Aging Test Purpose and Experimental Environment Description

- Test Purpose: Conduct systematic aging tests on newly developed LED linear lights to validate product durability and reliability.

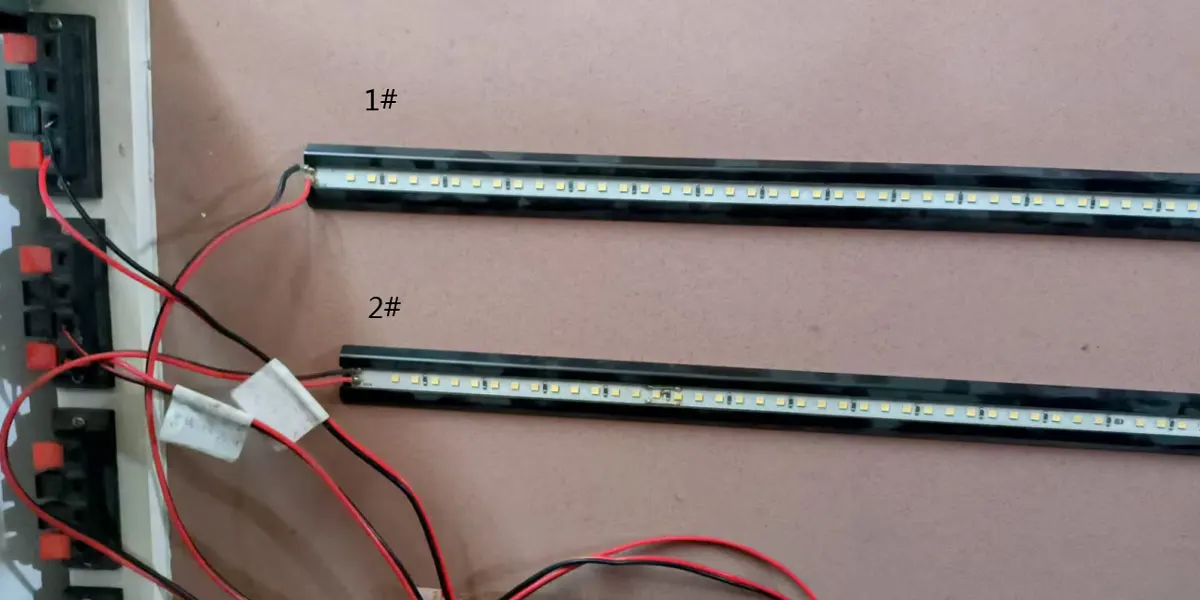

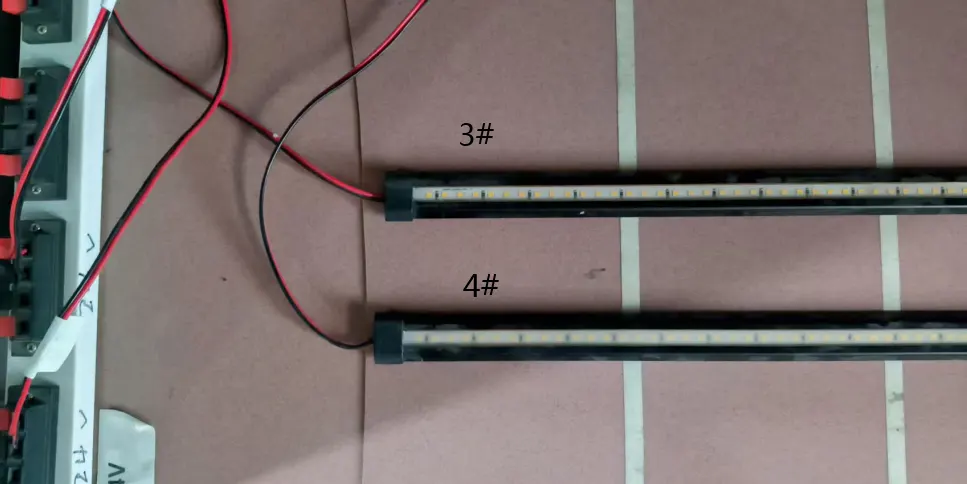

- Product Type: LED Linear Light, divided into 2 pcs without drop glue and 2 pcs with drop glue. LED Type: SMD2835; LED Supplier: Smalite LED.

- Test Duration: Total test time: 4000 hours. Different aging cycles were set for various product specifications, with detailed test records at 250/500/1000/1500/2000/2500/3000/4000 hours to statistically analyze the product’s optoelectronic performance metrics.

