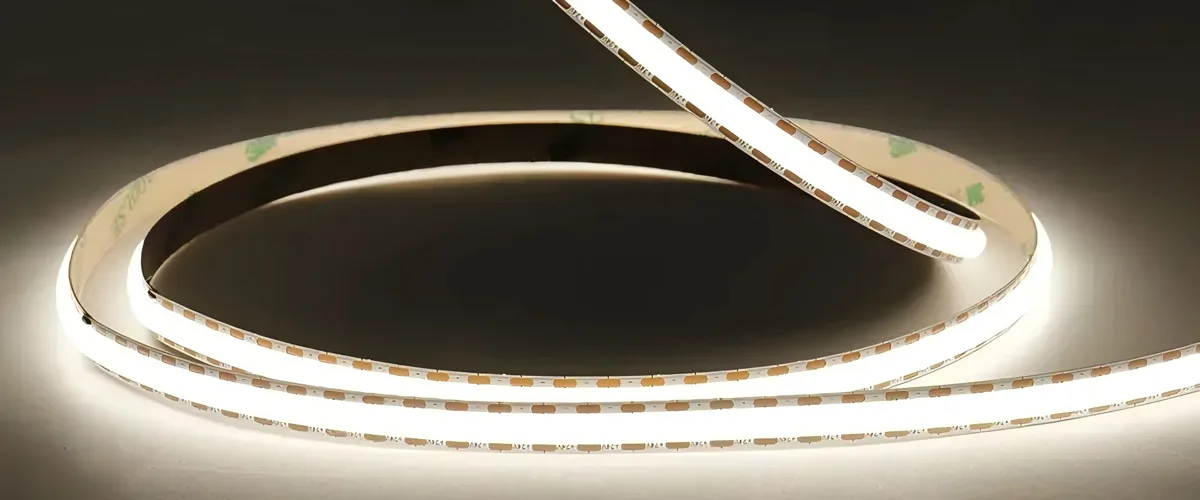

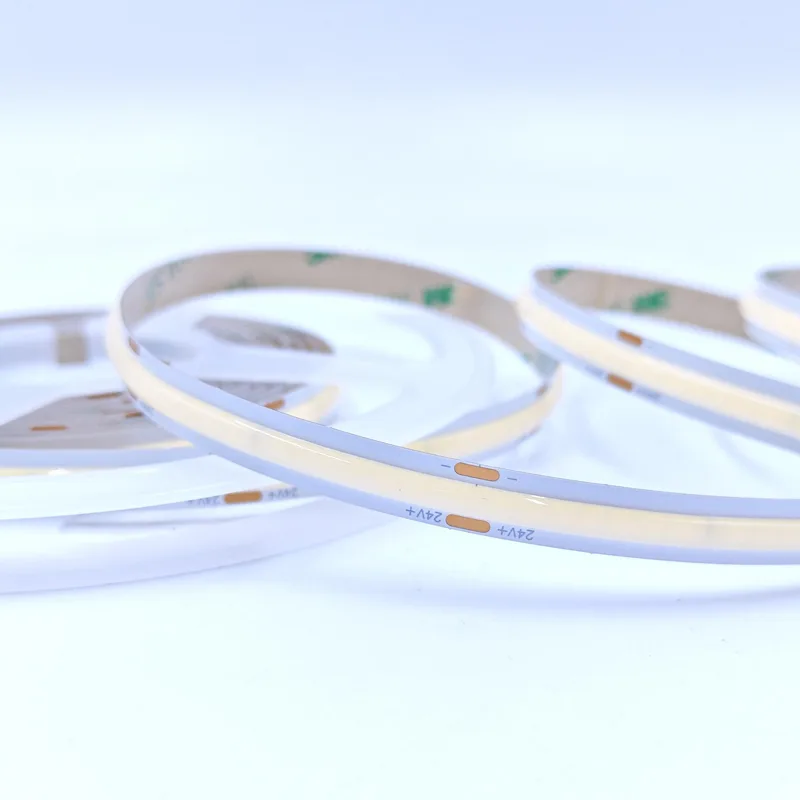

แถบ LED COB ใช้อาร์เรย์ชิป LED ความหนาแน่นสูง รวมชิป LED เข้ากับแผงวงจรเดียวเพื่อสร้างแสงที่ราบรื่นอย่างต่อเนื่อง วิธีนี้ช่วยขจัดเอฟเฟกต์ "ขาดๆ หายๆ" ที่พบได้ทั่วไปในแถบ LED อื่นๆ ให้แหล่งกำเนิดแสงที่แม่นยำและสม่ำเสมอยิ่งขึ้น ชิปถูกยึดติดกับแผงวงจรโดยตรง ทำให้เกิดการกระจายความร้อนที่ดีขึ้นและประสิทธิภาพที่สูงขึ้น อ่านบล็อก “เรียนรู้เพิ่มเติมเกี่ยวกับ COB LED Strips” สำหรับรายละเอียดเพิ่มเติม

คุณสมบัติหลักของแถบ LED COB:

- กระจายแสงได้สม่ำเสมอยิ่งขึ้น

- เอาต์พุตความสว่างสูงพร้อมการใช้พลังงานที่ลดลง

- การแสดงสีที่ยอดเยี่ยมเพื่อการสร้างสีที่ถูกต้อง

- การสร้างความร้อนน้อยที่สุดช่วยยืดอายุการใช้งาน

- กระบวนการผลิตที่คล่องตัว—ส่วนประกอบที่น้อยลงหมายถึงความทนทาน ความน่าเชื่อถือ และความคุ้มค่าที่มากขึ้น

- เหมาะอย่างยิ่งสำหรับพื้นที่ที่ต้องการแสงสม่ำเสมอ เช่น ไฟใต้ตู้ พื้นที่ทำงาน หรือแสงทางอ้อมในห้องนั่งเล่นและสำนักงาน

CSP คืออะไร (ซ.อก สคะน้า พีแอคเคจ) แถบ LED?

