在商业照明和家居设计中,LED 线性灯因其时尚的设计和均匀的光分布而广受欢迎。 然而,忽视统一眩光等级(UGR)可能会导致视觉疲劳甚至安全隐患。 通过科学选择合适的照明,我们可以获得“不看光源的情况下看光”的舒适体验。

根据国际标准,不同的场景对UGR有明确的要求。 办公室和教室通常要求 UGR≤19,而一些高端展厅和医院对 UGR 的要求更高,要求 UGR ≤16。 因此,UGR已成为购买LED线性灯时不可忽视的重要因素。

LED 线性灯能达到小于 19 的 UGR 吗?

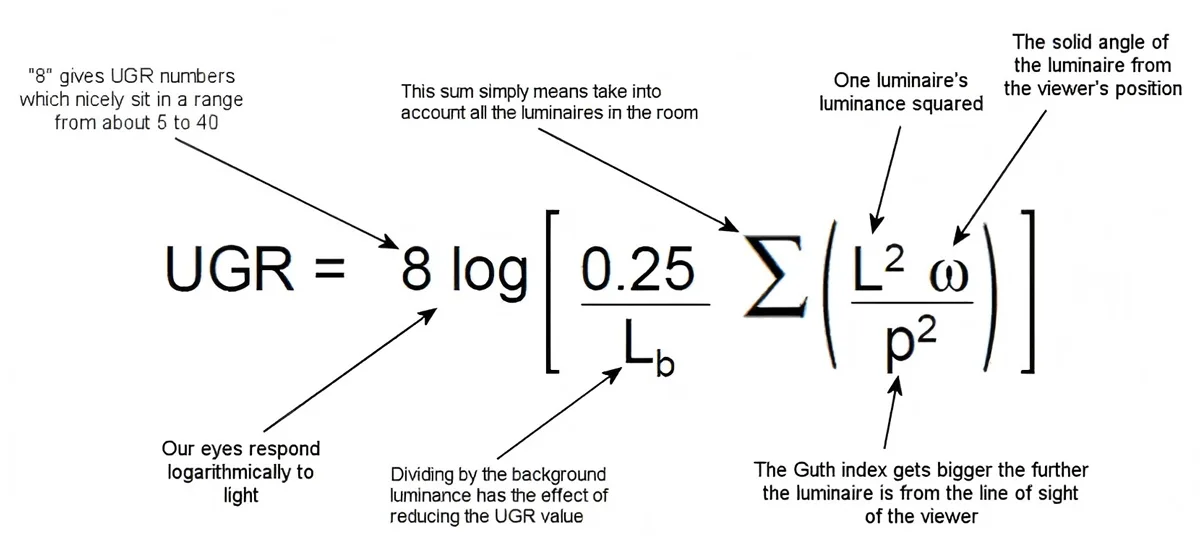

是的, LED 线性灯 可达到19以下的UGR。 统一眩光等级(UGR)是测量照明的眩光效应的关键参数。 办公室等健康的照明环境需要小于 19 的 UGR 以确保视觉舒适度。 例如,专为低眩光设计的LED线性灯通过符合建筑照明标准的微结构防眩光材料,可以将UGR值稳定在19以下。

