LED aydınlatma endüstrisi, konut, ticari, endüstriyel ve otomotiv uygulamalarında modern aydınlatmayı dönüştürdü. LED'ler yüksek enerji verimliliği, uzun çalışma ömrü ve kompakt boyut için tercih edilir. Ancak, performansları büyük ölçüde PCB tasarımına, SMT montaj kalitesine ve lehim eklemi güvenilirliğine bağlıdır. Küçük montaj kusurları bile titremeye, renk tutarsızlığına, sıcak nokta oluşumuna veya erken arızaya neden olabilir.

Bu kılavuz araştırıyor

- PCB LED güvenilirliğini artırmak için stratejiler

- SMT en iyi uygulamalarına, lehim eklemi optimizasyonuna ve termal yönetime odaklanmak.

- Üreticilerin yüksek kaliteli ve dayanıklı LED sistemleri elde etmelerine yardımcı olun.

PCB LED'lerinde yaygın güvenilirlik zorlukları

LED'ler termal, elektrik ve mekanik streslere karşı oldukça hassastır. Kötü tasarım veya montaj, performans ve ömrünü tehlikeye atabilir. Tipik zorluklar şunları içerir:

- Aralıklı bağlantılara yol açan çatlak veya açık lehim bağlantıları.

- PCB bükülmesine ve bileşenin bozulmasına neden olan termal stres.

- Yüksek akım yoğunluğu altında bakır izlerine zarar veren elektromigrasyon.

- taşıma, taşıma veya termal döngüden kaynaklanan mekanik stres.

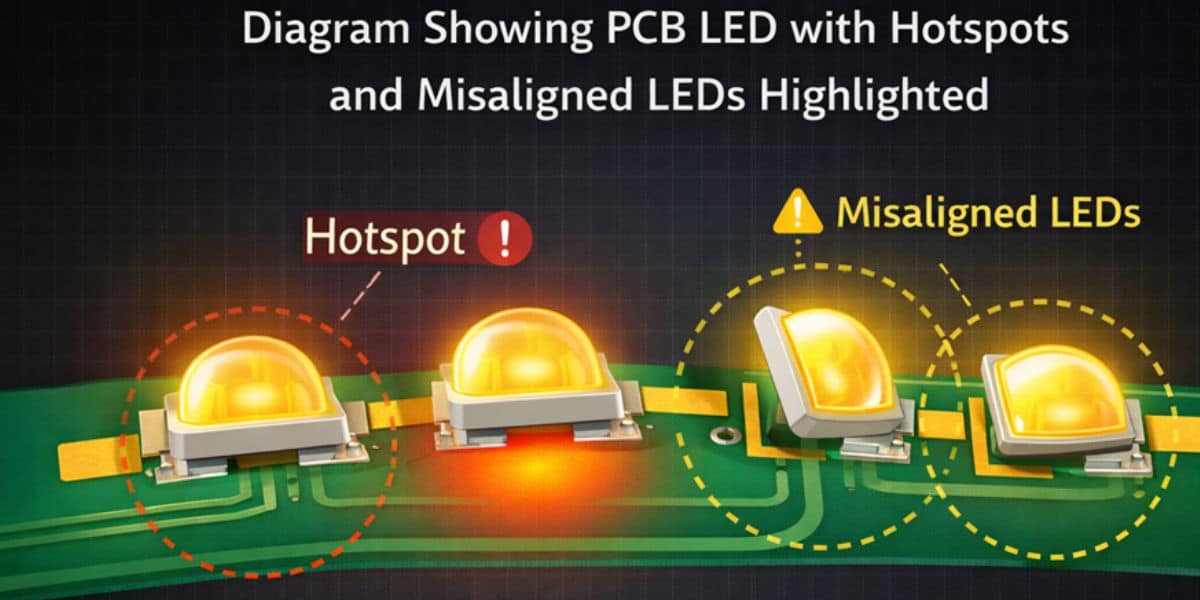

- Düzgün olmayan ışık çıkışı veya görünür sıcak noktalara neden olan yanlış hizalanmış LED'ler.

Tablo 1: PCB ve SMT Sorunlarının LED Güvenilirliği Üzerindeki Etkisi

| akıbet | neden olmak | LED sistemine etkisi |

| çatlak lehim derzleri | Termal döngü, mekanik stres | Titreşimli, açık devreler |

| Yanlış hizalanmış LED'ler | Al ve Yerleştir Hataları | Düzensiz ışık dağılımı |

| Termal Sıcak Noktalar | zayıf ısı dağılımı | Lümen amortismanı, erken başarısızlık |

| elektroşimi | Yüksek akım yoğunluğu, ince izler | Hasar izi, zaman içinde arıza |

| Lehim Boşlukları | Yanlış pasta biriktirme | Azaltılmış termal/elektrik iletkenliği |

Yüzeye Montaj Teknolojisi (SMT) Hususları

SMT, hassas LED yerleşimine, daha küçük form faktörlerine ve gelişmiş elektrik performansına izin verir. Ancak, zayıf SMT uygulamaları güvenilirliği azaltır.

