Backlit marble using LED sheet lighting is a controlled architectural lighting system where thin, translucent stone is illuminated from behind with precision-engineered light sources to create uniform glow, depth, and visual drama. In hotels and luxury retail spaces, this technique transforms natural stone into a luminous surface that reinforces brand identity, elevates spatial perception, and creates a high-end atmosphere without visible fixtures.

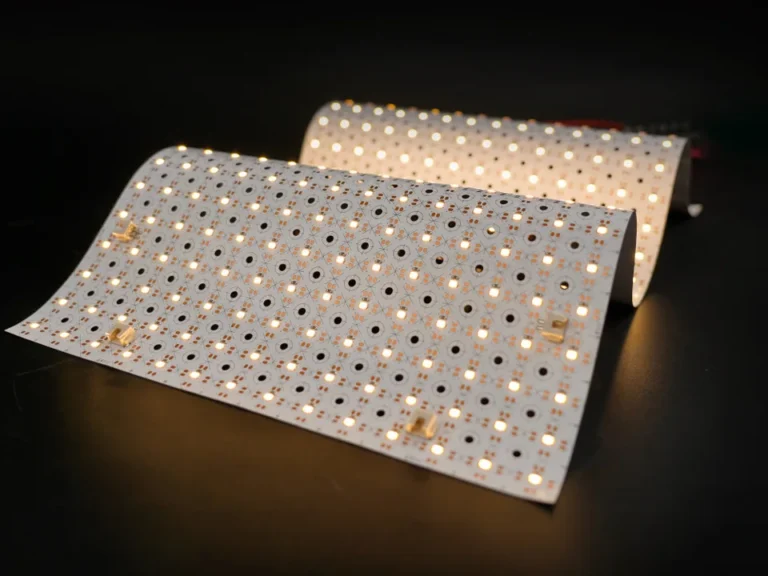

The system works by placing a calibrated lighting layer behind marble that has sufficient translucency to transmit light. The illumination must be evenly distributed, thermally controlled, and dimmable to maintain color stability and long-term performance. Achieving consistent brightness across the entire stone surface requires careful control of diffusion depth, lumen density, cavity spacing, and lighting layout.

This article will explain how to design, specify, and install LED sheet lighting for backlit marble in commercial luxury environments, covering design principles, technical specifications, lighting control strategies, installation planning, hospitality and retail applications, common failure points, and practical engineering considerations

