在当今高度电气化和数字化的世界中,我们的社会依赖于脆弱的电子设备——从家庭智能电视和电脑到工业环境中的精密控制单元。

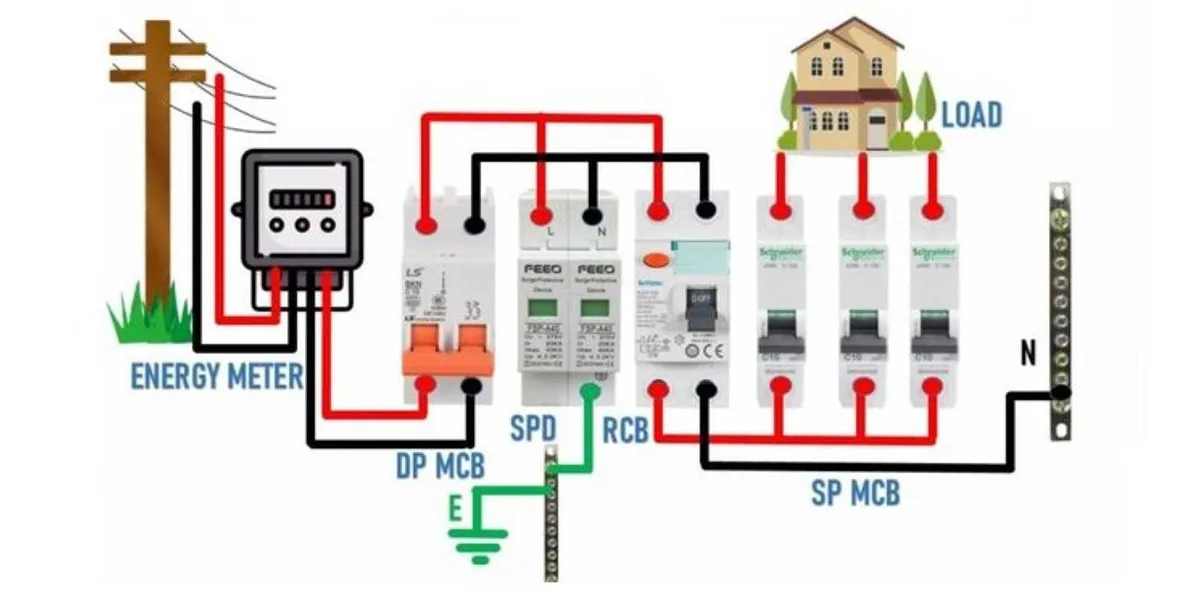

然而,电网中潜伏着一种无形的威胁:电涌。 这些可以在百万分之一秒内造成巨大的损失。 浪涌保护装置 (SPD) 作为抵御这种威胁的关键防御。 但并非所有 SPD 都是平等的。

了解 1 型、2 型和 3 型 SPDS 之间的区别对于构建全面有效的浪涌保护系统至关重要。 本文回顾了这三个 SPD 类别的角色、标准和应用,为您提供构建强大电子防御的完整指南。

什么是浪涌保护装置(SPD)?

浪涌从何而来?

浪涌,也称为瞬态过电压,是指具有天文持续时间(微秒到毫秒)但电压幅度远远超过正常工作水平的电流脉冲。 大致可分为两类:外部浪涌和内部浪涌。

外部浪涌(主要威胁)

