Bảng đèn LED là các thành phần cốt lõi tích hợp các đơn vị phát sáng LED, điện trở, tụ điện, IC điều khiển và các yếu tố khác vào chất nền PCB. Không giống như các mạch điện tử truyền thống, bảng đèn LED đặc biệt chú trọng đến hiệu suất nhiệt, khả năng mang dòng điện và độ ổn định lâu dài — tất cả đều phụ thuộc nhiều vào thiết kế và chất lượng sản xuất PCB.

Đặc biệt trong PCB dải LED và mô-đun, các thông số như độ dày đồng, vật liệu chất nền nhiệt, chiều rộng / khoảng cách theo dõi và điều khiển trở kháng ảnh hưởng trực tiếp đến hiệu quả phát sáng, độ ổn định nhiệt và tuổi thọ. Do đó, người ta phải cân bằng các cân nhắc chi phí với các thông số kỹ thuật và kiểm soát chất lượng khi lựa chọn dịch vụ sản xuất và lắp ráp PCB. Bài viết này khám phá những gì tạo nên sản xuất và lắp ráp PCB có giá trị cao, tập trung vào các ứng dụng LED.

Yêu cầu PCB cốt lõi cho dải LED và mô-đun

Là thành phần cốt lõi của ánh sáng hiện đại, dải đèn LED và mô-đun được sử dụng rộng rãi trong ánh sáng trang trí, đèn đuôi ô tô, màn hình quảng cáo và các ứng dụng nhà thông minh. Hiệu suất của chúng phụ thuộc rất nhiều vào khả năng tản nhiệt, hiệu quả dẫn điện và khả năng chống chịu thời tiết của PCB. Đặc biệt với sự gia tăng của công nghệ mini / micro LED, PCB phải hỗ trợ bố trí mật độ cao hơn và thiết kế nhiệt được tối ưu hóa. Ví dụ, trong các màn hình quảng cáo ngoài trời, PCB phải duy trì sự ổn định trong điều kiện nhiệt độ cao và độ ẩm cao để ngăn chặn sự phân rã ánh sáng do tản nhiệt không đầy đủ.

Với sự tiến bộ của công nghệ 5G và IoT, các mô-đun LED đặt ra nhu cầu cao đáng kể về tính toàn vẹn của tín hiệu PCB. Ví dụ, các mô-đun LED trong hệ thống lái xe tự lái ô tô yêu cầu thời gian phản hồi ở cấp độ mili giây, đưa ra những thách thức lớn hơn đối với độ chính xác định tuyến PCB và lựa chọn vật liệu.

Các loại PCB LED là gì?

PCB LED đóng vai trò là thành phần cốt lõi của các sản phẩm chiếu sáng LED. Các ứng dụng khác nhau đòi hỏi cấu trúc và vật liệu PCB khác nhau. Các loại phổ biến bao gồm.

| mẫu | thuộc về vật chất | Ứng dụng | phạm vi giá |

| PCB dải linh hoạt | Mạch in linh hoạt (FPC) | Khe cắm ánh sáng, tủ, môi trường lắp đặt không đều | 0,88 USD (bắt đầu) |

| Mô-đun LED PCB | Bảng sợi thủy tinh FR-4 / Bảng cơ sở nhôm | Đèn tuyến tính, đèn trần (FR-4 cho công suất thấp, nhôm cho công suất cao) | 1,35 USD (bắt đầu) |

| PCB dải cứng | Bảng cơ sở nhôm PCB / Bảng đồng FR-4 dày | chiếu sáng tuyến tính, chiếu sáng công nghiệp | 2.10 USD (bắt đầu) |

| Bảng PCB tùy chỉnh LED | Bảng PCB tùy chỉnh LED | Chiếu sáng cao cấp / chuyên nghiệp | 2.2USD (bắt đầu) |