CSP หรือแพ็คเกจชั่งชิป หมายถึงขนาดบรรจุภัณฑ์ LED ที่เทียบเท่ากับชิป LED (หรือไม่เกิน 20% ที่ใหญ่กว่า) ผลิตภัณฑ์ CSP ใช้ส่วนประกอบแบบบูรณาการโดยไม่มีการยึดติดลวด ซึ่งจะช่วยลดความต้านทานความร้อน ลดเส้นทางการถ่ายเทความร้อน และลดจุดล้มเหลวที่อาจเกิดขึ้น

แถบ LED CSP คล้ายกับแถบ SMD แบบดั้งเดิม แต่ใช้ LED CSP ที่ติดตั้งบน PCB ที่ยืดหยุ่นและปิดด้วยกาวเรืองแสงกึ่งโปร่งใส แถบ LED CSP ให้ความยืดหยุ่นและประสิทธิภาพสูง ทำให้ได้เปรียบเป็นพิเศษสำหรับการติดตั้งที่ซับซ้อนหรือแคบกว่า

คุณสมบัติหลักของแถบ LED CSP:

- ชิปที่มีขนาดเล็กลงช่วยให้สามารถออกแบบได้มีความยืดหยุ่นและกะทัดรัดมากขึ้น

- ประสิทธิภาพและความสว่างที่สูงขึ้นเนื่องจากบรรจุภัณฑ์ที่ลดลง

- ขนาดกะทัดรัดช่วยเพิ่มการกระจายความร้อนและยืดอายุการใช้งาน

- เหมาะอย่างยิ่งสำหรับการออกแบบแสงที่ซับซ้อนด้วยพื้นที่จำกัด

- เหมาะอย่างยิ่งสำหรับแสงกลางแจ้งและสถานที่ที่มีมุมแคบหรือเลย์เอาต์ที่ซับซ้อน

ไฟ LED STRIB SCob (ชิปสเตอริโอสโคปบนบอร์ด) คืออะไร?

ไฟแถบ LED SCob หรือชิปสามมิติบนกระดานแสดงถึงเทคโนโลยีไฟ LED แถบล่าสุดที่ผสมผสานเทคโนโลยี Surface Mount (SMT) เข้ากับนวัตกรรม COB (ชิปบนบอร์ด) เพื่อสร้างแสงแถบ LED แบบไฮบริด

แถบ LED SCob เชื่อมชิป SMD ขนาดเล็ก (เช่น SMD2216/2110/1612) เข้ากับ PCB ผสมผสานความทนทานของ SMT เข้ากับลักษณะแสงที่ไร้รอยต่อของ COB ได้อย่างราบรื่น แถบ LED SCob มีชื่อเสียงในด้านประสิทธิภาพการส่องสว่างสูงและแสงที่สม่ำเสมอ ทำให้โดดเด่นทั้งในด้านประสิทธิภาพแสงและประสิทธิภาพการใช้พลังงาน

อย่างไรก็ตาม แถบ Scob นี้ยังมีข้อเสียอยู่บ้าง ดังนั้น Signliteled จึงได้แนะนำแถบ Scob LED โดยใช้กระบวนการที่คล้ายกับแถบซัง กระบวนการนี้เหมือนกับแถบ COB: ชิป LED ความหนาแน่นสูงถูกรวมเข้ากับ PCB เดียวก่อน ตามด้วยการใช้ชั้นของกาวฟอสเฟอร์ และสุดท้ายมีการใช้ซิลิโคนสีขาวใสกึ่งโปร่งใสเพื่อสร้างชั้นป้องกัน ข้อดีของกระบวนการ SCob นี้คือการผสมผสานลักษณะการปล่อยแสงที่ราบรื่นและสม่ำเสมอของ COB เข้ากับความยืดหยุ่นของเทคโนโลยี SMD

คุณสมบัติหลักของแถบ LED SCob:

- ให้แสงสว่างขณะใช้ไฟฟ้าน้อย

- ให้แสงที่นุ่มนวลและสม่ำเสมอ หลีกเลี่ยงจุดด่างดำหรือจุดสว่างที่อาจเกิดขึ้น

- ห่อหุ้มด้วยกาวสีขาวนมช่วยให้สามารถรวมเข้ากับการออกแบบใด ๆ ได้อย่างราบรื่น

- ใช้เทคโนโลยี SMD และการออกแบบขายึดเพื่อความต้านทานการดัดและพับที่เหนือกว่า

- เหมาะสำหรับการใช้งานในเชิงพาณิชย์ อุตสาหกรรม หรือกลางแจ้ง

แถบไฟ LED SOB คืออะไร?

