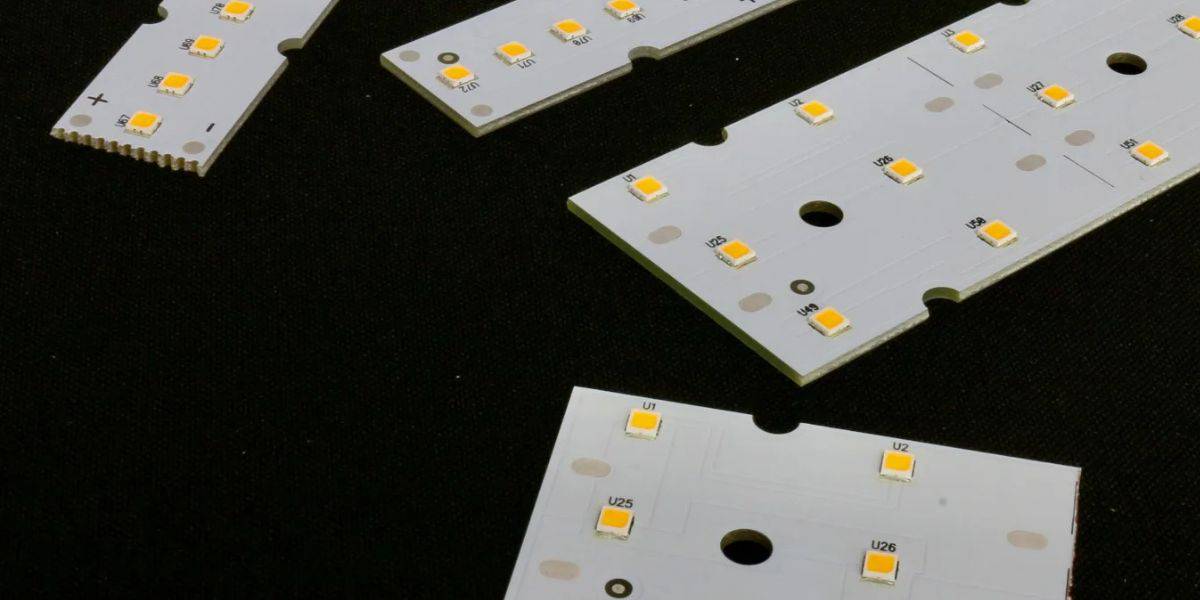

Güvenilir bir LED PCB SMT montaj ortağı, LED'leri sürekli olarak yüksek doğrulukla yerleştirebilen, pano seviyesinde ısıyı yönetebilen ve prototipler ve üretim çalışmaları arasında tekrarlanabilir sonuçlar sunabilen bir iş ortağıdır. LED PCB montajı, standart SMT'den daha karmaşıktır, çünkü küçük yerleştirme hataları, termal yanlış yönetim veya bileşen varyasyonu, ışık çıkışını ve ömrünü doğrudan azaltabilir. Bu bağlamda güvenilirlik, yalnızca hız veya fiyattan ziyade süreç kontrolü, öngörülebilir kalite ve karar şeffaflığı anlamına gelir.

Bir LED PCB SMT Montaj Ortağını Değerlendirmek İçin 10 Anahtar Soru

1 — LED PCB ve metal çekirdekli panolarla ilgili nasıl bir deneyime sahipsiniz?

LED PCB'lerle doğrudan deneyim önemlidir, çünkü LED düzenekleri ısı ve akım stresi altında farklı davranır. Alüminyum ve diğer metal çekirdekli levhalara aşina olan bir ortak, yerleşimin, lehim profillerinin ve işlemenin termal yolları nasıl etkilediğini anlar. Bu deneyim olmadan, yetenekli bir özel PCB üreticisi bile, erken arızalara veya tutarsız optik performansa yol açan LED'e özgü riskleri hafife alabilir.

2 — LED yerleştirme doğruluğu için hangi SMT ekipmanını kullanıyorsunuz?

LED güvenilirliği, özellikle yüksek yoğunluklu diziler ve doğrusal modüller için hassas yerleşim ve yönlendirmeye bağlıdır. Doğru SMT ekipmanı, tutarlı hizalama, lehim hacmi kontrolü ve minimum yeniden işleme sağlar. Bu soru, özel bir PCB üreticisinin yerleşim doğruluğunu ölçekte sürdürüp sürdürmeyeceğini veya kalitenin partiler arasında değişip değişmeyeceğini ve saha arıza riskini artırıp artırmayacağını değerlendirmenize yardımcı olur.

3 — LED PCB montajı sırasında termal performansı nasıl yönetirsiniz?

