LED灯带灯在装饰和功能照明中变得越来越流行。 对于商业项目、建筑景观照明或长期固定装置,LED灯带的使用寿命不仅是技术规格,而且直接影响安装后的维护费用、能效性能和整体投资回报。

因此,真正决定产品长期价值的因素往往是一个容易被忽视的问题:LED灯带灯能持续多久?

LED灯带的使用寿命可从25,000到100,000小时不等。 这意味着如果您每天使用 LED 灯条 8 小时,它们可以连续运行 8 到 34 年。 然而,并非所有灯带都达到了这一水平——LED芯片质量、散热设计、电源兼容性和安装环境等因素会显着影响其使用寿命。

了解 LED 灯条的使用寿命对于批发商、项目经理和承包商至关重要。 本文将解释 LED 灯条的平均寿命以及影响其寿命的关键因素,并分享延长其使用寿命的实用技巧。 无论您是大型项目的批量采购还是计划升级现有的照明系统,您都可以在这里找到有价值的见解。

LED灯带灯寿命行业标准

大多数人的预期寿命 LED 灯条 范围从 25,000 到 50,000 小时。 这意味着如果LED灯条持续亮起,理论上它们可以持续长达五年半。

然而,即使 LED 灯带的使用寿命相同,其含义也会因使用的测量标准而有很大差异。 此外,LED灯条在使用寿命时不会突然关闭;它们继续工作,尽管它们的亮度可能会降低。

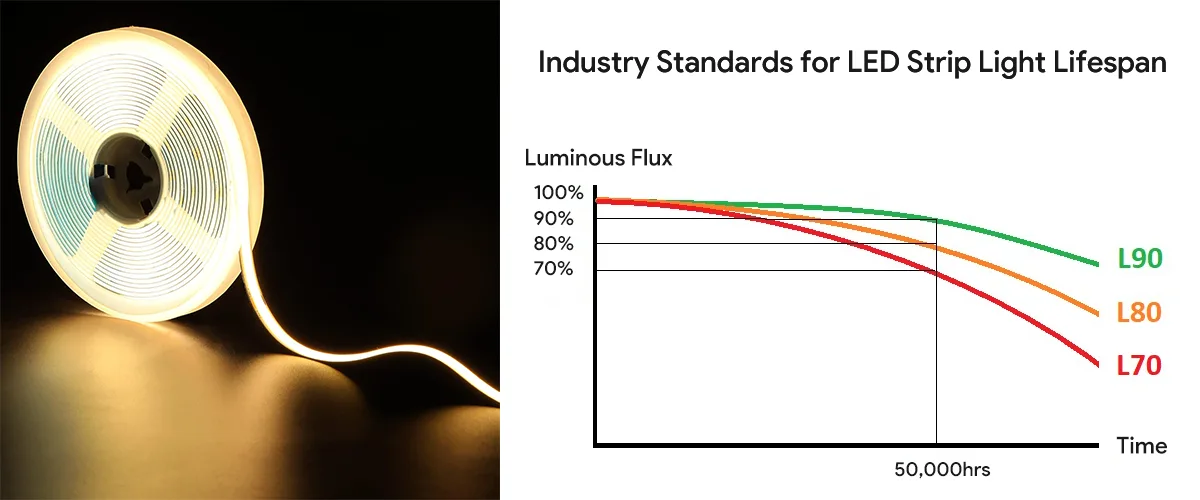

在照明行业中,LED灯条的寿命通常使用“额定寿命”(额定寿命)来衡量,这是指光源在标准测试条件下从初始亮度降至特定百分比所需的操作时间。 最常用的测量是L70标准,它是指从初始值中减少了70%光通量的使用时间。 通常,“L”代表“流明维护率”,而“70”表示LED的光输出在一定时间内已降低到其原始亮度的70%。

例如,如果LED灯带的额定寿命为50,000小时(L70),这意味着在理想条件下,在使用50,000小时时,其亮度仍将是其初始亮度的70%。 对于商业照明或工程应用,此亮度水平通常仍被认为是可接受的。

除了L70标准外,还有L90/L80和L50标准。 同样,L90、L80、L50的含义也很容易理解。 其中,L90代表了更高的性能标准,而L50代表更长的使用寿命,但标准较低。 在这些标准中,L70标准广泛应用于商业和住宅照明。