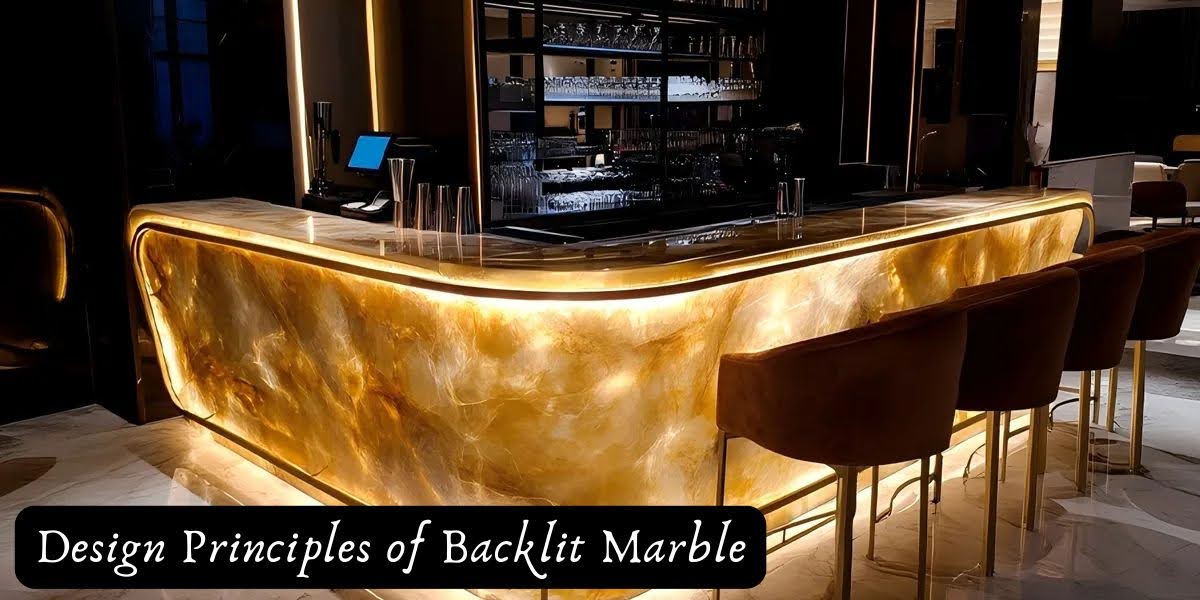

Design Principles of Backlit Marble

Backlit marble is not a decorative add-on. It is a lighting system integrated into architectural construction. The success of the installation depends on understanding stone behavior first, and lighting second.

Marble Thickness Logic

Marble thickness directly determines light transmission. Most luxury installations use stone between 15 mm and 30 mm thick. Thinner stone increases transmission but can expose structural inconsistencies. Thicker stone reduces transmission and demands higher lumen density.

The goal is not maximum brightness. The goal is balanced luminance that reveals veining without creating bright patches.

Translucency Variation

Natural marble is inconsistent by nature. Veins, mineral deposits, and color density affect light diffusion. Some sections transmit light easily while others block it almost completely.

This is why a uniform illumination LED light sheet is critical. Even if the stone varies, the light source must remain consistent to avoid amplifying natural inconsistencies.

Stone selection should include light transmission testing before fabrication.

Diffusion Behavior

Marble does not diffuse light evenly like engineered acrylic. It behaves directionally depending on grain orientation and mineral distribution.

Deeper cavity spacing improves blending but increases construction depth. Shallower cavities require higher-density lighting layers to avoid hotspots.

The lighting design must compensate for diffusion limitations within the stone.

Light Density Planning

Lumen density must match marble opacity. Designers should calculate output based on transmission percentage rather than relying on standard lighting values.

If the stone transmits only 20 to 30 percent of light, the rear lighting system must compensate without creating excessive heat buildup.

High-density sheets of LED lights reduce shadowing between diode points and help prevent spotting in thicker marble slabs.