Termal yönetim, LED ömrü ve renk kararlılığı için merkezi bir konumdadır. Güvenilir bir ortak, lehimleme, bileşen eki ve montaj sonrası işleme sırasında ısıyı dikkate alır. Bu soru, termal kontrolün sistem düzeyinde bir endişe olarak mı yoksa sonradan düşünülmüş bir düşünce olarak mı ele alındığını ortaya koymaktadır. Montaj sırasındaki zayıf termal uygulamalar, iyi tasarlanmış bir PCB özel düzenini bile reddedebilir.

4 — Hangi muayene ve kalite kontrol süreçlerini uyguluyorsunuz?

Muayene sadece bariz kusurları tespit etmekle ilgili değil, zaman içinde LED performansını etkileyen ince sorunları yakalamakla da ilgilidir. Tutarlı kalite kontrol, lehim boşluklarından veya yanlış hizalamadan kaynaklanan gizli arızaları önlemeye yardımcı olur. Bu soru, özellikle görev açısından kritik aydınlatma sistemleri için özel PCB montajını değerlendirirken, ortakları vaatlerden ziyade süreç disiplinine göre karşılaştırmanıza yardımcı olur.

5 — LED gruplama ve bileşen tutarlılığı nasıl ele alınır?

LED Binning parlaklığı, renk sıcaklığını ve görsel tekdüzeliği etkiler. Güvenilir bir ortak, bileşen varyasyonunu yönetmek ve tek bir pano içinde ve üretim alanları arasında tutarlılığı korumak için süreçlere sahiptir. Bu soru, görsel farklılıkların kabul edilemez olduğu ve tutarsız kaynak bulmanın aksi takdirde sağlam bir montaj sürecini baltalayabileceği uygulamalar için gereklidir.

6 — Hem prototip oluşturmayı hem de hacim üretimini destekleyebilir misiniz?

Partnerleri değiştirmeden prototipten hacme geçme yeteneği, riski ve yanlış iletişimi azaltır. Bu soru, aynı standartların ve kontrollerin farklı ölçeklerde uygulanıp uygulanmadığını değerlendirir. Öncü projeler için, erken yapılar ve seri üretim arasındaki tutarsızlıklar, genellikle prototipleme ve hacmi ilgisiz süreçler olarak ele alan ortaklara kadar uzanır.

7 — Tipik teslim süreniz ve zamanlama güvenilirliğiniz nedir?

Kurulum programlarına bağlı LED PCB projelerinde teslim süresi güvenilirliği, nominal hızdan daha önemlidir. Bu soru, bir ortağın kapasiteyi ne kadar iyi planladığını ve değişimi ne kadar iyi yönettiğini anlamanıza yardımcı olur. Kaçırılan programlar, deneyimli bir kişiyle çalışırken bile, LED performansını etkileyen aceleye getirilen kararları veya ikameleri zorlayabilir. özel PCB üreticisi.

8 — LED PCB projeleri için DFM geri bildirimini nasıl sağlarsınız?

Üretilebilirlik için tasarım, LED montajlarında kritiktir çünkü küçük yerleşim kararları ısı akışını ve yerleşim verimini etkiler. Güvenilir bir ortak, genel yorumlardan ziyade risk azaltmaya odaklanan net ve erken geri bildirimler sunar. Bu soru, DFM'nin bir karar aracı olarak mı kullanıldığını veya özel PCB montaj iş akışlarında bir formalite olarak mı ele alındığını gösterir.

9 — Tedarik zinciri ve bileşen tedarik risklerini nasıl yönetirsiniz?

LED bileşenler, ikamelere ve eksikliklere karşı hassastır. Güvenilir bir ortak, kaynak bulma, izlenebilirlik ve değişiklik bildirimi için süreçleri tanımlamıştır. Bu soru, tedarik kesintilerinin nasıl ele alındığını ve kararların PCB özel projelerinde performansı veya uyumluluğu etkilemeden önce bilgilendirilmenizi değerlendirmenize yardımcı olur.

10 — Ne tür iletişim, belge ve montaj sonrası destek sağlıyorsunuz?

Net iletişim, proje yaşam döngüsü boyunca riski azaltır. Bu soru, sorunların nasıl belgelendiğini, değişikliklerin nasıl onaylandığını ve montaj sonrası soruların nasıl ele alındığını değerlendirir. Güvenilir ortaklar, uzun vadeli LED sistem kararlılığı için kritik olan, sorunları tahmin etmeden teşhis etmenize yardımcı olan tutarlı kayıtlar ve destek sağlar.