根据行业经验,LED灯条的平均寿命因质量而异:

| 产品类型 | 通用寿命范围 (L70) | 应用示例 |

| 高品质工程级LED灯条 | 40,000–50,000 小时 | 商业空间、建筑外墙、长期装饰 |

| 中档商用LED灯条 | 25,000–35,000 小时 | 零售店、陈列室和家居装饰 |

| 低端或不合格的条带 | 10,000-20,000 小时 | 临时设置,一次性事件照明 |

与其他常见光源相比,LED灯条在使用寿命方面具有明显的优势:

- 白炽灯泡:约1000小时,低能效,频繁更换

- 荧光管:大约 8,000-15,000 小时,启动延迟和不环保的汞含量

- 卤素灯:大约2,000-4,000小时,高热量

- 高品质的LED灯条: 50,000 小时以上,高能效,低维护频率

重要的是要注意,额定寿命并不等同于实际寿命。 测试环境通常涉及恒定温度、稳定电压和实验室条件下良好的散热。 然而,在实际应用中,温度、湿度、安装方法和电能质量等因素都会影响寿命。 因此,在评估LED灯条的使用寿命时,不仅要考虑制造商提供的L70数据,还要考虑具体的使用环境和安装条件。

L70标准如何评估LED灯带的使用寿命

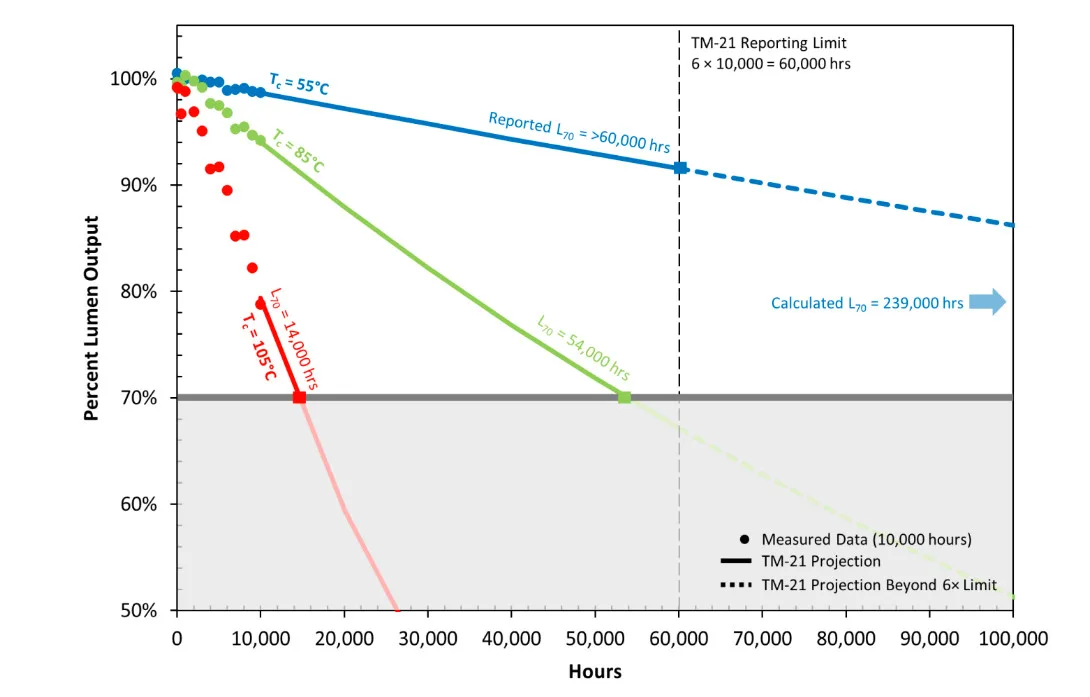

影响LED灯带寿命的因素有很多,例如LED芯片、材料选择和耐用性。 但是,有一个基本规则:工作温度越高,驱动电流越大,光输出衰减的速度就越快。

由于不同厂家和LED类型的材料和制造工艺有显着差异,LED照明行业已将LM-80测试方法作为流明维护的主要标准。 LM 代表照明方法。 LM-80 在特定条件下测量一段时间内特定条件下 LED 的流明输出或光输出。 这决定了照明灯具的使用寿命。 具体的测量方法如下:

- 在 LM-80 测试中,LED 会在预定温度(通常为 55°C、85°C 和 105°C)下进行测试,LED 样品将进行长时间的照明测试。

- 测试期间每 1,000 小时测量一次光输出变化,最大测试持续时间达到 10,000 小时。

- 为确保客观性,LM-80 测试通常由发布正式报告的第三方实验室进行。

然而,LED 的寿命测试周期非常长。 即使连续运行 24 小时,10,000 小时也需要大约 14 个月。 为了全面验证50,000小时的额定寿命,需要进行近六年的连续测试,这在快速发展的LED照明行业中显然是不切实际的。