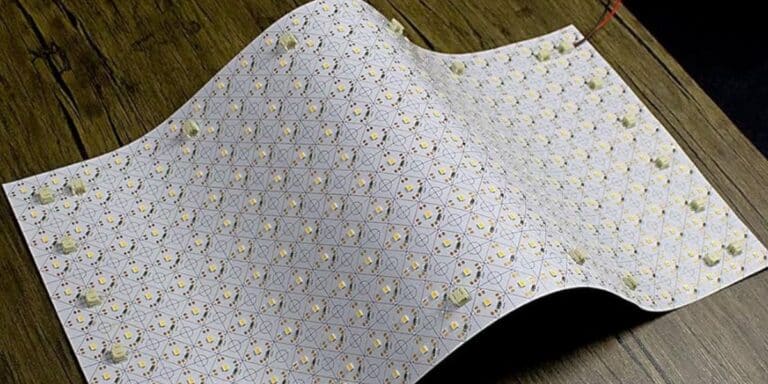

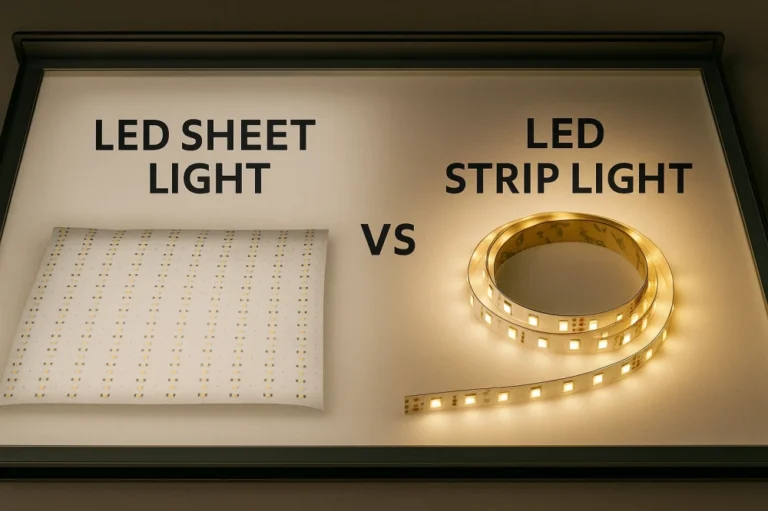

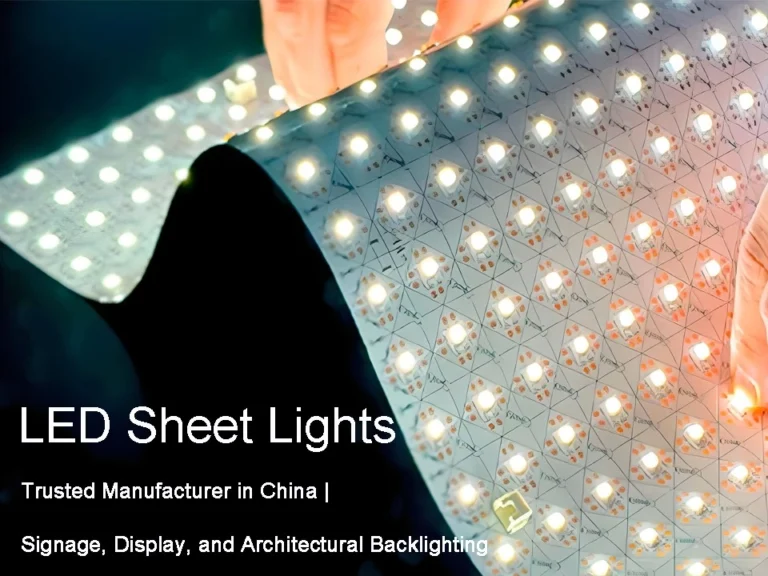

Why Custom LED Sheet Lighting Is Required

Marble panels in luxury hospitality and retail are rarely uniform rectangles. Reception desks curve. Bar fronts have angles. Elevator lobbies use segmented panels.

Standard lighting panels often create alignment gaps. Custom LED sheet lighting allows sizing to exact panel dimensions, minimizing dark seams and simplifying wiring.

Precision fitting is not aesthetic preference. It is a technical requirement for uniformity.

Technical Lighting Specifications

Backlit marble in hotels and luxury retail environments must meet performance standards beyond residential applications. Installations operate for extended hours, require dimming flexibility, and must maintain consistent color over years of operation.

High-output lighting is often necessary, but heat and electrical stability are equally important. The lighting system must support architectural tolerances while maintaining safe operating temperatures behind enclosed stone surfaces.

Key Technical Requirements for Backlit Marble

• Recommended lumen density ranges: typically 4,000 to 8,000 lumens per square meter depending on marble translucency and thickness

• Ideal cavity depth behind stone: 50 mm to 100 mm for standard marble; deeper cavities improve blending

• Heat dissipation logic: aluminum backing plates or conductive mounting surfaces to draw heat away from diodes