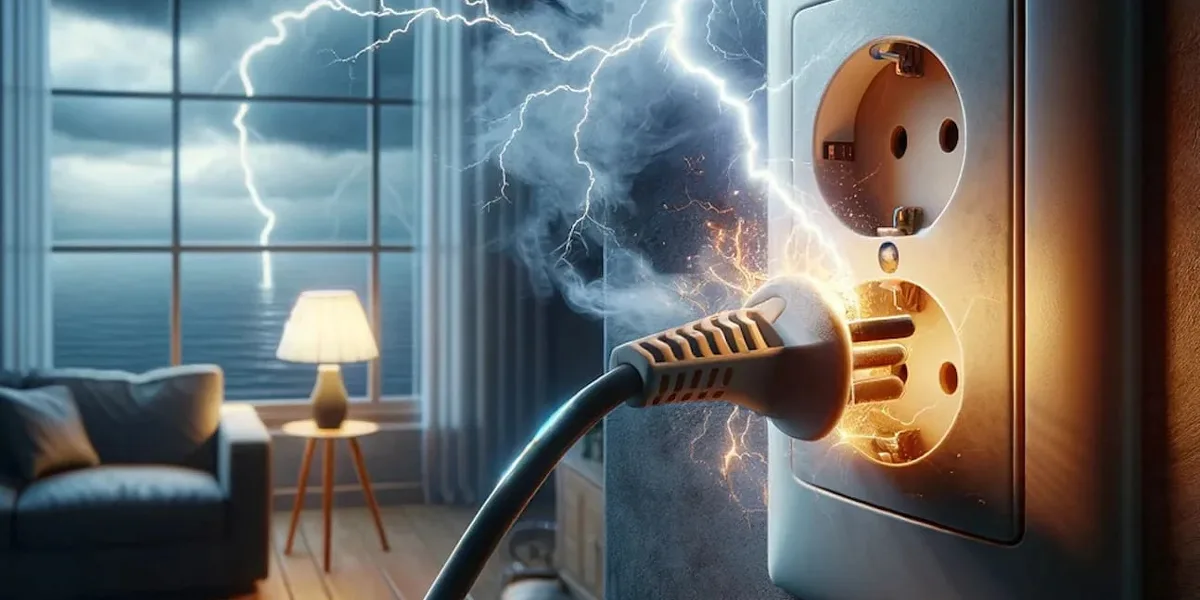

a) 直接雷击:雷击电网或附近的结构注入了数百万伏的电压——最极端的情况。

b) 感应雷击: 比较常见。 即使在数百米外的雷击时,其强大的电磁场也会在室内电源和信号线上产生过电压,然后将其传播到设备中。

内部浪涌(频繁发生)

建筑物内的大功率设备(如电梯、空调压缩机和焊接机)的开关操作会在电网中产生频繁的开关瞬态。 甚至像复印机和咖啡机这样的操作也产生频繁的、低能的瞬态过电压。

这些浪涌的累积效应就像一个“微型锤子”不断敲击电子元件,逐渐导致性能下降、数据损坏和设备寿命缩短。 然而,一个重大的浪涌事件类似于“电子心脏病发作”,能够立即造成永久性设备损坏甚至触发火灾。

浪涌保护装置(SPD)是专门设计用于应对这些威胁的电子安全设备。 其核心功能可以概括为“监控、转移和夹具”。

在正常电压条件下,SPD 呈现高阻抗,对电路没有影响。 检测到过电压后,它在纳秒内转变为低阻抗状态,为浪涌电流建立安全放电通路,同时将其端子上的电压(钳位电压)限制在受保护设备容差范围内的安全范围内。

因此,SPD 不是奢侈品,而是任何寻求保护资产、确保业务连续性和保护数据的现代电气系统的重要组成部分。

SPD 是如何工作的?

在正常情况下,SPD 对电路没有影响,并保持在高阻抗状态。 检测到危险的浪涌后,它会在纳秒内做出反应,切换到低阻抗状态。 这为浪涌电流创建了一个低电阻路径,将其快速“转移”到地,同时将其端子(称为钳位电压)的电压限制在一个安全范围内。 这可以保护并联连接的设备免受损坏。

可视化为高压水流量智能化泄压阀,如下图所示: 水压正常时,阀门保持紧闭。 当压力突然飙升(浪涌)时,阀门立即打开,释放过多的水流量(浪涌电流),以确保下游设备(您的电器)的安全。

电涌会对LED照明灯具造成什么损害?