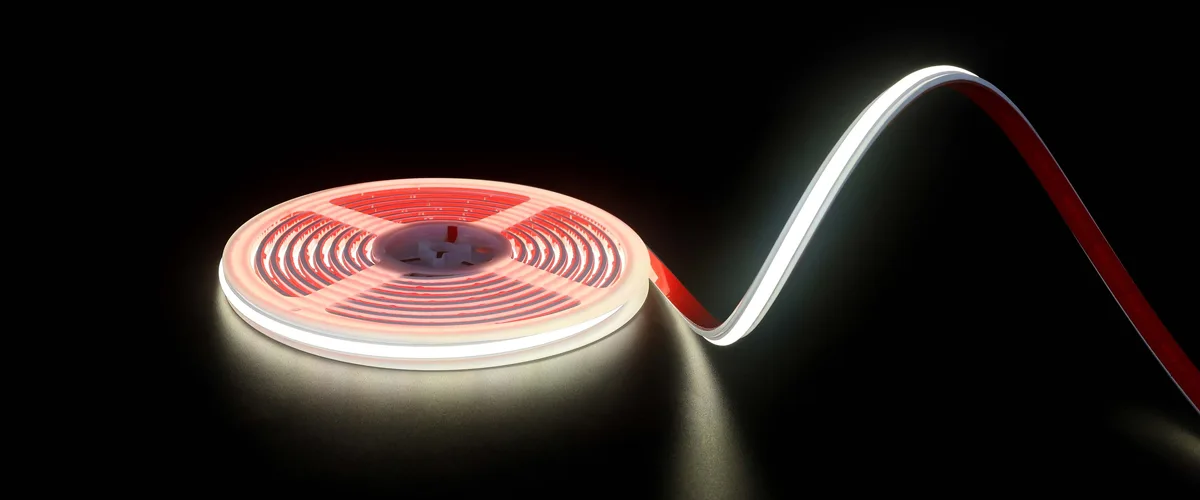

แถบไฟ LED SOB คล้ายกับแถบไฟนีออน LED ที่มีการออกแบบที่บางเฉียบและยืดหยุ่นโดยไม่มีจุดแสงที่มองเห็นได้ ทำจากประสิทธิภาพสูง แถบ LED SMD และซิลิโคนที่ขึ้นรูปเป็นชุดเดียวพร้อมฝาปิดแบบมืออาชีพทำให้มั่นใจได้ว่าโครงสร้างที่ทนทานมีความทนทานมากขึ้นทนต่อการดัดงอและมีแนวโน้มที่จะแตกหักน้อยลงและมีความยืดหยุ่นสูง แถบเหล่านี้มาพร้อมกับแผ่นรองกาวช่วยให้ติดตั้งบนพื้นผิวต่างๆ ได้ง่าย รวมถึงผนัง เพดาน เฟอร์นิเจอร์ และยานพาหนะ แถบไฟ LED SOB มีหลายสีและความสว่าง และสามารถปรับแต่งให้เหมาะกับโครงการหรือการออกแบบใดๆ

แถบไฟ LED SOB มีการออกแบบขั้นสูงที่ให้แสงสว่างที่เสถียร ประหยัดพลังงาน และอายุการใช้งานที่ยาวนาน ไม่ว่าจะเป็นระบบไฟสำหรับที่อยู่อาศัย พื้นที่เชิงพาณิชย์ หรือโครงการแสงกลางแจ้ง แถบไฟเหล่านี้มีโซลูชันที่เชื่อถือได้และมีสไตล์เพื่อตอบสนองความต้องการด้านแสง

คุณสมบัติหลักของแถบไฟ LED SOB:

- ให้แสงที่ราบรื่นและสม่ำเสมอเหมือนแถบไฟ LED COB

- ปราศจากแสงจ้าพร้อมความสม่ำเสมอของสีสูง การควบคุมความสว่างทำได้เมื่อจับคู่กับคอนโทรลเลอร์

- ตัวเรือนทำจากยางซิลิโคนที่ทำจากไอระเหยสูง ให้ความยืดหยุ่นและความสามารถในการขึ้นรูปได้ดีเยี่ยม

- แถบแสง SMD ใช้เทคโนโลยีการอัดรีดซิลิโคน ให้ประสิทธิภาพการปิดผนึกที่เหนือกว่า (กันน้ำ IP67)

- เหมาะอย่างยิ่งสำหรับไฟใต้ตู้ในห้องครัว แสงสว่างในสภาพแวดล้อมที่ชื้น และโครงการแสงสว่างกลางแจ้ง

การเปรียบเทียบไฟ COB, CSP, SCob และ SOB LED Strip

วิธีการบรรจุภัณฑ์ที่แตกต่างกันจะกำหนดประสิทธิภาพของไฟแถบ LED โดยตรงในแง่ของประสิทธิภาพการส่องสว่าง ความสม่ำเสมอ ความสามารถในการกระจายความร้อน และความเข้ากันได้ในการติดตั้ง ตารางต่อไปนี้จะเปรียบเทียบพารามิเตอร์ของเทคโนโลยีไฟ LED สี่แถบสำหรับการอ้างอิงของคุณในระหว่างการเลือกโครงการ

| วง | ซังนำ สการเดินทาง | นำ CSP สการเดินทาง | สก๊อบนำ สการเดินทาง | SOB LED สการเดินทาง |

| เทคโนโลยี | ชิป LED บนบอร์ด PCB | ไฟ LED CSP บนบอร์ด PCB | ไฟ LED SMD บนบอร์ด PCB | แถบ LED SMD ในตัวเรือนซิลิโคน |