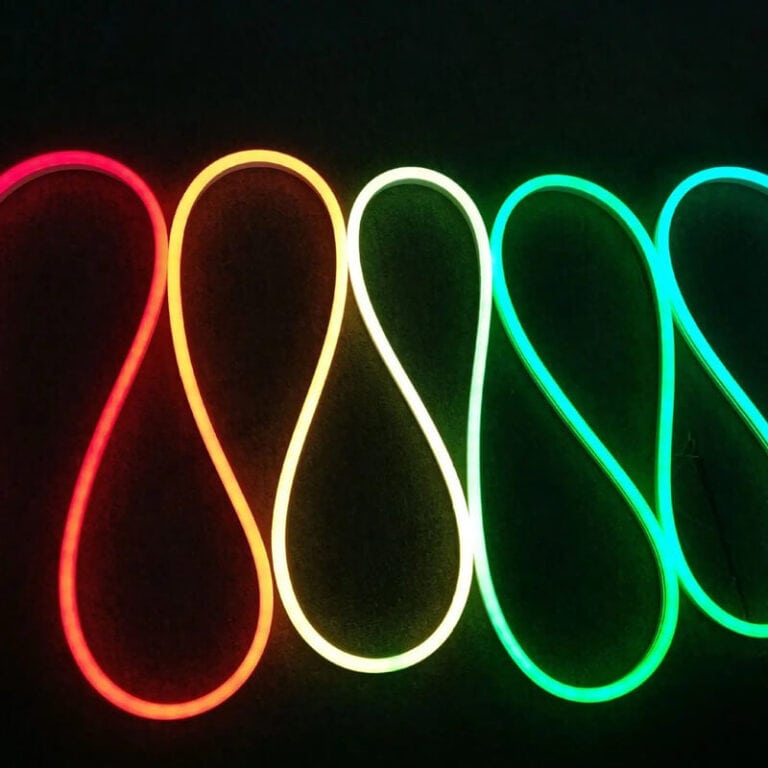

PCB dải linh hoạt

Mạch in linh hoạt (FPC) chủ yếu được sử dụng cho dải đèn led, cung cấp khả năng uốn cong và cấu hình mỏng lý tưởng cho các kênh ánh sáng, tủ và môi trường lắp đặt không đều. Các PCB này đòi hỏi sự cân bằng giữa tính linh hoạt và độ dẫn điện, thường đạt được thông qua lá đồng dày hơn hoặc cấu trúc hai lớp để tăng cường khả năng mang dòng điện và sự ổn định.

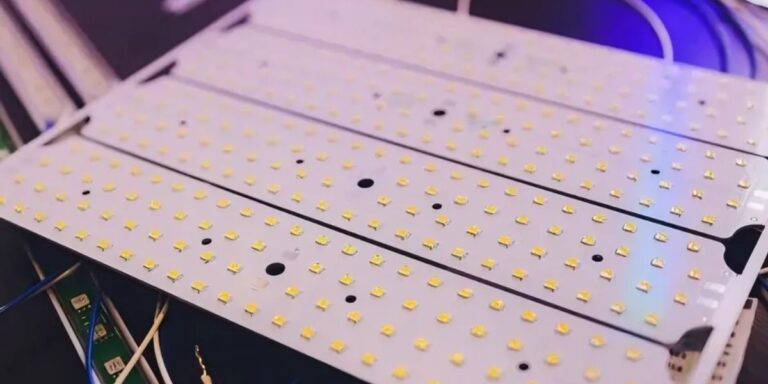

Mô-đun LED PCB

Mô-đun LED được sử dụng rộng rãi trong đèn tuyến tính và đèn trần. PCB thông thường bao gồm ván sợi thủy tinh FR-4 hoặc chất nền bằng nhôm. FR-4 cung cấp chi phí thấp hơn và phù hợp cho các ứng dụng điện thấp đến trung bình; chất nền nhôm cung cấp khả năng tản nhiệt vượt trội, làm cho chúng lý tưởng cho các mô-đun có độ sáng cao, mặc dù chúng yêu cầu độ tin cậy và tính nhất quán cao hơn trong các miếng hàn.

