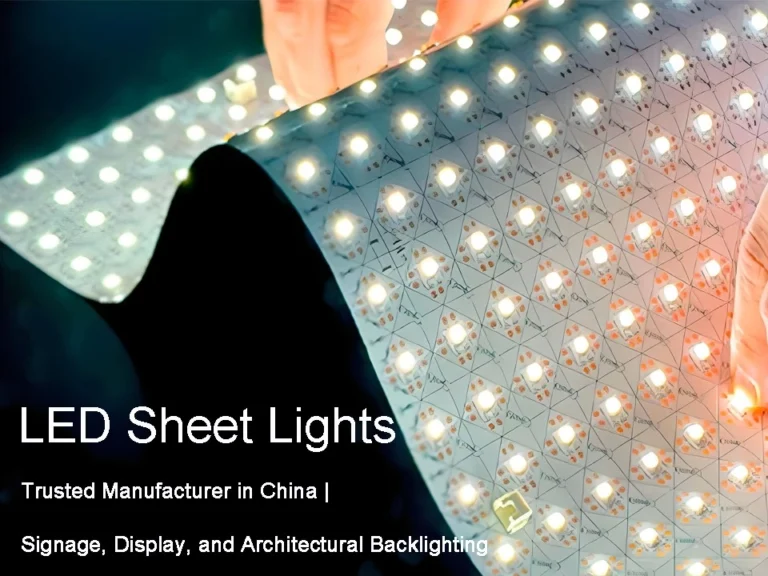

过去十年,LED照明技术发展迅速,市场对更薄、更亮、更节能的光源的需求不断增长。 在众多的创新解决方案中,LED 片灯已成为一种流行的选择,被广泛用作商业和广告应用的美学背光解决方案。

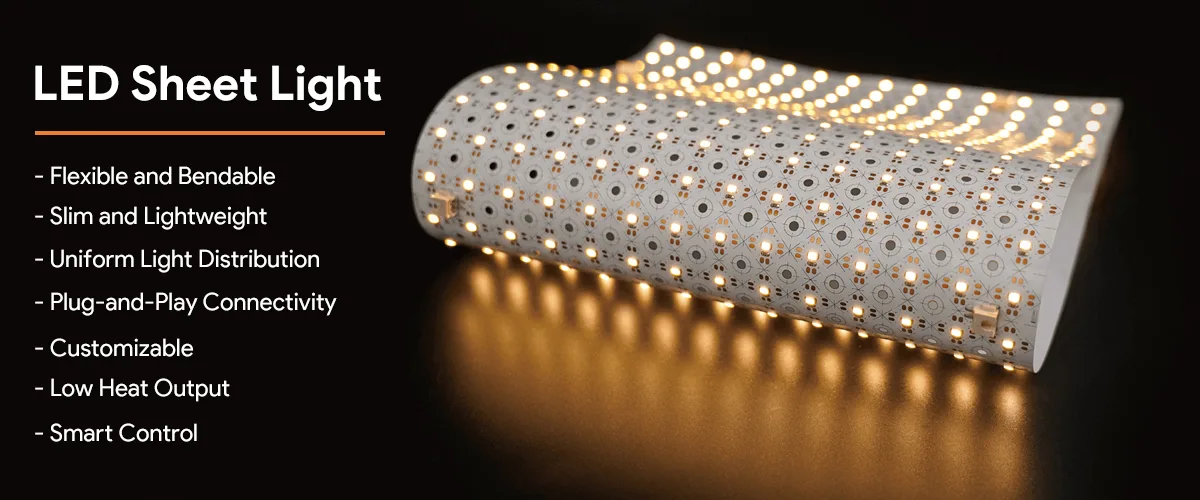

LED灯片 是平坦、灵活的面板形 LED 灯片,代表了先进的照明解决方案,将灵活性与一致的亮度相结合。 将LED技术的能效和长寿命与柔性照明面板的适应性相结合,支持高水平的定制。 其多功能性使它们特别适合广告商、零售商、建筑师和买家,寻求在增强视觉影响力的同时节省空间的解决方案。

本指南探讨了 LED 灯片的变革潜力,深入分析了它们的功能、优点、安装、实际应用和采购的关键考虑因素。 它使您能够为您的项目做出正确的选择。

什么是LED片灯?

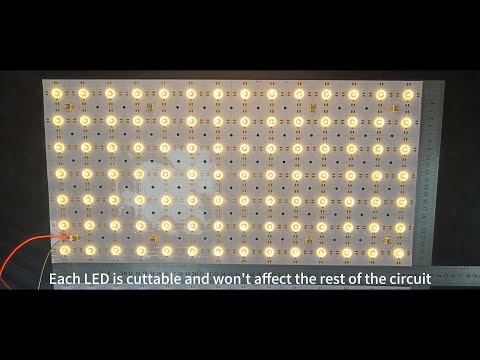

LED片灯是一种扁平的、柔性的片材,通常由许多小型SMD LED组成。 这些LED使用SMT技术嵌入薄而柔性的电路板上,允许将电路板切割成尺寸和定制。

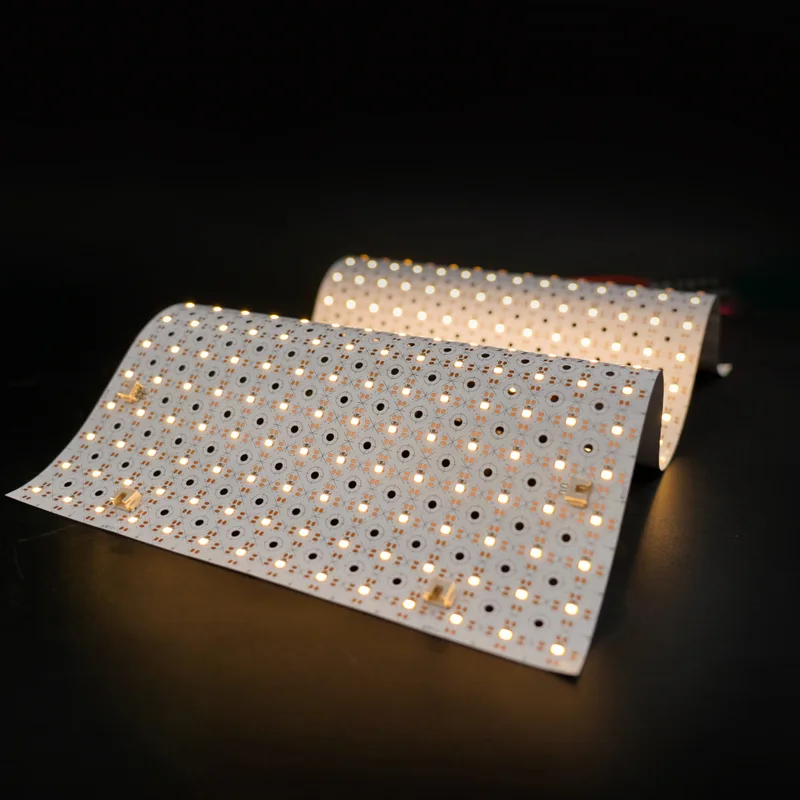

与刚性LED灯条不同,LED板可以切割成各种形状,并容易弯曲或折叠以适应弯曲的表面和不规则的轮廓。 平板LED 板可连接在一起以覆盖较大的区域,使其成为广泛且形状不规则的照明应用的理想解决方案。

