Introduction: Why is acoustic lighting becoming the new hot topic in the lighting industry?

Modern office spaces, commercial buildings, educational institutions, and healthcare environments are increasingly prioritizing “noise control” as a design priority, on par with lighting. Open-plan offices, shared spaces, and high-density foot traffic mean traditional fixtures can no longer adequately address growing acoustic challenges while meeting lighting requirements.

It is against this backdrop that acoustic lighting has rapidly gained popularity. It not only provides illumination but also effectively improves indoor acoustic environments through structural design and sound-absorbing materials. Yet for buyers, designers, and contractors, a core question remains: Have these acoustic lights truly undergone reliable, professional testing?

This article systematically examines the validation framework behind acoustic lighting from multiple critical testing dimensions. It helps clients gain clearer insight into product value while providing credible grounds for procurement decisions.

What is an acoustic light? How does it achieve noise reduction?

Acoustic lights are not simply fixtures with “an added layer of material” on their surface. They are composite products that deeply integrate acoustic design with lighting engineering.

Their core principles include

- Utilizing highly efficient sound-absorbing materials (such as acoustic fibers, polyester fibers, microporous materials, etc.)

- Increasing sound diffusion and absorption pathways through the luminaire structure

- Reducing sound reflections to lower reverberation time (RT)

Unlike ordinary decorative acoustic lamps, genuine acoustic lamps require validation through standardized acoustic testing to prove their actual sound absorption capabilities—not merely “conceptual design.”

Product Certification: UL and CE Compliance—Legal Barriers to Market Entry

Within the technical compliance framework for acoustic lamps, UL (U.S.), CE (EU), and TÜV (Germany and Europe) certifications are not merely routine testing items. They constitute mandatory or authoritative prerequisites for market access across different regions, collectively forming a compliance assurance network covering North America, Europe, and major global markets.

UL Sertifikası

Issued by Underwriters Laboratories (UL), this certification is not federally mandated but serves as a de facto access standard for commercial and public space lighting in North America. The UL mark signifies independent third-party verification of a product’s electrical safety, thermal performance, flame resistance, and long-term reliability, making it a core trust symbol for retailers, architects, and building owners during procurement.

CE Sertifikası

A mandatory compliance mark for products entering the European Union market, covering core directives including LVD (Low Voltage Directive), EMC (Electromagnetic Compatibility Directive), and RoHS (Restriction of Hazardous Substances). As electrically powered acoustic-optical composite devices, acoustic luminaires must comply with the EN 60598 series of safety standards and EN 55015/61547 electromagnetic compatibility requirements. The CE mark serves as direct proof of their legal compliance.

TÜV Certification

Issued by Germany’s TÜV (Technical Inspection Association), this certification holds exceptional authority in the European market, particularly renowned for its rigorous standards regarding safety and quality details. Key certification aspects include:

- Comprehensive safety testing: Covering mechanical strength, material aging resistance, and extreme environmental adaptability.

- Regular oversight of factory quality systems to ensure mass production consistency. While not mandatory in the EU, the TÜV mark significantly enhances product competitiveness in European markets. It serves as a vital symbol of quality and reliability, particularly in high-end commercial projects and industrial applications.

SGS Environmental Testing: The Foundation of Compliance, Sustainability, and Trust

In the international B2B market, SGS testing is virtually synonymous with “third-party trusted endorsement.” For acoustic lamps, SGS environmental testing primarily focuses on the following aspects:

- Material Environmental Compliance: Adherence to regulations like RoHS and REACH

- Restriction of Hazardous Substances: Heavy metals, halogens, and VOC emissions

- Production Consistency: Material batch stability and traceability

These tests not only address environmental responsibility but also directly determine whether products can enter European and American markets and pass compliance reviews for major projects. For buyers, an SGS report signifies reduced compliance risks and enhanced project security.