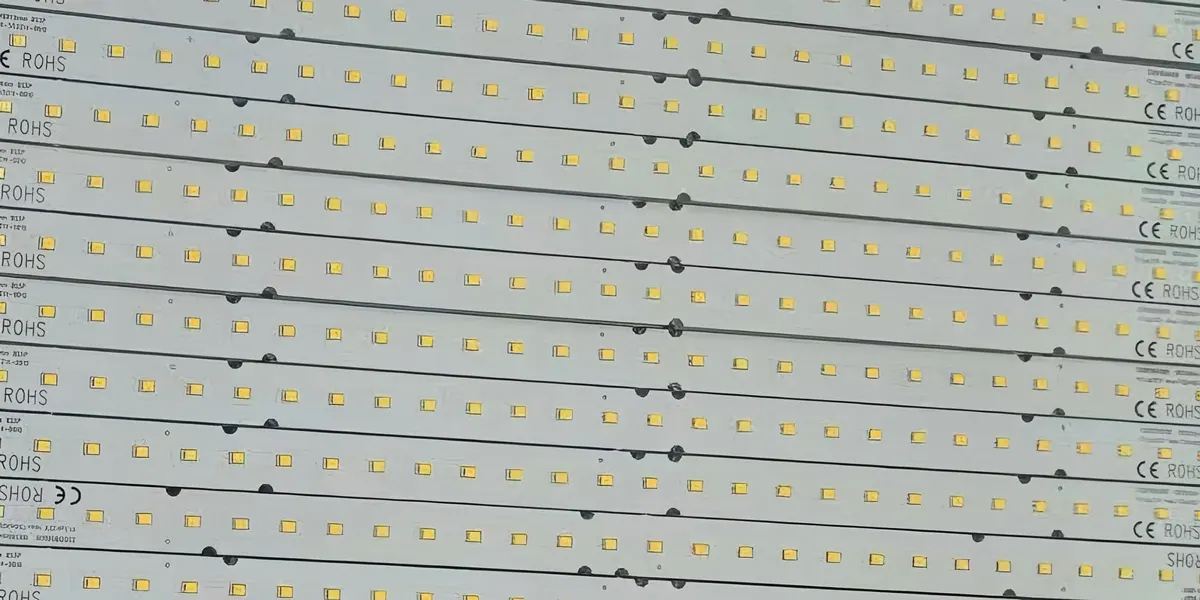

PCB dải cứng

dải ánh sáng cứng nhắc Thường sử dụng PCB làm từ nhôm hoặc bảng FR-4 đồng dày, mang lại độ cứng cấu trúc cao và tản nhiệt hiệu quả. Chúng thường được sử dụng trong các ứng dụng chiếu sáng tuyến tính và công nghiệp, giảm hiệu quả phân rã ánh sáng và kéo dài tuổi thọ.

PCB bảng đèn LED tùy chỉnh

Bảng đèn tùy chỉnh được thiết kế dựa trên yêu cầu công suất, kích thước và nhu cầu quản lý nhiệt, cho phép lựa chọn linh hoạt các cấu trúc PCB. Chúng tạo thành nền tảng quan trọng cho các giải pháp chiếu sáng cao cấp và chuyên biệt.

Khuyến nghị thực tế để lựa chọn nhà sản xuất PCB

Khi chọn nhà sản xuất PCB, hãy tiến hành đánh giá toàn diện dựa trên ba khía cạnh chính: chất lượng, năng lực và dịch vụ.

Đầu tiên, đánh giá hệ thống quản lý chất lượng. Ưu tiên các nhà sản xuất được chứng nhận ISO9001, ISO14001, v.v. và xác minh rằng họ có các quy trình kiểm tra hoàn chỉnh — bao gồm kiểm tra vật liệu đến và kiểm tra trong quy trình (AOI, kiểm tra đầu dò / cố định bay) —để đảm bảo tính ổn định của sản phẩm.

Thứ hai, đánh giá khả năng kỹ thuật và năng lực sản xuất, bao gồm kiểm soát độ dày đồng, lớp nền, độ chính xác theo dõi và kinh nghiệm liên quan với cụm bảng LED, PCB dải và PCB mô-đun. Điều này ngăn chặn các vấn đề quản lý nhiệt và tuổi thọ do quy trình sản xuất không đầy đủ.

Thứ ba, ưu tiên thời gian giao hàng và khả năng đáp ứng. Chu kỳ phân phối nhất quán và hỗ trợ kỹ thuật nhanh chóng giảm đáng kể rủi ro dự án. Cuối cùng, tập trung vào hiệu quả chi phí và tiềm năng hợp tác lâu dài. Giá cả không phải là tiêu chí duy nhất; các nhà sản xuất PCB có khả năng cung cấp chất lượng nhất quán, hỗ trợ kỹ thuật và dịch vụ sau bán hàng phù hợp hơn để hợp tác bền vững.

