Đối tác lắp ráp PCB PCB đáng tin cậy là đối tác lắp ráp đèn LED liên tục có độ chính xác cao, quản lý nhiệt ở cấp độ bảng và mang lại kết quả có thể lặp lại trên các nguyên mẫu và chạy sản xuất. Cụm LED PCB phức tạp hơn SMT tiêu chuẩn vì lỗi vị trí nhỏ, quản lý nhiệt hoặc biến đổi thành phần có thể trực tiếp làm giảm sản lượng ánh sáng và tuổi thọ. Độ tin cậy trong bối cảnh này có nghĩa là kiểm soát quá trình, chất lượng có thể dự đoán được và tính minh bạch của quyết định hơn là tốc độ hoặc giá cả.

10 câu hỏi chính để đánh giá đối tác lắp ráp PCB PCB SMT

1 - Bạn có kinh nghiệm gì với PCB LED và bảng lõi kim loại?

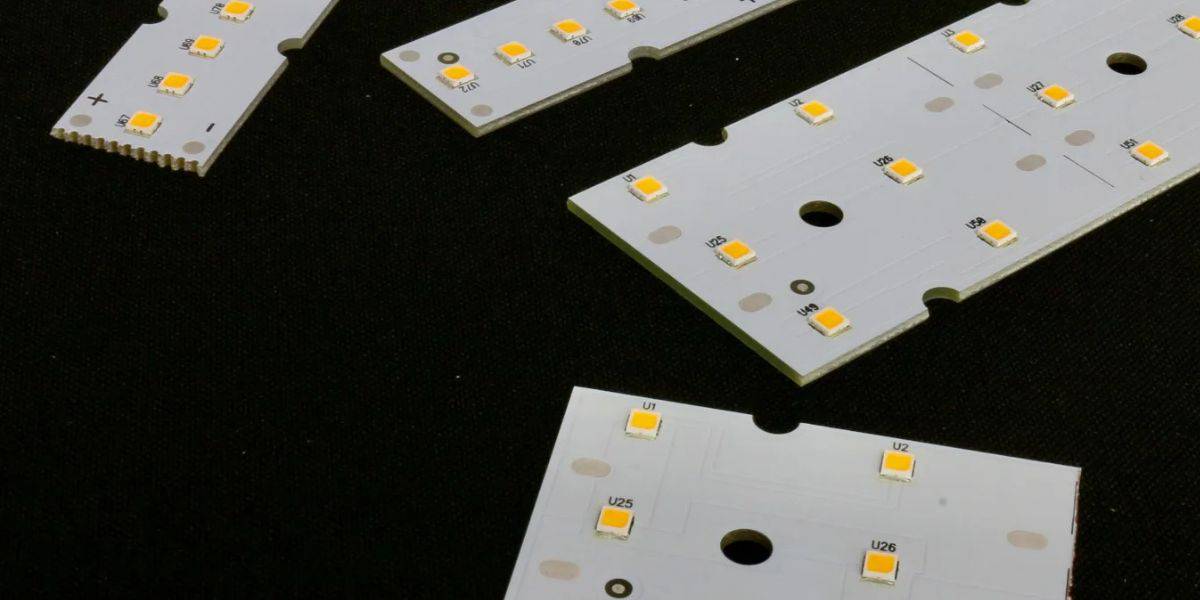

Kinh nghiệm trực tiếp với PCB LED là vấn đề vì các cụm LED hoạt động khác nhau dưới nhiệt và ứng suất hiện tại. Một đối tác quen thuộc với các tấm nhôm và các tấm lõi kim loại khác hiểu cách bố trí, cấu hình hàn và xử lý ảnh hưởng đến đường dẫn nhiệt. Nếu không có kinh nghiệm này, ngay cả một nhà sản xuất PCB tùy chỉnh có khả năng cũng có thể đánh giá thấp các rủi ro cụ thể của đèn LED, dẫn đến lỗi sớm hoặc hiệu suất quang học không nhất quán.