- Environmental Conditions

- Temperature: 28°C ± 5°C

- Humidity: 65% ± 5% (operating under continuous illumination)

- Test Voltage: Constant DC24V

- Installation Method: Product placed on aging rack

- Measurement Equipment: Integrating Sphere Optical Testing System / High-Precision Goniophotometer / LED Strip Aging Rack.

Without Drop Glue LED Linear Light Aging Test Data Table

| Aging Test Record Sheet for 1# LED Linear Light Without Drop Glue | |||||||||||

| Customer Number | DM001 | Order Number | DD202308001 | Test Equipment | Integrating Sphere | ||||||

| Product Name | LED Linear light | Model | 1# | Diital Multimeter | |||||||

| Vendor | Smalite LED | Start Time | 2023.8.9 | Photometric Distributor | |||||||

| Initial Test Data | Test Data After Aging | ||||||||||

| 250H | 500H | 1000H | 1200H | 1500H | 2000H | 2500H | 3000H | 4000H | |||

| Input Voltage (V) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

| lnput Current(A) | 1.33 | 1.28 | 1.24 | 1.27 | 1.24 | 1.25 | 1.26 | 1.25 | 1.28 | 1.29 | |

| Power(W) | 16 | 15.36 | 14.88 | 15.24 | 14.88 | 15 | 15.1 | 15 | 15.3 | 15.4 | |

| Endpoint Voltage(V) | 11.3 | 11.3 | 11.3 | 11.3 | 11.38 | 11.33 | 11.4 | 11.39 | 11.36 | 11.35 | |

| CCT(K) | 4055 | 4055 | 4062 | 4044 | 4000 | 3993 | 3990 | 3993 | 3973 | 3987 | |

| Ra | 93.5 | 93.3 | 93.3 | 93 | 93 | 93.1 | 92.8 | 93.2 | 93.3 | 93.2 | |

| Efficiency(lm/W) | 87.34 | 90.98 | 90.99 | 91.1 | 98.1 | 93.9 | 93.2 | 91.3 | 83.2 | 85.8 | |

| Conclusion | PASS | PASS | PASS | PASS | PASS | PASS | PASS | PASS | PASS | ||

| LED Type | SMD2835 | ||||||||||

| Resistance Spec | 1206/120Ω | Test Time | 2023-8-22 | 2023-9-4 | 2023-9-19 | 2023-10-22 | 2023-11-27 | 2023-12-21 | 2024-3-13 | 2024-4-24 | 2024-8-7 |

| Size | 1270×25.6x6mm | ||||||||||

| Aging Test Record Sheet for 2# LED Linear Light Without Drop Glue | |||||||||||

| Customer Number | DM001 | Order Number | DD202308001 | Test Equipment | Integrating Sphere | ||||||

| Product Name | LED Linear light | Model | 2# | Dgital Multimeter | |||||||

| Vendor | Smalite LED | Start Time | 2023.8.9 | Photometric Distributor | |||||||

| Initial Test Data | Test Data After Aging | ||||||||||

| 250H | 500H | 1000H | 1200H | 1500H | 2000H | 2500H | 3000H | 4000H | |||

| Input Voltage (V) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

| lnput Current(A) | 1.18 | 1.15 | 1.13 | 1.13 | 1.11 | 1.16 | 1.16 | 1.15 | 1.13 | 1.15 | |

| Power(W) | 14.2 | 13.8 | 13.5 | 13.5 | 13.3 | 13.9 | 13.9 | 13.8 | 13.5 | 13.8 | |

| Endpoint Voltage(V) | 10.6 | 10.6 | 10.6 | 10.5 | 10.66 | 10.62 | 10.7 | 10.65 | 10.59 | 10.55 | |

| CCT(K) | 4092 | 4095 | 4109 | 4087 | 4041 | 4041 | 4046 | 4048 | 4031 | 3998 | |

| Ra | 93.1 | 93.1 | 93.4 | 93 | 93.1 | 93 | 92.7 | 93 | 93.2 | 93.3 | |

| Efficiency(lm/W) | 88.55 | 93.26 | 90.26 | 92.6 | 98.4 | 95 | 94.8 | 91.2 | 88.2 | 85.8 | |

| Conclusion | PASS | PASS | PASS | PASS | PASS | PASS | PASS | PASS | PASS | ||

| LED Type | SMD2835 | ||||||||||

| Resistance Spec | 1206/120Ω | Test Time | 2023-8-22 | 2023-9-4 | 2023-9-19 | 2023-10-22 | 2023-11-27 | 2023-12-21 | 2024-3-13 | 2024-4-24 | 2024-8-7 |

| Size | 1270×25.6x6mm | ||||||||||

Analysis of Aging Results for Without Drop Glue Linear Lights

1. Analysis of Electrical Performance Changes

- Input Current Changes (A)

- 1# Initial: 1.33A; 4000H: 1.29A.