由于其双面胶粘背衬,LED 片灯易于安装,无需任何复杂的步骤。 对于更永久的安装,也可以使用螺钉或紧固件。 此外,连接多个 LED 板很简单,可以让您扩展或创建无缝的大型照明表面。

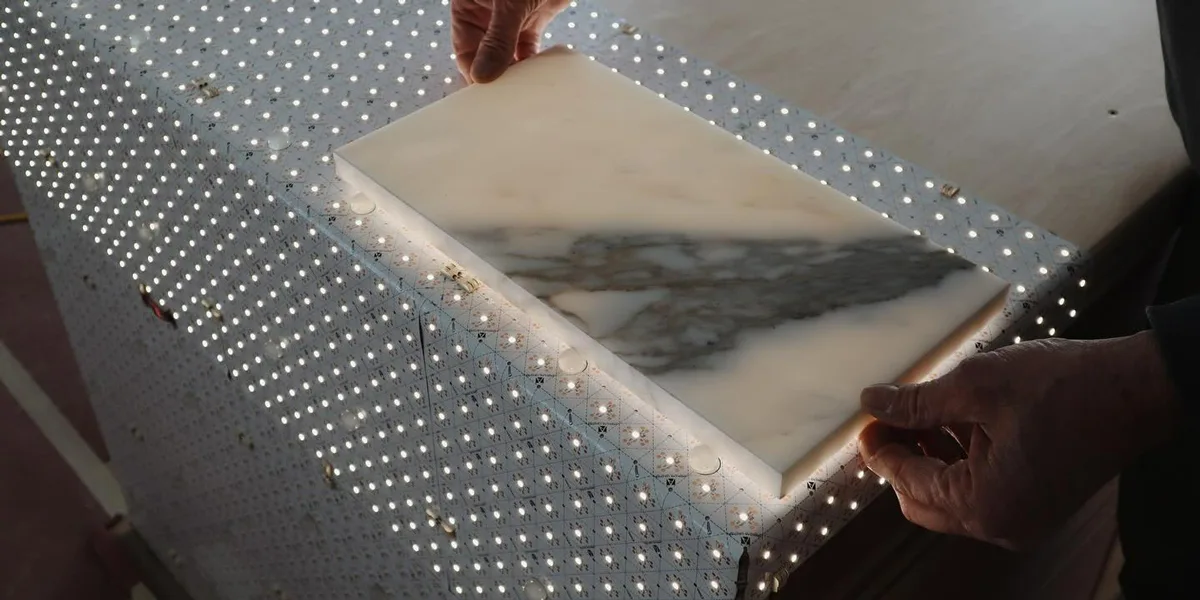

如今,LED 单片照明广泛用于酒吧、餐馆和零售商店,以照亮大理石和玛瑙等石头表面,以及玻璃和亚克力等半透明材料。 此外,LED 板材在标牌照明项目中受到设计师的青睐。

主要特点和优势

- 灵活和 B残:与刚性LED面板不同,柔性LED面板可以弯曲并符合各种形状和表面。 这种灵活性使应用在弯曲或不平坦的表面上,提供多功能照明解决方案。

- 苗条和 L重量轻:这些光片通常非常薄且轻便,因此易于安装在传统照明解决方案可能不适合的狭窄或狭窄空间中。

- 均匀配光:LED以均匀和密集的图案排列,以最大限度地分布光,同时最大限度地减少热点和阴影。 这使得它们非常适合需要平稳、连续照明的应用。

- 即插即用连接:通过板载 XH 接口和 XH 连接器轻松连接 LED 灯。 一旦切割成所需的形状,这些连接器就可以使 LED 片材作为即插即用的解决方案。 XH 连接器提供多种引脚配置。

- 可定制:灵活的 LED 板可以切割成特定的形状和尺寸,以满足定制的照明要求。 它们可以针对各种应用进行定制,从复杂的小型设计到大型安装。

- 低 H吃 O吞就:LED 片材通常比传统光源产生更少的热量,使其适合温度敏感的地方。 例如,它们可以安装在封闭的标牌内而不会过热。

- 智能控制:附加控制器允许您调整白光、RGBW 和 RGB LED 灯条灯的亮度或颜色。 一些控制器支持蓝牙、射频遥控器、移动应用程序、Wi-Fi 集线器、开关或调光器,实现完全可定制的照明设计。