因此,LED照明工程行业引入了TM-21外推算法。 该算法使用 LM-80 前几千小时测试的数据来预测光输出衰减的趋势,并提供 L70 等寿命参数(光输出维护率降至 70% 的估计小时数)。

在TM-21中L70、L80和L90的三个层次中,LED照明行业认为L70矩阵是标准矩阵。 该 L70 值通常在产品规格或保修文件中指定,并作为评估 LED 灯条寿命的重要参考指标。

影响LED灯带寿命的关键因素

虽然LED灯带的额定寿命可以达到数万小时,但不同项目的实际寿命可能存在显着差异。 这主要取决于以下关键因素:

1。 LED的质量 C臀部和 O在那里 C组件

LED芯片是灯带灯的核心发光元件,其质量直接决定了亮度的保留和寿命。

高品质芯片(如 Cree、Nichia 和 Osram 等国际品牌的芯片)在光衰减控制和一致性方面表现出更高的稳定性,即使经过长时间的操作,色温变化和亮度下降也最小化。 低成本芯片虽然更便宜,但在高温或长时间运行条件下容易加速光衰、明显的颜色差异,甚至是故障。

此外,高质量的LED芯片通常具有更高的发光效率,将更多的电能转化为光能而不是热量,从而减少热量的产生。

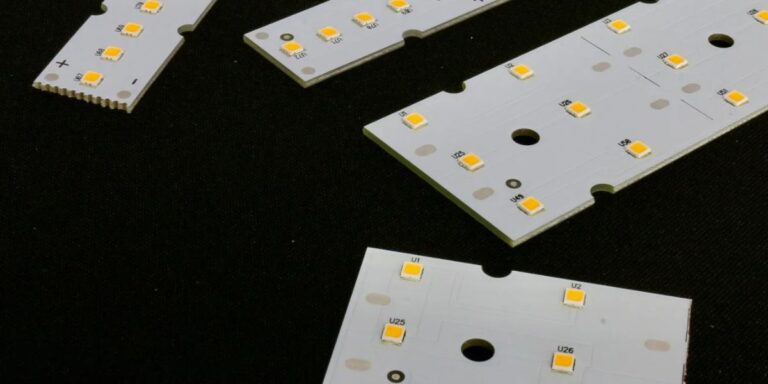

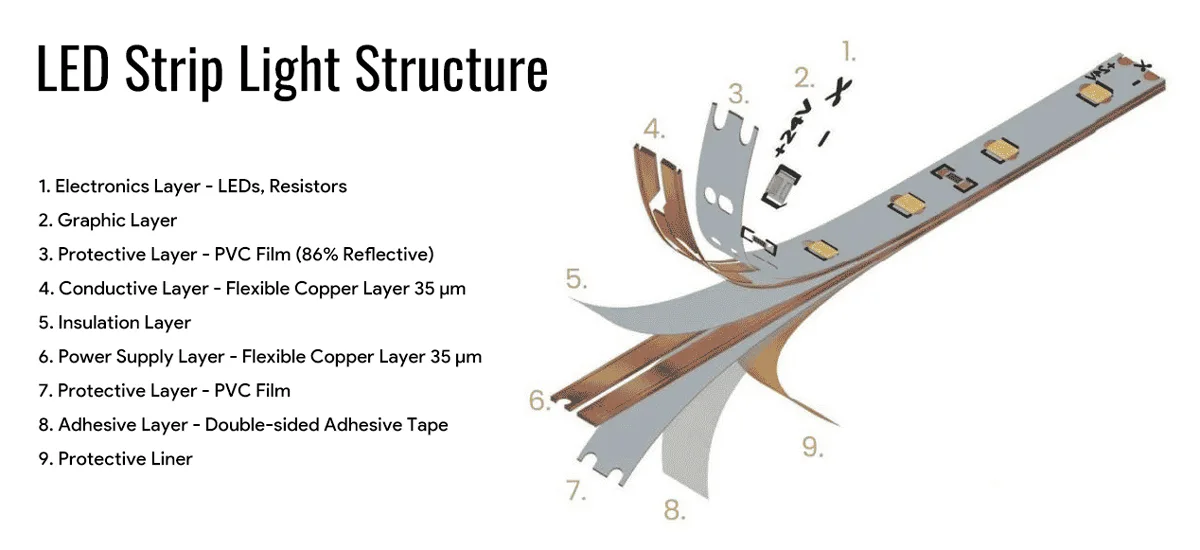

此外,使用较厚的铜柔性电路板和优质的粘合背衬(如3M VHB双面胶带)也可以加速散热。 合理的芯片布局,例如在整个板上分布多个芯片,还可以增强散热面积。 先进的包装技术进一步延长了LED灯条的使用寿命。

