This aging test primarily verifies the reliability of newly developed products by simulating the actual operating environment of LED strips under continuous power supply over an extended period while recording relevant data changes. It provides experimental evidence for the reliability validation of potting silicone LED strips, ensuring stable performance during long-term use.

Aging Test Objectives and Experimental Environment Description

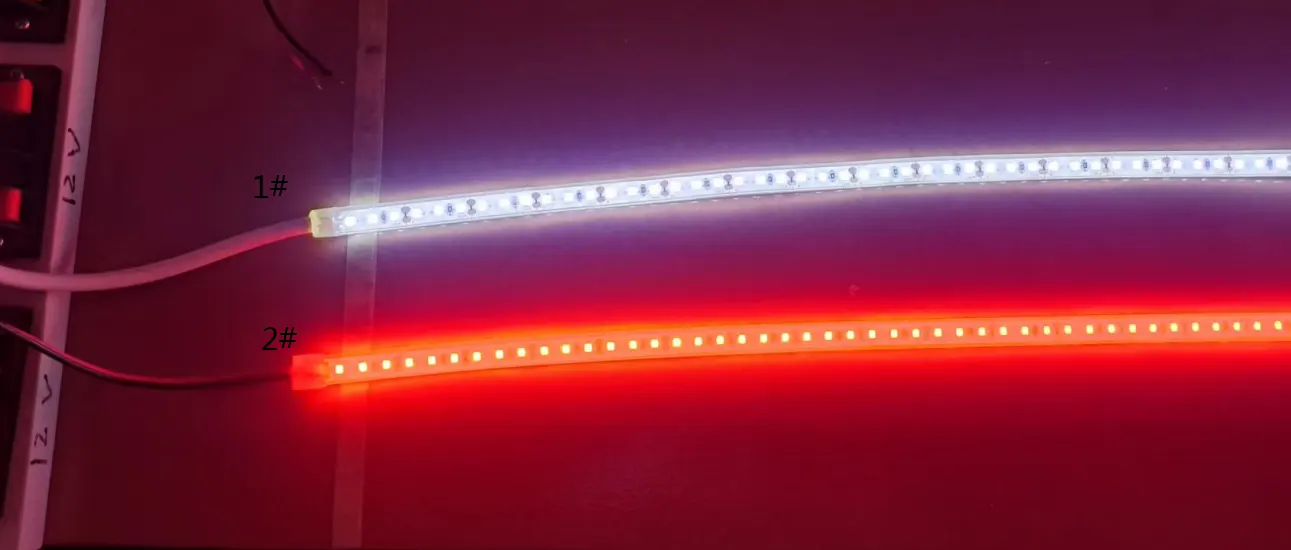

- Product Name: Potting silicone LED Strip Light, Model #1: 25000K Cool White; Model #2: 1000K Red Light

- Aging Test Duration: Test records at 1000H, 1500H, 2000H, 2500H, and 3000H, with statistical analysis of the product’s photometric performance metrics.

- Test Purpose: Conduct systematic aging tests on the newly developed potting silicone LED strip (DE007) to validate product durability and reliability.

- Environmental Conditions

- Temperature: 25°C ±5°C

- Humidity: 65% ±5% (operating continuously under illumination)

- Mounting Method: Product placed on aging rack

- Measurement Equipment

- Integrating sphere optical testing system / High-precision spectrophotometer

- LED strip aging rack

- Constant-voltage power supply

Potting Silicone LED Strip Light White Light Aging Test Data Table

| Aging Test Record Sheet for White Light Potting Silicone LED Strip | |||||||

| Customer Number | DE007 | Order Number | Test Equipmentt | Integrating Sphere | |||

| Product Name | Potting Silicone LED Strip | Model | 1# | Digital Multimeter | |||

| Vendor | Smalite LED | Start Time | 2023.8.9 | Photometric Distributor | |||

| Initial Test Data | Test Data After Aging | ||||||

| 1000H | 1500H | 2000H | 2500H | 3000H | |||

| Input Voltage(V) | 12 | 12 | 12 | 12 | 12 | 12 | |

| lputc Current(A) | 1.308 | 1.336 | 1.3 | 1.3 | 1.3 | 1.3 | |

| lput Power(W) | 15.7 | 16.03 | 15.6 | 15.6 | 15.59 | 15.6 | |

| CCT(K) | 25680 | 25300 | 19854 | 18248 | 19149 | 18431 | |

| Ra | 27.7 | 28 | 27.7 | 27.9 | 28.1 | 29.2 | |

| Effect(lm/W) | 106.5 | 103 | 82.3 | 81.3 | 80.46 | 79.2 | |

| Conclusion | PASS | NG | NG | NG | NG | ||

| LED Type | 2835 | ||||||

| Resistance Spec | 1206/110Ω | Test Time | 2024-1-12 | 2024-2-10 | 2024-2-21 | 2024-3-13 | 2024-4-23 |

| Size | 1.5M*10mm*4mm | ||||||

| Remark: Cold white light,1.5Meter,120LED/M. | |||||||

Potting Silicone LED Strip Light Red Light Aging Test Data Table

| Aging Test Record Sheet for Red Light Potting Silicone LED Strip | |||||||

| Customer Number | DE007 | Order Number | Test Equipment | Integrating Sphere | |||