LED灯片的种类

了解可用的 LED 片灯类型是为您的项目选择正确的片状灯的关键。 SignliteLED 提供一系列产品以满足您的需求。

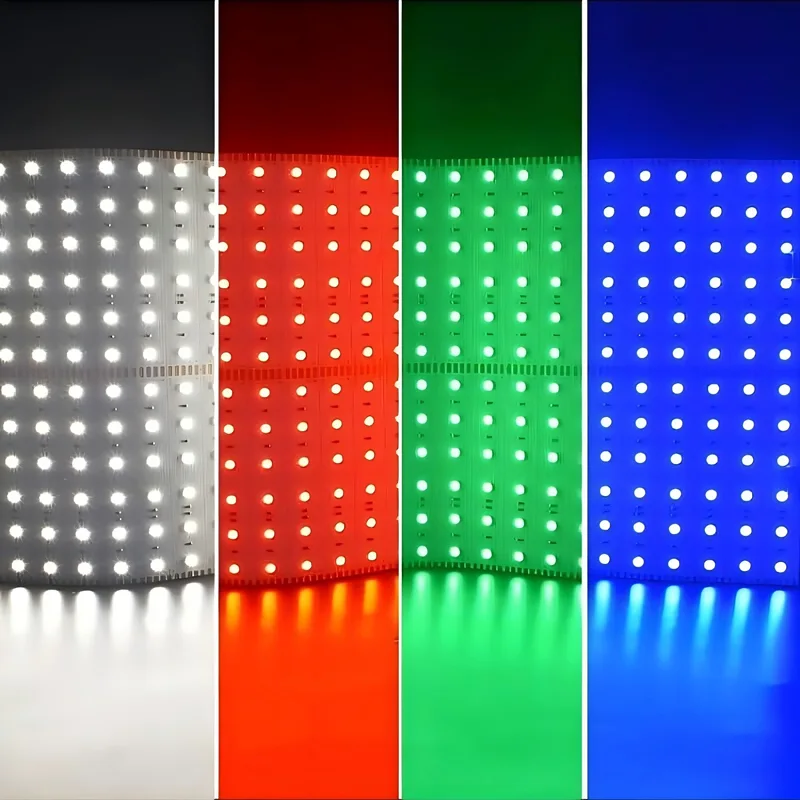

单色 LED 板

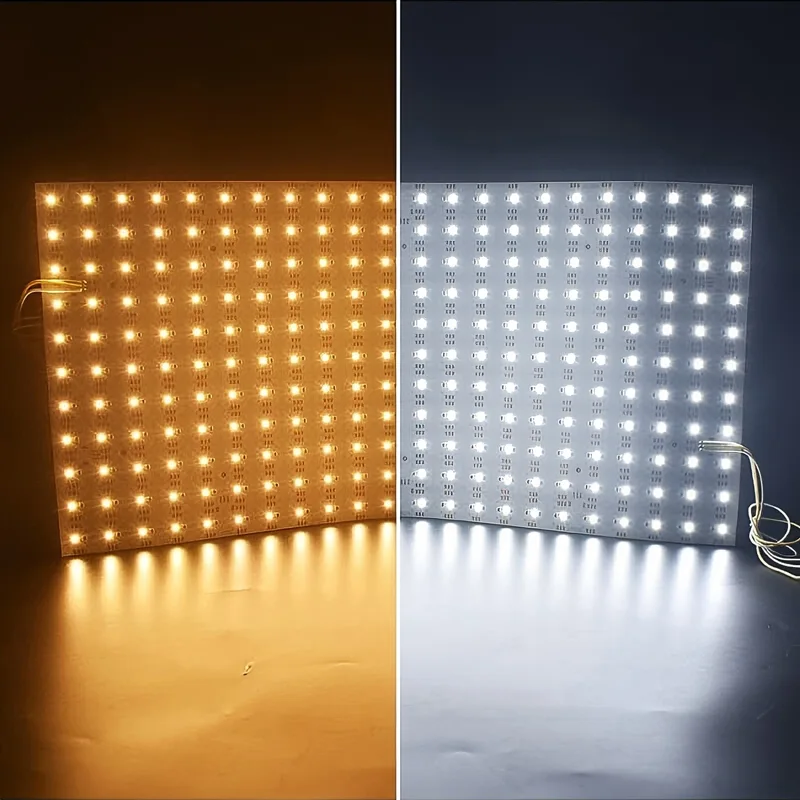

单色 LED 板是最基本和使用最广泛的类型。 它们提供单色照明,并具有各种色温,例如 2700K(暖白)、3000K、4000K(中性白色)和 6500K(冷白)。 它们非常适合创建均匀的环境背光。

主要型号: 机床X4925T242C

LED 类型: SMD2835

LED 数量 242件/件

输入电压: DC24V

动力 28W/片

颜色: 2700K/3000K/4000K/6000K

流明: 2800LM/片

国际广播电台: 80/90

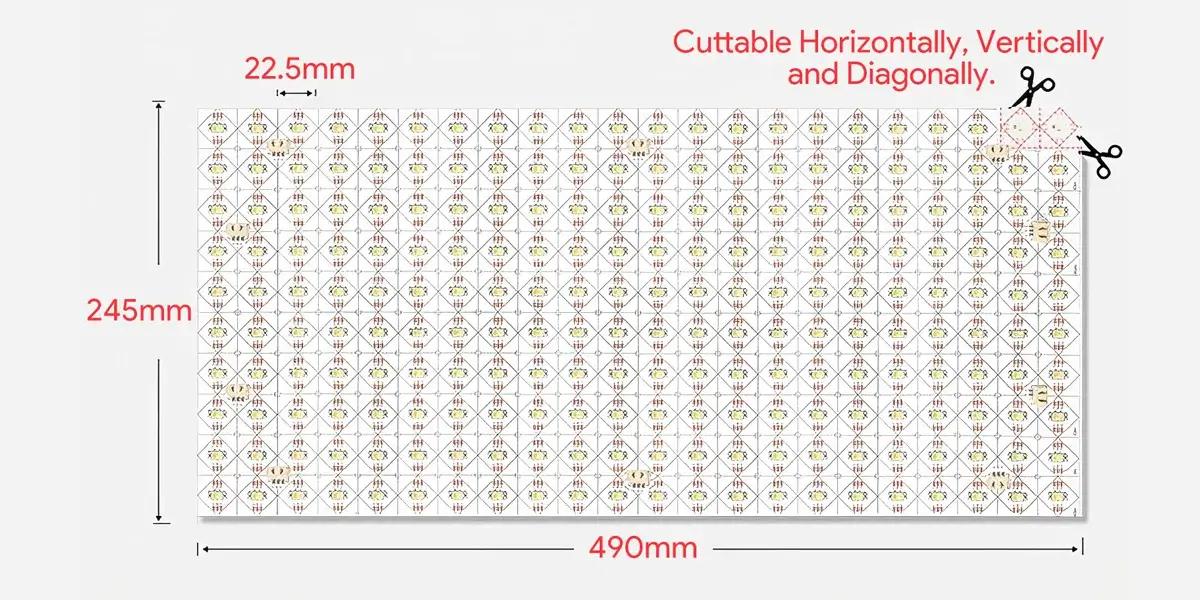

尺寸( l x w ): 490 mm x 245 mm

最小切割单位: 22.3 mm x 22.3 mm

可调光: 是

光束角度: 120°

IP 等级: IP20/IP54

寿命: 50,000 小时

保修单: 3年

认证: CE, RoHS

背面有3M双面胶带。

可调谐的白色 LED 板

可调谐的白色 LED 板具有可调色温 (CCT) 的功能。 可以将色温从暖色调2700K调到6500K,这样可以更好地控制灯光。 调整光线以适应您的心情或需求:明亮的冷色调非常适合工作空间,而暖色调营造出轻松的环境。