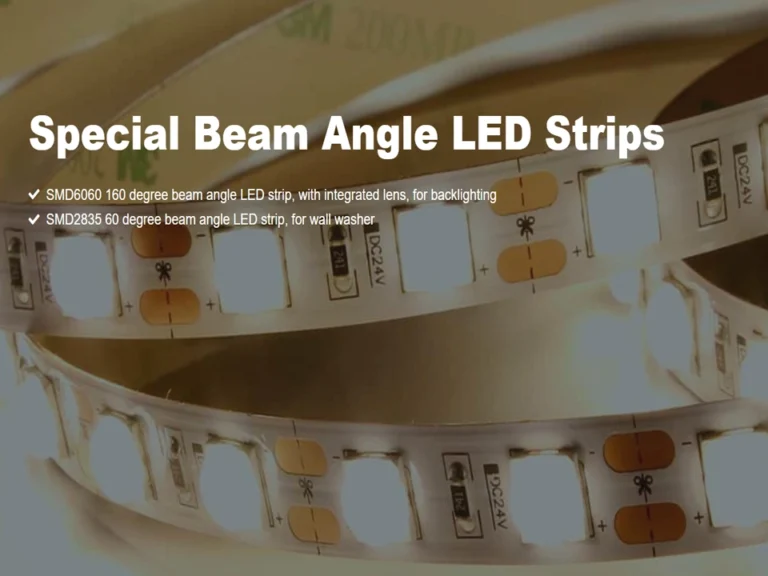

许多人认为,由于LED照明灯具持久且节能,它们本质上是“耐用且坚固的”。 然而,现实情况恰恰相反——LED 照明灯具对电涌极为敏感,主要是因为它们的核心组件:驱动器电源。

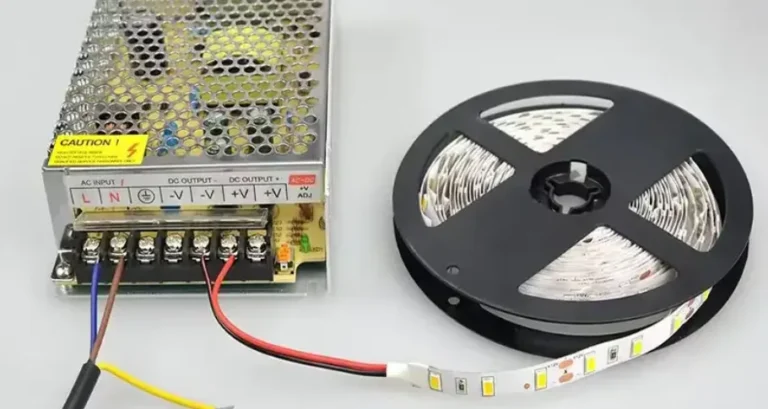

1。 开关电源损坏

如下所示,LED 芯片本身在低直流电压(例如 3V)和恒定电流下运行。 我们每天使用的 220V 交流电源必须通过称为“驱动电源”的组件进行转换。 该驱动器本质上是一个精密的开关电源,里面装有敏感的半导体组件(如 MOSFET、IC 控制器、整流二极管等)。

这些半导体组件极为脆弱,电压容限远低于传统白炽灯或荧光灯泡。 即使是一个小的电压尖峰也可能导致它们发生故障。 因此,浪涌保护的开关电源对于延长照明灯具的使用寿命至关重要。