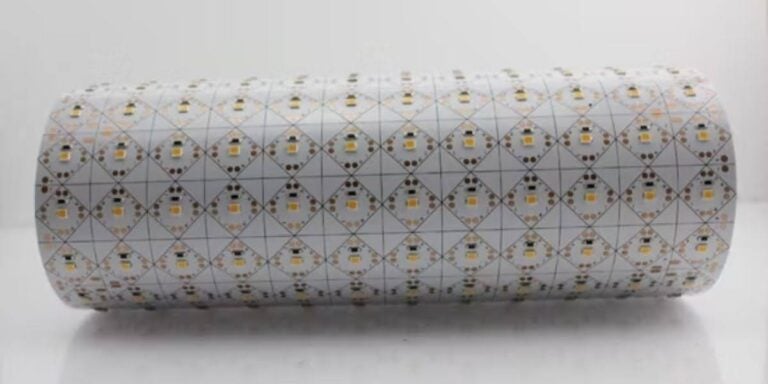

• When to use flexible LED light sheet: curved reception desks, cylindrical columns, or irregular feature walls

• Difference between LED light sheet panel and LED light sheet panels in large installations: single panel systems work for small surfaces; multiple LED light sheet panels require synchronized wiring and brightness calibration across seams

• Why high-density sheet of LED lights prevents hotspots: tighter diode spacing reduces visible point sources, especially with thin marble

After defining these requirements, electrical planning should consider voltage drop across large surfaces. Uniform brightness depends on consistent power distribution. Parallel wiring layouts often perform better in large hotel lobbies or long retail walls.

For a visual reference of how LED sheet layouts are positioned behind marble panels in commercial installations, see the example below.

Marble Thickness vs Lighting Configuration Guide

| Marble Thickness | Recommended Lumen Density | Minimum Cavity Depth | Lighting Type Recommendation |

| 15 mm | 4,000–5,000 lm/m² | 50 mm | Standard LED sheet lights with medium density |

| 20 mm | 5,000–6,500 lm/m² | 60–80 mm | High-density LED light sheet panel |

| 25 mm | 6,000–7,500 lm/m² | 80–100 mm | High-output custom LED sheet lighting |

| 30 mm | 7,000–8,000+ lm/m² | 100 mm | High-density sheet of LED lights with thermal backing |

Values must be verified through mock-up testing. Stone variability can shift requirements significantly.