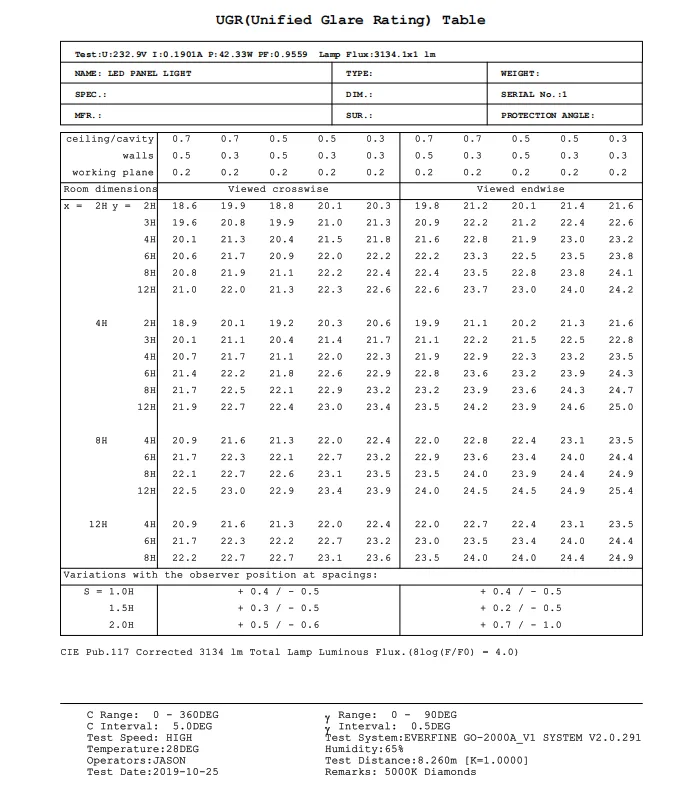

然而,作为直接光源,如果设计不当,线性灯可能会带来眩光风险。 如下图所示,其UGR值可达22,超过CIE推荐的上限,导致经常出现瞳孔收缩和头痛等不适。 因此,在选择产品时,建议将明确标记为满足 UGR 要求的产品优先排序。

为什么线性灯的眩光等级(UGR)应小于19?

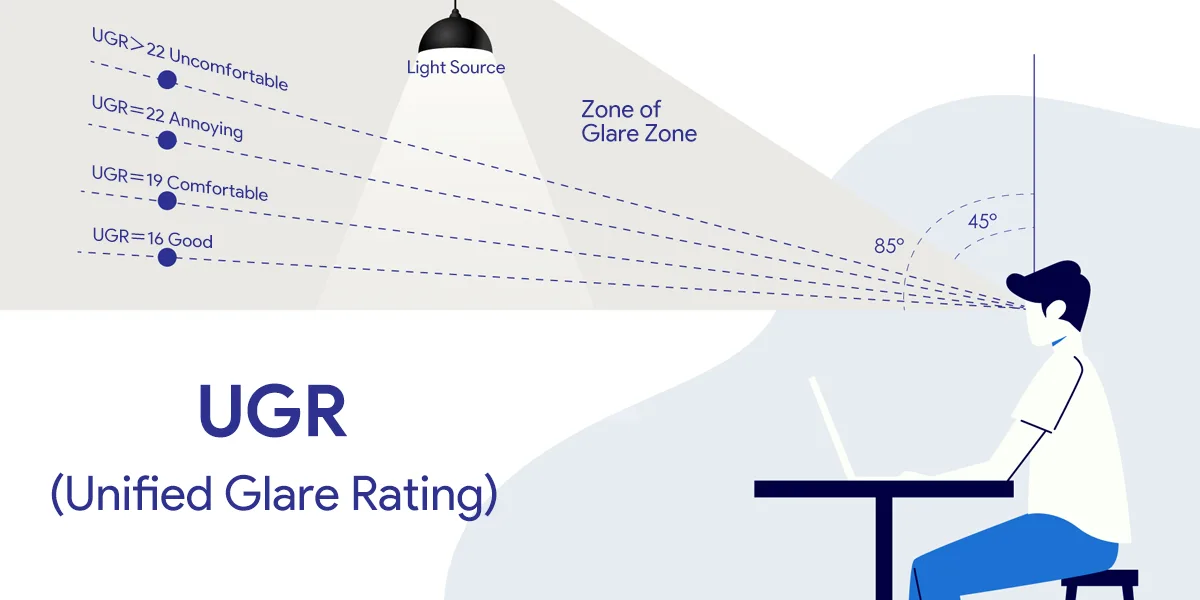

UGR(统一眩光等级)是评估室内线性照明眩光水平的国际公认标准。 UGR值越低,眩光越弱,视觉舒适度越高。 UGR 值受多种因素的影响,包括光源亮度、位置和环境光照水平。

当 UGR 超过 19 时,学生经常调整,导致视觉疲劳。 长时间暴露可导致视网膜损伤、视力恶化和白内障风险增加。 仅在中国,超过 60% 的青少年患有近视,眩光污染已被确定为主要促成因素之一。

当前标准要求健康照明环境中的 UGR 值低于 19。 要求 UGR 小于 19 的要求主要基于以下原因:

- 确保视觉舒适:UGR 值为 19 标志着中等和显着眩光之间的阈值。 当 UGR ≥ 19 时,刺眼的感觉会显着增加,可能会导致视觉疲劳或不适。 然而,当 UGR < 19 时,眩光仍在可接受的范围内,使其适合需要长时间关注的办公室和教室等环境。

- 「适应工作场所要求: 在办公区域和其他需要精确视觉任务的环境中,UGR ≤ 19 标准平衡照度和舒适度,防止眩光干扰工作效率。 例如,GB50034-2013 标准明确规定,一般办公区域的 UGR 上限为 19,模拟了自然光环境的舒适体验。

- 「应用场景」: UGR 值的分级设计考虑了不同位置的容差水平——UGR < 19 适用于高需求环境(如办公室),而引起明显眩光的 UGR ≥ 19 仅推荐用于视觉舒适度较低的工业设施或商店。

UGR 值是如何分级的?

UGR 值的舒适度(均匀眩光等级)已由国际标准明确定义。 具体舒适度阈值和适用场景如下:

当UGR<13时,光线柔和,人眼几乎无法察觉到眩光。 这适用于具有极高视觉舒适度要求的空间,例如艺术画廊和高端住宅。

当 UGR < 16 时,它落在舒适范围内,轻微的眩光不会影响视觉任务。 这是教室、阅览室和其他需要精确工作的环境的推荐标准。 例如,教室中的眼部保护面板灯必须控制 UGR ≤ 16 以保护青少年的视力。

UGR价值和人类感知状态分级

| 范围 | 人的感知 | 适用场景示例 |

| 乌尔格兰 < 13 | 没有明显的眩光 | 医院、高端展厅、专科院校 |

| 13 ≤ UGR ≤ 16 | 轻微的眩光 | 医院、老年活动中心 |

| 16 ≤ UGR < 19 | 中度眩光,可接受但可能导致疲劳 | 普通办公室、会议室 |

| 19 ≤ UGR < 22 | 明显不适的阈值 | 工业厂房、仓库 |

| ·UGR ≥ 22 | 强烈的眩光,引起头痛 | 避免长时间的人工占用 |

在舒适和不适之间的心理阈值是UGR = 19,但健康的视觉环境(如学习空间)的目标应该是UGR≤16。

应用场景的强制性标准:

- 教育设施:教室强制性 UGR ≤ 19;高质量照明解决方案应优化为 ≤ 16;

- 办公环境: UGR > 19 导致经常出现的瞳孔收缩,导致视觉疲劳;合格分数≤19;

- 工业场所: UGR ≤ 22 是允许的,但必须使用防眩光配件以降低健康风险。

眩光保护实践建议

| ��声 | 技术原理 | 减低UGR效果 |

| 「微棱镜扩散板」 | 分解高强度光束 | 减少到≤16 英寸 |

| 「间接照明设计 | 避免人眼周围的 30° 干涉区 | 减少 30% |

| 「低光材质」 | 减少环境反射眩光 | 优化2-3点 |

注:UGR 测量需要使用鱼眼镜头分布式光度计;如果误差超过 ±10%,则需要校准。

欧美线性照明的UGR要求

欧洲和美国对 LED 线性照明的 UGR 要求有明确的分级标准。 具体规定和实施要点如下。

强制性 UGR 分级标准

欧盟核心标准:所有室内线性照明必须满足 UGR ≤ 19 的最低安全阈值。 超过此值将导致未能获得 CE 认证。 特殊地点有更严格的要求: 教育/办公区域:UGR 必须≤16,如教室和开放式办公室;艺术画廊/医疗设施:UGR 必须≤13,必须使用蜂窝防眩光结构。

北美特殊要求: UL 1598 标准明确要求 LED 照明灯具控制光生物危害(不包括 4400-780 nm 波段);能源之星认证要求商业照明设备的 UGR ≤ 22,并且必须指示蓝光水平(RG0 豁免水平优先)。