Sound Absorption Performance Testing: Measuring Actual Noise Reduction

The international standard for the frequency range of human speech typically refers to the voice transmission bandwidth standard in digital telephone communications, spanning 300 Hz to 3400 Hz. Our everyday speech primarily relies on the 500 Hz to 3000 Hz frequency range, which contains most of the energy and clarity information in speech—crucial for understanding language. The human auditory range spans 20 Hz to 2000 Hz, yet the vast majority of speech information is concentrated within the narrower 300–3400 Hz frequency band.

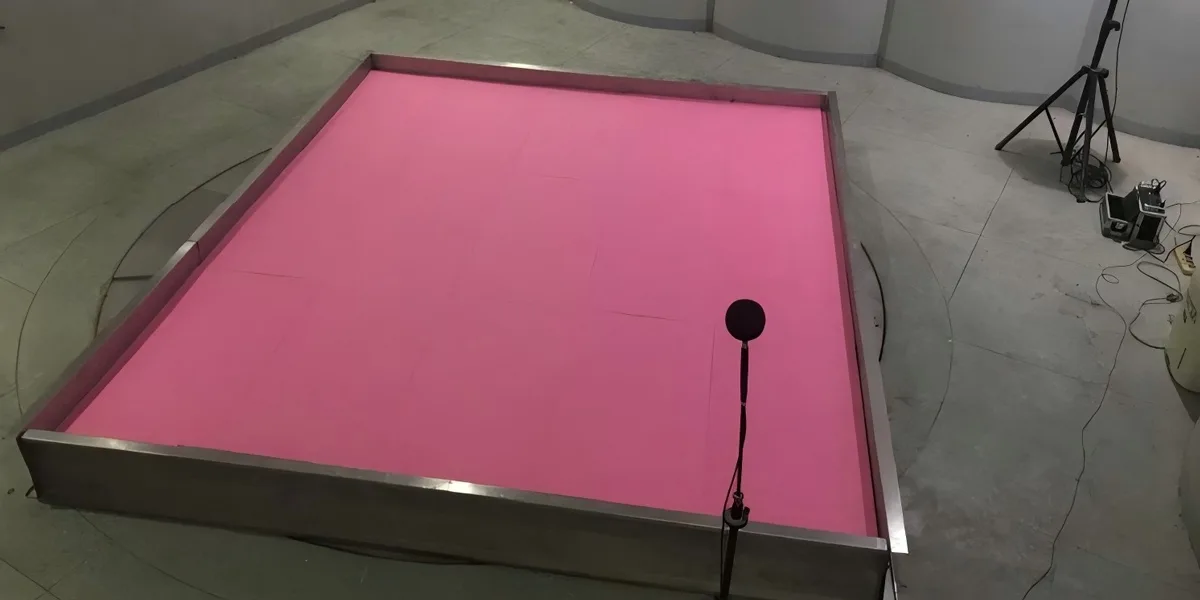

The sound absorption capability of acoustic panels must be quantified through professional acoustic laboratory testing, primarily using instruments such as the B&K 2270 Investigation, 2716 power amplifier, 4292 omnidirectional loudspeaker, and 4189 microphone.

Common test metrics include:

- Sound Absorption Coefficient (SAC)

- Gürültü azaltma katsayısı (NRC)

- Sound absorption performance across frequency bands (low-frequency / mid-frequency / high-frequency)

- Testing Standard: Based on EN ISO 354:2003 / ISO 354 “Acoustics—Measurement of sound absorption in a reverberation room”