Standart ve güvenilir LED PCB SMT montaj ortağının karşılaştırılması

| değerlendirme alanı | ortak | Güvenilir Ortak |

| LED PCB deneyimi | Genel SMT maruziyeti | Kanıtlanmış LED ve metal çekirdekli odak |

| Termal yönetim yeteneği | tasarımdan varsayıldı | Montaj sırasında aktif olarak yönetilen |

| Muayene Yöntemleri | Temel görsel kontroller | Süreç odaklı denetim stratejisi |

| prototipleme hızı | Hızlı ama tutarsız | Kontrollü ve tekrarlanabilir |

| üretim ölçeklenebilirliği | prototiplemeden ayrı | Tüm birimler arasında hizalanmış |

| DFM desteği | Genel veya geç | Erken, LED'e özgü geri bildirim |

| Tedarik zinciri taşıma | Reaktif kaynak kullanımı | Planlı ve şeffaf |

Bu soruların neden bir karar çerçevesi olarak işe yaradığı

Bu on soru, pazarlama iddialarından ziyade operasyonel gerçekliği ortaya çıkarmak için tasarlanmıştır. Her biri, küçük süreç boşluklarının büyük aşağı akış sorunlarına neden olabileceği LED PCB SMT montajına özgü bir risk alanına odaklanır. Yanıtları yan yana değerlendirmek, yalnızca ilk yapımlar sırasında değil, tüm ürün yaşam döngüsü boyunca önemli olan güvenilirlik göstergeleri konusunda ortakları karşılaştırmanıza olanak tanır.

Bu çerçevenin kullanılması, iç paydaşların hizalanmasına da yardımcı olur. Mühendislik ekipleri teknik riske odaklanabilirken, tedarik öngörülebilirliği ve iletişimi değerlendirebilir. Sonuç, öznel yargıyı ve kısa vadeli düşünmeyi azaltan karar verme için ortak bir temeldir.

Kaçınılması gereken yaygın değerlendirme hataları

Yaygın bir hata, deneyimli herhangi bir SMT sağlayıcısının LED PCB'ler için uygun olduğunu varsaymaktır. Bir diğeri, süreç kontrolünü anlamadan teklif edilen teslim süresine veya birim maliyetine öncelik vermektir. Bazı ekipler, bu araçların pratikte nasıl kullanıldığını sormadan ekipman listelerini de aşırı değer biçiyor. Bu tuzaklardan kaçınmak, disiplinli bir sorgulamayı ve kararların zaman içinde performansı nasıl etkilediğine odaklanmayı gerektirir.

LED PCB ve SMT montaj maliyeti yapısı

LED PCB SMT montajı için maliyet değerlendirmesi, öncelikle PCB sınıflandırmasına, temel malzemeye, katman sayısına, montaj karmaşıklığına ve üretim geri dönüş süresine bağlıdır. Genel SMT projelerinden farklı olarak, LED PCB montajları, hem üretim hem de montaj maliyetlerini doğrudan etkileyen ek termal ve yerleştirme doğruluğu kısıtlamaları getirir.

Aşağıdaki fiyatlandırma referansları, tedarikçi değerlendirmesi sırasında alıcılar tarafından yaygın olarak referans alınan PCB üretim platformlarından, çevrimiçi fiyatlandırma hesaplayıcılarından ve sektör kriterlerinden elde edilen halka açık verilere dayanmaktadır. Tüm değerler Yaklaşık referans aralıkları Resmi teklifler değil, bütçeleme, karşılaştırma ve erken tedarik planlaması için tasarlanmıştır.

PCB sınıflandırması ve tipik üretim maliyet aralıkları

| PCB Sınıflandırması | Tipik katman sayısı | taban malzemesi | Ortak LED Uygulamaları | Yaklaşık PCB üretim maliyeti (USD / birim, prototip hacimleri) |

| tek katmanlı PCB | 1 | Fr4 | Gösterge LED'leri, düşük güçlü aydınlatma | $1 – $5 |

| çift katmanlı PCB | 2 | Fr4 | Doğrusal LED panolar, kompakt armatürler | $3 – $10 |

| Alüminyum MCPCB | 1–2 | Alüminyum çekirdek | Yüksek güçlü LED aydınlatma, termal-kritik tasarımlar | $5 – $20 |

| 4 katmanlı PCB | 4 | FR4 (standart veya yüksek TG) | Yoğun LED kontrol ve sürücü panoları | $10 – $25 |

| HDi PCB | 4-6+ | FR4 / Yüksek TG | Kompakt, yüksek yoğunluklu LED modüller | $30 – $60+ |

Maliyet aralıkları, hızlandırılmış üretim, özel kaplamalar veya gelişmiş elektrik gereksinimleri olmadan standart özellikleri yansıtır.