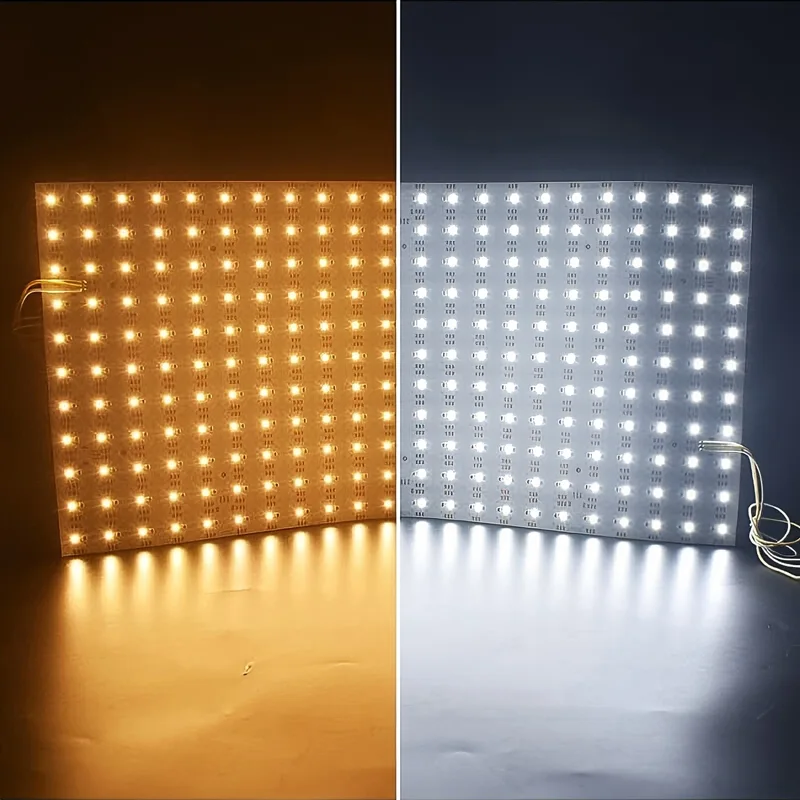

Tunable White LED Sheets

- Size( L x W ): 250mmx250 mm/ 490mmx245mm

- LED type: 2835 SMD

- LED quantity: 200PCS/484PCS

- Working voltage: DC 24V

- Power: 16W/40W

- Color temperature adjustable range: 2700K-6500K

- Luminous flux: 1600lm/3800lm

- CRI: >90Ra

- Minimum cutting length: 25mmx25mm/ 22.3mmx22.3mm

- Dimmable: YES

- Beam angle: 120°

- Waterproof level: IP20 non-waterproof, IP54 waterproof

- Warranty: 3 years

Lighting Control & Color Strategy

Color temperature selection defines the emotional impact of backlit marble in luxury spaces.

In hotels, 2700K lighting creates warmth and intimacy, suitable for reception desks and lounge areas. 3000K provides a balanced warm-neutral tone common in contemporary hospitality. 4000K introduces crisp clarity often used in high-end retail jewelry showcases where material detail must remain sharp.

The chosen color temperature must align with the brand identity and interior material palette.