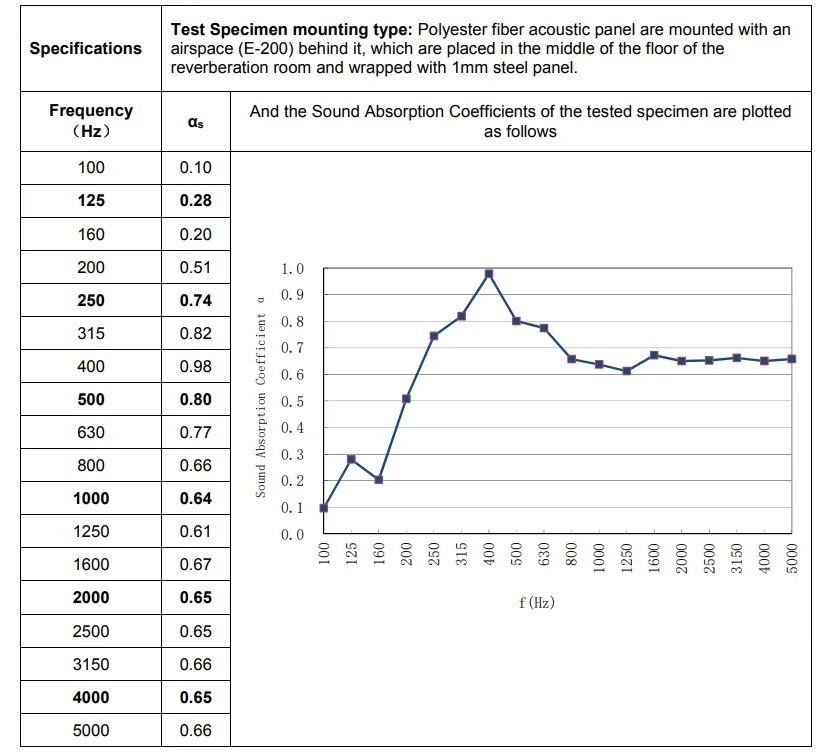

To achieve sound absorption and noise reduction, the relevant materials must possess “sound-absorbing” properties. Below is the test report for the primary material used in SignliteLED’s acoustic lighting products—polyester fiber acoustic panels—submitted for inspection:

As shown above, the tested polyester fiber panels exhibit sound absorption coefficients consistently above 0.74 across the core speech and common noise frequency range of 250 Hz-1250 Hz, with peak values at 250 Hz and 800 Hz. This indicates excellent absorption of human speech, telephone ringing, and office equipment noise, making it highly suitable for enhancing speech intelligibility in offices, conference rooms, and schools.

Below 125 Hz, the sound absorption coefficient is lower (<0.3), a typical characteristic of thin, porous materials. To address low-frequency noise (e.g., air conditioner hum, traffic rumble), thicker materials or specialized low-frequency absorption structures are typically required.

Reports indicate this polyester fiber acoustic panel excels at absorbing mid-to-high frequency noise (particularly 250-1250 Hz), achieving industry-leading performance at specific frequencies. When used in acoustic lighting fixtures, this material delivers noticeable noise reduction for human speech. Actual application should reference this data based on specific noise spectra and installation conditions.

Standardized testing environments accurately reflect the noise reduction capabilities of acoustic lighting in real spaces. Such data is particularly crucial for architectural acoustics designers and system integrators, serving as key differentiators between acoustic lighting and conventional fixtures.

Ultra ince ince yuvarlak akustik led kolye ışık

Giriş Voltajı: AC100-277V / AC220-240V, 50-60Hz

Konut Boyutu: 120 mm

Yayılan yön: aşağıya doğru

Size(DxH): 500x80mm

CCT: 3000K / 4000K / 6000K

Güç: 15W

Aydınlık akı: 100-110 lm/w

CRI: >90

PF: >0.90

Flicker Ücretsiz: Evet

Işın Açısı: 120°

IP Sınıfı: IP20

Garanti: 5 yıl

Akustik panel renk seçeneği: Kırmızı / Yeşil / Mavi / Gri 48'den Fazla Renk Seçeneği

Fire Performance Testing: Safety in Public and Commercial Spaces

Acoustic ceiling panels are extensively used in suspended ceilings, public areas, and high-occupancy spaces, making fire resistance a critical consideration. Flame retardancy testing of materials is therefore essential. In public and commercial environments, acoustic panel materials must meet both waterproofing and fire resistance requirements. According to the American ASTM E84 standard, fire ratings are classified into three levels: A, B, and C. Level B (FSI 26-75) represents the basic requirement, ensuring controlled flame spread during a fire and a smoke index not exceeding 450, thereby safeguarding safe evacuation. The European EN 13501-1 standard requires materials to achieve at least Class B (equivalent to B1). This rating evaluates flame spread and heat release through a single-body combustion test, ensuring low fire risk.