最后,确保他们有所有必要的测试报告,例如 LM80 或 LM70 和其他认证。

对于工程或商业照明项目,建议使用高质量的 LED 芯片和其他组件对 LED 灯带进行优先排序,以确保长期运行中的可靠性。

2 . 散热和安装环境

LED是冷光源,但芯片在运行过程中仍会产生热量。 如果不及时散热,则会加速光衰减甚至导致烧毁。 因此,良好的散热结构可以有效降低芯片温度,延长寿命。 通过铝散热器或放置在导热表面上的适当散热有助于保持 LED 性能。

散热与安装环境密切相关,因此安装环境同样重要。 高温、封闭空间或通风不良会显着缩短 LED 灯条的使用寿命。 这是因为LED灯条的工作温度范围为-20°C至50°C,温度过高或过低以及湿度过高,会缩短LED灯条的使用寿命。

环境温度过高会增加热应力,加速 LED 芯片的老化。 在低温环境中,PCB板变脆,降低了电解电容器的性能。 在高湿度条件下,湿气会导致电子元件氧化、封装材料的老化和加速光衰减。

在室外高温地区,应考虑带铝散热器的防水LED灯条,并尽可能避免直接暴露在阳光下。

3.电源 秒上行和领导 秒绊倒 V电压 M栓

LED灯条需要稳定的电源长期有效地运行,通常在低压下工作,例如DC5V、DC12V和DC24V,因此,这些通用LED灯条通常使用低压恒压电源,需要稳定的电源电压以防止过载或闪烁。

如果电源电压超过LED灯条的输入电压,则会导致LED芯片承受过大的电流,从而导致发热增加和加速老化。 短时间内电压和电流的突然波动也可以加速芯片磨损并缩短条带的使用寿命。

如果电源不足或不稳定,不仅会影响亮度,还可能显着缩短条带的使用寿命。 因此,选择优质电源驱动器,保证10%–20%的功率裕度是必不可少的。

LED灯带的功率与发热直接相关。 在同样的散热设计和生产材料下,高功率条能发出更大的亮度,同时产生更多的热量,从而影响寿命。

这是因为较高的电流导致更高的功率和更亮的灯条。 虽然更高的驱动电流可以使 LED 更亮,但它也会产生更多的热量。 因此,最大化电流供应增加了每个LED的内部温度,显着缩短了其预期寿命。

4。 使用模式

LED灯条的使用寿命也与它们的使用方式密切相关。 全功率下长时间运行会使LED承受高热负荷,加速光衰减并逐渐缩短LED灯条的使用寿命。

光带在短时间内频繁的开/关循环,不仅会导致LED经常发生温度变化,导致材料老化,还导致反复热膨胀和收缩,导致电子元件失效。 此外,频繁的开/关循环还会影响电源的使用寿命。 电源的开/关循环状态的快速变化会磨损内部组件,缩短其使用寿命。

因此,应使用适度调光(如 PWM 调光或 0-10V 调光)来降低 LED 灯条的工作温度并延长其使用寿命。 此外,与连续照明相比,间歇性操作对LED芯片散热更有利。

对于需要长时间操作的商业照明,可以通过智能控制系统(如 DALI)优化亮度和运行时间,以延长使用寿命。

想了解更多关于 LED 灯条调光选项和信息的信息吗? 阅读博客文章“如何调暗LED灯条:调光方法和兼容性的综合指南”