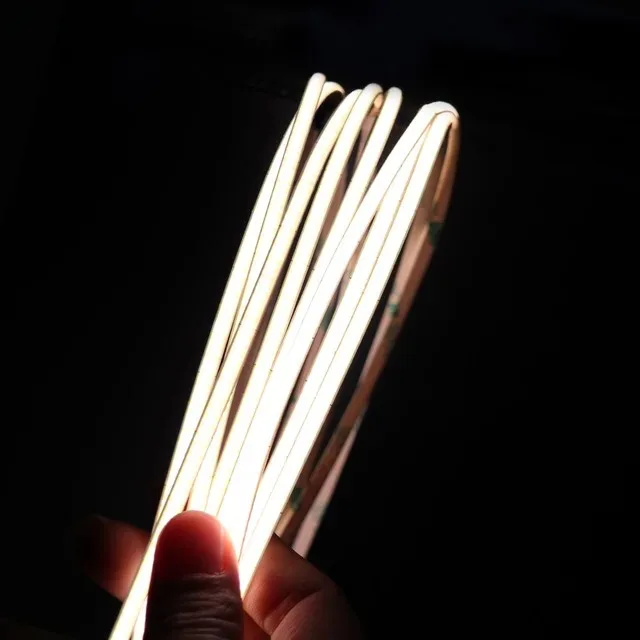

2. 烧坏 LED 芯片

大电流会直接切断金线连接或损坏 LED 芯片,导致芯片部分或完全变黑和故障。

3. 渐进式组件退化

这种类型的损害更加微妙和广泛。 不会立即破坏灯具的重复微小的浪涌会对其内部半导体材料造成累积性损坏。 随着时间的推移,夹具可能会莫名其妙地变暗、闪烁、出现颜色漂移或发出驾驶员的异常噪音。

固定装置的预期寿命从 50,000-100,000 小时下降到一两年——甚至更短。 您可能会假设您购买了“不合标准的产品”,但真正的罪魁祸首可能是频繁的内部激增。

将 SPD 添加到照明设备的好处

LED照明灯具,特别是在商业、工业或户外应用(如路灯、泛光灯和工业/矿灯)中,比传统灯具的采购和安装成本要高得多。 对单个固定装置的损坏不仅涉及更换设备本身的成本,还涉及维护/更换的大量人工费用,尤其是在高海拔或复杂环境中。

安装SPD的成本明显低于因浪涌损坏而频繁更换LED驱动器或整个固定装置而产生的长期费用。 它是照明投资的关键保障。

因此,配备电涌保护装置 (SPDS) 的 LED 照明系统(尤其是户外、商业和工业照明)并不是可选的奢侈品,而是必要的保护措施。 它使能:

- 防止突然的、昂贵的设备故障。

- 避免隐藏、逐步降低性能和缩短寿命。

- 降低维护费用,增强照明系统可靠性。

- 适用于个人家用设备:使用内置基本电涌保护的优质电源板。

- 适用于整个建筑或别墅:在主配电面板上安装 2 型 SPD,为所有家庭电路提供行李箱保护。

- 对于室外 LED 灯具(街灯、景观灯)和大型工厂/商城照明电路,必须在相应区域配电面板内的照明电路中专门安装 2 型 SPD。 对于特别昂贵或关键的固定装置,请考虑在夹具内或终端添加 3 型 SPD 以进行颗粒保护。