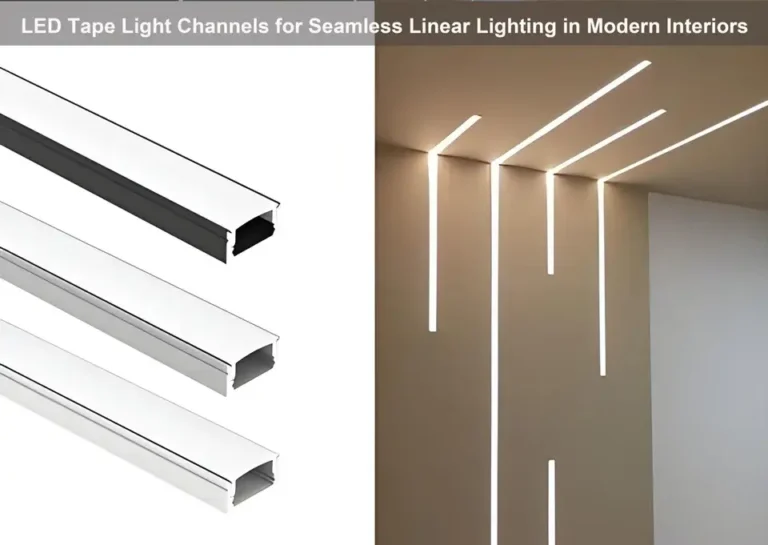

2 - Bạn sử dụng thiết bị SMT nào để có độ chính xác khi đặt đèn LED?

Độ tin cậy của đèn LED phụ thuộc vào vị trí và định hướng chính xác, đặc biệt là đối với các mảng mật độ cao và mô-đun tuyến tính. Thiết bị SMT phù hợp đảm bảo căn chỉnh nhất quán, kiểm soát âm lượng hàn và làm lại tối thiểu. Câu hỏi này giúp bạn đánh giá liệu một nhà sản xuất PCB tùy chỉnh có thể duy trì độ chính xác của vị trí ở quy mô hay không hoặc chất lượng sẽ khác nhau giữa các lô, làm tăng rủi ro lỗi tại hiện trường.

3 - Làm thế nào để bạn quản lý hiệu suất nhiệt trong quá trình lắp ráp PCB LED?

Quản lý nhiệt là trung tâm của tuổi thọ LED và độ ổn định màu sắc. Một đối tác đáng tin cậy xem xét nhiệt trong quá trình hàn, gắn thành phần và xử lý sau lắp ráp. Câu hỏi này cho thấy liệu kiểm soát nhiệt được coi là mối quan tâm ở cấp hệ thống hay là một suy nghĩ sau đó. Thực hành nhiệt kém trong quá trình lắp ráp có thể phủ nhận ngay cả một bố cục tùy chỉnh PCB được thiết kế tốt.

4 - Bạn áp dụng quy trình kiểm tra và kiểm soát chất lượng nào?

Kiểm tra không chỉ là phát hiện các lỗi rõ ràng mà còn là việc nắm bắt các vấn đề tinh tế ảnh hưởng đến hiệu suất của đèn LED theo thời gian. Kiểm soát chất lượng nhất quán giúp ngăn ngừa các lỗi tiềm ẩn do lỗ hổng hàn hoặc lệch. Câu hỏi này giúp bạn so sánh các đối tác dựa trên kỷ luật quy trình hơn là lời hứa, đặc biệt là khi đánh giá lắp ráp PCB tùy chỉnh cho các hệ thống chiếu sáng quan trọng.

5 - Làm thế nào để bạn xử lý sự nhất quán của đèn LED và thành phần?

Binning LED ảnh hưởng đến độ sáng, nhiệt độ màu và độ đồng nhất của hình ảnh. Một đối tác đáng tin cậy có các quy trình để quản lý sự thay đổi thành phần và duy trì tính nhất quán trong một bảng duy nhất và trên các lô sản xuất. Câu hỏi này là điều cần thiết cho các ứng dụng mà sự khác biệt về hình ảnh là không thể chấp nhận được và nơi mà nguồn cung ứng không nhất quán có thể làm suy yếu quy trình lắp ráp âm thanh khác.

6 - Bạn có thể hỗ trợ cả tạo mẫu và sản xuất số lượng lớn không?

Khả năng chuyển từ nguyên mẫu sang khối lượng mà không cần thay đổi đối tác làm giảm rủi ro và thông tin sai lệch. Câu hỏi này đánh giá xem các tiêu chuẩn và kiểm soát giống nhau có áp dụng ở các quy mô khác nhau hay không. Đối với các dự án LED, sự mâu thuẫn giữa các bản dựng sớm và sản xuất hàng loạt thường bắt nguồn từ các đối tác coi việc tạo mẫu và khối lượng là các quy trình không liên quan.