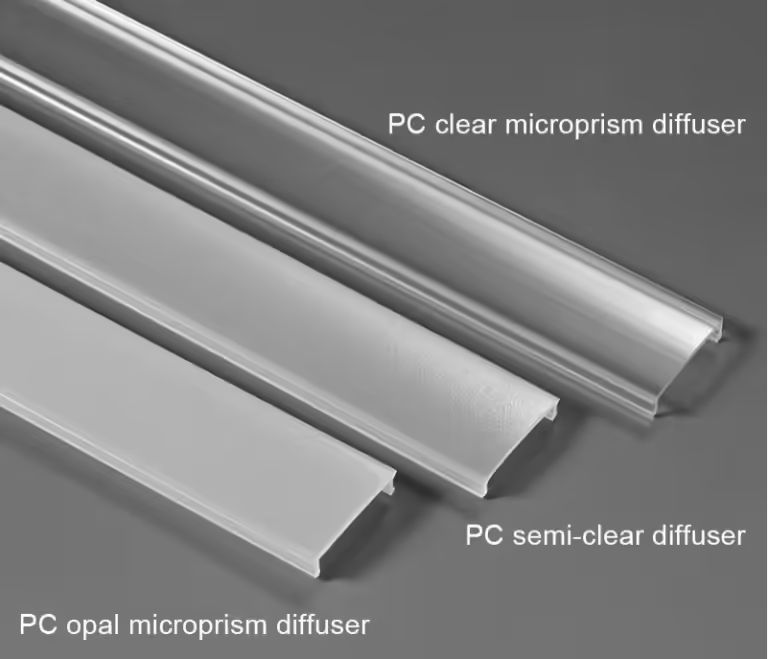

| รูปโฉม | ขาวดำและสีคู่เป็นซิลิโคนสีเหลือง ในขณะที่ RGB หลายสีเป็นซิลิโคนสีขาวนวล | พื้นผิวซิลิโคนสีขาวใสหรือน้ำนม | พื้นผิวซิลิโคนสีขาวนม | ตัวเรือนซิลิโคนสีขาวนวล พื้นผิวโปร่งแสง คล้ายกับแถบนีออน |

| ผิว ความอดกลั้น | sdcm≥3 | sdcm≤3 | sdcm≤3 | sdcm≤3 |

| ผิว อาร์ที่สิ้นสุด ฉันกสุนี | CRI>90 | CRI 80-90 ไม่จำเป็น | CRI 80-90 ไม่จำเป็น | CRI 80-90 ไม่จำเป็น |

| มุมลำแสง | 180° | 165 °-180 ° | 140 °-180 ° | 120 °-180 ° |

| ประสิทธิภาพแสง | 110-140lm/w | 90-110lm/w | 110-140lm/w | 60-85LM/W |

| ความสม่ำเสมอของแสง | การปล่อยแสงต่อเนื่องโดยไม่มีจุดไฟส่องสว่าง | การปล่อยแสงต่อเนื่องโดยไม่มีจุดไฟส่องสว่าง | การปล่อยแสงต่อเนื่องโดยไม่มีจุดไฟส่องสว่าง | การปล่อยแสงต่อเนื่องโดยไม่มีจุดไฟส่องสว่าง |

| การจัดการความร้อน | ดีกว่า | มกุฎ | สายกลาง | สายกลาง |

| ดิ้นได้ | โดยทั่วไป | มกุฎ | รสเด็ด | รสเด็ด |

| ระดับต้นทุน | USD$0.72-4.24/เมตร | USD$5-10/เมตร | USD$1.57-7.15/เมตร | USD$0.98-1.19/เมตร |

| การใช้งาน | ตกแต่งบ้าน ไฟตู้ ไฟกระจก แสงอ่อนๆ สำหรับร้านค้า | แสงไฟอุตสาหกรรม ไฟป้าย ไฟแบ็คไลท์กล่องไฟ | อาคารอาคาร กันซึมกลางแจ้ง โครงการวิศวกรรมที่กำหนดเอง | ไฟบ้าน พื้นที่เชิงพาณิชย์ แสงกลางแจ้ง |

ดังแสดงในตาราง หากโครงการของคุณจัดลำดับความสำคัญของความสม่ำเสมอของแสงและการติดตั้งที่ยืดหยุ่น แถบไฟ COB หรือ SCob เป็นทางเลือกที่ดีกว่า หากคุณจัดลำดับความสำคัญของขนาดและประสิทธิภาพการกระจายความร้อน แถบไฟ CSP จะเหมาะสมกว่า แถบไฟ SCOB และ SOB ช่วยเพิ่มความสามารถในการบำรุงรักษาและความเข้ากันได้ของโครงการเหนือแถบไฟ COB ซึ่งแสดงถึงแนวโน้มใหม่ในแถบไฟ LED เกรดวิศวกรรม