通过投资SPD,您可以确保您的LED照明投资实现其承诺的寿命和高性能,从而实现真正的物有所值。

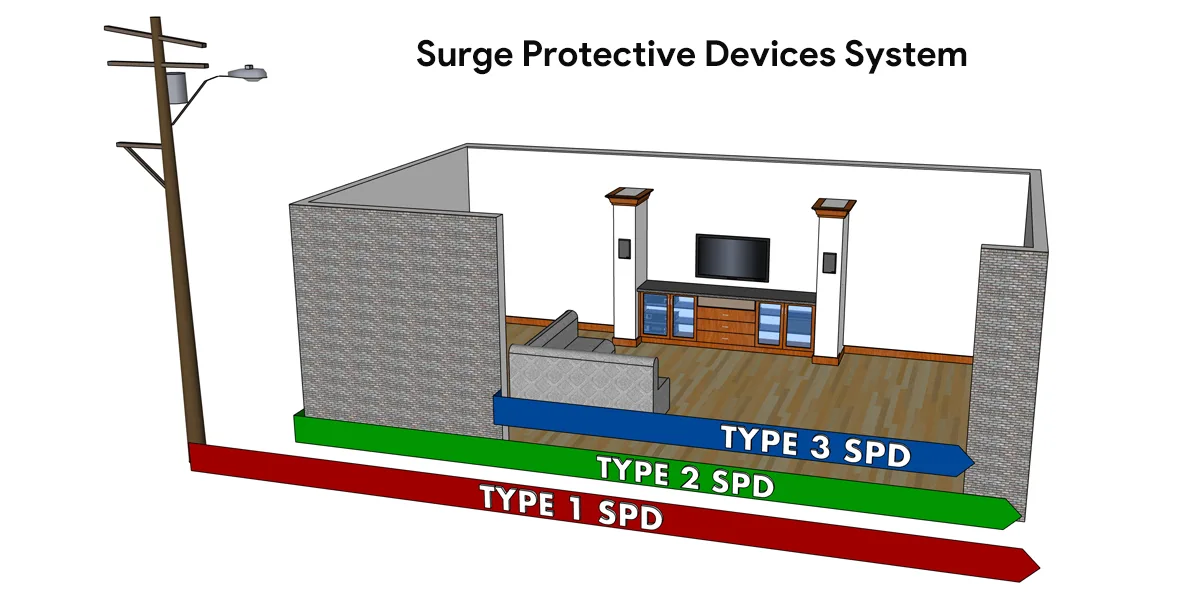

如何理解SPD分级?

您可能会问:如果 SPD 存在,为什么要将它们分类为不同的类型? 答案是没有一个 SPD 可以独立处理所有类型的浪涌威胁。

雷击产生的能量与内部开关操作产生的能量有很大不同。 因此,有效的保护策略涉及建立分层的、协同的防御系统。 这个概念被称为“能量协调”或“分层放电”。 想象一下它是城堡的防御系统:

- 1型作为坚固的外墙和大门,旨在承受最强烈的正面攻击。

- 类型 2:城堡内的巡逻警卫,向破坏外墙和内部干扰的落后者讲话。

- 类型 3:国王卧室门口的私人警卫,提供最后和最精致的保护层。

只有当这三道防线共同工作时,城堡(您的电气系统)才能获得最全面的保护。

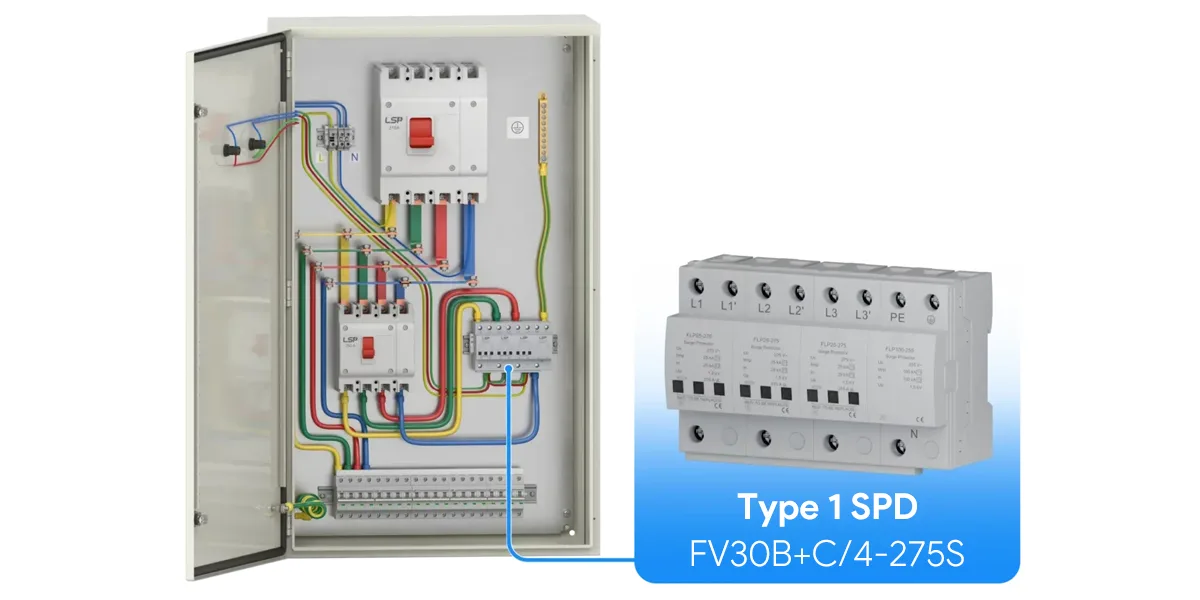

1 型 SPD:对抗外部浪涌的第一道防线

1 型 SPD 是额定最高的设备,旨在转移由直接撞击引起的部分雷电电流。 根据国际标准(例如,IEC 61643-1),它们必须经受 10/350µs 模拟雷电电流波形的测试。 这种波形代表了直接雷击的巨大能量,其持续时间极长,使设备承受着严重的压力。 安装位置:安装在建筑物主配电板 (MDB) 内,通常在电源入口点。