1: SMT için PCB Tasarımı

İyi tasarlanmış bir PCB düzeni güvenilirliği destekler:

| tasarım öğesi | En iyi uygulama |

| Ped boyutu ve şekli | Uygun lehim ıslamasını sağlayın ve köprülemeyi önleyin |

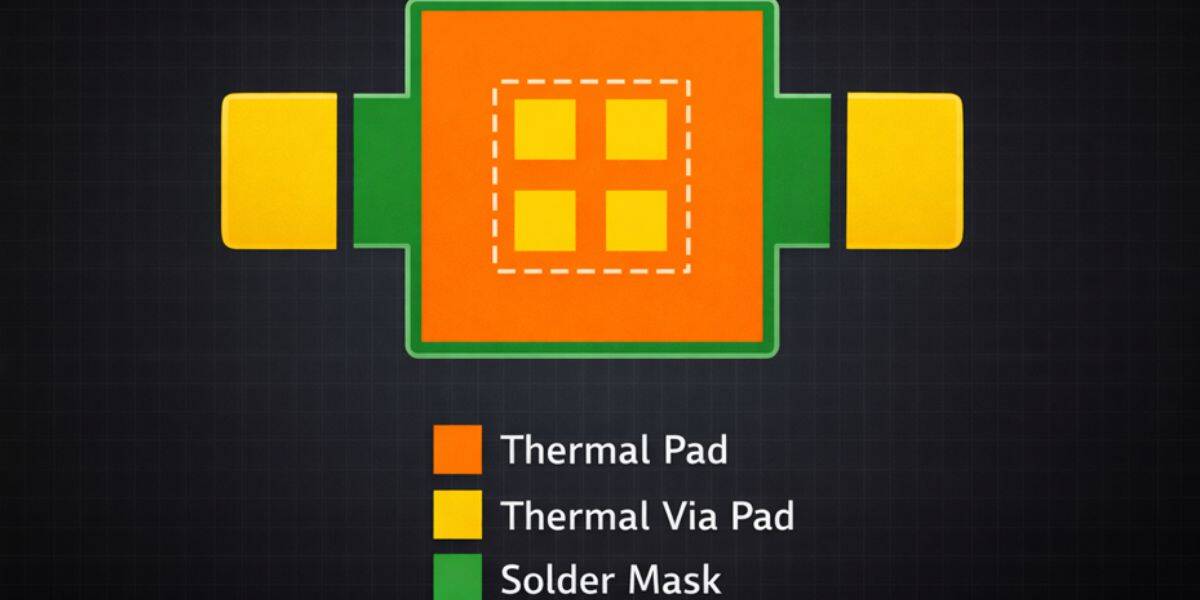

| Termal Pedler | Yüksek güçlü LED'ler için ısı dağılımını iyileştirin |

| Lehim maskesi tasarımı | Lehim dökülmesini önleyin ve yerleştirme doğruluğunu koruyun |

| İz Genişliği ve Bakır | Düşük direnci koruyun ve akımı verimli bir şekilde yönetin |

2: Pick-and-Place doğruluğu

Düzgün aydınlatma için doğru yerleştirme kritiktir:

- Meme seçimi, yerleştirme hızı ve basıncı optimize edilmelidir.

- Yanlış hizalama, optik tutarsızlıklar ve mekanik stres yaratabilir.

- Düzenli kalibrasyon, yerleşim hatalarını ve yeniden işlemeyi azaltır.

3: Lehim Macunu Uygulaması

Lehim pasta kalitesi ve uygulaması hayati önem taşır:

- Düşük boşluklu, yüksek kaliteli macun tutarlı ıslanma sağlar.

- Hassas şablonlar, yetersiz veya aşırı lehimleri önler.

- Akı içeriği oksidasyonu önlemek için uygun olmalıdır.

Lehim eklemi güvenilirliği

Lehim bağlantıları, LED'ler ve PCB'ler arasındaki mekanik ve elektrik bağlantısını oluşturur. Kötü lehimleme birincil arıza nedenidir.

1: Lehim alaşımı seçimi

- SAC305 (SNAGCU) kurşunsuz standarttır.

- Düşük eriyen alaşımlar, yeniden akış sırasında termal stresi azaltır.

- Alaşım, PCB kaplamaları (enig, hasl, OSP) ile uyumlu olmalıdır.