主要型号: 普特4925T484C

LED 类型: SMD2835

LED 数量 484 件/件

输入电压: DC24V

动力 40W/片

颜色: 2700-6500K

流明: 3800LM/片

国际广播电台: 80/90

尺寸( l x w ): 490 mm x 245 mm

最小切割单位: 22.3 mm x 22.3 mm

可调光: 是

光束角度: 120°

IP 等级: IP20/IP54

寿命: 50,000 小时

保修单: 3年

认证: CE, RoHS

背面有3M双面胶带。

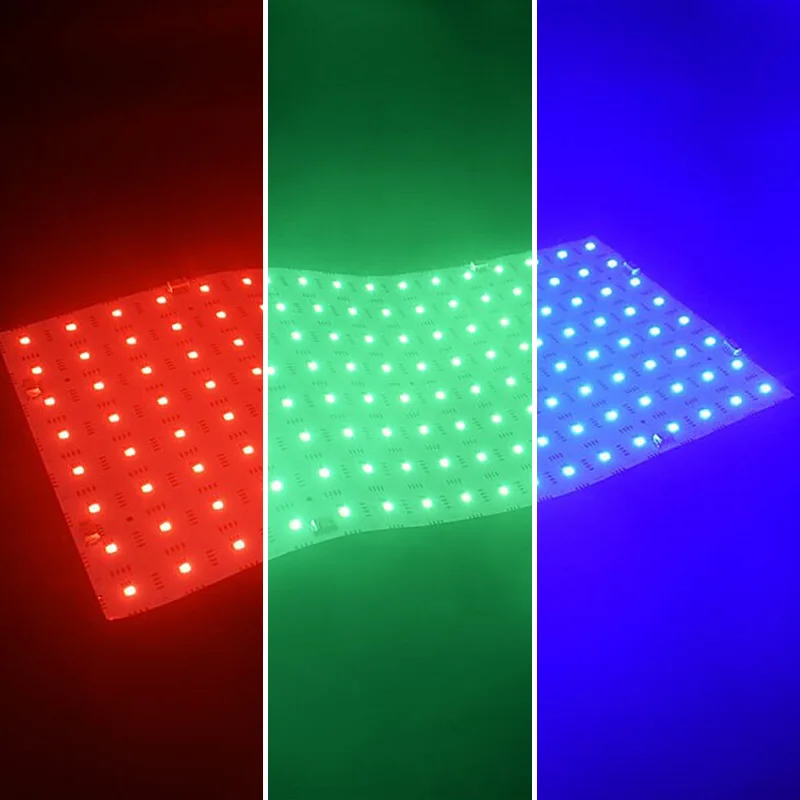

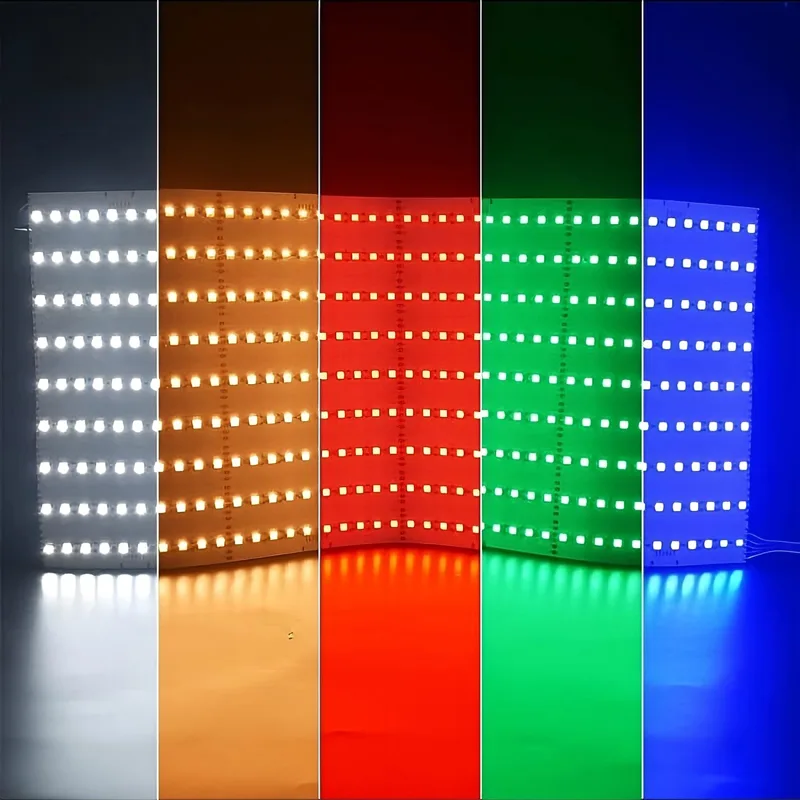

RGB LED 表

RGB LED 表单通过组合红色、绿色和蓝色的原色,创造了数百万种颜色变化。 广泛应用于广告灯箱、装饰背光和零售展示,它们毫不费力地实现了动态的色彩氛围。 与 RGBW 面板不同,RGB 面板缺少专用白光芯片,主要用于需要丰富色彩效果的应用。

主要型号: PAQ4925T128C

LED 类型: SMD5050 3合1

LED 数量 128 件/件

输入电压: DC24V

动力 45W/片

颜色: RGB

尺寸( l x w ): 490 mm x 245 mm

最小切割单位: 39.6 毫米 x 39.6 毫米

可调光: 是

光束角度: 120°

IP 等级: IP20/IP54

寿命: 50,000 小时

保修单: 3年

认证: CE, RoHS

背面有3M双面胶带。

RGBW LED 板

RGBW LED 板与专用白色 LED 集成全光谱 RGB 色彩控制。 与传统的 RGB 面板相比,RGBW 提供更丰富、更纯净的白色以及动态的颜色选择,使其成为酒吧、舞台、夜总会和活动场所的理想选择。

主要型号: PAH4925T288C

LED 类型: SMD5050 4合1

LED 数量 288 件/件

输入电压: DC24V

动力 48W/片

颜色: RGBW

尺寸( l x w ): 490 mm x 245 mm

最小切割单位: 20.4 毫米 x 122.5 毫米

可调光: 是

光束角度: 120°

IP 等级: IP20/IP54

寿命: 50,000 小时

保修单: 3年

认证: CE, RoHS

背面有3M双面胶带。

RGBCCT LED 板

RGBCCT LED 板集成了 RGB 色彩控制和可调色温 (CCT) 白光。 这意味着它们提供充满活力的动态色彩效果,同时允许根据需要调整白光色温——范围从 2700k 暖白到 6500k 冷白。 这种类型特别适合需要装饰氛围和功能照明的项目,例如酒店大厅、展览空间和多功能的商业环境。

主要型号: PAH4925T360C

LED 类型: SMD5050 5合1

LED 数量 360 件/件

输入电压: DC24V

动力 60W/片

颜色: RGB+WW+CW

流明: 2160lm/片

国际广播电台: 80/90

尺寸( l x w ): 490 mm x 245 mm

最小切割单位: 125 毫米 x 125 毫米

可调光: 是

光束角度: 120°

IP 等级: IP20/IP54

寿命: 50,000 小时

保修单: 3年

认证: CE, RoHS

背面有3M双面胶带。

像素 LED 表

像素 LED 表代表最高级的选项。 具有大量可编程像素,通过允许单独控制面板的不同区域,实现流动效果、渐变和交互式照明。 此功能可让您创建多色照明或类似彩虹的效果。 这些灯还可以与音乐同步,使其成为各种时尚照明效果的理想选择。

主要型号: PAA2525T100A

LED 类型: SMD5050 内置 WS2812

LED 数量 100 件/件

输入电压: DC12V

动力 13W/片

颜色: RGBIC

尺寸( l x w ): 250 mm x 250 mm

最小切割单位: 25 毫米 x 25 毫米

可调光: 是

光束角度: 120°

IP 等级: IP20/IP54

寿命: 50,000 小时

保修单: 3年

认证: CE, RoHS

背面有3M双面胶带。

项目中的LED片灯应用

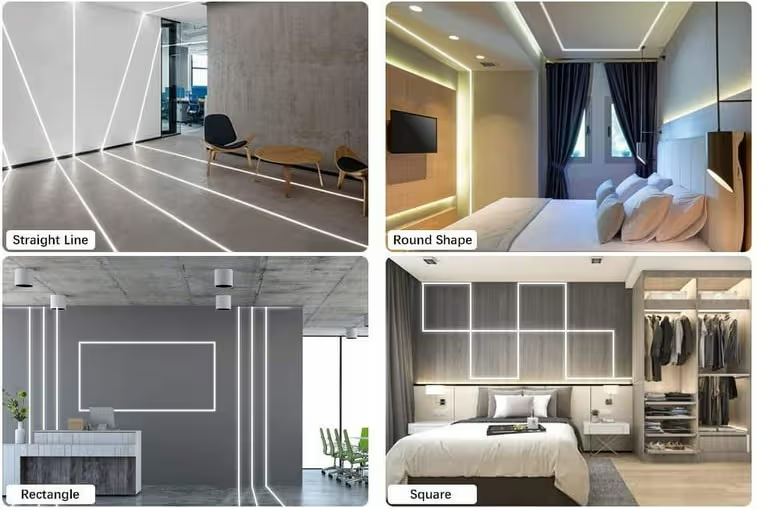

柔性的 LED 片灯很薄,几乎可以切成任何形状。 这使它们成为照亮大型、奇形或有角度的物体和表面的理想选择,包括圆形、平面和各种定制应用程序。 此外,方便的即插即用连接意味着更快、更具成本效益的安装。

因此,灵活的 LED 灯具广泛应用,包括标牌和显示屏背光、台面照明、建筑照明、舞台和活动照明,以及艺术装置或定制照明设计等创意项目。

石台面背光

在俱乐部、酒吧、高档餐厅或酒店等场所,背光突出了玛瑙、大理石或由 PVC、亚克力或玻璃制成的台面的自然美景。 石头的独特纹理投射光影图案,在昏暗的环境中营造出独特而令人印象深刻的氛围。

