LED照明行业已经在住宅、商业、工业和汽车应用领域改变了现代照明。 LED 适合高能效、长寿命和紧凑的尺寸。 然而,它们的性能在很大程度上取决于 PCB 设计、SMT 组装质量和焊点可靠性。 即使是轻微的组装缺陷也会导致闪烁、颜色不一致、热点形成或过早失效。

本指南探讨

- 提高PCB LED可靠性的策略

- 专注于SMT最佳实践、焊点优化和热管理。

- 帮助制造商实现高质量和耐用的 LED 系统。

PCB LED 的常见可靠性挑战

LED 对热、电和机械应力高度敏感。 糟糕的设计或组装会影响性能和寿命。 典型的挑战包括:

- 破裂或打开的焊点导致间歇连接。

- 导致 PCB 翘曲和组件退化的热应力。

- 高电流密度下的电迁移破坏铜迹线。

- 处理、运输或热循环的机械应力。

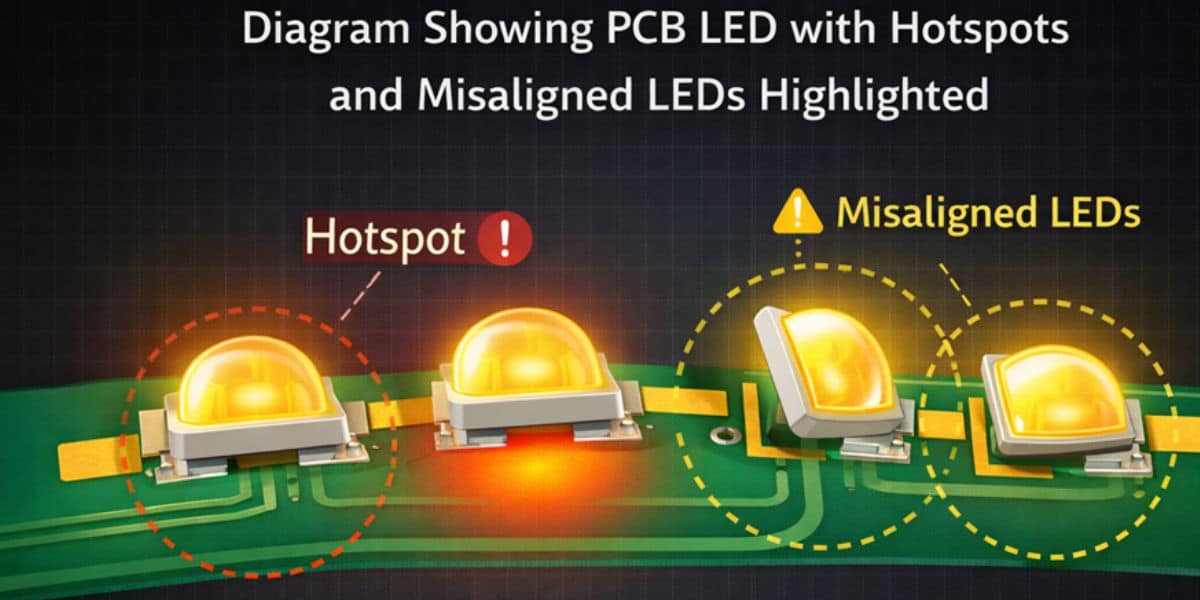

- 未对齐的 LED 导致光输出不均或可见热点。

表 1:PCB 和 SMT 问题对 LED 可靠性的影响

| 打 | 惹 | 对 LED 系统的影响 |

| 破裂的焊点 | 热循环,机械应力 | 闪烁,开路 |

| 未对齐的 LED | 接入错误 | 光分布不均 |

| 热点 | 散热不良 | 流明折旧,早期失败 |

| 电迁移 | 高电流密度,细迹 | 痕迹损坏,随时间故障 |

| 焊料空隙 | 不当的糊剂沉积 | 降低热/导电性 |

表面贴装技术 (SMT) 注意事项

SMT 允许精确放置 LED 、更小的外形和改进的电气性能。 然而,不良的 SMT 实践会降低可靠性。

1:SMT的PCB设计

精心设计的PCB布局支持可靠性:

| 设计元素 | 最佳实践 |

| 垫尺寸和形状 | 确保正确的焊料润湿并避免桥接 |

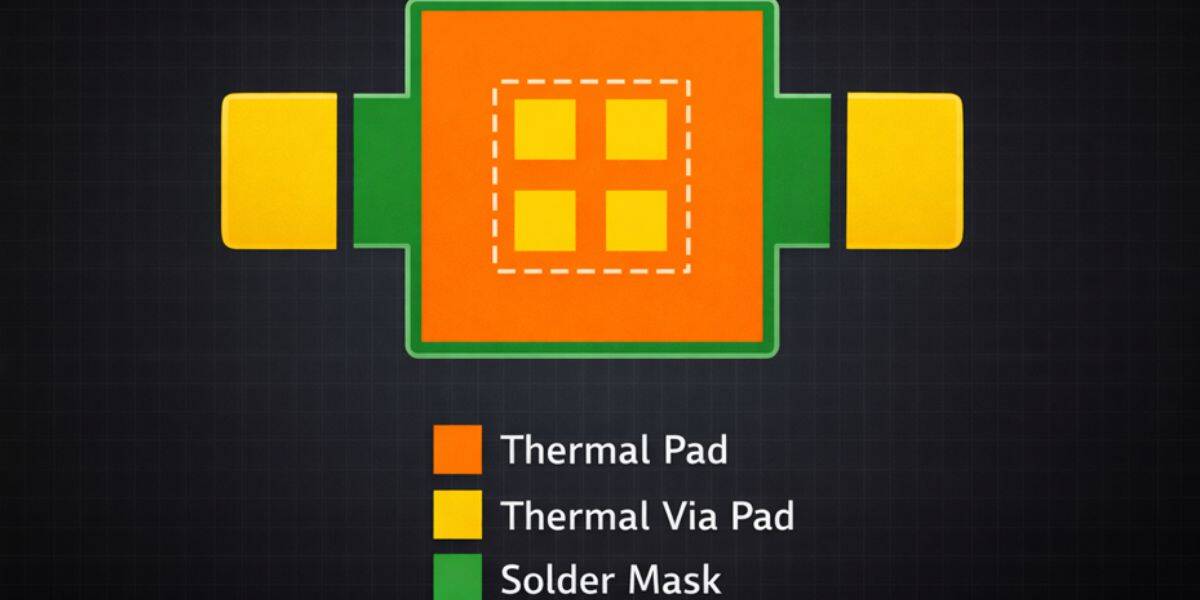

| 导热垫 | 改善大功率LED的散热 |

| 阻焊层设计 | 防止焊料溢出并保持放置精度 |

| 走线宽度和铜 | 保持低电阻并有效处理电流 |

2:拾取和放置精度

正确的放置对于均匀照明至关重要:

- 喷嘴的选择、放置速度和压力必须优化。

- 错位会产生光学不一致和机械应力。

- 定期校准可减少放置错误和返工。

3:焊膏应用

焊膏质量和应用至关重要:

- 低空隙率、高质量的膏体可确保持续润湿。

- 精密模板可防止焊料不足或过多。

- 助焊剂含量必须适合防止氧化。

焊点可靠性

焊点形成LED和PCB之间的机械和电气连接。 焊接不良是主要的故障原因。

1:焊料合金选择

- SAC305 (SNAGCU) 是无铅标准。

- 低熔点合金减少回流过程中的热应力。

- 合金必须与 PCB 饰面(ENIG、HASL、OSP)兼容。

2 :回流配置文件优化

回流温度必须控制:

- 预热、浸泡和峰值温度必须与制造商的建议相匹配。

- 避免过热的 LED 或焊盘以防止热冲击。

- 受控冷却可降低开裂风险。

3:焊点几何形状

适当的接头形状可提高强度和导电性:

- 圆角高度应覆盖焊盘,而无需过多的焊料。

- 光滑的凹角,减少空隙的形成。

- 共面性确保稳定的电接触。

4:检验与质量控制

- 自动光学检查 (AOI) 检测可见缺陷。

- X 射线检查可识别导热垫中的隐藏空隙。

- 定期流程审核保持一致的质量。

表 2:LED 推荐的焊料圆角规格

| LED 类型 | 圆角高度 (mm) | 接合角 | 札记 |

| 0.2–0.5 w LED | 0.2–0.3 | 45–60° | 标准表面安装LED |

| 1–3 W LED | 0.3–0.5 | 45–70° | 大功率LED需要热支持 |

| >5 W LED | 0.4–0.6 | 60–75° | 使用热过孔和金属芯 PCB |

SMT LED 的热管理

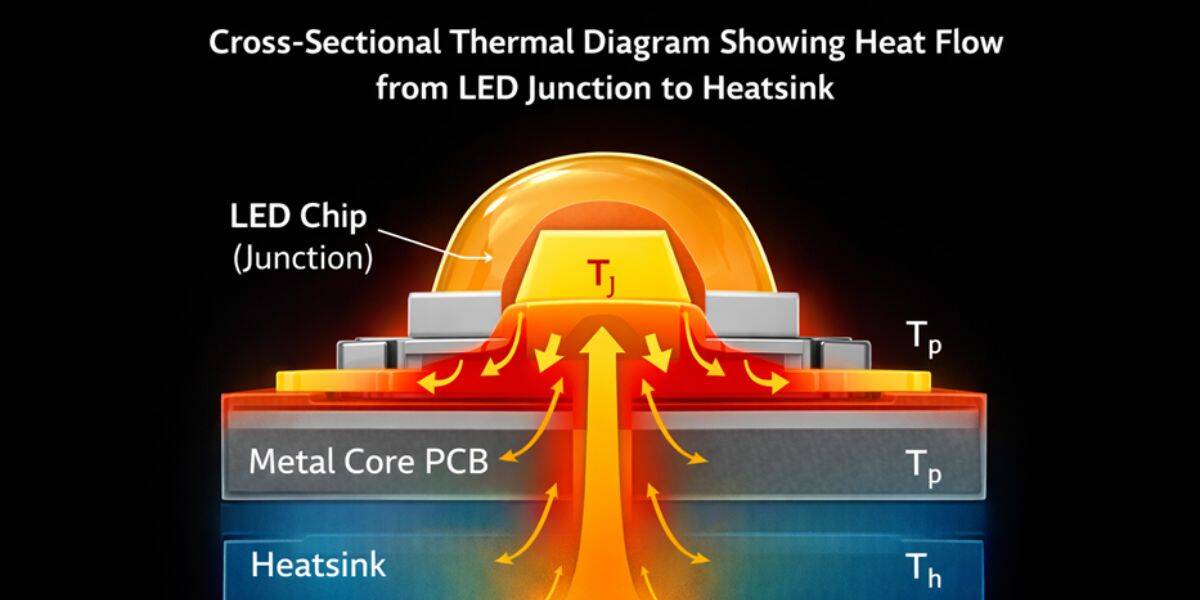

热是最 LED可靠性的关键因素。 高温加速流明折旧并缩短寿命。

关键策略:

- 铝芯PCB可改善散热。

- LED下的热通路将热量传递到较大的铜平面。

- 散热器和 TIM 对高功率应用至关重要。

- 正确的 LED 间距可防止热点并确保温度分布均匀。

常见的SMT和焊接问题

| 打 | 惹 | 解决方案 |

| 墓石 | 回流过程中表面张力不均匀 | 调整焊膏体积和轮廓 |

| 焊接桥接 | 过量焊料,未对准的焊盘 | 减少糊料沉积,改善模板 |

| 冷焊接点 | 湿润性差,低温 | 优化回流曲线和焊料类型 |

| 废物 | 捕获的空气或助焊剂 | 使用低空隙膏,适当回流 |

可靠的PCB LED组装的最佳实践

可制造性设计 (DFM):使用 SMT 功能对准焊盘、走线和热路径。

- 使用优质焊膏: 低空隙、一致的合金,具有适当的通量。

- 控制回流曲线: 防止过热和快速冷却。

- 检查: AOI、X 射线和手动检查。

- 处理: 运输和组装过程中的机械应力最小化。

- 热设计: 金属芯PCB、热通路和散热器。

- 标准化流程: 文档确保了可重复性。

案例研究:大功率LED模块

高位工业LED模块因热循环而频繁出现焊点故障。

实施的改进:

- 切换到铝芯PCB。

- 优化的焊膏沉积。

- 受控回流曲线。

- LED 下方添加了热过孔。

结果:

- 30% 减少焊点缺陷。

- 5,000 小时后改进流明维护。

PCB LED组装的新兴趋势

- 低温焊接合金可减少热应力。

- 无铅焊接可确保在不降低可靠性的情况下合规。

- 人工智能辅助检测比传统方法更快地检测缺陷。

- 具有高导热性的先进PCB材料可改善散热。

- 3D 热模拟在生产前预测热点。

制造商的其他提示

- 使用模板设计软件进行精确的焊膏沉积。

- 进行热模拟以防止生产前的热点。

- 定期校准拾取和放置机器。

- 保持装配区域的湿度和温度可控。

- 为高湿度环境使用保护涂层。

结论

PCB LED 可靠性取决于 SMT 组装质量、焊点完整性和热管理。 适当的设计、焊接和工艺控制可防止故障、增强性能并延长 LED 的使用寿命。 实施优化布局、高质量焊接和先进热策略的制造商实现了可靠、持久的 LED 系统,光输出稳定。

对于高性能、耐用的 LED 解决方案,Trust Signliteed 适用于专业设计的 PCB LED 组件。 我们专注于 SMT 优化、精确焊接和先进的热管理,以提供可靠的照明。

联系方式今天签名 提高产品质量,减少故障,并确保卓越的 LED 性能。

常见问题

SMT(表面贴装技术)可实现精确的 LED 放置、缩小尺寸并提高电气和热性能。

焊点提供机械支撑和电连接;不良的接头会导致故障或闪烁。

典型的缺陷包括墓碑、焊接桥接、冷接头和空隙,所有这些都会降低性能和使用寿命。

通过热通路、铝芯 PCB 和散热器进行高效散热,可防止过热并延长使用寿命。

自动光学检查 (AOI)、X 射线检查和手动检查可检测未对准、空隙和桥接等缺陷。