Khi so sánh các báo giá từ các nhà sản xuất PCB khác nhau, hãy tránh chỉ tập trung vào giá bảng trần. Xác minh xem có bao gồm kiểm tra điện, kiểm tra AOI và xử lý bề mặt tấm đệm hay không. Đồng thời đánh giá xem nhà sản xuất có hỗ trợ độ dày đồng tùy chỉnh và vật liệu nền theo yêu cầu thiết kế hay không. Đối với bảng, dải và mô-đun LED, tiến hành xem xét DFM trước khi sản xuất hàng loạt để chủ động tránh sự không phù hợp trong quy trình thiết kế, giảm thiểu việc làm lại, chậm trễ và chi phí bổ sung.

Xu hướng tùy biến trong PCB LED

Các ứng dụng LED hiện đại đang phát triển theo hướng mạnh mẽ, tùy biến và trí thông minh. Đáng chú ý, việc thiết lập tiêu chuẩn Zhaga cho phép các mô-đun tuyến tính LED đạt được sự linh hoạt trong thiết kế, thuận tiện bảo trì và tính bền vững lâu dài thông qua các thông số kỹ thuật cụ thể, thúc đẩy ngành chiếu sáng theo hướng phát triển mô-đun. Bảng đèn tùy chỉnh hỗ trợ thay thế nhanh các mô-đun ở nhiều hình dạng khác nhau (chẳng hạn như hình tròn hoặc tuyến tính), thích ứng với đèn chiếu sáng, đèn tuyến tính, v.v. Với thiết kế plug-and-play, chúng hỗ trợ mở rộng mô-đun song song để đáp ứng các yêu cầu đầu ra lumen đa dạng, cho phép lắp đặt đèn nhanh chóng miễn phí công cụ.

Bảng chiếu sáng tùy chỉnh mang lại những lợi thế sau:

- Lắp đặt & Bảo trì: Thiết kế plug-and-play cho phép cài đặt không cần dụng cụ. Việc sử dụng mô-đun tiêu chuẩn hóa giúp giảm chi phí thiết kế, tạo điều kiện thay thế trong tương lai và giảm chi phí tổng thể.

- sự chắc chắn: được chứng nhận bởi các trung tâm kiểm tra độc lập để đảm bảo hiệu quả phát sáng cao, ánh sáng xanh thấp, và các đặc điểm khác. Quản lý nhiệt vượt trội và PCB với độ dày đồng cao giúp tăng cường đáng kể khả năng sử dụng và chất lượng sản phẩm.

- Đổi mới hiệu quả: Các nhà sản xuất nâng cấp bất kỳ đèn điện nào không cần thiết kế lại từ đầu. Chúng có thể tuân thủ các thành phần chiếu sáng lõi tiêu chuẩn Zhaga trong khi sửa đổi các phần cụ thể. Thiết kế mô-đun tạo điều kiện thay thế một phần, giảm chi phí bảo trì tổng thể. Điều này không chỉ giúp tiết kiệm chi phí R&D mà còn đẩy nhanh việc ra mắt sản phẩm mới.

Những xu hướng này yêu cầu các nhà sản xuất và lắp ráp PCB phải sở hữu khả năng xử lý mạnh mẽ hơn, chẳng hạn như công nghệ đa lớp và chuyên môn sản xuất chất nền kim loại.

Signitel có lợi thế nào trong dịch vụ sản xuất và lắp ráp PCB?

Sản xuất nhanh chóng và lợi thế chi phí thấp

SigniLited cung cấp các dịch vụ sản xuất điện tử một cửa bao gồm mua sắm linh kiện điện tử, sản xuất và chế biến PCB, đặt SMT, thử nghiệm PCBA và lắp ráp cuối cùng. Tận dụng mua hàng quy mô lớn và hệ thống kiểm soát chất lượng nghiêm ngặt, công ty duy trì quan hệ đối tác lâu dài với nhiều nhà cung cấp linh kiện hàng đầu trong nước và quốc tế. Điều này đảm bảo chất lượng vật liệu ổn định và giao hàng đáng tin cậy, với lợi thế mua sắm trực tiếp được chuyển cho khách hàng. Lợi thế chi phí đáng kể tồn tại đối với các vật liệu phổ biến như đèn LED, điện trở, tụ điện và cuộn cảm, giảm áp lực hàng tồn kho của khách hàng một cách hiệu quả, cải thiện hiệu quả doanh thu sản xuất và rút ngắn thời gian dẫn đầu.