เทคโนโลยีบรรจุภัณฑ์แบบแถบแสง LED สี่ประเภท ได้แก่ COB, CSP, SCOB และ SOB แต่ละประเภทแสดงถึงการแสวงหาประสิทธิภาพการส่องสว่างที่แตกต่างกัน ตรรกะการออกแบบโครงสร้าง และการวางแนวสถานการณ์การใช้งาน แม้ว่าทั้งสี่จะสามารถตัดได้ รองรับการควบคุม RGB และใช้กันอย่างแพร่หลายในไฟตกแต่ง ไฟเชิงพาณิชย์ และโครงการแสงทางสถาปัตยกรรม แต่ก็ยังมีความแตกต่างอย่างมีนัยสำคัญในด้านประสิทธิภาพ ประสบการณ์ผู้ใช้ และความสามารถในการปรับตัวทางวิศวกรรม

แถบไฟ LED COB: การกระจายแสงที่สม่ำเสมอที่สุดและคุ้มค่าที่สุด

แถบไฟ LED ซัง ให้แสงที่ราบรื่นและปราศจากเกรนอย่างแท้จริงด้วยโครงสร้างกาวที่ต่อเนื่องกัน ทำให้เป็นแถบแสงที่มีความสม่ำเสมอของแสงที่ดีที่สุดในตลาดในปัจจุบัน หลังจากหลายปีของความก้าวหน้าทางเทคโนโลยี ประสิทธิภาพการส่องสว่างของแถบไฟ COB ได้ปรับปรุงอย่างมีนัยสำคัญเป็น 110–140 lm/w และยังคงให้เอาต์พุตความสว่างที่ดีแม้ใน CRI สูง (90 RA)

ข้อได้เปรียบหลัก ได้แก่ ความต่อเนื่องของแสงที่แข็งแกร่ง ไม่มีฮอตสปอต และความสบายในการมองเห็นสูง ทำให้เหมาะสำหรับการติดตั้งพื้นผิวในร่ม ถาดวางสายเคเบิล ไฟกระจก ไฟแสดงนิทรรศการ และการใช้งานอื่นๆ อย่างไรก็ตามพวกเขายังมีข้อ จำกัด ทางเทคนิคบางอย่างเช่น

- เนื่องจากชั้นกาวเรืองแสงหนาอาจเกิดการแตกร้าวหรือเศษ LED เมื่องอในมุมขนาดใหญ่

- การปรับอุณหภูมิสีและ CRI จำเป็นต้องปรับอัตราส่วนกาวเรืองแสงใหม่ ทำให้การปรับแต่งมีความท้าทาย

แถบ LED COB เหมาะสำหรับสภาพแวดล้อมแสงที่มีความต้องการสูงเพื่อความสม่ำเสมอของแสงและความสบายในการมองเห็น

แถบ LED CSP: ค่าใช้จ่ายสูงสุด แต่ประสิทธิภาพแสงต่ำสุด

แถบ LED CSP ใช้บรรจุภัณฑ์แบบชิปเปล่าเพื่อขจัดบรรจุภัณฑ์แบบดั้งเดิม ในทางทฤษฎี ส่งผลให้เส้นทางการกระจายความร้อนสั้นลงและประสิทธิภาพบรรจุภัณฑ์ที่สูงขึ้น ทำให้เหมาะสำหรับโมดูลแหล่งกำเนิดแสงที่มีกำลังสูง อย่างไรก็ตามประสิทธิภาพที่แท้จริงของพวกเขาในผลิตภัณฑ์สตริปนั้นค่อนข้างอนุรักษ์นิยม:

- ประสิทธิภาพแสงเฉลี่ยอยู่ที่ 90–110 lm/w ต่ำกว่าแถบซังกระแสหลักร่วมสมัย

- กระบวนการผลิตที่ซับซ้อนและอัตราผลตอบแทนต่ำส่งผลให้ต้นทุนต่อหน่วยโดยรวมสูงสุดในสามประเภท

แถบ LED CSP เหมาะสำหรับระบบไฟส่องสว่างหรือไฟแบ็คไลท์ในอุตสาหกรรมที่มีข้อกำหนดด้านพื้นที่โครงสร้างที่เข้มงวดอย่างยิ่งและความเข้ากันได้กับฝาครอบการแพร่กระจาย ไม่แนะนำสำหรับโครงการตกแต่งหรือภาพสูง

แถบ LED SCob: โซลูชันที่ครอบคลุมระดับวิศวกรรม แต่การกระจายความร้อนที่ด้อยกว่าเล็กน้อย

แถบ LED SCob เป็นโซลูชันเทคโนโลยีไฮบริดที่ใช้บรรจุภัณฑ์ชิป SMD รวมกับชั้นฝาครอบเจลซิลิโคนที่มีความโปร่งใสสูงเพื่อให้ได้รูปลักษณ์ที่เปล่งแสงอย่างต่อเนื่อง พวกเขารวมเอาเอฟเฟกต์ภาพของ COB เข้ากับความสะดวกในการบำรุงรักษาของโครงสร้าง SMD ซึ่งออกแบบมาโดยเฉพาะสำหรับสถานการณ์ทางวิศวกรรม (เช่น แสงกลางแจ้งขนาดใหญ่และการล้างส่วนหน้า)