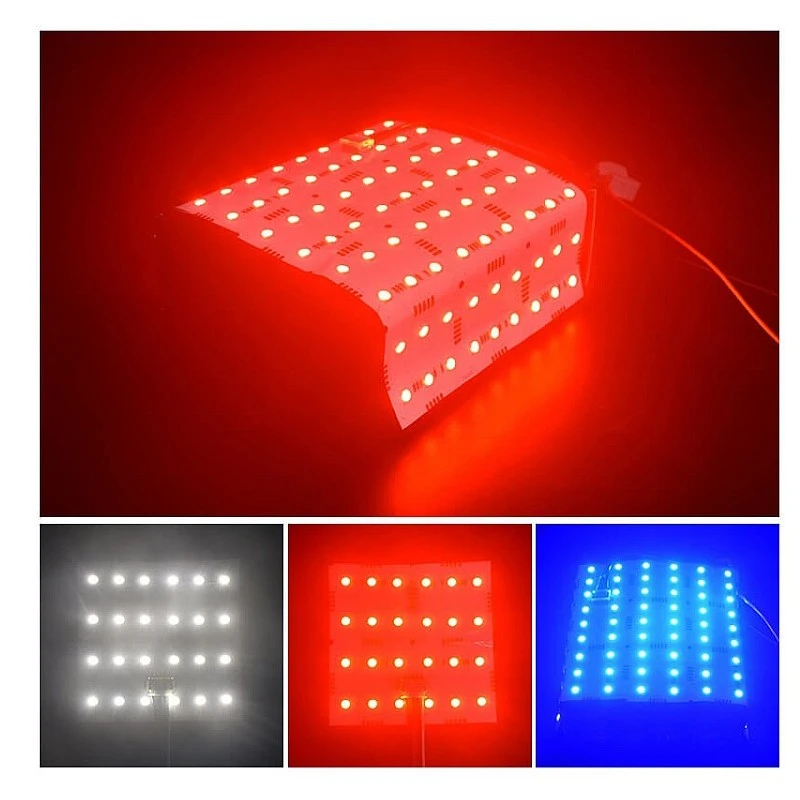

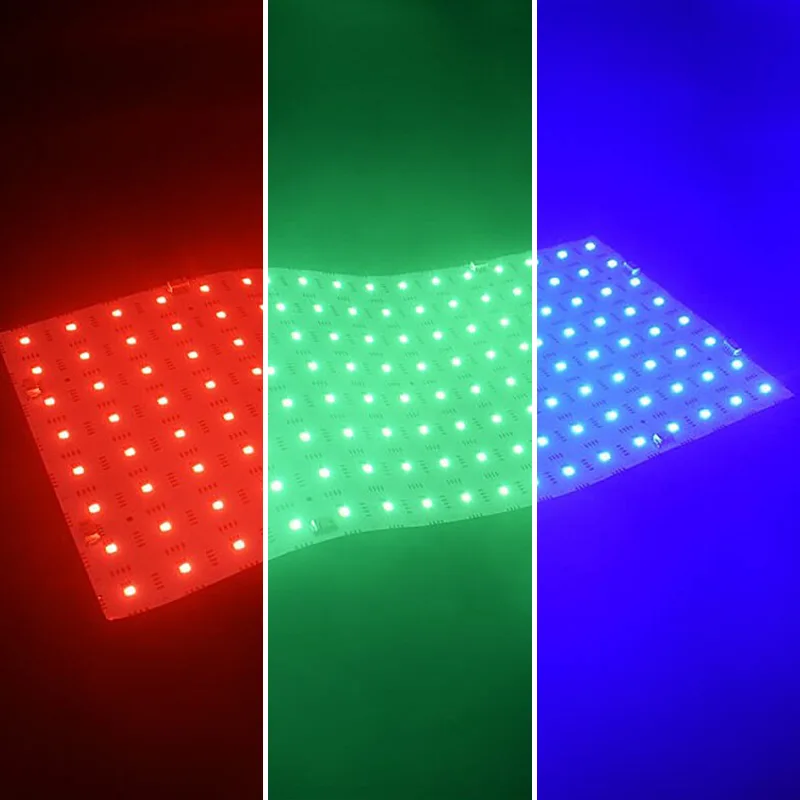

Dimmable and rgbw LED light sheets become relevant when spaces transition from day to night. Hotel bars often shift from bright daytime presentation to softer evening ambience. Retail flagships may use subtle dynamic color accents for brand events.

RGBW systems should not be used casually. They must maintain a consistent white baseline to preserve marble authenticity. Over-saturated color undermines the natural stone aesthetic.

Lighting control systems should integrate with building automation for scheduled dimming and energy management. Gradual transitions maintain visual comfort and extend component lifespan.

Stone color also influences lighting decisions. White Carrara reacts differently than honey onyx. Designers must test color temperature against actual slab samples before finalizing specifications.

Consistency across multiple installations is essential. Large hotel chains and luxury retail brands rely on repeatable lighting conditions across global locations. Calibration ensures uniform brand experience.

RGBW LED Sheets

- Size( L x W ): 250mmx250mm/ 490mmx250mm

- LED type: 5050 RGBW 4 In 1 SMD

- LED quantity: 150PCS/ 288PCS

- Working voltage: DC 24V

- Power: 24W/ 48W

- Emitting color: RGB+3000K, RGB+4000K, RGB+6500K

- Light Efficiency: 90LM/W

- Minimum cutting length: 50mmx50mm/ 20.4mmx122.5mm

- Beam angle: 120°

- Dimmable: YES

- Waterproof Level: IP20 non-waterproof, IP54 waterproof

- Warranty: 3 years

Installation Best Practices for Hotels and Luxury Retail

Installation determines whether design intent translates into flawless execution. Even properly specified lighting fails if installed without structural precision.

• Surface preparation: mounting substrate must be flat, clean, and structurally rigid to prevent panel misalignment

• Mounting structure stability: aluminum frames or steel substructures should prevent vibration and sagging behind marble

• Diffuser layer selection: optional high-transmission diffusion film can help blend diode spacing in thinner marble

• Ventilation planning: passive airflow gaps or concealed ventilation channels reduce thermal buildup

• Access panels for maintenance: removable sections allow driver servicing without dismantling stone

• Moisture considerations in spa areas: sealed electrical components and humidity-resistant housings are necessary

• Edge light containment: opaque perimeter framing prevents light leakage at panel borders

Poor installation creates uneven brightness lines between panels. Precision alignment ensures seamless visual flow across large surfaces.