Khả năng đảm bảo chất lượng

Signelited đã thiết lập một hệ thống quản lý chất lượng toàn diện, thực hiện kiểm soát toàn bộ quy trình đối với các nguyên liệu, quy trình sản xuất và các lô hàng đến. Đối với bảng LED, dải và các sản phẩm mô-đun, công ty cung cấp các bài kiểm tra lão hóa và xác minh độ tin cậy để chủ động giảm thiểu rủi ro ứng dụng. Thông qua các hoạt động tiêu chuẩn hóa và cơ chế cải tiến liên tục, chúng tôi nâng cao tỷ lệ năng suất và sự ổn định phân phối, cung cấp các dịch vụ sản xuất PCBA đáng tin cậy, chất lượng cao.

Giải pháp sản xuất và lắp ráp tích hợp

SigniLited tích hợp sâu sản xuất PCB với lắp ráp SMT, được bổ sung bởi quản lý đơn đặt hàng kỹ thuật số và hỗ trợ BOM. Điều này cho phép xác nhận thiết kế nhanh chóng và phát triển nguyên mẫu chức năng — đặc biệt phù hợp với bảng, dải và mô-đun LED — tăng đáng kể hiệu quả của chuỗi cung ứng đồng thời giảm chi phí sản xuất tổng thể.

Khả năng sản xuất PCBA hiệu quả về chi phí

Công ty bao gồm cả sản xuất tạo mẫu và tạo khối PCB nhanh chóng, với khả năng sản xuất PCB nhiều lớp và laminate phủ kim loại (MCCB) phù hợp cho các ứng dụng LED công suất từ trung bình đến cao. Thông qua năng lực sản xuất ổn định, quy trình trưởng thành và dịch vụ thử nghiệm toàn diện, chúng tôi cung cấp các giải pháp sản xuất PCBA bền vững, hiệu quả về chi phí.

Khả năng hỗ trợ kỹ thuật và R&D toàn diện

Ngoài thế mạnh sản xuất và lắp ráp, Signiteled còn sở hữu khả năng hỗ trợ kỹ thuật và R&D trưởng thành. Các nhóm có kinh nghiệm của chúng tôi trong kỹ thuật điện tử, quy trình PCB và phát triển ứng dụng LED cung cấp hỗ trợ dự án giai đoạn đầu, bao gồm đánh giá giải pháp, đánh giá DFM và tối ưu hóa BOM. Công ty cung cấp sự phát triển hợp tác từ đầu đến cuối từ thiết kế và tối ưu hóa PCB đến tạo mẫu và sản xuất hàng loạt, cho phép đáp ứng nhanh chóng các yêu cầu tùy chỉnh, rút ngắn chu kỳ phát triển sản phẩm và cải thiện tỷ lệ thành công thiết kế lần đầu tiên. Việc tích hợp liền mạch giữa R&D và sản xuất giúp tăng cường khả năng cạnh tranh của sản phẩm về hiệu suất, độ tin cậy và kiểm soát chi phí.

Tác động của đặc tính vật liệu PCB đối với sản phẩm LED

- Loại vật liệu cơ sở: FR-4 giá thể thấp nhưng tản nhiệt trung bình, làm cho chúng phù hợp với các dải công suất thấp như chiếu sáng trang trí dân dụng. Chất nền nhôm mang lại khả năng tản nhiệt vượt trội cho các mô-đun công suất cao như đèn pha ô tô. Chất nền gốm chịu được nhiệt độ cao, lý tưởng cho môi trường khắc nghiệt như thiết bị chiếu sáng công nghiệp.

- Độ dày lá đồng: Lá đồng dày hơn (ví dụ, 2 oz) tăng cường khả năng mang dòng điện, giảm sinh nhiệt và cải thiện độ ổn định của dải. Ví dụ, các thử nghiệm giảm điện áp trên các dải LED điều khiển 24V cho thấy lá đồng 2 oz mang lại độ ổn định dòng điện cao hơn 30% so với lá 1 oz.