7 - Thời gian dẫn đầu và độ tin cậy lên lịch trình điển hình của bạn là gì?

Độ tin cậy thời gian dẫn quan trọng hơn tốc độ danh nghĩa trong các dự án PCB LED gắn liền với lịch trình lắp đặt. Câu hỏi này giúp bạn hiểu được đối tác lập kế hoạch năng lực và quản lý sự thay đổi tốt như thế nào. Lịch trình bị bỏ lỡ có thể buộc các quyết định gấp rút hoặc thay thế ảnh hưởng đến hiệu suất LED, ngay cả khi làm việc với một người có kinh nghiệm nhà sản xuất PCB tùy chỉnh.

8 - Làm thế nào để bạn cung cấp phản hồi DFM cho các dự án PCB LED?

Thiết kế cho khả năng sản xuất Phản hồi là rất quan trọng trong các cụm đèn LED vì các quyết định bố trí nhỏ ảnh hưởng đến dòng nhiệt và năng suất vị trí. Một đối tác đáng tin cậy cung cấp phản hồi sớm, rõ ràng tập trung vào giảm rủi ro hơn là nhận xét chung chung. Câu hỏi này cho thấy liệu DFM có được sử dụng như một công cụ quyết định hay được coi là một hình thức trong quy trình lắp ráp PCB tùy chỉnh hay không.

9 - Làm thế nào để bạn quản lý rủi ro chuỗi cung ứng và nguồn cung ứng thành phần?

Linh kiện LED rất nhạy cảm với sự thay thế và thiếu hụt. Một đối tác đáng tin cậy đã xác định các quy trình tìm nguồn cung ứng, truy xuất nguồn gốc và thông báo thay đổi. Câu hỏi này giúp bạn đánh giá cách thức xử lý gián đoạn nguồn cung và liệu bạn có được thông báo trước khi quyết định ảnh hưởng đến hiệu suất hoặc tuân thủ trong các dự án tùy chỉnh của PCB hay không.

10 - Bạn cung cấp loại hỗ trợ liên lạc, tài liệu và hỗ trợ sau lắp ráp nào?

Giao tiếp rõ ràng làm giảm rủi ro trong suốt vòng đời của dự án. Câu hỏi này đánh giá cách các vấn đề được ghi lại, các thay đổi được phê duyệt như thế nào và các câu hỏi sau hội đồng được xử lý như thế nào. Các đối tác đáng tin cậy cung cấp hồ sơ và hỗ trợ nhất quán giúp bạn chẩn đoán các vấn đề mà không cần phỏng đoán, điều này rất quan trọng đối với sự ổn định hệ thống LED lâu dài.

So sánh một đối tác lắp ráp PCB SMT tiêu chuẩn và đáng tin cậy

| khu vực đánh giá | Đối tác tiêu chuẩn | Đối tác đáng tin cậy |

| Trải nghiệm PCB LED | Tiếp xúc SMT chung | Đèn LED và tiêu điểm kim loại đã được kiểm chứng |

| Khả năng quản lý nhiệt | giả định từ thiết kế | được quản lý tích cực trong quá trình lắp ráp |

| Phương pháp kiểm tra | Kiểm tra trực quan cơ bản | Chiến lược kiểm tra theo quy trình |

| Tốc độ tạo mẫu | nhanh nhưng không nhất quán | Kiểm soát và lặp lại |

| Khả năng mở rộng sản xuất | tách biệt với tạo mẫu | Căn chỉnh trên tất cả các tập |

| Hỗ trợ DFM | Chung hoặc muộn | Phản hồi sớm, cụ thể bằng đèn LED |

| Xử lý chuỗi cung ứng | tìm nguồn phản ứng | có kế hoạch và minh bạch |

Tại sao những câu hỏi này hoạt động như một khung quyết định

Mười câu hỏi này được thiết kế để hiển thị thực tế hoạt động hơn là các tuyên bố tiếp thị. Mỗi cái tập trung vào một khu vực rủi ro cụ thể cho lắp ráp PCB PCB, nơi các khoảng trống quy trình nhỏ có thể gây ra các vấn đề lớn ở hạ nguồn. Đánh giá câu trả lời cạnh nhau cho phép bạn so sánh các đối tác về các chỉ số độ tin cậy quan trọng trong toàn bộ vòng đời sản phẩm, không chỉ trong quá trình xây dựng ban đầu.