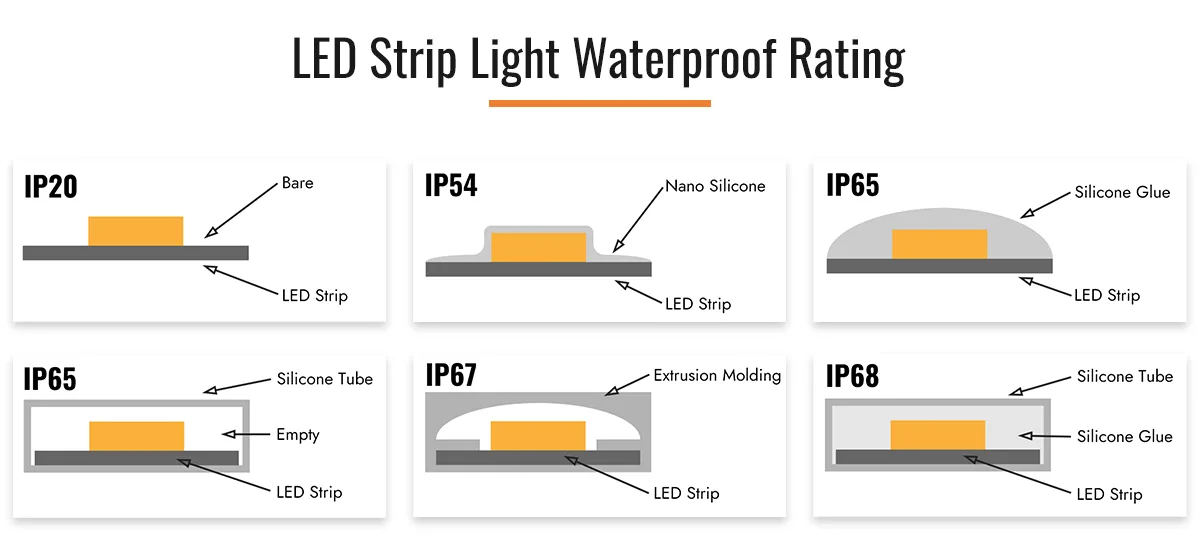

5.防水防尘等级(IP等级)

IP 等级不仅影响安装位置的选择,而且间接影响使用寿命。 IP 等级表示对固体和液体入口的保护级别。 IP等级越高,防尘、防潮、防水性能越好。 因此,IP 等级较低的 LED 灯具不防尘或防水。 有关 LED 灯条的 IP 等级的更多信息,请阅读博客文章“LED灯带防水IP等级指南”

在室外或潮湿的环境中,应选择IP65、IP67甚至IP68防水灯带灯,以防止潮湿和灰尘侵入,以及腐蚀和短路。 但是,如果您使用 IP 等级较低的 LED 灯条,它们的使用寿命可能会缩短,甚至可能会很快发生故障。

因此,选择适当的 IP 保护等级对于延长灯条的使用寿命至关重要。 但是,请注意防水密封结构会影响散热。 如果保护等级过高但灯带安装在高温环境中,实际上可能会加速老化。 因此,您可能需要根据安装位置使用适当的 LED 铝通道来协助散热。

因此,您应该根据实际环境找到保护和散热之间的平衡。

如何延长LED灯条的使用寿命

如果安装或使用不当,即使是高质量的 LED 灯条也可以显着降低其实际使用寿命。 以下方法可以帮助您显着延长项目中 LED 灯条的使用寿命,并从长远来看降低维护成本。

1。 取 High-Q多功能LED 秒绊倒 L权利

高品质LED灯带灯 不仅提供优越的照明性能,而且使用寿命更长。 与以后经常更换低质量条形灯相比,从一开始就选择优质的带灯节省了时间和精力。

高品质的LED灯具采用耐用材料制成,例如2-4盎司双层纯铜FPCB。 这确保了流畅的电流,减少了热量积聚,并促进了更快的散热。 此外,这些带灯中使用的 LED 芯片、电阻器、双面胶带和所有其他组件都是最高质量的。

选择有信誉的 LED 条带制造商并检查相关的灯带认证标准是最直接的方法。 SignliteLED 以最具竞争力的价格和持久的性能提供最全面的 LED 条带产品。 对于某些产品,我们提供 UL 或 ELT、CE 和 RoHS 等认证,进一步确保可靠性。

高效高品质2835 LED灯带灯

模型: FQX10T128C

每米 LED 数量: 128

LED 类型: SMD2835

PCB宽度: 10 毫米

色温: 2700K/3000K/4000K/5000K/6500K

Ra: >80

输入电压: DC24V

每米功率: 12瓦

效率: 190-200lm/W

切割单位: 62.5 毫米/8 个 LED

IP 等级: IP20/IP54/IP65/IP67/IP68

保修单: 5 年

2.选择 High-Q多功能LED P嗷 秒上

稳定性 LED 电源 是LED灯条长期运行的先决条件。 LED电源是电子元件组件,从长远来看,它也是一个潜在的故障点。 因此,应优先考虑经CE、UL、FCC等认证的电源产品,以确保安全稳定。

其次,选择完全匹配LED灯条的电压和电流的恒压LED电源,并保留20%–30%的功率裕度。

LED灯条通常在低压直流12V和24V下工作。 如果 12V 电源与 24V LED 灯条一起使用,则条带不会亮起。 同样,将 24V 电源连接到 12V LED 灯条会导致 LED 过多,从而显着缩短其使用寿命甚至烧毁 LED。

对于长距离安装,建议使用多点电源或大功率电源驱动板带,避免末端亮度衰减。

如何选择优质的LED电源? 阅读博客“如何为 LED 灯条选择合适的电源?”