- phép hàn chì trung bìnhhỏi: Mặt nạ hàn trắng phản chiếu ánh sáng giúp tăng hiệu quả phát sáng, thích hợp cho các ứng dụng có độ sáng cao như chiếu sáng sân khấu. Mặt nạ hàn màu đen được sử dụng trong các cài đặt được che giấu, cân bằng tính thẩm mỹ và chức năng, chẳng hạn như dải ánh sáng ẩn trong nhà thông minh.

Làm thế nào để phân biệt chất lượng PCB?

- kiểm tra trực quan: PCB chất lượng cao có miếng đệm phẳng và dấu vết sắc nét, không có gờ. Sản phẩm kém chất lượng thường có vết xước hoặc cong vênh, ảnh hưởng đến độ tin cậy của mối hàn. Ví dụ, trong AOI (kiểm tra quang học tự động), tỷ lệ lỗi đối với PCB cao cấp dưới 0,1%, trong khi các sản phẩm không đạt tiêu chuẩn có thể vượt quá 5%.

- không gian nốt thứ sáu trongvị quan trong kỳ họp: Dung sai phải tuân thủ nghiêm ngặt các thông số kỹ thuật thiết kế. Ví dụ, sai lệch đường kính lỗ có thể gây ra lỗi lắp đặt thành phần. Kiểm tra các thông số quan trọng bằng cách sử dụng các công cụ đo chính xác — phải kiểm soát dung sai độ rộng / khoảng cách của đường dây trong vòng ± 0,05 mm.

- thuộc về cơ quan số kim hiệuđánh số: Kiểm tra tính liên tục đảm bảo tính toàn vẹn của mạch, trong khi kiểm tra điện trở cách điện ngăn ngừa ngắn mạch. Việc sàng lọc cơ bản có thể được thực hiện bằng các công cụ đơn giản như đồng hồ vạn năng, nhưng các thiết bị chuyên nghiệp như máy đo LCR cung cấp dữ liệu chính xác hơn.

- bề dày đồng: PCB Đồng lựa chọn độ dày là rất quan trọng trong bảng đèn LED. Các lớp đồng dày hơn hỗ trợ dòng điện cao hơn và tản nhiệt tốt hơn, ngăn chặn hư hỏng do nhiệt độ tăng quá mức. Đối với dải LED tiêu chuẩn, 2 oz đồng được coi là đủ. Tuy nhiên, đối với dải đèn LED công suất cao hoặc hoạt động mở rộng, 3 oz trở lên được khuyến nghị để đảm bảo độ sáng ổn định, giảm điện áp tối thiểu và độ tin cậy lâu dài.

Phương pháp kiểm tra PCB LED

- Kiểm tra hiệu suất điện: Kiểm tra độ rơi điện áp đánh giá độ ổn định của dòng điện. Nguồn điện dòng điện không đổi mô phỏng điều kiện tải thực tế để ngăn độ sáng không đều. Ví dụ, ở dòng điện 1A, PCB chất lượng cao phải có điện áp giảm nhỏ hơn 0,5V.

- Kiểm tra hiệu suất nhiệt: Hình ảnh nhiệt hồng ngoại phát hiện các điểm nóng cục bộ để xác định các sai sót tản nhiệt. Ví dụ, sau khi hoạt động liên tục trong 1 giờ, chất nền nhôm phải thể hiện sự phân bố nhiệt độ đồng đều mà không bị quá nhiệt cục bộ.

- Kiểm tra độ tin cậy: Nhiệt độ đi xe đạp mô phỏng các biến thể theo mùa, trong khi kiểm tra độ rung xác minh độ bền vận chuyển. Ví dụ, trong thời gian từ -40 ° C đến 85 ° C, PCB chất lượng cao nên duy trì tỷ lệ hỏng hóc dưới 0,01%.

- Kiểm tra hiệu suất quang học: Một quả cầu tích hợp đo nhiệt độ màu và độ sáng nhất quán để ngăn chặn sự thay đổi hiệu quả sáng giữa các mô-đun. Ví dụ: trong màn hình quảng cáo, sự khác biệt về màu sắc giữa các mô-đun nên được kiểm soát trong ΔE <3.