Sử dụng khung này cũng giúp sắp xếp các bên liên quan nội bộ. Các nhóm kỹ thuật có thể tập trung vào rủi ro kỹ thuật, trong khi mua sắm có thể đánh giá khả năng dự đoán và giao tiếp. Kết quả là cơ sở chung để ra quyết định làm giảm khả năng phán đoán chủ quan và tư duy ngắn hạn.

Những sai lầm đánh giá phổ biến để tránh

Một sai lầm phổ biến là giả định rằng bất kỳ nhà cung cấp SMT nào có kinh nghiệm đều phù hợp với PCB LED. Một cách khác là ưu tiên thời gian dẫn đầu hoặc chi phí đơn vị được trích dẫn mà không hiểu kiểm soát quy trình. Một số đội cũng đánh giá quá cao danh sách thiết bị mà không cần hỏi những công cụ đó được sử dụng như thế nào trong thực tế. Việc tránh những cái bẫy này đòi hỏi phải có sự đặt câu hỏi có kỷ luật và tập trung vào việc các quyết định ảnh hưởng đến hiệu suất của đèn LED theo thời gian như thế nào.

Cấu trúc chi phí lắp ráp PCB và SMT

Đánh giá chi phí cho lắp ráp PCB PCB phụ thuộc chủ yếu vào phân loại PCB, vật liệu cơ sở, số lượng lớp, độ phức tạp lắp ráp và thời gian quay vòng sản xuất. Không giống như các dự án SMT chung, các cụm PCB LED đưa ra các ràng buộc bổ sung về nhiệt và vị trí ảnh hưởng trực tiếp đến cả chi phí chế tạo và lắp ráp.

Các tham chiếu giá sau đây dựa trên dữ liệu công khai từ các nền tảng sản xuất PCB, máy tính giá trực tuyến và các tiêu chuẩn ngành thường được người mua tham chiếu trong quá trình đánh giá nhà cung cấp. Tất cả các giá trị là Phạm vi tham chiếu gần đúng dự định lập ngân sách, so sánh và lập kế hoạch mua sắm sớm, không phải báo giá chính thức.

Phân loại PCB và phạm vi chi phí chế tạo điển hình

| Phân loại PCB | Số lượng lớp điển hình | vật liệu cơ sở | Các ứng dụng LED phổ biến | Chi phí chế tạo PCB gần đúng (USD / đơn vị, khối lượng nguyên mẫu) |

| PCB một lớp | 1 | fr4 | Đèn LED báo, đèn chiếu sáng công suất thấp | $1 - $5 |

| PCB hai lớp | 2 | fr4 | Bảng LED tuyến tính, đồ đạc nhỏ gọn | $3 - $10 |

| MPCCB nhôm | 1–2 | lõi nhôm | Đèn LED công suất cao, thiết kế nhiệt độ cao | $5 - $20 |

| PCB 4 lớp | 4 | FR4 (tiêu chuẩn hoặc cao-TG) | Điều khiển LED dày đặc và bảng điều khiển | $10 – $25 |

| HDI PCB | 4–6+ | FR4 / cao-TG | Mô-đun LED nhỏ gọn, mật độ cao | $30 - $60+ |

Phạm vi chi phí phản ánh các thông số kỹ thuật tiêu chuẩn mà không cần sản xuất nhanh, hoàn thiện đặc biệt hoặc yêu cầu điện nâng cao.

Bộ điều khiển chi phí lắp ráp PCB PCB

Chi phí lắp ráp SMT cho PCB LED bị ảnh hưởng bởi một số biến mức quy trình ảnh hưởng đến thời gian máy, nỗ lực kiểm tra và kiểm soát nhiệt trong quá trình sản xuất.

| điều khiển xe | Tác động chi phí điển hình (USD/board, khối lượng nguyên mẫu) | giải thích |

| Mật độ vị trí LED | +$1.50 - $4.00 | Số lượng LED cao hơn làm tăng chu kỳ vị trí, sử dụng bộ nạp và thời gian kiểm tra |

| Vật liệu cơ sở PCB (MCCB so với FR4) | +$2.00 – $6.00 | Bảng nhôm lõi yêu cầu cấu hình nhiệt được kiểm soát và quy trình tái tạo chậm hơn |

| Kích thước gói LED (định dạng SMD nhỏ) | +$1.00 – $3.00 | Các gói nhỏ hơn yêu cầu dung sai vị trí chặt chẽ hơn và các bước xác minh |

| điều khiển binning LED | +$0.50 - $2.00 | Tách, theo dõi và xử lý lô hàng giới thiệu chi phí quy trình bổ sung |

| Mức độ kiểm tra (AOI và kiểm tra thủ công) | +$1.00 – $3.00 | Các giai đoạn kiểm tra bổ sung tăng cường lao động và sử dụng thiết bị |

Tác động chi phí lắp ráp là các tham chiếu chỉ định trên mỗi bảng bắt nguồn từ các mô hình định giá SMT thường được xuất bản.