ข้อดีของพวกเขามีความโดดเด่นอย่างมาก:

- การกระจายแสงที่สม่ำเสมอด้วยรูปลักษณ์สีขาวน้ำนม รักษาความงามระดับพรีเมียมก่อนและหลังการส่องสว่าง

- กระบวนการผลิตที่เสถียรเข้ากันได้กับสายการผลิต SMT แบบดั้งเดิมเหมาะสำหรับการปรับแต่ง OEM

- ปรับแต่งโมเดล LED ได้ง่ายเพื่อปรับ CRI และ CCT ได้อย่างรวดเร็ว

- รองรับ PCB หนา 3-5 ออนซ์ ช่วยเพิ่มการกระจายความร้อนและความทนทานอย่างมีนัยสำคัญ

อย่างไรก็ตาม Scob Strip ยังมีข้อ จำกัด :

- ใช้ชิป SMD + โครงสร้างซิลิโคนทำให้การกระจายความร้อนไม่ดีและเพิ่มความเสี่ยงต่อความเสียหายของ LED

- เนื่องจากการกระจายความร้อนไม่ดี ค่าอ่อนของลูเมนจึงเกิดขึ้นได้เร็วกว่า

โดยรวมแล้ว SCOB เป็นตัวเลือกในอุดมคติสำหรับโครงการวิศวกรรมขนาดกลางถึงขนาดใหญ่ที่มีข้อกำหนดที่ครอบคลุมสำหรับความสว่างสูง ติดตั้งง่าย แหล่งจ่ายไฟระยะไกล และความสวยงามของภาพ

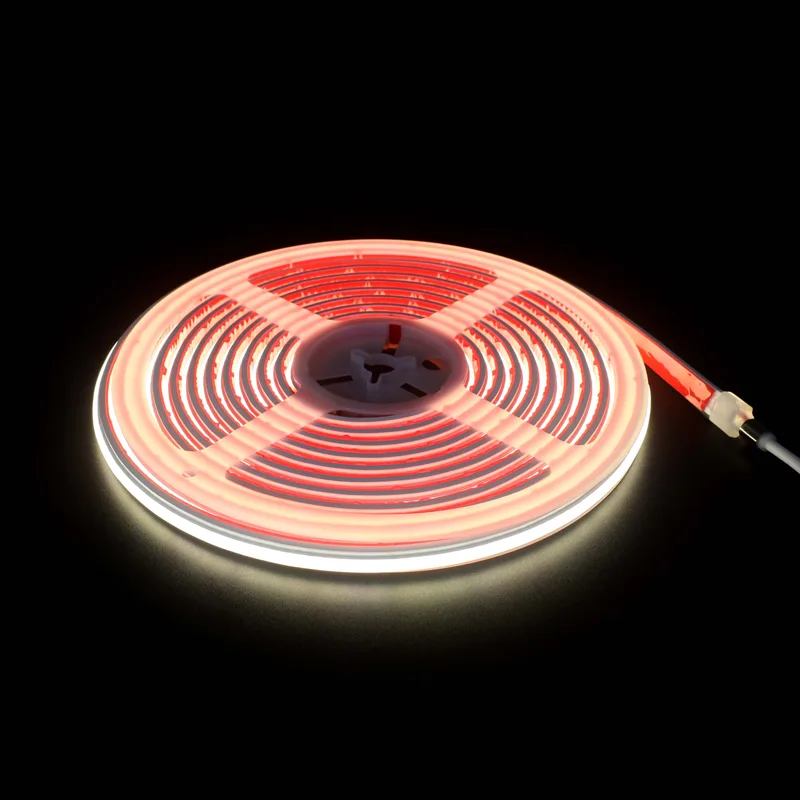

SOB LED Strips: รวมการกันน้ำและแสงต่อเนื่อง แต่ด้วยการกระจายความร้อนที่ จำกัด และประสิทธิภาพแสง

SOB LED Strips เป็นเทคโนโลยีบรรจุภัณฑ์แถบ LED ชนิดหนึ่งที่ใช้ซิลิโคนเจลสำหรับการขึ้นรูปการอัดรีดโดยรวม รวมกับโครงสร้างแสงที่ต่อเนื่องของแถบ LED COB ให้ความยืดหยุ่นที่ยอดเยี่ยมและมีความสม่ำเสมอสูงของการปล่อยแสง เมื่อเทียบกับแถบ LED COB แถบ LED SOB มีชั้นการแพร่กระจายที่สมบูรณ์ด้านนอก ขจัดจุดไฟได้อย่างมีประสิทธิภาพ และให้แสงที่นุ่มนวลและกระจาย

ข้อได้เปรียบหลักอยู่ที่การให้แสงสว่างอย่างต่อเนื่องและระดับการป้องกันสูง (IP67) ทำให้สามารถใช้ได้อย่างกว้างขวางในด้านแสงคอนทัวร์กลางแจ้ง การตกแต่งทางสถาปัตยกรรม กล่องไฟรูป 3 มิติ และสถานการณ์อื่นๆ ที่มีข้อกำหนดพิเศษสำหรับรูปแบบและการป้องกัน

อย่างไรก็ตามแถบ LED SOB ยังมีข้อ จำกัด ทางเทคนิคดังต่อไปนี้:

- การสะสมความร้อนอย่างรุนแรง: แม้ว่าโครงสร้างที่เคลือบด้วยซิลิโคนจะให้การปิดผนึก แต่ก็ยับยั้งการกระจายความร้อน ซึ่งอาจเร่งการสลายตัวของแสง

- ประสิทธิภาพการส่องสว่างต่ำ: ประสิทธิภาพการส่องสว่างของแถบ LED SOB LED กระแสหลักในปัจจุบันมีตั้งแต่ 60–90 lm/w ซึ่งต่ำกว่าผลิตภัณฑ์ COB ที่เปรียบเทียบกันได้อย่างมีนัยสำคัญ

แถบ LED SOB เหมาะสำหรับโครงการไฟประดับระดับกลางถึงล่างที่จัดลำดับความสำคัญของการผสมผสานด้านสุนทรียศาสตร์และประสิทธิภาพการกันน้ำ/กันฝน แต่ไม่แนะนำสำหรับการใช้งานที่มีความต้องการสูงสำหรับประสิทธิภาพการส่องสว่างและการกระจายความร้อน

เมื่อใดควรเลือกไฟแถบ COB, CSP, SCob หรือ SOB LED

ในการออกแบบโครงการแสง การเลือกไฟแถบ LED ไม่ได้ถูกกำหนดโดยพารามิเตอร์แหล่งกำเนิดแสงเท่านั้น แต่ยังมีความเกี่ยวข้องอย่างใกล้ชิดกับข้อกำหนดเฉพาะของสถานการณ์การใช้งาน ต่อไปนี้เป็นคำแนะนำการใช้งานทั่วไปตามคำแนะนำการใช้งานแถบ LED สี่ประเภท ได้แก่ COB, CSP, SCob และ SOB เพื่อช่วยให้คุณจับคู่โซลูชันผลิตภัณฑ์ที่เหมาะสมที่สุดได้อย่างรวดเร็ว

การใช้งานที่ดีที่สุดสำหรับไฟ LED แถบ LED

- แสงสว่างสำหรับที่อยู่อาศัย: เหมาะสำหรับแสงรอบข้างในห้องนั่งเล่น ห้องนอน และห้องครัว

- จอแสดงผลขายปลีก: การกระจายแสงที่สม่ำเสมอทำให้แถบไฟซังเป็นตัวเลือกที่เหมาะสำหรับการแสดงผลิตภัณฑ์หรือแสงในการจัดเก็บ

- พื้นที่ทำงาน: แสงที่ราบรื่นและต่อเนื่องช่วยลดอาการปวดตา ทำให้เป็นตัวเลือกที่เหมาะสำหรับโฮมออฟฟิศหรือที่ทำงาน

ใช้ดีที่สุดสำหรับแถบไฟ LED CSP

- แสงกลางแจ้ง: แถบไฟ CSP มีขนาดกะทัดรัดและทรงพลัง ทำให้เหมาะสำหรับลานเฉลียง ดาดฟ้า และสวน

- แสงสำเนียงสถาปัตยกรรม: แถบไฟ CSP มีความยืดหยุ่นและสามารถโค้งงอได้ง่ายเพื่อให้เข้ากับมุม ทำให้เหมาะอย่างยิ่งสำหรับการเน้นคุณสมบัติการออกแบบที่ซับซ้อน

- การติดตั้งแบบกำหนดเอง: ความยืดหยุ่นของ CSP ทำให้เหมาะสำหรับผู้ที่ชื่นชอบ DIY ที่กำลังมองหาโซลูชันแสงที่ไม่เหมือนใครในพื้นที่แคบ

ใช้ดีที่สุดสำหรับแถบไฟ LED SCob

- แสงซุ้มสถาปัตยกรรม: การสร้างแสงโครงร่าง การล้างผนังด้านหน้าภายนอก และแสงพื้นผิวโค้งของสะพาน

- แสงระยะยาว: โครงการวิศวกรรมที่ต้องการการติดตั้งอย่างต่อเนื่องในระยะทางไกลพร้อมการบำรุงรักษา

- โครงการวิศวกรรมที่กำหนดเอง: สถานการณ์ที่มีข้อกำหนดสองประการสำหรับความต่อเนื่องของความสว่าง สุนทรียศาสตร์ และการบำรุงรักษาหลังการติดตั้ง

ใช้ดีที่สุดสำหรับแถบไฟ LED SOB

- ไฟใต้ตู้: เคาน์เตอร์ครัวส่องสว่างเพื่อเพิ่มการมองเห็นและความสวยงามที่ทันสมัย

- ไฟแสดงผล: ดึงดูดความสนใจไปยังผลิตภัณฑ์และรายการส่งเสริมการขายในจอแสดงผลขายปลีก

- ถนนและทางเท้า: ส่องสว่างทางเดินกลางแจ้งเพื่อความปลอดภัยและบรรยากาศ

- ดาดฟ้าและลานเฉลียง: สร้างพื้นที่นั่งเล่นกลางแจ้งแสนสบายพร้อมไฟประดับที่ส่องประกายระยิบระยับ