- Kiểm tra chất lượng hàn: Kiểm tra quang học tự động AOI và quét tia X phát hiện các mối hàn lạnh hoặc cầu hàn để cải thiện tỷ lệ năng suất. Ví dụ, trong các mô-đun điện tử ô tô, kiểm tra tia X đạt được tỷ lệ phát hiện lỗi là 99,9%.

- Kiểm tra khả năng thích ứng môi trường: Thử nghiệm phun muối đánh giá khả năng chống ăn mòn ngoài trời, trong khi các thử nghiệm chống thấm xác nhận xếp hạng IP. Ví dụ, trong thử nghiệm xếp hạng IP65, các mô-đun phải hoạt động liên tục trong 24 giờ mà không bị hỏng trong điều kiện phun nước.

Các vấn đề và giải pháp chung

- Độ sáng dải LED không đồng đều: Có thể do phân phối dòng điện PCB không đồng đều hoặc phân loại LED không chính xác. Các biện pháp đối phó bao gồm tối ưu hóa thiết kế định tuyến và sàng lọc các thành phần nghiêm ngặt, chẳng hạn như sử dụng các mạch ổ đĩa dòng điện không đổi.

- tản nhiệt mô-đun kém: Không đủ độ dày của lớp nền nhôm hoặc không đủ ứng dụng dán nhiệt là những nguyên nhân chính. Tăng độ dày bề mặt và cải thiện các quy trình ứng dụng cải thiện đáng kể hiệu suất, ví dụ, nâng độ dày lớp nền nhôm từ 1,5 mm lên 2,0 mm.

- khuyết tật hàn: Chất lượng dán hàn kém hoặc máy đặt không đủ độ chính xác gây ra các mối hàn lạnh. Lựa chọn vật liệu có độ tin cậy cao và thiết bị hiệu chuẩn giúp giảm hư hỏng, ví dụ, sử dụng thiết bị kiểm tra quang học tự động và hàn không chì.

Phần kết luận

Khả năng cạnh tranh cốt lõi của các nhà cung cấp PCB cao cấp nằm ở sự lặp lại công nghệ, kiểm soát chất lượng và các dịch vụ tùy chỉnh. Với nhu cầu ngày càng tăng đối với máy chủ AI và các ứng dụng LED nhỏ, ngành công nghiệp PCB đang tiến tới các giải pháp tần số cao, tốc độ cao và mức độ tổn thất thấp. Điều này đặt ra yêu cầu cao hơn về lựa chọn vật liệu và quy trình sản xuất. Nên cân bằng chi phí và hiệu suất dựa trên các yêu cầu của dự án: những đổi mới vật liệu trong tương lai, chẳng hạn như các tấm ốp đồng mới, sẽ nâng cao hơn nữa hiệu suất của sản phẩm LED. Ví dụ, việc áp dụng các chất nền gốm nitride nhôm có thể cải thiện đáng kể hiệu suất nhiệt.

Với sự áp dụng rộng rãi và tiến bộ công nghệ của các sản phẩm chiếu sáng LED, nhu cầu về bảng mạch — từ PCB dải LED và PCB mô-đun LED đến các ứng dụng chiếu sáng công suất cao — đang tăng nhanh chóng. Do đó, giá trị của “Sản xuất và lắp ráp PCB” đã trở thành trọng tâm trong chuỗi ngành. Các công ty sản xuất và lắp ráp PCB cung cấp giá trị tối ưu trong các tình huống ứng dụng LED, nhấn mạnh tầm quan trọng của việc lựa chọn PCB trong thiết kế bảng LED.

hỏi Ẩn

PCB linh hoạt (FPC) là lý tưởng cho các dải LED do khả năng uốn cong và thiết kế nhẹ.

Độ dày đồng phù hợp đảm bảo dòng điện ổn định và giảm tích tụ nhiệt, kéo dài tuổi thọ LED.

PCB nhôm rất tuyệt vời cho đèn LED công suất cao, nhưng FR-4 hoặc FPC có thể tiết kiệm chi phí hơn cho ánh sáng trang trí hoặc công suất thấp.

Yêu cầu mẫu, xem xét các báo cáo thử nghiệm và xác nhận các quy trình kiểm tra như AOI và kiểm tra điện.