LED PCB SMT montajı maliyet sürücüleri

LED PCB'ler için SMT montaj maliyeti, üretim sırasında makine süresini, muayene çabasını ve termal kontrolü etkileyen çeşitli işlem düzeyinde değişkenlerden etkilenir.

| Maliyet Sürücüsü | Tipik maliyet etkisi (USD / Board, prototip hacimleri) | açıklama |

| LED Yerleştirme Yoğunluğu | +$1.50 – $4.00 | Daha yüksek LED sayıları yerleştirme döngülerini, besleyici kullanımını ve inceleme süresini artırır |

| PCB Taban Malzemesi (MCPCB ve FR4) | +$2.00 – $6.00 | Alüminyum çekirdekli levhalar kontrollü termal profiller ve daha yavaş yeniden akış işlemleri gerektirir |

| LED Paket Boyutu (Küçük SMD Formatları) | +$1.00 – $3.00 | Daha küçük paketler daha sıkı yerleştirme toleransları ve doğrulama adımları gerektirir |

| LED Binning Kontrolü | +$0.50 – $2.00 | Parti ayırma, izleme ve işleme ek süreç ek yükü sunar |

| Muayene seviyesi (AOI ve manuel kontroller) | +$1.00 – $3.00 | Ek denetim aşamaları, işgücü ve ekipman kullanımını artırır |

Montaj maliyeti etkileri, yaygın olarak yayınlanan SMT fiyatlandırma modellerinden türetilen, pano başına gösterge niteliğindedir.

LED PCB projelerinde geri dönüş süresi ve maliyet etkisi

Üretim teslim süresi seçimi, özellikle sıkı termal ve yerleştirme kontrolü gerektiren projeler için, toplam LED PCB SMT montaj maliyeti üzerinde ölçülebilir bir etkiye sahiptir.

| Üretim geri dönüş süresi | Tipik maliyet artışı | Ortak kullanım durumu |

| Standart (10-15 iş günü) | temel çizgi | Planlanan üretim yapıları ve kalifikasyon çalışmaları |

| Hızlandırılmış (5-7 iş günü) | +20% ila +40% | Pilot üretim ve program odaklı programlar |

| Ekspres (24–72 saat) | +50% ila +100% | Acil değişimler veya zaman açısından kritik dağıtımlar |

Tedarik ve mühendislik ekipleri için maliyet yorumu

Bu maliyet referansları, tedarik ve mühendislik ekiplerinin, gerçekçi, sınıflandırmaya dayalı fiyatlandırma beklentilerini kullanarak LED PCB SMT montaj ortaklarını değerlendirmesine olanak tanır. PCB tipi, malzeme seçimi, montaj karmaşıklığı ve teslim süresinin toplam maliyeti nasıl etkilediğini anlayarak, alıcılar daha bilinçli kararlar verebilir ve uzun vadeli güvenilirlik ve üretim istikrarını hesaba katmadan yalnızca başlık fiyatlandırmasına dayalı seçimlerden kaçınabilir.

Çözüm

Güvenilir bir LED PCB SMT montaj ortağı seçmek, satın alma görevi yerine bir risk yönetimi kararıdır. Bu kılavuzdaki on soru, üretim teorisi veya satış iddialarına sürüklenmeden deneyim, süreç kontrolünü ve tutarlılığı değerlendirmek için yapılandırılmış bir yol sağlar. Karar vericiler, LED'e özgü risklere, iletişim kalitesine ve uzun vadeli istikrara odaklanarak, aydınlatma ürünlerinin tüm yaşam döngüsü boyunca öngörülebilir performansı destekleyen ortakları seçebilirler.

SSS

LED PCB SMT montajı farklıdır çünkü LED'ler ısıya, yerleştirme doğruluğuna ve bileşen varyasyonuna duyarlıdır. Küçük montaj sorunları, ışık çıkışını veya ömrünü azaltabilir ve bu da süreç kontrolünü birçok standart SMT uygulamasından daha kritik hale getirebilir.

Ana riskler arasında erken LED arızası, tutarsız parlaklık, renk değişimi ve yeniden işleme gecikmeleri bulunur. Bu sorunlar genellikle kurulumdan sonra, düzeltmeler maliyetli olduğunda ve itibara etkisi yüksek olduğunda ortaya çıkar.

Termal işleme, LED güvenilirliğinin merkezinde yer alır. Montajla ilgili ısı stresi, PCB tasarımının kendisi sağlam olsa bile, LED'lere zarar verebilir veya termal yolları zayıflatabilir.

Evet. Küçük yerleştirme hataları, lehim kusurları veya kontrolsüz ısıya maruz kalma, LED ömrünü önemli ölçüde kısaltabilir ve zaman içinde sistem kararlılığını azaltabilir.

Kalite sorunları tekrarlandığında, iletişim şeffaflıkta olmadığında veya üretim sonuçları değişmeyen tasarımlara rağmen koşular arasında değiştiğinde ortakları değiştirmeyi düşünmelisiniz.