特点:放电大规模的雷电电流(通常是数十千安培)。 其主要目的不是将电压限制在非常低的水平,而是安全地“吸收”最致命的初始打击。

典型组件:通常使用火花间隙或气体放电管,因为这些组件可以承受极高的能量影响。

适用场景:主要用于配备外部防雷系统(例如,避雷针)或架空电力线提供的建筑物。 它构成了整个电涌保护系统的基础。

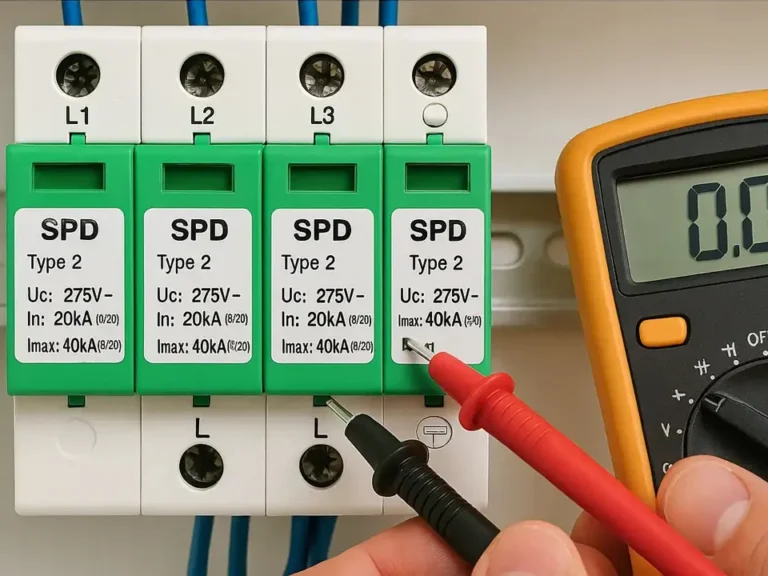

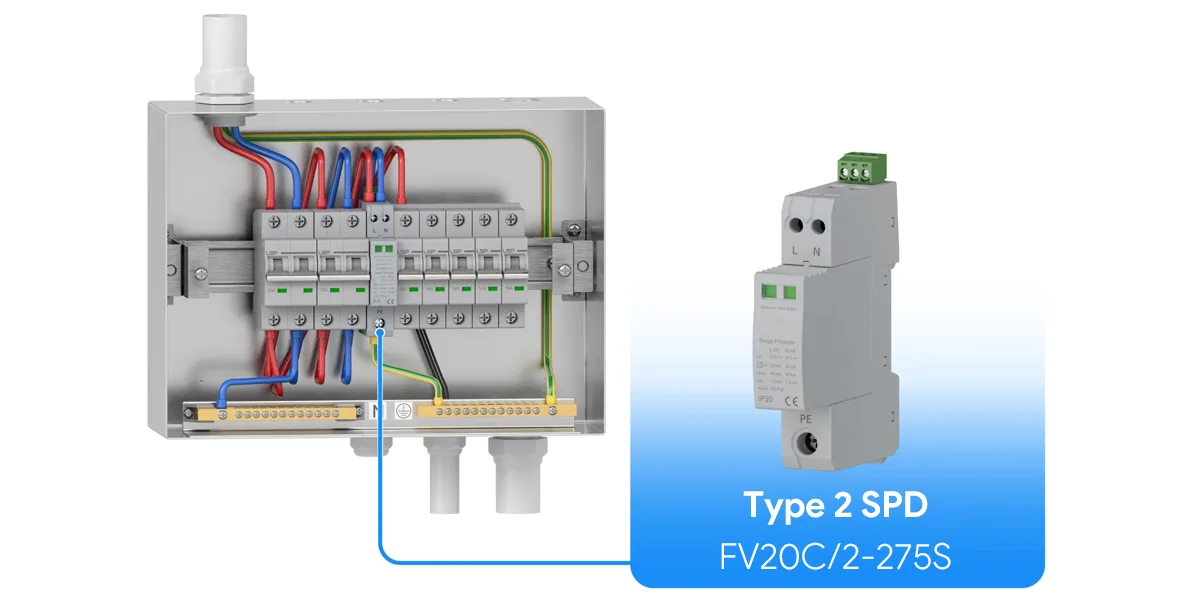

2 型 SPD:初级保护,保护配电系统

2 型 SPD 是使用最广泛的 SPD,是电涌保护系统的主要保护级别。 采用8/20μs电流波形进行测试,模拟受1型SPDS限制后传输的残余浪涌,以及内部开关操作产生的浪涌。

安装地点:安装在子配电板内,为特定楼层、区域或负载组提供保护。

特点:进一步限制了 1 型 SPD 未完全处理的过压和放电浪涌电流以及内部产生的浪涌。 它将电压限制在大多数家用和商用电器的安全水平(例如,低于设备耐压额定值)。

典型设备:最常见的是金属氧化物变阻器 (MOV),因为它具有出色的响应速度和钳位电压特性。