2 : Yeniden akış profili optimizasyonu

Yeniden akış sıcaklığı kontrol edilmelidir:

- Ön ısıtma, ıslatma ve en yüksek sıcaklıklar üreticinin tavsiyelerine uymalıdır.

- Termal şoku önlemek için aşırı ısınma LED'leri veya pedleri önleyin.

- Kontrollü soğutma, çatlama risklerini azaltır.

3: Lehim eklem geometrisi

Uygun eklem şekli, gücü ve iletkenliği artırır:

- Fileto yüksekliği, fazla lehim olmadan pedi kaplamalıdır.

- Pürüzsüz, içbükey filetolar boşluk oluşumunu azaltır.

- Eş düzlemlilik, kararlı elektrik teması sağlar.

4: Muayene ve kalite kontrolü

- Otomatik optik inceleme (AOI) görünür kusurları algılar.

- X-ışını incelemesi, termal pedlerdeki gizli boşlukları tanımlar.

- Düzenli süreç denetimleri tutarlı kaliteyi korur.

Tablo 2: LED'ler için önerilen lehim filetosu özellikleri

| LED Tipi | Köşe yüksekliği (mm) | ortak açısı | nota lar |

| 0.2–0.5 W LED'ler | 0.2–0.3 | 45–60° | Standart yüzey montaj LED'i |

| 1–3 W LED'ler | 0.3–0.5 | 45–70° | Yüksek güçlü LED'ler termal destek gerektirir |

| >5 W LED'ler | 0.4-0.6 | 60–75° | Termal Vias ve Metal Çekirdekli PCB kullanın |

SMT LED'ler için termal yönetim

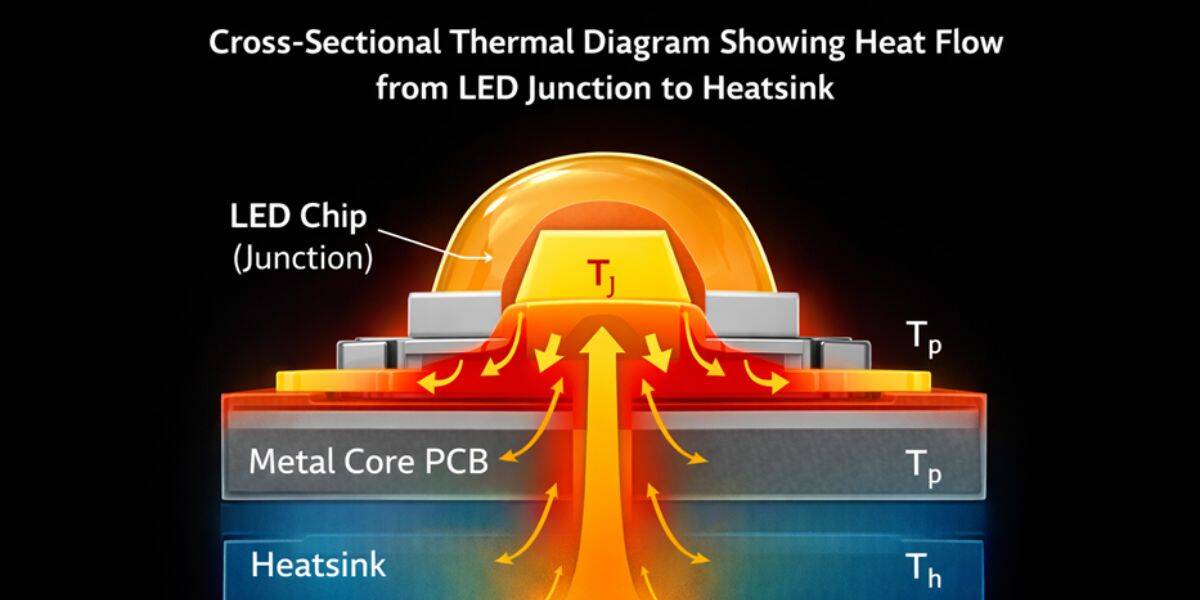

Isı en çok LED güvenilirliği için kritik faktör. Yüksek sıcaklıklar lümen amortismanını hızlandırır ve ömrünü azaltır.

Temel stratejiler:

- Alüminyum çekirdekli PCB'ler ısı dağılımını iyileştirir.

- LED'ler altındaki termal yollar, ısıyı daha büyük bakır düzlemlere aktarır.

- Soğutucular ve TIM'ler, yüksek güçlü uygulamalar için gereklidir.

- Doğru LED aralığı, sıcak noktaları önler ve eşit sıcaklık dağılımı sağlar.