RGB LED Sheets

- Size( L x W ): 490mmx245 mm

- LED type: 5050 SMD

- LED quantity: 128pcs

- Working voltage: DC24V

- Power: 45W

- Color: RGB

- Dimmable: YES

- Cut length: 39.6 mm

- Beam angle: 120°

- Waterproof level: IP20 non-waterproof, IP54 waterproof

- Lifespan: >35,000 hours

- Warranty: 3 years

Applications in Hotels and Luxury Retail

Backlit marble enhances focal points in hospitality and retail architecture.

Reception desks often incorporate LED sheet lights to create a glowing stone facade that establishes first impressions. Proper density selection ensures the desk front appears evenly illuminated without revealing internal framing.

Feature walls in hotel lobbies frequently use large-format LED light sheet panels placed behind book-matched marble slabs. Uniform lighting allows natural veining to appear continuous and dramatic.

Bar fronts benefit from dimmable systems that adapt throughout the day. A flexible led light sheet can accommodate curved bar geometries while maintaining consistent brightness.

Luxury boutiques use backlit marble in display backdrops where merchandise must stand out without harsh glare. A calibrated sheet of led lights ensures jewelry or accessories remain visually dominant.

Spa backdrops often require warm, calming illumination integrated with moisture-resistant systems. Elevator lobbies use illuminated stone walls to create premium transition spaces.

Logo statement walls in retail flagships rely on precise custom led sheet lighting to highlight branding elements embedded within marble panels.

In each application, the lighting system must remain invisible. The stone surface should appear naturally luminous rather than mechanically lit.

Common Design Failures

Backlit marble installations fail when lighting is treated as secondary.

Using low-density sheets leads to visible spotting, especially in thinner slabs. The result looks fragmented rather than seamless.

Insufficient cavity depth creates harsh shadow transitions. Light does not have enough space to blend before hitting the stone.

Overdriving LEDs to compensate for poor design increases heat and shortens lifespan. Brightness should be achieved through density, not excessive current.

Poor heat control results in color shift over time. Marble installations in hotels often run 12 to 18 hours daily. Thermal management must be engineered accordingly.

Lack of dimming integration restricts flexibility. Fixed-output systems fail to adapt to changing ambient conditions.

Uneven installation between adjacent panels produces visible brightness differences. Calibration across multiple LED light sheet panels is essential.

Precision planning prevents these issues before fabrication begins.

Conclusion

Uniformity defines luxury in backlit marble installations. Guests and customers may not analyze the lighting system, but they immediately perceive inconsistencies.

Custom LED sheet lighting is necessary because marble varies in size, thickness, and translucency. Standardized solutions rarely deliver seamless results in commercial hospitality and retail environments.

Lighting must be engineered before stone fabrication. Cavity depth, structural framing, ventilation, and electrical routing should be integrated into architectural planning from the start.

Long-term reliability depends on proper lumen density, heat management, and calibrated installation. When executed correctly, backlit marble becomes a durable architectural feature rather than a maintenance burden.

Careful specification ensures that light enhances natural stone rather than overpowering it.

FAQs

Most commercial applications use marble between 15 mm and 25 mm thick. Thinner slabs transmit more light but require careful structural support. Thicker slabs require higher lumen density and deeper cavities.

Typical installations range from 4,000 to 8,000 lumens per square meter depending on translucency. Mock-up testing with actual stone samples is recommended before final specification.

Yes. Flexible LED light sheet systems are suitable for curved reception desks, cylindrical columns, and rounded bar fronts, provided proper heat dissipation backing is used.

Not always. Static white systems work for consistent environments. RGBW systems are beneficial when day-to-night transitions or event-based lighting changes are required.

Use high-density sheets of LED lights, maintain sufficient cavity depth, and consider adding diffusion layers when necessary.

A minimum of 50 mm is recommended for thin marble. Thicker slabs may require 80 to 100 mm for proper blending.

Yes. Even efficient LED sheet lights generate heat. Passive ventilation gaps or conductive mounting surfaces extend system lifespan.

When properly installed and thermally managed, commercial-grade LED light sheet panels typically operate for 40,000 to 50,000 hours before noticeable lumen depreciation.