Mean Well XLG 系列 IP67 恒压 LED 电源

模型: XLG-75、XLG-100、XLG-150、XLG-200、XLG-320

输入电压: AC100-305V

输出电压 DC12V/DC24V

输出电流: 5A-18A@DC24V, 3.1A-13A@DC12V

动力 75W-320W

有效性: 89%-94%

PF: >0.95

调光: 3 合 1 可调光

IP 等级: IP67

认证: UL、CE、ROHS

保修单: 5 年

3. 专注于 H吃 D发病和 我安装 秒跑段

适当的通风对于确保LED灯条的低温操作至关重要。 确保房间内有足够的气流,以散发 LED 灯条产生的热量。 封闭或通风不良的安装环境容易积聚热量。

室内安装时,请使用 LED 铝型材 光通道利用金属的热导率协助芯片散热。 这些不仅增强了美学效果,确保了安全安装,而且还可以作为散热器,以实现有效的散热。 在室外或高温环境中,避免将LED灯直接暴露在强烈的阳光下;可能需要额外的遮阳和通风结构。

安装过程中,避免过度弯曲或将LED灯带放置在散热受限的区域。

4.设计 R好 O表演 M颂词

无需全天候运行全功率LED灯条。 不使用时关闭灯带,以尽量减少磨损。 或者,使用照明控制器或调光器(例如 PWM 调光或 0-10V 调光)对灯条进行适度调暗并降低亮度,这不仅节省了能源,还降低了工作温度。

对于商业照明,在低流量或非工作时间,降低亮度或间歇性地操作以最大限度地减少灯带上的 LED 热负荷。 对于显示灯光,使用定时器控制器精确设置条带的开/关时间。

5.选择 A适当 P排骨 R在

IP 保护等级决定了 LED 灯条承受环境条件的能力。 低 IP 等级的 LED 灯条(例如 IP20)安装在户外时会很快失效,因为它们无法承受灰尘、雨水、风和极端的外部环境条件。 因此,选择适当的 IP 保护等级对于确保 LED 灯条的使用寿命至关重要。

- 对于室内干燥环境,请选择 IP20–IP33 等级的 LED 灯条,以确保高效散热。

- 对于潮湿、多尘或室外环境,请使用防水 IP65、IP67 或 IP68 防水灯条,以防止湿气和灰尘进入。

- 请记住,防水密封层保护 LED 的同时,它们也增加了散热的挑战,因此平衡保护和散热很重要。

6. 定期 M维护和 我检查

LED灯条上积聚的灰尘和碎屑会捕获热量,影响光输出并降低亮度。 因此,您必须定期检查和清洁灯条。 清洁时,使用干布或微湿布轻轻擦拭灯条。

但是,请注意,并非所有 LED 灯条都是防水的。 因此,用水清洗IP等级较低的LED灯条可能会损坏它们。

此外,每 3-6 个月检查灯条的连接端子、接线、电源输出和表面状况,以防止或修理损坏。 例如,如果您注意到局部光衰减或无法正常工作的 LED,请立即修复或更换它们以防止问题恶化。 通过实施这些适当的维护措施,您可以延长 LED 灯条的使用寿命。

通过在选择和安装到操作和维护的每个阶段实施这些措施,不仅可以显着延长LED灯条的使用寿命,还可以在整个项目生命周期中降低更换和维护成本,从而实现更高的投资回报。

常见的LED灯条寿命降解和故障信号

在长时间运行期间,LED 灯条可能不可避免地经历轻微衰减或局部故障。 如果这些指标能够及时识别,它不仅可以最大限度地减少照明中断对项目的影响,而且还可以降低维护成本。 以下是寿命退化和失败的几种常见表现:

1。 显着的光衰减(亮度下降)

当LED灯带的亮度明显低于安装时,即使电源正常工作,这可能表明LED芯片接近其使用寿命的尽头。

- 轻微的光衰减通常是由自然老化引起的,可以通过增加亮度或更换光带的一部分来解决。

- 如果在短时间内发生明显的光衰减,通常与散热不良或电源电压异常有关。

2.色温偏移(色差增大)