Thời gian quay vòng và tác động chi phí đến các dự án PCB LED

Lựa chọn thời gian sản xuất có thể có tác động có thể đo lường được tổng chi phí lắp ráp PCB PCB, đặc biệt đối với các dự án đòi hỏi kiểm soát nhiệt và vị trí nghiêm ngặt.

| Thời gian quay vòng sản xuất | Tăng chi phí điển hình | trường hợp sử dụng phổ biến |

| Tiêu chuẩn (10–15 ngày làm việc) | tầm thường | Các bản dựng sản xuất theo kế hoạch và chạy theo trình độ |

| Tăng tốc (5-7 ngày làm việc) | +20% đến +40% | Các chương trình sản xuất thí điểm và theo lịch trình |

| Express (24–72 giờ) | +50% đến +100% | thay thế khẩn cấp hoặc triển khai quan trọng theo thời gian |

Giải thích chi phí cho các nhóm mua sắm và kỹ thuật

Các tham chiếu chi phí này cho phép các nhóm mua sắm và kỹ thuật đánh giá các đối tác lắp ráp PCB SMT bằng cách sử dụng các kỳ vọng định giá thực tế, dựa trên phân loại. Bằng cách hiểu cách PCB, lựa chọn vật liệu, độ phức tạp của lắp ráp và thời gian dẫn đầu ảnh hưởng đến tổng chi phí, người mua có thể đưa ra quyết định sáng suốt hơn và tránh lựa chọn chỉ dựa trên giá tiêu đề mà không tính đến độ tin cậy lâu dài và ổn định sản xuất.

Phần kết luận

Chọn một đối tác lắp ráp PCB SMT đáng tin cậy là một quyết định quản lý rủi ro hơn là một nhiệm vụ mua hàng. Mười câu hỏi trong hướng dẫn này cung cấp một cách có cấu trúc để đánh giá kinh nghiệm, kiểm soát quy trình và tính nhất quán mà không đi vào lý thuyết sản xuất hoặc yêu cầu bán hàng. Bằng cách tập trung vào các rủi ro cụ thể của đèn LED, chất lượng giao tiếp và sự ổn định lâu dài, những người ra quyết định có thể chọn các đối tác hỗ trợ hiệu suất có thể dự đoán được trong toàn bộ vòng đời của các sản phẩm chiếu sáng của họ.

hỏi Ẩn

Cụm đèn LED PCB SMT khác nhau vì đèn LED nhạy cảm với nhiệt, độ chính xác vị trí và sự thay đổi của thành phần. Các vấn đề nhỏ lắp ráp có thể làm giảm sản lượng ánh sáng hoặc tuổi thọ, làm cho việc kiểm soát quá trình trở nên quan trọng hơn nhiều so với nhiều ứng dụng SMT tiêu chuẩn.

Các rủi ro chính bao gồm lỗi LED sớm, độ sáng không nhất quán, sự thay đổi màu sắc và độ trễ làm lại. Những vấn đề này thường xuất hiện sau khi cài đặt, khi các bản sửa lỗi tốn kém và tác động đến uy tín cao.

Xử lý nhiệt là trọng tâm của độ tin cậy LED. Ứng suất nhiệt liên quan đến lắp ráp có thể làm hỏng đèn LED hoặc làm suy yếu đường dẫn nhiệt, ngay cả khi bản thân thiết kế PCB là âm thanh.

vâng. Lỗi vị trí nhỏ, lỗi hàn hoặc tiếp xúc nhiệt không kiểm soát có thể làm giảm đáng kể tuổi thọ của đèn LED và giảm độ ổn định của hệ thống theo thời gian.

Bạn nên cân nhắc việc thay đổi đối tác khi các vấn đề về chất lượng lặp lại, giao tiếp thiếu tính minh bạch hoặc kết quả sản xuất khác nhau giữa các lần chạy mặc dù thiết kế không thay đổi.