UGR 测量验收规范

| 项目 | 欧盟标准 | 北美补充要求 |

| 「观测高度」 | 坐1.2m/站立1.5m | 符合 CIE 117-1995 标准 |

| 测量设备 | 143°视野成像亮度计 | 必须通过 UL 光度校准 |

| 背景亮度校正 | 消除了固定装置的直接光干扰 | 添加镜像反射检测项目 |

欧洲和北美洲的UGR标准比较

| 指示器 | 欧盟 | 北美 |

| 执法力度 | 禁止市场流通的 UGR > 19 | 能源之星认证自愿执行 |

| 技术重点 | 眩光控制(UGR)作为核心焦点 | 光伏安全+能效双重控制 |

| 升级方向 | 到2025年实施UGR≤16 | 加强纽扣电池配件的安全标准(UL4200A) |

| 核心阈值 | UGR ≤ 19 强制阈值(CE 认证基本要求) | 没有联邦级强制性阈值;能源之星建议≤ 22 |

| 特殊场景要求 | 教育/医疗设施 UGR ≤ 13 | 工业照明允许 UGR ≤ 25 英寸(必须符合 UL 1598 电气安全标准) |

光学 P参数 C奥尔西斯

- 欧盟:强制使用 143° 视野成像亮度计,以消除来自灯具的直接光的干扰;

- 北美:必须通过 UL 光度校准设备并添加镜像反射检测。

观察参考

- 欧盟统一采用1.2 m/立高1.5m的坐姿高度;

- 北美符合欧盟标准,但允许制造商定义自己的测试高度(需注册)。

欧洲国家将从2025年开始对UGR≤16覆盖范围(包括商业空间)的镜像天花板实施强制性要求。:灯具表面亮度≤2000 cd/m²;反射率<60%的磨砂灯罩。

无线控制的照明灯具必须另外遵守: FCC 射频认证(47 CFR 第 15 部分)和纽扣电池配件必须符合 UL 4200A 3。

趋势警报:欧盟2025年的新法规将将光生物安全(RG0)纳入UGR评估系统,北美将同时升级UL 153蓝光控制标准。

LED直线灯的UGR值如何测量?

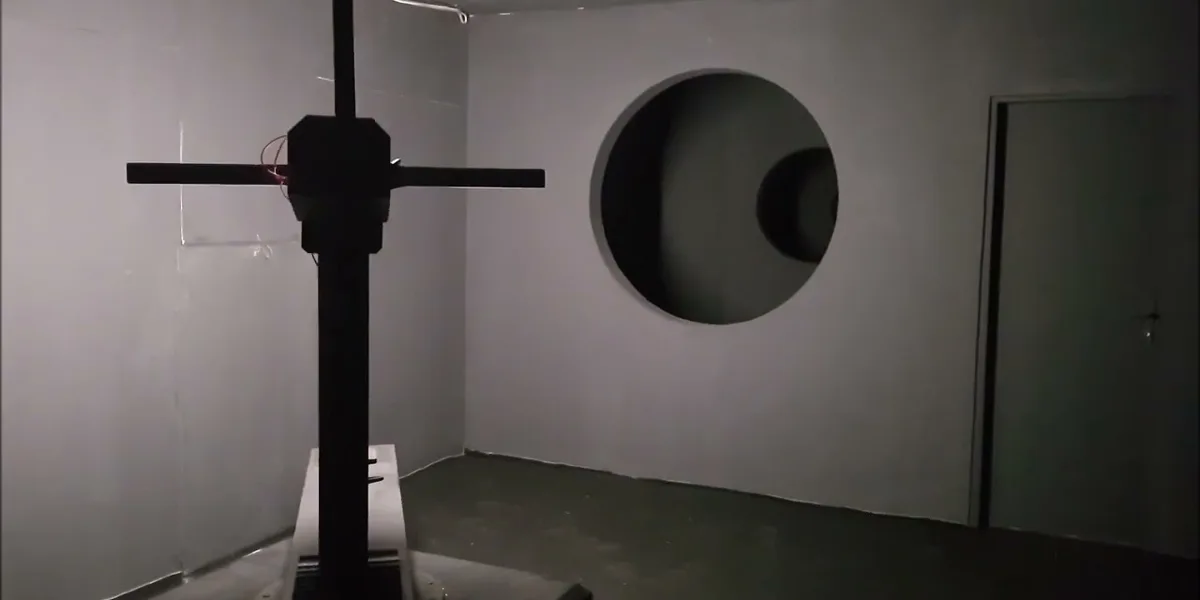

的UGR值 LED 线性灯 通常使用测角光度计测量,可以使用标准软件获得光度数据并模拟计算。 具体的测试程序和关键点如下:

将线性灯具固定到测角仪的旋转支架上。 通过旋转夹具或反射器,捕获 360° 空间的光强度分布数据,生成包含光通量和光强分布等参数的 IES 格式的光度文件。

长线性灯通常属于双轴对称灯具的类别(例如长面板灯),需要测试两个对称平面的配光曲线:纵向平面(C0-C180)和横向平面(C90-C270)。

数据验证

确保 IES 文件包含完整的光分布信息(如半峰值边缘角和光束扩散角),并且灯具的发光立体角 ω 在 0.0003 到 0.1 SR 的范围内以满足 UGR 计算条件。

将 IES 文件导入仿真软件

将线性灯具的 IES 文件加载到 Dialux 等专业软件时,请确认该文件采用完全对称或双轴对称格式(不对称灯具无法生成 UGR 表)。 如果 IES 文件没有自动调整,请使用校正工具调整对称性。

设置标准仿真环境

根据 CIE 117-1995 标准,构建虚拟房间并定义关键参数:

- 空间尺寸:根据 X=2h、4h、8h、12h 动态设置长度和宽度(其中 h 是观察者眼睛到灯具安装高度的高度);

- 反射率:输入天花板和墙壁的实际反射系数(默认值:天花板 0.7,墙壁 0.5);

- 观察者位置:保持水平视线,与灯具的中心点有默认距离。

- 生成 UGR 表和校正:软件输出“参考 UGR 照度评估表”(未校正的 UGR 表),它表示 1000 lm 光通量下的裸光源的理论值。

- 实际 UGR 校正公式:实际 UGR = 表值 + 10 × log(灯具的实际光通量 / 1000)。 例如,当灯具的光通量为2000 lm时,将3个表值加上3(10×log₂ ≈ 3)。

- 应用限制: UGR 仅适用于室内环境和双边对称灯具;采用这种方法的极化设计(如非对称分布式洗墙灯具)的线性灯具不能直接评估。

- 测量的 UGR 和模拟结果之间的差异:仿真结果为标准环境参考值;实际安装受空间尺寸、反射材料等影响。

如何有效降低线性灯的UGR值?

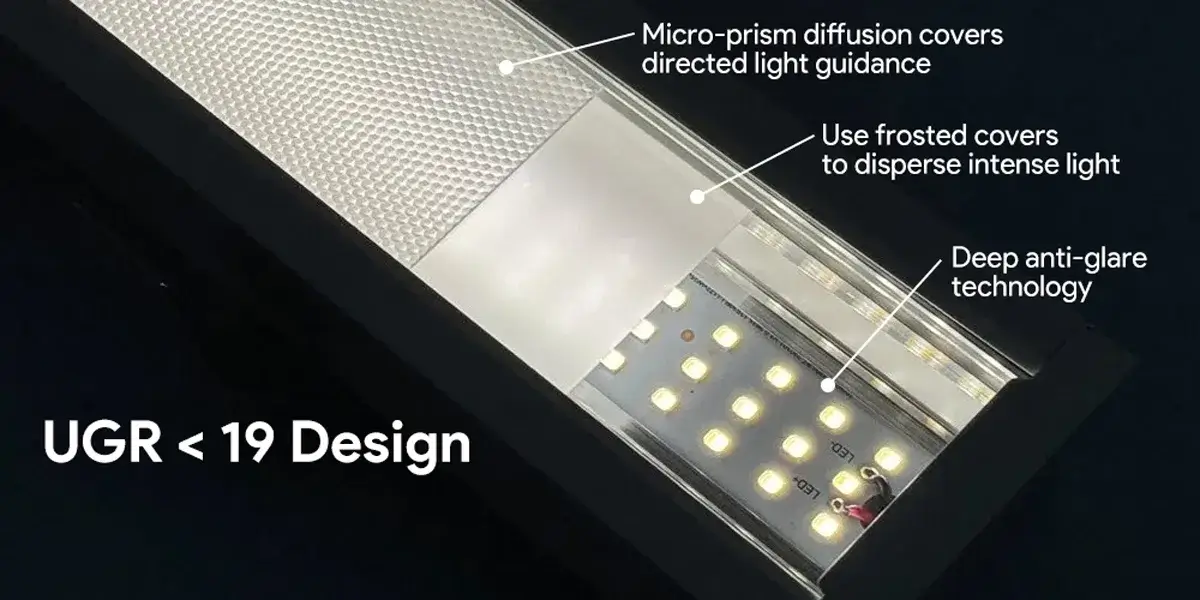

- 光学结构优化:采用眩光角度设计和深防眩光技术,眩光角度≥25 cm,阻挡直射光线的眼睛。 对于工业环境,建议安装高度≥3.5 m 的灯,并与反射器结合以减少眩光。