คำแนะนำผลิตภัณฑ์ที่มีสัญญาณ: COB/SCOB/SOB แถบไฟ LED

เพื่อตอบสนองความต้องการที่หลากหลายของโครงการแสงสว่างที่แตกต่างกันในแง่ของประสิทธิภาพการส่องสว่างโครงสร้างและการบำรุงรักษา Signlited นำเสนอโซลูชั่นแถบไฟ LED COB, SCob และ SOB ที่ครอบคลุมซึ่งรองรับความยาวที่กำหนดเองแรงดันไฟฟ้า CRI, CRI, การให้คะแนนการป้องกัน IP และการรวมเข้ากับระบบควบคุมอัจฉริยะ (เช่น DALI, DMX, 0-10V เป็นต้น)

ขายร้อน Signliteled – ไฟ LED Strip แบบโมโน

รุ่นหลัก: FYX08T480C

ปริมาณชิป LED ต่อเมตร: 320/384/480/528

ศูนย์วิจัยกฤษณ์เคมี: >90

ความกว้างของแผงวงจร: 8 มม./10 มม.

อุณหภูมิสี: 2700K/3000K/4000K/6500K

แรงดันไฟฟ้าขาเข้า: DC12V/DC24V

กำลังไฟฟ้าต่อเมตร: 8W/10W/11W/14W

ประสิทธิภาพ: 110–140lm/w

เกรด IP: IP20/IP54/IP65/IP67/IP68

การรับประกัน: 3 ปี

ผลิตภัณฑ์ใหม่ที่มีป้ายกำกับ - ไฟแถบ LED SCob

รุ่นหลัก: FSX08T320C/FSX08T480C

ปริมาณชิป LED ต่อเมตร: 320/480

ศูนย์วิจัยกฤษณ์เคมี: >90

ความกว้างของแผงวงจร: 8mm

อุณหภูมิสี: 2700K/3000K/4000K/6500K

แรงดันไฟฟ้าขาเข้า: DC12V/DC24V

กำลังไฟฟ้าต่อเมตร: 10W/12W

ประสิทธิภาพ: >125lm/w

เกรด IP: IP20/IP65

การรับประกัน: 3 ปี

ผลิตภัณฑ์ใหม่ที่มีป้ายกำกับ - IP67 SOB LED Strip Light

รุ่นหลัก: อีคิว 10T240C

ปริมาณชิป LED ต่อเมตร: 240

ศูนย์วิจัยกฤษณ์เคมี: 80/90

ความกว้างของแผงวงจร: 8mm

อุณหภูมิสี: 2700K/3000K/4000K/6500K

แรงดันไฟฟ้าขาเข้า: DC24V

กำลังไฟฟ้าต่อเมตร: 11W

ประสิทธิภาพ: 61-80lm/w

เกรด IP: ip67

การรับประกัน: 3 ปี

บทสรุป

เทคโนโลยีแถบ LED สี่รายการ ได้แก่ COB, CSP, SCob และ SOB แต่ละรายการมีข้อดีของตัวเอง การเลือกทางวิทยาศาสตร์ตามข้อกำหนดด้านแสงเฉพาะและสภาพแวดล้อมของแอปพลิเคชันเป็นสิ่งสำคัญ

ไฟแถบ LED COB พร้อมเอฟเฟกต์แสงที่นุ่มนวลอย่างต่อเนื่องและต่อเนื่อง เหมาะอย่างยิ่งสำหรับการตกแต่งในร่มที่มีการจัดลำดับความสำคัญของแสงที่สม่ำเสมอและความสบายในการมองเห็น ไฟแถบ LED CSP พร้อมการกระจายความร้อนที่มีประสิทธิภาพและความยืดหยุ่นที่ยอดเยี่ยม ตอบสนองความต้องการระดับมืออาชีพของการใช้งานแบ็คไลท์ที่มีความสว่างสูงในอุตสาหกรรม ไฟแถบ LED SCob ผสมผสานข้อดีของทั้งสองอย่าง ให้ความสะดวกสบายในการบำรุงรักษาและความยืดหยุ่นในโครงการวิศวกรรมมากขึ้น แถบ LED SOB เป็นโครงสร้างที่เกิดขึ้นใหม่ในช่วงไม่กี่ปีที่ผ่านมาใช้กระบวนการอัดรีดเพื่อสร้างชั้นแสงที่ยืดหยุ่นได้ซึ่งให้เอฟเฟกต์แสงต่อเนื่องเหมือน COB ในขณะที่มีระดับการป้องกันที่สูงขึ้นทำให้เหมาะอย่างยิ่งสำหรับแสงคอนทัวร์กลางแจ้งและการใช้งานที่มีความต้องการกันน้ำสูง

ในฐานะผู้จัดจำหน่ายโซลูชั่น LED Strip อย่างมืออาชีพ SignLiteled มุ่งมั่นที่จะจัดหาคุณภาพสูงให้คุณ ไฟ LED แถบที่กำหนดเอง เพื่อช่วยให้โครงการของคุณบรรลุผลแสงที่เหมาะสมและประสิทธิภาพที่เชื่อถือได้ ติดต่อเราวันนี้เพื่อรับการสนับสนุนด้านเทคนิคอย่างมืออาชีพและโซลูชันตัวอย่างที่ปรับแต่งได้ และเริ่มต้นการเดินทางสู่แสงที่ยอดเยี่ยม!