Özetle, acoustic lighting materials must meet either ASTM E84 Class B or EN 13501-1 B1 fire ratings and possess basic water resistance to fulfill public space safety requirements.

USA ASTM E84 and EU EN 13501-1 Fire Resistance Rating CKARŞILAŞTIRMA Table

| standart | Test Method and Rating Basis | Grade Classification Definition | Main Application Markets |

| USA ASTM E84 | Steiner Tunnel Test – Evaluates surface flame spread and smoke generation. – Key indicators: Flame Spread Index (FSI), Smoke Development Index (SDI). – Result is intuitive, only evaluates surface combustion characteristics. | Class A: FSI ≤ 25, SDI ≤ 450. Class B: 26 ≤ FSI ≤ 75. Class C: 76 ≤ FSI ≤ 200. Classification is directly based on FSI value, with no complex degradation mechanism. | North American markets (USA, Canada) Widely used in building codes such as NFPA, IBC. |

| EU EN 13501-1 | Multi-test Comprehensive Evaluation 1. EN 13823 (Single Burning Item Test, SBI): Evaluates flame propagation and heat release. 2. EN ISO 11925-2 (Small Flame Ignition Test): Evaluates ignitability. Simultaneously evaluates smoke generation (s1/s2/s3) and molten droplet (d0/d1/d2). | 7 main grades (A1 → A2 → B → C → D → E → F): A1 is the highest non-combustible grade. B grade: Material is “difficult to ignite” with additional smoke and droplet ratings (e.g., B-s1, d0). Strict “no reverse degradation” rule. | EU markets and globally recognized Mandatory for CE marking and EU building regulations. |

ASTM E84 Fire Resistance Classification (USA)

The classifications are as follows:

| Classification | Flame Spread Index, FSI | Smoke-Developed Index, SDI |

| Class A | 0-25 | 0-450 |

| Class B | 26-75 | 0-450 |

| Class C | 76-200 | 0-450 |

Appendix: EN 13501-1 Fire Classification (EU)

Table 1—Classes of reaction to fire performance for construction products excluding floorings and linear pipe thermal insulation products.

| Class | Test method(s) | Classification criteria | Additional classification | |

| A1 | EN ISO 1182 a Ve | △T≤30℃, and △m≤50%, and tf=0(i.e.no sustained flaming) | – | |

| EN ISO 1716 | PCS≤2.0MJ/kg a Ve PCS≤2.0MJ/kg b C Ve PCS≤1.4MJ/m² D Ve PCS≤2.0MJ/kg Ve | – | ||

| A2 | EN ISO 1182 a veya | Ve | △ T≤50℃, and △m≤50%, and tf≤20 s | – |

| EN ISO 1716 | PCS≤3.0MJ/kg a Ve PCS≤4.0MJ/m² b Ve PCS≤4.0MJ/m² D Ve PCS≤3.0MJ/kg Ve | – | ||

| EN 13823 | FIGRA≤120W/s and LFS<edge of specimen and THR600s≤7.5MJ | Smoke production f Ve Flaming droplets/particles g | ||

| B | EN 13823 and | FIGRA≤120W/s and LFS<edge of specimen and THR600s≤7.5MJ | Smoke production f Ve Flaming droplets/particles g | |

| EN ISO 11925-2 Ben Exposure=30s | Fs≤150mm within 60 s | |||

| C | EN 13823 and | FIGRA≤250W/s and LFS<edge of specimen and THR600s≤15MJ | Smoke production f Ve Flaming droplets/particles g | |

| EN ISO 11925-2 Ben Exposure=30s | Fs≤150mm within 60 s | |||

| D | EN 13823 and | FIGRA≤750W/s | Smoke production f Ve Flaming droplets/particles g | |

| EN ISO 11925-2 Ben Exposure=30s | Fs≤150mm within 60 s | |||

| E | EN ISO 11925-2 Ben Exposure=15s | Fs≤150mm within 20 s | flaming droplets/particles hırt | |

| F | EN ISO 11925-2 Ben Exposure=15s | Fs>150mm within 20 s | – | |

Passing fire tests ensures that luminaires and their acoustic materials do not become fire hazards even under abnormal conditions. This is a mandatory requirement for projects such as hospitals, schools, and commercial complexes.