Ortak SMT ve lehimleme sorunları

| akıbet | neden olmak | Çözüm |

| mezar taşı | Yeniden akış sırasında düzensiz yüzey gerilimi | Lehim pastası hacmini ve profilini ayarlayın |

| lehim köprüsü | Aşırı lehim, yanlış hizalanmış pedler | Pasta biriktirmeyi azaltın, şablonu geliştirin |

| Soğuk lehim eklemleri | Kötü ıslanma, düşük sıcaklık | Yeniden akış profilini ve lehim türünü optimize edin |

| boşaltma | Sıkışmış hava veya akı | Düşük boşluklu macun, uygun yeniden akış kullanın |

Güvenilir PCB LED montajı için en iyi uygulamalar

Üretilebilirlik için tasarım (DFM): SMT yetenekleriyle pedleri, izleri ve termal yolları hizalayın.

- Yüksek kaliteli lehim macunu kullanın: Uygun akı ile düşük boşluklu, tutarlı alaşım.

- Kontrollü yeniden akış profili: Aşırı ısınmayı ve hızlı soğumayı önler.

- Muayene: AOI, X-ray ve manuel kontroller.

- İşleme: Taşıma ve montaj sırasında mekanik stresi en aza indirin.

- Termal tasarım: Metal çekirdekli PCB'ler, termal yollar ve soğutucular.

- Standartlaştırılmış süreçler: Belgeler tekrarlanabilirliği sağlar.

Örnek olay: Yüksek güçlü LED modülü

Yüksek Baylı Endüstriyel LED modülü, termal döngü nedeniyle sık sık lehim bağlantısı arızaları yaşadı.

Uygulanan iyileştirmeler:

- Alüminyum çekirdekli PCB'lere geçiş yaptı.

- Optimize edilmiş lehim macunu biriktirme.

- Kontrollü yeniden akış profilleri.

- LED'ler altında termal yollar eklendi.

Sonuçlar:

- Lehim eklemi kusurlarında 30% azalması.

- 5.000 çalışma saatinden sonra geliştirilmiş lümen bakımı.

PCB LED montajında ortaya çıkan trendler

- Düşük sıcaklıkta lehimleme alaşımları termal stresi azaltır.

- Kurşunsuz lehimleme, güvenilirliği azaltmadan mevzuata uygunluk sağlar.

- AI destekli inceleme, kusurları geleneksel yöntemlerden daha hızlı algılar.

- Yüksek termal iletkenliğe sahip gelişmiş PCB malzemeleri, ısı dağılımını iyileştirir.

- 3D termal simülasyonlar, üretimden önce sıcak noktaları tahmin eder.

Üreticiler için ek ipuçları

- Hassas lehim pastası biriktirme için şablon tasarım yazılımı kullanın.

- Üretimden önce sıcak noktaları önlemek için termal simülasyonlar yapın.

- Al ve yerleştir makinelerini düzenli olarak kalibre edin.

- Montaj alanlarında kontrollü nem ve sıcaklığı koruyun.

- Yüksek nemli ortamlar için koruyucu kaplamalar kullanın.

Çözüm

PCB LED güvenilirliği SMT montaj kalitesine, lehim bağlantı bütünlüğüne ve termal yönetime bağlıdır. Uygun tasarım, lehimleme ve süreç kontrolü arızaları önler, performansı artırır ve LED ömrünü uzatır. Optimize edilmiş yerleşim düzenlerini, yüksek kaliteli lehimlemeyi ve gelişmiş termal stratejileri uygulayan üreticiler, tutarlı ışık çıkışı ile güvenilir, uzun ömürlü LED sistemleri elde ederler.

Yüksek performanslı, dayanıklı LED çözümleri için, ustalıkla tasarlanmış PCB LED montajları için işaretlenmiş güven. Güvenilir aydınlatma sağlamak için SMT optimizasyonu, hassas lehimleme ve gelişmiş termal yönetime odaklanıyoruz.

bugün sinyal verilen kişi Ürün kalitenizi artırmak, arızaları azaltmak ve üstün LED performansı sağlamak için.

SSS

SMT (yüzeye montaj teknolojisi) hassas LED yerleşimi sağlar, boyutu küçültür ve elektrik ve termal performansı artırır.

Lehim bağlantıları mekanik destek ve elektrik bağlantısı sağlar; Kötü derzler arızalara veya titremeye neden olabilir.

Tipik kusurlar arasında mezar taşlama, lehim köprüsü, soğuk derzler ve boşluklar bulunur, bunların tümü performansı ve ömrü azaltır.

Termal yollar, alüminyum çekirdekli PCB'ler ve soğutucular sayesinde verimli ısı dağılımı, aşırı ısınmayı önler ve ömrünü uzatır.

Otomatik optik inceleme (AOI), X-ışını incelemesi ve manuel kontroller, yanlış hizalama, boşluklar ve köprüleme gibi kusurları algılar.