字母标志照明

LED 片灯的灵活性和自由切割特性使它们可以弯曲和修剪成各种形状和字母,使其成为标志背光的理想选择。 只需将这些光片切成所需的字母或形状,将它们固定在相应大字母模具的底部,并用扩散器覆盖。

与 LED 模块相比,LED 片灯具有更高的 LED 密度,提供更均匀的照明。 但是,它们不防水,仅用于室内使用。

大商业拉伸 顶棚照明

LED 板是照亮整个大型商业天花板和创造统一照明的理想解决方案。 模块化 LED 板易于连接,经久耐用。 板材安装在天花板上,并覆盖有半透明的拉伸膜,提供连续的无缝照明。

这些LED片材覆盖了广阔的区域,外观干净、明亮、美观,非常适合购物中心、剧院、办公室、餐厅和类似场所的天花板照明。

装饰照明

这些灵活且可定制的 LED 板使您能够为您家中的任何区域添加重点照明。 强调光照可以融入到独特的空间中,如拱门、壁龛、后挡板、半透明的台面、艺术品、镜子或其他建筑特征。

零售、商业和显示器照明

LED 单灯照亮了零售商店或产品展示中的关键元素,让您展示最具吸引力的零售和展览物品。

示例包括独特的装饰、珠宝展示、特色产品展示、菜单板、搁架、视觉商品、结账区域、徽标等。 它们甚至可以放在半透明的石头后面,以创建独特的柜台和展示。

LED 片灯与其他照明解决方案

随着LED技术的进步和对更环保的解决方案的不断增长的需求,背光技术发生了巨大的转变。 LED 片灯已成为业界新的最爱。

相比之下,传统的背光照明解决方案,曾经广受欢迎,已经从照明阶段逐渐消失。

LED 单灯与传统照明

在传统的背光应用中,荧光灯管或冷阴极荧光灯(CFL)曾经是主流。 然而,这些灯具存在重大缺点:体积大、闪烁、启动时间缓慢以及汞等有害物质的存在。 随着LED技术的进步,LED片灯逐渐取代了它们成为更有效的选择。

LED灯片的优点包括:

- 更苗条的轮廓:尺寸仅为几毫米,非常适合空间受限的安装;

- 统一照明:高密度LED阵列消除了黑点和不均匀的光分布,提供更自然的背光;

- 节能环保:高能效,无危险物质;

- 使用寿命更长:平均使用寿命为 25,000-50,000 小时,显着降低维护成本;

- 设计灵活性:可切割或连接以满足不同的尺寸和形状要求。

LED 灯与荧光灯

荧光灯是传统照明中常见的背光源,但与LED片灯相比,它们的缺点是显而易见的:

| 比拟 尺寸 | 荧 灯 | 发光二极管 皮 光 |

| 能源效率 | 低转化率,30%–50% 电费浪费 | 转换率高,高达95%的光转换,更佳的发光功效,更低的能耗 |

| 寿命 | 通常为 10,000–15,000 小时 | 通常 25,000–50,000 小时以上 |

| 环境影响 | 包含汞、回收和处置问题 | 无汞、环保、可回收 |

| 光质 | 容易闪烁,颜色不稳定 | 无闪烁、柔软、稳定的光 |

| 安装灵活性 | 体积大、应用范围有限 | 超薄,可根据需要切割或定制 |

| 颜色选项 | 2700K–4100K 有限公司 | 2700K~6500K,RGB,RGBW,RGBCCT |

| 成本比较 | 低初始成本,更高的长期运营成本 | 初始成本较高,长期支出更低 |

简而言之,LED 灯片灯不仅提供更低的操作成本,而且更环保和更安全,使其更适合现代照明项目中的长期应用。

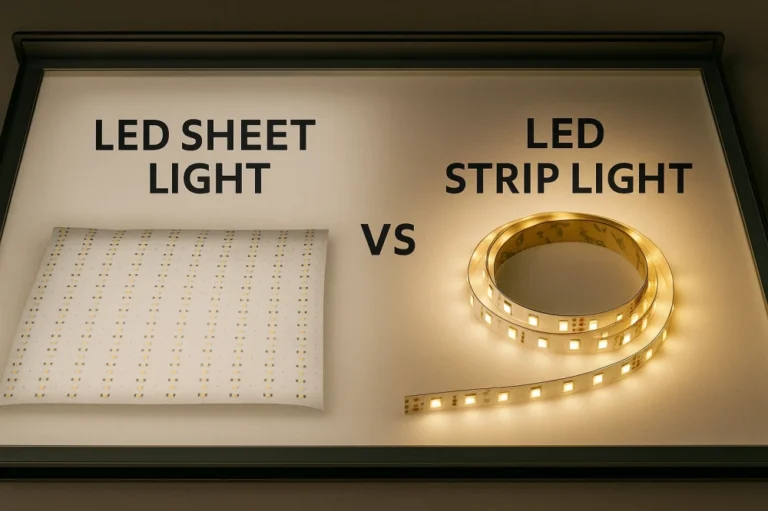

LED 单灯与 LED 灯条

LED 灯条——SMD 或 COB 类型——基于 LED 芯片排列的绳索状结构,而 LED 片材灯是扁平的、方形的和纸状的。

LED 片灯和 LED 灯条都是常见的 LED 光源,但它们的用途不同:

光源形式

- 片灯提供大面积、均匀的表面照明;

- 条带由连续排列的LED组成,更多地用作“线性光源”。

灯光效果

- 片灯缺少可见光点,为要求高质量背光的应用提供卓越的均匀性。

- 如果没有扩散器,LED 条可能会产生可见光斑或点状视觉效果。

安装方法

- 片灯通常具有刚性结构,适用于平坦或嵌入式安装;

- 灯带提供了出色的灵活性,允许弯曲和布线,用于曲面或复杂的建筑照明。

典型应用

- 单板灯:广告灯箱、展示柜、装饰墙、台面背光;

- 灯带:环境照明、橱柜照明、线性重点照明和 DIY 创意照明。

LED 灯片在能效、寿命、光均匀性和环境可持续性方面优于传统的背光和荧光灯。 与LED灯条相比,片灯更适合要求高光均匀性和覆盖广泛区域的大型安装的专业照明场景,而灯条在灵活性和装饰应用方面表现出色。

照明解决方案的选择取决于具体的项目要求:

- 对于均匀、柔和的背光,LED 片灯是最佳解决方案;

- 对于灵活的照明布置或线性安装,LED 灯条更适合。

项目和买家的LED板材购买指南

在商业照明和广告应用中,LED片灯逐渐取代了传统光源,因其超薄设计、均匀照明和灵活的安装方法而越来越受欢迎。 无论您是照明承包商、广告灯箱制造商还是散装采购商,选择正确的 LED 片材都需要仔细考虑亮度、规格、认证和成本。 下面是对关键点的详细分解。