高质量的 LED 灯条应在长时间运行后将色温变化或变化保持在可接受的范围内。

- 如果某些 LED 呈现明显的变黄或淡蓝色,这可能是由于 LED 包装的老化、开裂或荧光粉末分离造成的。

- 在商业照明应用中,这种明显的颜色差异会损害整体视觉质量并需要及时更换。

3.本地化 N上-我照明(秒英格尔秒肺动脉 F艾伦)

如果 LED 灯条的一部分完全停止照明而其他部分仍保持功能,这通常是由于以下原因:

- 段中 LED 芯片或电阻器的烧毁

- LED 之间的 PCB 电路中断

- 端子上的焊接松动或焊接不良

这种问题经常发生在安装过程中过度弯曲或连接点应力的区域。

4。 闪烁或 我过时的 F雷

- 持续闪烁通常是由不稳定的 LED 电源、接触不良或 LED 调光器故障引起的。

- 如果故障是间歇性的,则可能会通过 LED 电源过热保护或连接电路的暂时断开来触发。

5. 变黄或 A的ging A导航 L艾尔

对于具有防水粘合层的LED灯条,如果表面硅胶或PU粘合剂显示出变黄、硬化或开裂,不仅影响美观,还会导致光效率降低和散热受损,从而加速LED老化。 这在低质量的防水材料或长时间紫外线照射的环境中常见。

6.异常 H大火 T温度

如果在操作过程中LED灯条的表面温度明显高于平时,即使到太热而无法触摸,这可能是潜在故障的早期警报信号。 过热通常发生在以下两种情况:

- 电源过载:驱动器的输出功率不足,或同时为过多灯条供电,导致组件在长时间的过载条件下运行。

- 通风和散热不良:灯带安装在一个封闭的通道中,接触面上的散热性能差,或者暴露在过高的环境温度下,防止热量迅速释放。

如果您注意到这些问题,则表明需要进行故障排除或考虑更换。 及时识别和解决这些性能下降和故障迹象,可以有效延长整个系统的使用寿命,避免因单段故障而更换整个灯带的需要。 此外,这作为确定升级到高质量、持久LED灯条是否必要的重要参考。

常见的LED灯条寿命降解和故障信号比较表

| 症侯 | 可能原因 | 推荐行动 |

| 亮度明显下降 | LED芯片 光衰减(高温、过载运行)、不稳定电源输出、光学材料老化 | 检查驱动器输出和安装环境温度;更换电源或优化散热设计 |

| 色温偏移(蓝色或淡黄色) | 荧光粉老化、LED包装材料降解、高温加速变色 | 检查环境温度和驱动电流;必要时更换整个条带 |

| 本地化闪烁或关闭 | 电路焊点松动,单独的LED故障,电源触点不良 | 检查连接点和焊料质量;更换损坏的部分 |

| 整个条带闪烁 | 不稳定的电源电压、驱动器故障、负载超过额定功率 | 测试电源输出稳定性;更换与额定功率匹配的驱动器 |

| 异常高温 | 电源过载,通风和散热不足,环境温度过高 | 检查电源和负载匹配;改善安装位置的通风条件 |

| 防护失效(进水、进水) | IP 保护等级不足或封装密封不良 | 更换适合环境要求的灯带型号;加强防护措施 |

| 明显的变形或脱离 | 粘合剂表面上的水分,老化的粘合材料,安装不当 | 更换安装方法或粘合材料;确保表面清洁干燥 |

有关 LED 灯条问题的更多信息,请阅读博客文章“LED 灯条常见故障及解决指南”