| Product Name | Potting Silicone LED Strip | Model | 2# | Digital Multimeter | |||

| Vendor | Smalite LED | Start Time | 2023.8.9 | Photometric Distributor | |||

| Initial Test Data | Test Data After Aging | ||||||

| 1000H | 1500H | 2000H | 2500H | 3000H | |||

| Input Voltage(V) | 12 | 12 | 12 | 12 | 12 | 12 | |

| lputc Current(A) | 1.466 | 1.487 | 1.4 | 1.47 | 1.46 | 1.46 | |

| Iput Power(W) | 17.59 | 17.82 | 17.4 | 17.62 | 17.61 | 17.52 | |

| CCT(K) | 1001 | 1001 | 1001 | 1001 | 1001 | 1001 | |

| Ra | 86 | 86.2 | 86.2 | 86 | 86.2 | 86.1 | |

| Effect(lm/W) | 45.8 | 40.66 | 34.5 | 36.5 | 35.2 | 33.8 | |

| Conclusion | PASS | NG | NG | NG | NG | ||

| LED Type | 2835 | ||||||

| Resistance Spec | 1206/200Ω | Test Time | 2024-1-12 | 2024-2-10 | 2024-2-21 | 2024-3-13 | 2024-4-23 |

| Size | 1.5M*10mm*4mm | ||||||

| Remark: Red light,1.5Meter,120LED/M. | |||||||

Aging Performance Trends and Conclusions

For convenience and clarity, we present the statistical analysis of the two sets of data for Sample 1 and Sample 2 as follows.

Aging changes for Sample 1 under white light exposure:

| Aging Duration(H) | Input Voltage(V) | Input Current(A) | Input Power(W) | CCT(K) | Ra | Efficacy(lm/W) | Conclusion |

| 0 | 12 | 1.308 | 15.70 | 25680 | 27.7 | 106.5 | |

| 1000 | 12 | 1.338 | 16.03 | 25300 | 28 | 103 | PASS |

| 1500 | 12 | 1.3 | 15.6 | 19854 | 27.7 | 82.3 | NG |

| 2000 | 12 | 1.3 | 15.6 | 18248 | 27.9 | 81.3 | NG |

| 2500 | 12 | 1.3 | 15.59 | 19149 | 28.1 | 80.46 | NG |

| 3000 | 12 | 1.3 | 15.6 | 18431 | 29.2 | 79.2 | NG |

Aging changes for Sample 2 under red light exposure:

| Aging Duration(H) | Input Voltage(V) | Input Current(A) | Input Power(W) | CCT(K) | Ra | Efficacy(lm/W) | Conclusion |

| 0 | 12 | 1.466 | 17.59 | 1001 | 86.0 | 45.8 | |

| 1000 | 12 | 1.466 | 17.82 | 1001 | 86.2 | 40.66 | PASS |

| 1500 | 12 | 1.47 | 17.40 | 1001 | 86.2 | 34.5 | NG |

| 2000 | 12 | 1.40 | 17.62 | 1001 | 86.0 | 36.5 | NG |

| 2500 | 12 | 1.46 | 17.61 | 1001 | 86.2 | 35.2 | NG |

| 3000 | 12 | 1.46 | 17.52 | 1001 | 86.1 | 33.8 | NG |

Comprehensive Aging Analysis

- Input Parameter Stability: After aging, both light strips exhibited minimal fluctuations in input voltage, current, and power, indicating stable performance at the power supply input.

- Color Temperature: The color temperature of the #2 red light remained stable with virtually no change. The CCT color temperature of the #1 cool white light decreased by 22% after 1000 hours of aging, showing a trend of color shift due to aging. However, the 25000K color temperature falls within an “abnormal color temperature range,” far exceeding conventional physical logic and industry standards. Confirm with the customer whether this is acceptable.

- Color Rendering Index (CRI): The color rendering performance of #2 red light remains relatively stable, while #1 white light shows slightly poorer rendering, decreasing by approximately 5.4%.

- Luminous Efficacy: The luminous efficacy of #1 white light steadily decreased from 106.5 (initial) to 79.2 (3000H), with aging significantly reducing efficacy.

Overall conclusion: Unqualified! This test demonstrates that after prolonged aging, the performance of potting silicone light strips (particularly luminous efficacy) fails to meet design requirements.

Improvements and Recommendations

- Material Optimization: Consider replacing or optimizing the encapsulation silicone material to enhance its aging resistance, optical stability, and heat dissipation properties, thereby mitigating issues like lumen depreciation and color temperature drift.

- Chip Replacement: Both current LED strip models exhibit unacceptable lumen depreciation after 1500 hours. Replace with a more stable 2835 chip model featuring lower lumen depreciation and higher power output.

- Power Design: Model 1 operates at 11W/m and Model 2 at 12W/m. Power consumption should be reduced to below 10 W/m to lower LED chip current, effectively decreasing chip temperature. This stabilizes chip operation, increases luminous efficacy, and delays light decay.

- PCB Board: Select heat-conductive materials with superior thermal performance. Appropriately increase the thickness of copper foil to accelerate heat conduction and dissipation, thereby reducing light decay.