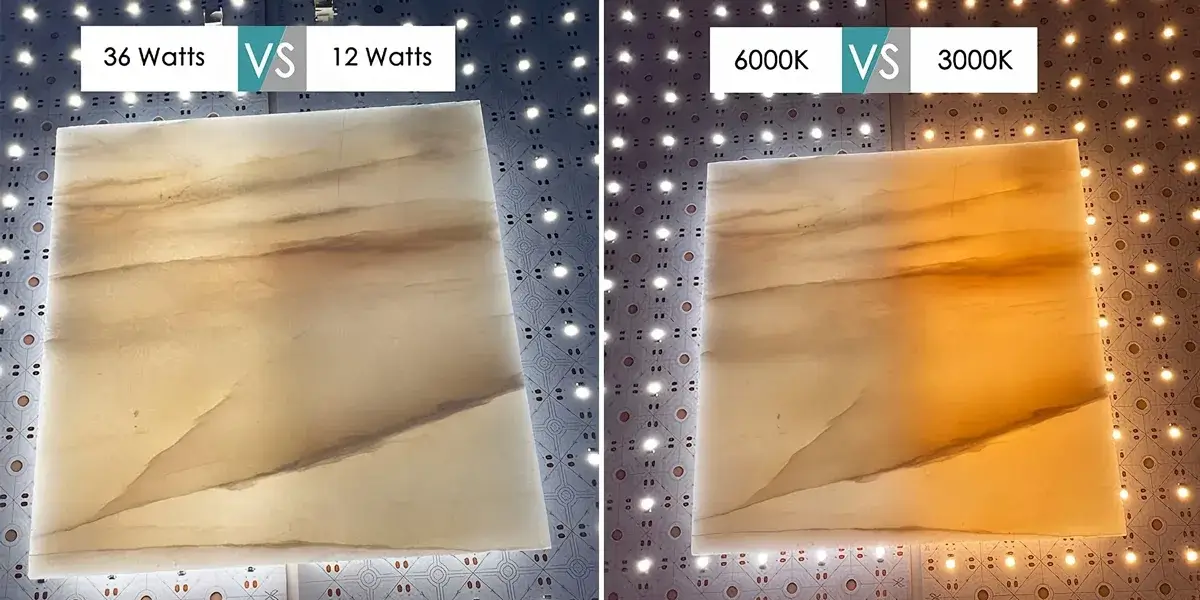

亮度和色温

亮度是决定 LED 板是否满足项目要求的核心指标。 对于广告灯箱、展示柜或大理石台面,通常需要极高的亮度以确保出色的视觉冲击力。

因此,在评估亮度时,买家不仅要关注额定流明值,还要考虑 LED 片材和漫射材料之间的相互作用。 这是因为并非所有材料在照明下的性能相同。 扩散受材料厚度、不透明度、光源与材料之间的距离、表面纹理甚至颜色的影响。

不同应用的亮度要求有很大差异:

- 广告灯箱、展示柜:通常需要高亮度(>4000 lm/m²)以确保图像的生动可见性。

- 室内装饰灯:中等亮度适宜,平衡视觉舒适度与能源效率。

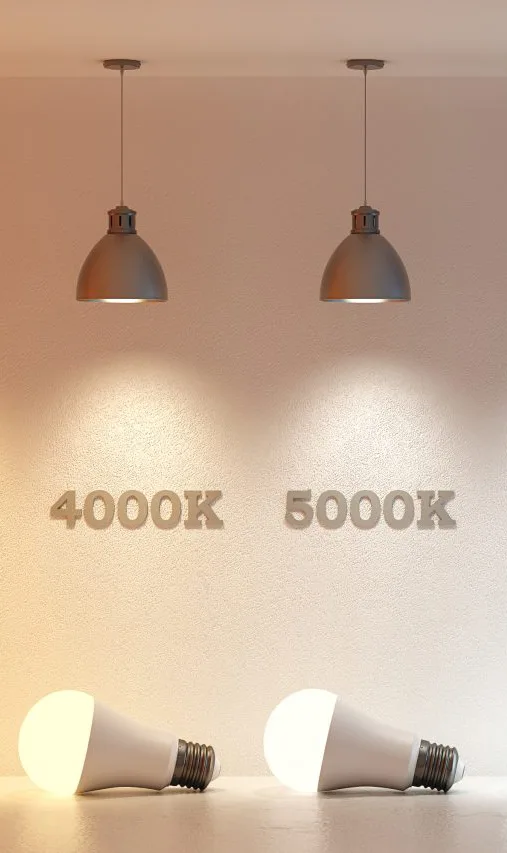

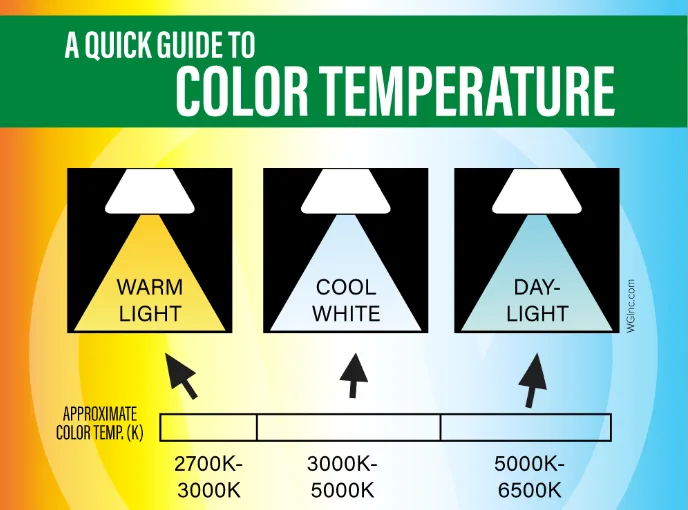

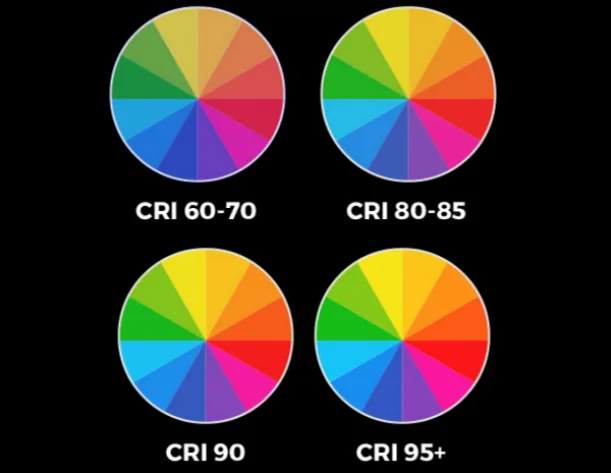

色温选择同样重要,直接影响空间氛围和视觉体验。 对于出口项目,建议确认制造商是否提供多种色温选项以满足不同的市场美学需求。 此外,选择 CRI > 90 可确保色彩准确性。

- 2700K–3000K:暖白光营造出舒适的氛围,是餐厅、酒店和类似环境的理想选择。

- 4000K–4500K:自然白光平衡舒适,显示屏可视性,适合零售商店和办公空间。

- 6000K–6500K:冷白光,强调图像清晰度并提供更高的对比度,通常用于广告和展示。

有关色温函数和比较的更多信息,请参阅以下博客。

LED 照明色温比较:2700K 与 3000K

LED 照明色温比较:3000K 与 4000K

LED 照明色温比较:4000K 与 5000K

LED 照明色温比较:5000K 与 6000K

3000K vs 4000K vs 5000K vs 6000K:有什么区别?