Optical Performance Testing: Noise Reduction Ssığınak Not Come at To Expense of Lçakmak Quality

An excellent noise-reducing light must strike a balance between acoustic and optical performance.

Key optical testing focuses on:

- Luminous Flux and Luminous Efficacy: Selection should be based on space size and purpose. For example, a typical bedroom may require 800-1500 lm, while an office workspace may need 3000-5000 lm.

- Renk sıcaklığı tutarlılığı: No rigid standard exists, but the core principle is to select based on space function and usage requirements. Typically ranging from 2700K to 5000K, prioritizing comfort and practicality.

- Renk İşleme İndeksi (CRI): Ra≥80 ensures accurate color reproduction.

- Glare Control (UGR): Typically maintained at UGR ≤ 19, a universal standard for indoor lighting that ensures visual comfort and reduces eye strain.

These tests ensure that sound-dampening lights enhance acoustic environments while delivering comfortable, stable, high-quality illumination—avoiding the pitfall of “silent but ineffective” solutions.

Electrical Safety Testing: Core Measures for Personnel and System Protection

Regardless of application scenarios, the fundamental nature of lighting fixtures as electrical products remains unchanged. To ensure the safety and reliability of lighting equipment such as acoustic ceiling lights, a comprehensive electrical safety testing system must be implemented, covering the following critical aspects:

Insulation Performance Testing

Evaluates insulation performance between live parts and accessible metal components. The test voltage is typically 500VDC, requiring insulation resistance values not less than:

- 2MΩ (Basic Insulation)

- 4MΩ (Reinforced Insulation)

Withstand Voltage Testing

Conducted according to different standards:

- European Standard: Test voltage of 1000VAC or 1414VDC, superimposed with 2 times the rated voltage. Leakage current must not exceed specified limits (e.g., 5mA) during testing.

- UL Standard (US): Fixed luminaires must withstand a 1500V voltage test for 1 second with leakage current not exceeding 1.0mA. Portable luminaires: Leakage current must not exceed 0.5mA.

Grounding and Leakage Current Testing

- Ground Continuity Test: Acoustic luminaires are primarily used indoors and typically classified as Class II luminaires (double insulation design), eliminating the need for grounding. Therefore, ground continuity testing is not mandatory.

- Leakage Current Test: For Class II luminaires, leakage current requirements are stricter, mandating leakage current not exceeding 0.25mA to ensure user safety.

Significance and Value

These tests form a core component of international lighting standards (e.g., IEC60598, UL1598). By simulating extreme operating conditions, they validate the long-term reliability of luminaires, effectively preventing risks of electric shock, short circuits, or fire hazards. This provides dual safeguards for personnel safety and the stable operation of building systems.

Durability and Lifespan Testing: Long-Term Performance Assurance

Product longevity is as critical as maintenance costs. Reliable lifespan testing data enables predictable maintenance cycles, significantly reducing total cost of ownership.

Testing Scope and Methods:

LED Light Source Aging Testing

- Accelerated Aging Test: Conducted per IEC 62506 standard: 6,000 hours of continuous operation at 85°C and 85% humidity, simulating 15 years of normal use.

- Luminous Flux Decay Monitoring: Measured every 500 hours using an integrating sphere photometer to ensure decay rate ≤30% (for rated power ≥10W) and CRI (Ra) change ≤5%.

- Failure Mode Analysis: Document degradation phenomena such as LED chip encapsulant yellowing and phosphor layer detachment to prevent sudden failures.