- 2# Initial: 1.18A; 4000H: 1.15A.

- Trend: Slow decrease of approximately 3%.

- Post-aging LED junction temperature slightly increases → Internal resistance rises → Current marginally decreases. The minimal current drop indicates a stable power supply drive and LED quality, with no significant degradation or leakage occurring.

- Power Change (W)

- 1#: Initial: 16W; 4000H: 15.5W Change: Approx. 3% decrease;

- 2#: Initial: 14.2W; 4000H: 13.8W Change: Approx. 2.8% decrease.

- Both power and current exhibit synchronized, slight decreases, aligning with normal aging curves. Absence of abnormal power fluctuations confirms the stability of the product’s driver system and LED chips.

- Optical Performance (Luminous Flux) Change Analysis

- 1#: Initial Luminous Efficiency: 87.34 LM/W; 4000H Luminous Efficiency: 84.88 LM/W; Decrease: Approximately 2.8 LM/W (≈3.2%).

- 2#: Initial Luminous Efficiency: 88.55 LM/W, 4000H Luminous Efficiency: 85.8 LM/W, Decrease: Approximately 2.75 LM/W (≈3.1%).

- This demonstrates exceptional aging performance. Typically, COB/LEDs exhibit a normal decay rate of 5–12% after 3000–4000 hours of aging. This product exhibits only about 3% decay, demonstrating excellent LED quality.

2. Color Temperature (CCT) Stability Analysis

- 1# Initial: 4055K; 4000H: 3993K. Color Temperature Drift: Approximately -62K (≈1.5%).

- 2# Initial: 4092K; 4000H: 3998K. Color Temperature Drift: Approximately -94K (≈2.3%).

- A ±100K variation within the 4000K range is considered excellent.

Color temperature consistency is well-maintained, making it suitable for applications sensitive to color consistency, such as commercial lighting, display case lighting, and brand store lighting.

3. Color Rendering Index (Ra) Variation

- 1#: Initial: 93.5; 4000H: 93.1. Ra Change: Decrease of 0.4.

- 2#: Initial: 93.1; 4000H: 93.3. Ra Change: Increase of 0.2.

Ra remains stable at ≥93, indicating highly consistent light quality. This indicates a stable phosphor system and chip quality, with no color shift or CRI fluctuation issues.

4. Comprehensive Conclusions

- Excellent aging performance (positionable as mid-to-high-end lighting products).

- Luminous efficacy decay below industry average.

- Exceptionally stable color temperature and CRI, suitable for high-end commercial lighting.

- High data consistency with no anomalies.

- LED quality is reliable. Based on the above characteristics, the LED quality is determined to be high-grade: only 3% decay after 4000 hours (better than the industry average of 5–8%). Minimal CCT drift, stable CRI, and no data fluctuations across different stages indicate that Smalite LED chips, brackets, and phosphor systems all perform stably. They can be applied in real-world environments requiring long-term reliability.

Test Conclusion: PASS.

Drop Glue LED Linear Light Aging Test Data Table

| Aging Test Record Sheet for 3# LED Linear Light with Drop Glue | ||||||||

| Customer Number | DM001 | Order Number | DD202308001 | Test Equipment | Integrating Sphere | |||

| Product Name | LED Linear light | Model | 3# | Digital Multimeter | ||||

| Vendor | Smalite LED | Start Time | 2023.9.21 | Photometric Distributor | ||||

| Initial Test Data | Test Data After Aging | |||||||

| 250H | 500H | 1000H | 1500H | 2000H | 3000H | |||

| Input Voltage(V) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Input Current(A) | 1.27 | 1.27 | 1.27 | 1.28 | 1.28 | 1.27 | 1.29 | |

| Power(W) | 15.2 | 15.2 | 15.2 | 15.3 | 15.3 | 15.2 | 15.4 | |

| Endpoint Voltage(V) | ||||||||

| CCT(K) | 3938 | 3866 | 3879 | 3884 | 3852 | 3822 | 3815 | |

| Ra | 92.9 | 92.9 | 92.8 | 92.7 | 92.9 | 92.9 | 93 | |

| Efficiency(lm/W) | 67.8 | 69.1 | 69.0 | 68.1 | 66.3 | 65.9 | 64.7 | |

| Conclusion | PASS | PASS | PASS | PASS | PASS | PASS | ||

| LED Type | SMD2835 | |||||||

| Resistance Spec | 1206/120Ω | Test Time | 2023-10-12 | 2023-11-27 | 2023-12-21 | 2024-3-13 | 2024-4-24 | 2024-8-7 |