尺寸、厚度和切割选项

LED 板的一个显着优势是它们的高灵活性。 虽然市场上的产品通常有标准尺寸,但大多数项目——尤其是广告灯箱和展览装置——都需要定制尺寸。

在选择产品时,买家应确认供应商是否提供定制切割服务,了解切割线的分布和精度。 过大的切割间隔可能会限制尺寸灵活性,增加安装的复杂性。

关于厚度,普通的 LED 板范围从 1.3mm 到 6.7mm(由于 PCB 上的 XH 连接器)。 超薄结构有助于隐藏在灯箱或装饰面板后面,同时有效地节省安装空间。

镜头和 IP 等级

一些 LED 片材采用光学扩散透镜,以最大限度地减少光点和阴影,从而提供更均匀的背光。 虽然大多数 LED 片材没有透镜,但它们以更高的 LED 密度进行补偿。 因此,买家应根据其安装项目中使用的扩散材料进行选择。

IP 等级取决于应用环境。 对于室内显示器或干燥设置,IP20 就足够了。 但是,对于户外广告牌或高湿度空间,必须选择IP54或IP65产品,以确保防水和防尘性能。

注意防水LED板不能用于需要弯曲的应用中,因为涂覆在PCB上的硅胶涂层降低了柔韧性。 此外,请记住,更高的保护等级会增加成本,因此应根据项目环境进行合理的权衡。

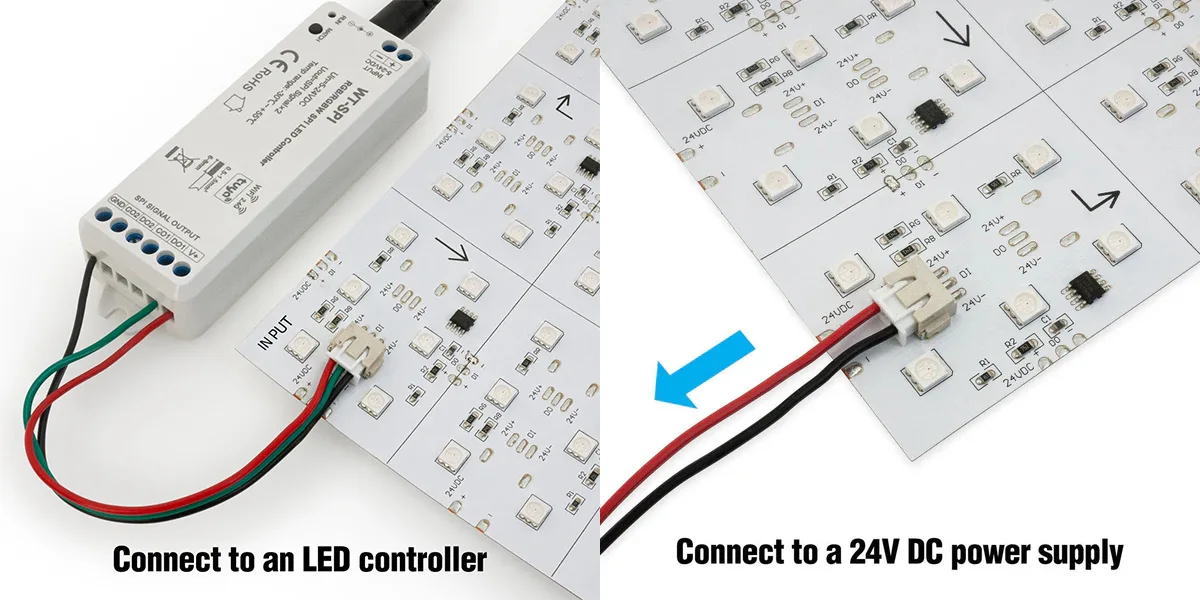

电源选项

电源电压必须与 LED 片的额定电压相匹配。 兼容性对于正确的 LED 操作至关重要。 大多数 LED 板使用 DC24V 恒压驱动器,较小的部分使用 12VDC。

A 优质电源 增强照明性能。 劣质驱动器会引起闪烁,在背光扩散应用中变得更加明显和分散注意力。

调光功能是采购过程中的另一个关键因素。 对于需要不同环境或节能控制的项目,请选择支持 0-10V、PWM、DALI 或 DMX 的 LED 片材、电源和控制器。 商业买家应主动讨论电源接口并与供应商调光兼容性,以避免以后的集成复杂性。

认证与合规

认证和合规性对于跨国项目或出口订单是必不可少的。 欧洲市场通常需要 CE 和 RoHS 认证,而北美通常要求 UL 或 ETL 商标。

对于高端客户,TUV 认证提供了额外的可信度。 买方应避免仅仅依赖供应商的口头保证,而是要求访问完整的测试报告和验证证书的真实性。

进一步的建议是让买家验证是否符合能源效率和环境法规。 例如,一些市场正在逐步对照明产品要求更严格的能源效率标准。 主动合规计划有助于保持长期供应链的竞争力。

成本注意事项

价格仍然是采购决策中的关键因素。 然而,在选择 LED 片材时,仅比较单价通常是不够的。 买家必须评估初始投资和长期运营成本。

高品质的 LED 板的使用寿命超过 50,000 小时,并在流明维护、保护等级和电源稳定性方面具有优越的优势,从而显着降低了未来的维护和更换成本。 相反,由于光衰、闪烁或损坏,选择低端产品以节省成本通常会在几年内导致更高的更换费用。

此外,对于大宗采购商,与供应商建立长期合作伙伴关系可以确保更优惠的定价和更稳定的供应周期。 一些制造商甚至提供 OEM/ODM 服务,帮助客户创建差异化的定制产品以提高市场竞争力。

如何安装LED灯片?

正确的组装和安装对于最大限度地提高 LED 灯片的性能至关重要——尤其是在性能、可靠性和寿命问题时。 LED 灯片带有粘性背衬;只需剥去背衬并将片材粘贴到任何所需的位置即可。 安装只需几分钟,比钉子或螺钉提供更大的便利。

有关安装详情,请阅读博客“如何切割、安装和设置 LED 灯片灯”

分步指南

步骤 1:准备光片和电源

测量计划连接 LED 灯片的区域的尺寸。 使用这些测量值来确定您需要购买的光片的尺寸和数量。 此外,计算所需的电源容量并为 LED 灯片选择合适的电源和控制器。

原理:电源电压必须与LED灯片电压相匹配,驱动功率应为LED灯片总功率的1.2倍。 计划安装时,确保连接的 LED 板的总长度不超过推荐的最大工作长度。

步骤 2:清洁安装表面

表面上的污垢会阻碍 LED 板的安装并影响粘附强度。 为防止这种情况,使用湿棉布清除安装表面的灰尘和污垢颗粒。 清洁后,确保表面完全干燥,然后再继续。

第三步:切割LED片

当需要切割 LED 板以达到所需的形状时,必须首先切割该片材。 大多数可切割的 LED 板都用切割线预先标记,通常由剪刀图标或虚线表示。

这些线条指示可以安全切割板材的位置,而不会损坏电路。 找到切割线后,使用锋利的剪刀沿指定线进行切割。

步骤 4:连接 LED 板

一旦将 LED 板切成所需的形状或尺寸,使用电线或 XH 无焊接连接器连接各个 LED 板。

第 5 步:安装 LED 板

LED 板通常采用 3M 双面胶粘背衬,便于安装。 只需剥去胶带,将纸张粘在干净的表面上。 这是使用最广泛的方法,非常适合墙壁、石材台面、金属表面和天花板等光滑表面。

与粘合剂相比,螺钉安装提供了更大的强度和可靠性。 使用此方法时,在安装表面的指定位置钻孔。 确保这些孔与光片上预钻的螺孔精确对齐。

步骤 6:连接电源和测试

安装 LED 灯片后,连接电源并进行功能测试。 连接时,确保光片的极性(+/-)与电源正确匹配:将 LED 灯片的正极端子连接到电源的正极,将灯片的负极端子连接到电源的负极。

接线完成后,打开开关以确保所有区域的均匀照明。

可以剪LED灯片吗?