应用场景:在所有电气装置中几乎不可或缺的保护装置。 在没有外部防雷系统的小型建筑中,它甚至可以作为一级保护。

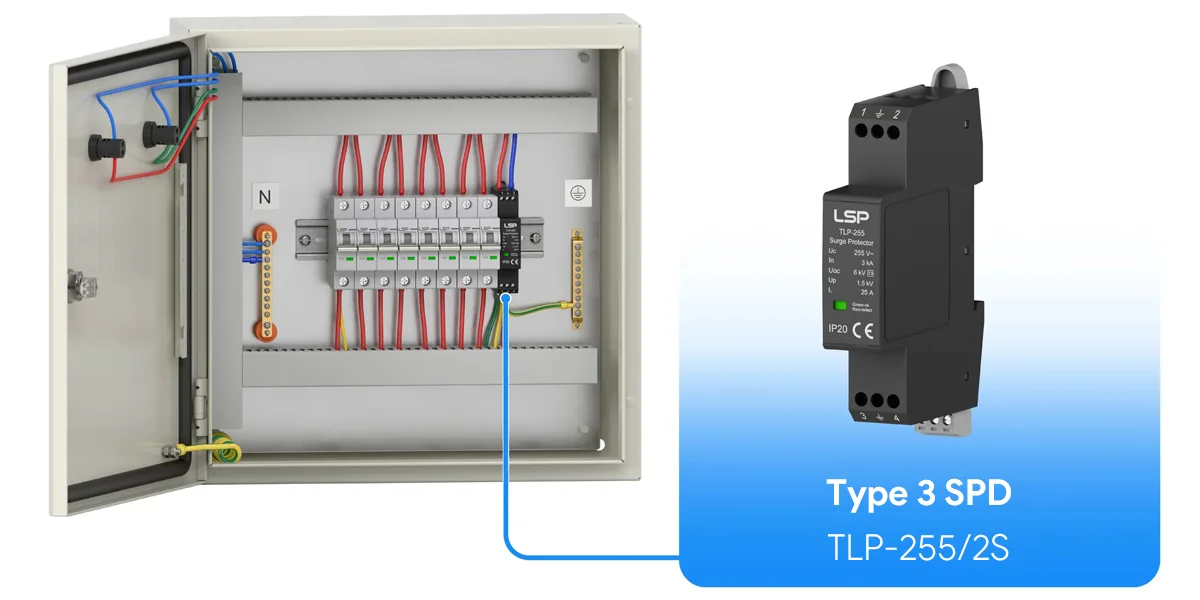

3 型 SPD:终端设备的精密保护

3 型 SPD 提供最精细的保护级别,专为保护高度敏感或昂贵的终端设备而设计。 它使用复合波(1.2/50µs 电压波和 8/20µs 电流波)进行测试,测试电流值明显低于 2 型。

3 型 SPD 进一步抑制了绕过前两个保护级别的微小残余过电压。 虽然能量低,但这些电压峰值会降低设备的使用寿命或通过长时间的积累导致数据损坏。 切勿单独使用,应安装在 2 型 SPD 的下游。

安装地点:

– 在设备端,包括具有 SPD 功能的电源插座(例如,一些先进的电源板)。

– 专用插件 SPD。

– 设备内嵌入式 SPD 模块。

组合单元:市场上也有 2+3 型组合 SPD。 这些将两个保护级别集成到一个模块中,为安装多个独立 SPD 的场景提供便捷高效的解决方案。

如何选择和部署您的 SPD 系统?