Driver Power Supply Lifespan Testing

- Constant Current/Constant Voltage Aging: Continuous operation at 1.2 times rated current for 3000 hours at 40°C ambient temperature, monitoring output voltage fluctuation ≤ ±5%.

- Switching Cycle Test: Simulate frequent on/off scenarios with 10,000 switching operations at 10-second intervals, verifying no capacitor rupture or IC burnout.

- Overload Protection Verification: When input voltage fluctuates ±15%, the power supply must activate protection mechanisms within 0.1 seconds to prevent LED overcurrent damage.

High Temperature & Humidity Stability Verification

- Dual 85 Test: After 500 hours at 85°C/85% RH, the luminaire’s insulation resistance must remain ≥100MΩ with no leakage or short circuits.

- Thermal Shock Test: Withstands 100 cycles from -40°C to 85°C, verifying no degradation in bonding strength between acoustic foam and metal frame.

Fixtures passing these tests achieve an L70 lifespan (time to 70% luminous flux maintenance) of 50,000 hours—equivalent to 15 years of maintenance-free operation in commercial spaces. The driver power supply MTBF (Mean Time Between Failures) is ≥50,000 hours, with a failure rate below 0.5%.

Seismic and Mechanical Stability Testing: Adapted to Real-World Environments

During transportation, installation, and long-term use, luminaires endure vibration, impact, and suspension stresses. Seismic testing ensures safety and reliability in commercial projects (e.g., airports, subways) and public spaces.

Testing Content and Methods:

Luminaire Structural Strength Verification

- Vibration Table Simulation for Transportation: Per ISTA 3A standards, random vibration testing at 5 Hz-500 Hz frequency range with peak acceleration of 5g, lasting 2 hours.

- Impact Testing: Free-fall drop test from 1.2 meters onto a concrete surface. Luminaire housing must show no cracks, with internal component displacement ≤2mm.

Internal Component Fixing Reliability

- Sine Vibration Test: Vibrate at 0.75mm amplitude between 10 Hz and 55 Hz for 30 minutes to verify no loosening of LED module or power board screws.

- Torque Test: Apply 50 N·m torque to the suspension bracket for 10 minutes with no plastic deformation.

Long-Term Suspension and Vibration Safety

- Fatigue Test: Simulates subway vibration conditions with 10 cycles at 2g acceleration. No detachment occurs at the connection between the sound-absorbing cotton and the lamp body.

- Wind Load Test: Withstands 30 minutes at 15m/s wind speed (equivalent to Force 7 winds). Lamp tilt angle ≤5°, with no risk of falling.

Conclusion: Why “Tested Sound-Absorbing Lights” Are Worth the Investment

Sound-absorbing lights should transcend being merely a “novel concept product” and instead represent a rigorously validated system solution. From SGS environmental testing to acoustic absorption, fire resistance, optical performance, electrical safety, lifespan, and seismic resilience evaluations—each validation reduces risk and builds trust. These tests not only demonstrate technological advancement but also enhance consumer confidence.

Amidst escalating noise pollution, acoustic lighting stands out in the industry through innovative design and reliable quality. Choosing comprehensively tested acoustic lighting fixture means selecting tranquility, health, and longevity for your space. For procurement professionals, opting for fully tested acoustic lighting translates to:

- Higher project approval rates

- Lower maintenance and compliance costs

- A more stable and sustainable user experience

SSS

Yes. When tested under standardized acoustic conditions, certified noise reduction lamps demonstrate measurable sound absorption that improves overall room acoustics.

SGS is globally recognized. Its testing confirms material safety, environmental compliance, and product reliability, which is especially important for international projects.

Not when properly designed. Optical testing ensures that brightness, color quality, and visual comfort remain consistent despite the use of sound-absorbing materials.

Yes. Fire resistance, electrical safety, and durability tests are specifically conducted to meet the safety requirements of public and commercial spaces.

Reliable manufacturers provide official test reports from accredited laboratories, which can be reviewed during project evaluation or procurement.