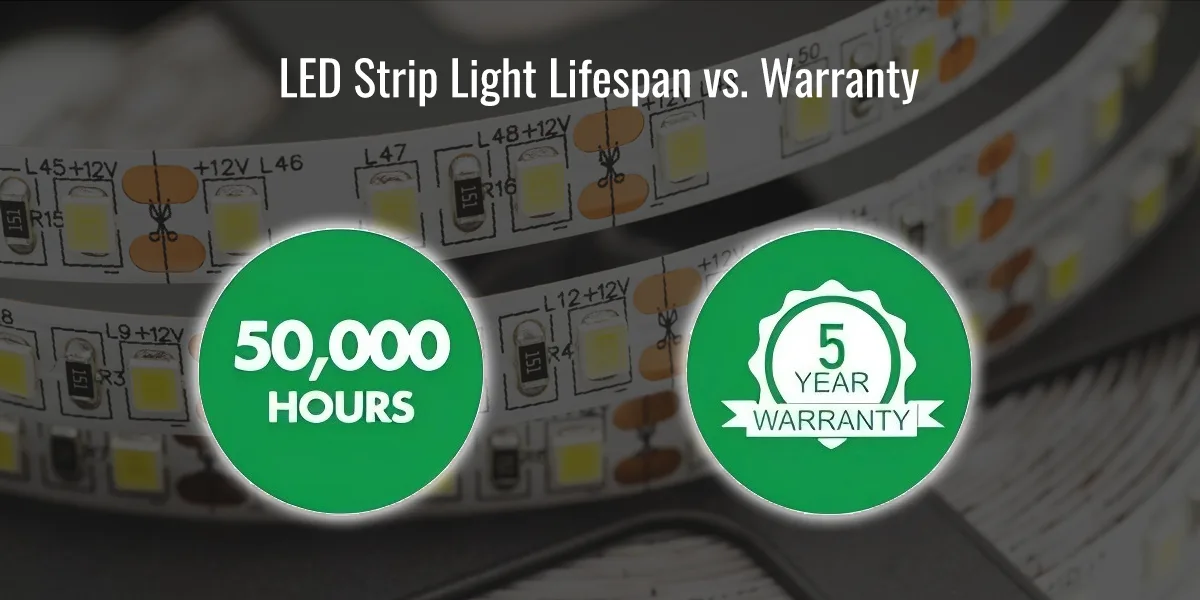

LED灯条寿命与保修

何时 采购LED灯条,许多人可能会将“额定寿命”与“保修”混淆。 事实上,虽然这两个概念是相关的,但它们并不等价。

额定寿命通常是基于L70等行业标准的预测值;例如,50,000小时的额定寿命表示特定条件下的理论使用时间。 另一方面,保修是制造商在实际使用条件下对产品性能和质量的承诺。 LED灯带的常见保修范围为1至3年,高端工程级产品可提供长达5年的时间。

为什么LED灯带灯的使用寿命和保修有如此大的差异?

原因在于寿命测试是在受控条件下进行的。 在实际应用中,温度波动、功率稳定性和安装方法等因素都会影响 LED 灯条的性能。

LED 条制造商在设置保修时会考虑这些不确定性,并包含安全裕度。 例如,额定寿命为 50,000 小时的条带可能仅提供 3 年甚至 2 年的保修,不是因为产品质量差,而是因为在各种复杂使用场景中承保风险。

这也意味着保修政策本身是产品质量和品牌声誉的重要指标。 高质量的 LED 灯带制造商通常愿意提供更长的保修,并明确涵盖保修范围内的流明折旧和色温漂移等核心性能问题。 这不仅反映了制造商对产品流程和质量控制的信心,而且还可以保证客户的长期投资。

因此,在选择LED灯条时,不仅要查看规格中列出的寿命数据,还要仔细评估保修条款。 与纸上列出的寿命数据相比,稳定、透明且明确定义的保修政策通常更能反映制造商的能力和可靠性。

摘要和购买建议

LED灯条的使用寿命不仅取决于几个变量,还取决于高质量的产品和适当的维护。 从这篇文章中,我们可以得出几个关键的结论:

- 寿命受多种因素影响:芯片质量、散热条件、电源兼容性、保护等级和使用习惯都直接决定了LED灯条的光衰率和故障概率。

- 行业标准提供可量化的寿命指标: L70、LM-80 和 TM-21 提供了评估寿命的参考方法,但这些数据必须与实际使用环境一起解释。

- 保修政策是关键指标: 长寿命与透明全面的保修覆盖范围真正反映了产品的长期价值。

LED灯条不仅节能时尚,而且是对LED照明的长期投资。 您需要做出明智的选择并正确维护它们,这不仅可以节省金钱并减少浪费,还可以让您在未来几年享受连续和稳定的照明。

对于B2B采购来说,最优选择不是寿命参数最高的产品,而是寿命和保修期一致的供应商,具有完整的测试报告,并具有稳定的供应能力。 这不仅降低了安装后的维护成本,而且还确保了项目交付后的长期稳定运行。

如果您的项目正在寻求具有全面保修支持的高质量、持久的 LED 灯带灯,请联系 SignliteLED 技术团队。 我们将为您提供测试数据、样本和详细报价,并可提供 定制LED灯条解决方案 帮助您有效地完成选择和决策。