- 表 T重新 T技术:使用蜂窝防眩光网削弱杂散反射,实现UGR 30% 的减少(特别适合高反射环境); 或者,使用磨砂/哑光灯罩散射强光,确保光散射均匀,表面反射率<60%;

- 微P有主义的 D融洽 P安纳尔斯:定向光引导,将UGR从21降低到14。

- 安装和 L不在外 C控制:优先安装嵌入式灯泡;避免灯光暴露;线性灯应嵌入天花板或墙壁(嵌入深度≥2cm);表面安装时,偏光镜片必须用于将光线射向工作表面。 灯泡不得放置在眼睛水平的 30° 范围内(高度 ≥ 1.8 m 的高度更安全);镜面天花板必须与磨砂灯罩配对以抑制二次反射。

- 墙体材料控制:使用哑光漆(反射率<60%),避免使用高反射材料(如白墙或瓷砖);安装弯曲的反射光槽,将直射光转换为漫射光(测量的UGR从21降低到13)。

- rg0-L电平 B路 L右边 C控制:使用全光谱光源减少光生物刺激;

- 剧烈 D铭 秒系统:动态降低高亮区域的对比度(必须通过 FCC/CE 认证)。

- 札记:透明LED灯泡是暴露的光源,会引起严重的眩光;避免高功率密集布置,灯间距≥1.5倍的灯具宽度;镜像家具、桌子和屏幕等反射性表面应与灯具的投影角度偏移。

- 影响 V更新:使用 143° 视野成像亮度计测量校正后的 UGR 值,以确保≤19(办公室)或≤13(医疗/教育)。

此外,为了满足 UGR ≤19,照明项目必须采用三重技术控制:

- 光学 D设计:使用微结构光扩散板降低表面亮度;

- 谋:避免人眼干扰区(在 30° 向上视场内);

- 材料 秒选举:使用低光泽材料减少反光眩光。 例如,教室照明的 UGR ≤ 19(国家标准 GB7793-2010),而高端灯具(如路灯)进一步优化至 UGR ≤ 16。

- 光学优化:安装微棱镜扩散板:UGR 可从 21 减少到 14;使用偏光镜头:工业设置允许 UGR ≤ 25,但必须与反射率≤ 60% 的墙壁配对。

- 安装禁忌:严禁将裸灯放置在人眼30°水平视野内;离地面1.8米的高度更安全;在镜像天花板设置中,必须使用磨砂灯罩。

SIGNLITELED LED 线性灯的四大核心优势

出色的光学性能:采用UGR < 19 的降低眩光设计,光线通过棱镜扩散板均匀地散射,并辅以高精度光学透镜系统,有效控制光点边界的锐利,达到博物馆级的眩光抑制标准。

工业级结构设计:采用航空级铝合金型材和纳米涂层技术,具有IP66防护等级,能够承受-30°C至60°C的极端环境。 其创新的模块化组装结构支持从 0° 到 90° 的多维调整,可在弯曲或不规则空间中安装。

剧烈 E俄罗斯国家一级的 我安宁:内置DALI/PWM双协议驱动,兼容主流智能控制系统。 石墨烯散热技术实现了超过93%的能效转换,结合了超过50,000小时的使用寿命,与传统照明设备相比节省了40%以上的能源。

有区别的 V油腻的: 产品经过CE 和RoHS 认证,提供5 年保修。 定制的服务系统可以满足商业空间、艺术画廊和其他场景的特殊色温(可调范围为 2700K 至 6500K)和显色指数(RA ≥ 95)。

凭借其出色的光学性能、耐用的工业级结构、智能控制兼容性和高度定制化的服务,SignliteLEDs LED 线性灯 已成为现代建筑照明和高端商业空间的理想选择。 无论您是在进行新的建设项目还是照明升级,SignliteLED 都可以为您提供更高效、更智能、更面向设计的照明解决方案。