在容易发生雷击或严重功率波动的环境中,选择适当的SPD和构建协调系统至关重要。 正确的SPD选择和安装不仅可以防止昂贵的维修,而且还确保生产和日常生活的连续性,使其成为需要全面考虑的技术决策。

首先,评估建筑物的环境:雷击频率、隔离状态、架空或地下电源、结构中是否存在避雷针以及内部设备的价值和灵敏度。 这将决定您是否需要 1 型保护或 2+3 型组合是否足够。

- 遵循层次原则:

– 具有外部防雷系统或高风险区域的建筑物:实施 1 型 → 2 型 → 3 型完整的架构。

– 标准商业或住宅建筑:在主要服务入口处至少安装 2 型 SPD,并在关键设备点处补充 3 型 SPD。

– 小型建筑物或公寓单元:在服务面板内安装高性能 2 型 SPD,并使用 3 型电涌保护的电源板作为有价值的设备。

- 电压保护电平(上): 这代表SPD的钳位电压。 较低的值表示更好的保护。 确保 UP 低于受保护设备的耐压额定值。

- 额定放电电流 (in) 和最大放电电流 (imax):这些表明SPD能够消散浪涌电流。 更高的价值意味着更大的复原力。

- 对于 1 型 SPDS,请关注脉冲电流 (IIMP)。

- 确保正确安装:SPD 性能高度依赖于安装。 最小化接地引线长度至关重要,因为过长的引线产生的感应电压会显着降低保护。 使用专用工具或母线将 SPD 直接连接到接地系统,长度最小。

- 维护和使用寿命:SPD 是消耗设备。 特别是基于 MOV 的 SPD 在反复的浪涌事件后逐渐降解。 选择带有远程信号触点或可视报警窗口的 SPD 以监控其状态并便于及时更换。

选择合适的SPD类型和建立协调保护系统是确保电气设备安全和延长其使用寿命的关键。 了解它们的区别和互连将帮助您为您的家庭或企业建立真正强大的“电子防御线”。 附录提供了用于选择不同 SPD 类型的参考参数:

电涌电流和额定放电电流参数的推荐值

| 闪 镇 品位 | C用户单位 | 分行电箱 | 电脑室配电箱和需要保护的电子设备端口 | ||

| LPZ0 和 LPZ1 的边界 | LPZ1和LPZ2的边界 | 后续保护区的边界 | |||

| 10/350μs | 8/20μs | 8/20μs | 8/20μs | 1.2/50μs 和 8/20μs | |

| I类测试 | 二级测试 | 二级 考查 | 二级 考查 | 复合波 III 类测试 | |

| 小鬼(卡) | in(ka) | 我,(卡) | 我,(卡) | u(kv)/IX(ka) | |

| A | ≥20 | ≥80 | ≥40 | ≥5 | ≥10/≥5 |

| B | ≥15 | ≥60 | ≥30 | ≥5 | ≥10/≥5 |

| C | ≥12.5 | ≥50 | ≥20 | ≥3 | ≥6/≥3 |

| D | ≥12.5 | ≥50 | ≥10 | ≥3 | ≥6/≥3 |

结论

总之,类型 1、2 和 3 型 SPD 各自发挥着不同的作用,形成了从宏观到微观层面的分层防御系统。 投资设计良好的浪涌保护系统不仅是保护硬件,还涉及对数据安全、业务连续性和保护生命和财产的战略投资。 通过了解它们各自的功能并协同部署它们,您可以为您的电子资产建立一个强大的障碍,以抵御不可预测的电气威胁。