| Size | 1270×25.6x6mm | |||||||

| Aging Test Record Sheet for 4# LED Linear Light with Drop Glue | ||||||||

| Customer Number | DM001 | Order Number | DD202308001 | Test Equipment | Integrating Sphere | |||

| Product Name | LED Linear Light | Model | 4# | Digital Multimeter | ||||

| Vendor | Smalite LED | Start Time | 2023.9.21 | Photometric Distributor | ||||

| Initial Test Data | Test Data After Aging | |||||||

| 250H | 500H | 1000H | 1500H | 2000H | 3000H | |||

| Input Voltage(V) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Input Current(A) | 1.27 | 1.27 | 1.28 | 1.28 | 1.28 | 1.24 | 1.249 | |

| Power(W) | 15.2 | 15.2 | 15.3 | 15.3 | 15.36 | 14.88 | 14.99 | |

| Endpoint Voltage(V) | 11.3 | |||||||

| CCT(K) | 3756 | 3691 | 3662 | 3651 | 3665 | 3673 | 3649 | |

| Ra | 92.3 | 92.4 | 92.3 | 92.1 | 92.4 | 92.5 | 92.5 | |

| Efficiency(lm/W) | 69.1 | 70.4 | 68.2 | 68.3 | 65.2 | 64.5 | 65.9 | |

| Conclusion | PASS | PASS | PASS | PASS | PASS | PASS | ||

| LED Type | SMD2835 | |||||||

| Resistance Spec | 1206/120Ω | Test Time | 2023-10-12 | 2023-11-27 | 2023-12-21 | 2024-3-13 | 2024-4-24 | 2024-8-7 |

| Size | 1270×25.6x6mm | |||||||

Analysis of Aging Results for Drop Glue LED Linear Lights

1. Analysis of Electrical Performance Changes

- Input Current Changes (A)

- #3 Initial: 1.27A; 3000H: 1.29A.

- #4 Initial: 1.27A; 3000H: 1.25A.

- Trend: Unit 3 increased by 1.6%, and Unit 4 decreased gradually by approximately 1.6%.

- Current fluctuations were minimal, indicating stable power supply drivers and LED quality without significant degradation or leakage.

- Power Change (W)

- #3: Initial: 15.2W; 3000H: 15.4W. Change: Approximately a 1.3% increase.

- #4: Initial: 15.2W; 3000H: 15W. Change: Approximately 1.3% decrease.

- Minimal power fluctuation indicates stable product driver systems and LED chips.

- Optical Performance (Luminous Flux) Change Analysis

- #3: Initial efficacy: 67.8 lm/W; 3000H efficacy: 64.7 lm/W. Decrease: Approximately 3.1 lm/W (≈4.6%).

- #4: Initial luminous efficacy: 69.1 lm/W; 3000H luminous efficacy: 65.9 lm/W. Decrease: Approximately 3.2 lm/W (≈3.1%).

- The 3000H product exhibits approximately 4.6% decay, indicating LED quality within acceptable limits.

2. Color Temperature (CCT) Stability Analysis

- #3 Initial: 3938K; 3000H: 3815K. Color temperature drift: approximately -123 K (≈3.1%).

- #4 Initial: 3756K; 3000H: 3649K. Color temperature drift: approximately -107K (≈2.8%).

The 4000K color temperature shows a negative drift of about 120K, which falls within the acceptable range of ±150K.

3. Color Rendering Index (Ra) Change

- 3#: Initial: 92.9; 3000H: 93. Ra change: Increased by 0.1.

- 4#: Initial: 92.3; 3000H: 92.5. Ra change: Increased by 0.2.

Ra was maintained at ≥92, indicating stable light color quality. No color shift or Ra fluctuation issues occurred.

4. Overall Conclusion

- Stable aging performance

- Normal luminous efficacy decay; CCT drift slightly higher but within acceptable range

- Reliable LED quality. Based on the above characteristics, LED quality meets requirements: 4.6% decay at 3000 hours, slightly elevated CCT drift, stable CRI, and no data fluctuations across stages. Meets product development expectations and is suitable for routine applications.

Test Conclusion: PASS.

Conclusion

By publicly sharing these test results, our goal is to provide our buyers with confidence and transparency, ensuring that every purchased custom LED linear light has been verified for durability, stability, and long-lasting performance, guaranteeing compliance with international quality standards. Simultaneously, we will continuously optimize and improve noncompliant products to elevate their quality to higher standards.

We will adhere to rigorous testing standards and quality control processes to deliver more reliable and durable LED linear light products to our customers. Should you require customized product test reports or other certifications, please feel free to contact our team at any time.