答案是肯定的。 LED灯片可切割。 黑色水平线、垂直线和 45° 对角线(通常用虚线表示)在纸张上标出,以方便切割。

您可以使用普通剪刀沿黑色线或虚线剪切出所需的形状,并将切割的 LED 灯片放入空间有限的槽或凹槽中。

LED 板的最小切割单元是一个 LED。 切割时,请仔细遵循特定标记。 不正确的切割会损坏电路和 LED,导致灯失效。

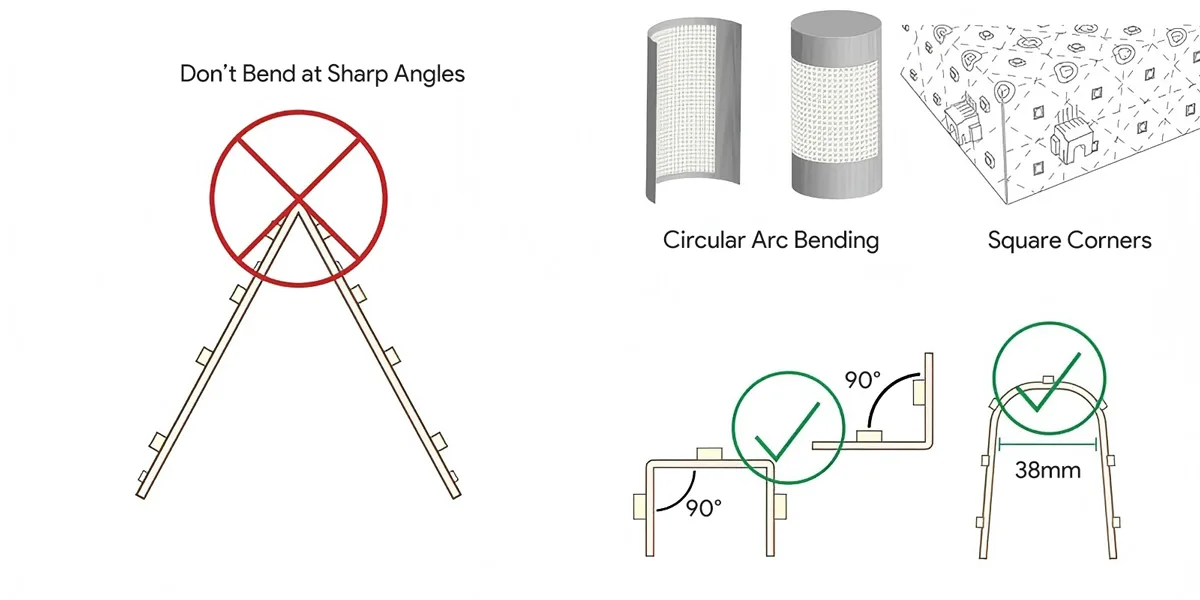

LED 片灯可以弯曲或折叠吗?

是的,您当然可以弯曲或折叠它们。 由于 LED 灯片使用柔性电路板,无论您需要将它们弯曲成圆形还是创建波浪形,柔性 LED 片材都可以完美满足您的需求。

但是,在弯曲过程中必须遵循某些指导方针。 应避免尖锐角度,因为它们会损坏电路板,但 90 度硬弯曲和柔和的曲线是可以接受的。 过度弯曲或折叠可能会损坏芯片并导致电路断裂。

以下是弯曲或折叠LED片灯的一些技巧:

- 遵循制造商的最小弯曲半径指南(通常≥90°)。 超过此限制可能会损坏 LED 芯片/电路。

- 缓慢而轻轻地弯曲以形成角度和形状。

- 避免创建锐角(<90°)。 使用圆形边缘防止损坏。

- 方角使用柔性 LED 板;请勿任意折叠。 确保角边缘与工作表上的黑色切割线对齐。

如何连接不同的LED片灯?

LED 板主要以两种方式连接:通过连接器或接线。

LED 无焊接头

此方法利用安装在 LED 板上的卡扣式或夹式连接器。 即插即用设计不需要专门的工具,便于快速轻松地安装。 连接器可随时拆卸。

步骤:

- 将连接器的一端与 LED 板上的连接器插座对齐。

- 将 LED 连接器轻轻地插入连接器插槽中。

- 然后将连接器的另一端插入第二个灯片上的连接器插座中。

- 要将其他光片串联连接,请重复上述步骤。

焊丝

焊接确保了更安全和可靠的电气连接。 LED灯片上的每个LED单元都有一个用于焊接电线的铜焊盘。

程序:

- 剥去电线末端(红色 = 正面,黑色 = 负极)。

- 在 LED 板上的铜焊盘上涂抹少量助焊剂。

- 预热烙铁后,将一层均匀的焊料涂在焊盘上。

- 将电线焊接到相应的极性位置并牢固地固定。

- 焊点冷却后,进行电源测试。

LED片灯的最大运行速度是多少?

计划安装时,确保连接的 LED 灯片的总长度不超过推荐的最大运行长度。 因此,您需要考虑以下几点:

1。 匹配电源瓦数与光片功率

确认每个单独的 LED 灯片的功耗。 然后,将要安装的所有工作表的额定功率相加。 最后,确保电源的驱动功率是 LED 灯片总功率的 1.2 倍。

例如,在为 4 x 24V 60W LED 片供电时,电源电压也应为 24V。 4 x 60W 板的总功率为 4 x 60W = 240W,因此电源容量应为 240W x 1.2 = 288W,由于很少有 288W 电源可用,您可以选择稍高的 300W 型号。

2 . 无焊接连接器的最大电流限制

无焊接连接器的最大额定电流为 5A,如果您需要连接更多的 LED 片,考虑使用附加连接器来分配电流。

或者,您可以将电线直接焊接到 LED 板上以处理更高的电流。 例如,对于总计约 300W 的四块 LED 板,我们建议使用 18 AWG 线进行焊接。

3. 电压降

向电路中添加额外的 LED 片材时,电压降会变得更加明显。 这种下降会导致亮度不均或性能问题。

基于LED灯条的长度和电压降理论,一般建议不要将超过10个串联的LED灯片(相当于5米)连接起来。 但事实是这样吗? 考虑到前面提到的电源匹配和连接端子的电流限制,我们建议将串联连接限制为 3-5 个 LED 片。

因此,对于较大的安装,将电源放置在最短总运行长度的点或使用多个电源。 例如,如果一个 LED 板最多连接 3 张,则单串联链不应超过 3 张。 如果您的项目需要 12 张 LED 板,请将安装分成四个部分,每个部分都配备了独立的电源或适当的接线配置。

结论

LED 灯具具有灵活、超薄的设计、均匀的照明和适应性强的切割能力,正在成为灯箱背光、天花板照明和商业展示的理想解决方案,为您的空间带来时尚的美感。

对于项目承包商和批发买家来说,选择合适的 LED 片灯不仅提供卓越的照明性能,而且在项目时间、成本控制和持续维护方面提供长期价值。

如果您的项目需要高质量的定制 LED片材照明解决方案,SignliteLed 作为您可靠的 OEM/ODM 合作伙伴。