Commercial facilities need a surge protective device strategy that is repeatable, maintainable, and coordinated across multiple panels and sensitive loads. “Top” selection depends on choosing the correct Type 1 vs Type 2 vs Type 3 device for the installation zone, and verifying performance using UL 1449 ratings and system fit (voltage, SCCR, grounding). In practice, the best result comes from staged protection, not one universal device.

What “Top” Means in Commercial Surge Protection

In commercial electrical installations, “top” does not mean the largest kA number or the lowest clamping value printed on a datasheet. It means the device performs predictably under real operating conditions: repeated switching events, variable fault levels, long feeder runs, and mixed loads (IT, HVAC, lighting, process equipment). A well-chosen surge protection device is one that integrates into the distribution architecture without creating maintenance blind spots or coordination problems.

Commercial environments also impose operational constraints that residential sites rarely face: downtime cost, compliance documentation, panel space limitations, and the need to standardize parts across a building portfolio. For this reason, selection should focus on system behavior: how the SPD interacts with upstream protection, downstream equipment immunity, and the facility grounding system.

A “top” commercial SPD is typically characterized by:

- Reliability under repeated surge stress, not just a single high-energy event

- Coordination across multiple protection layers, so upstream devices do not overload downstream devices

- Diagnostics and monitoring, enabling maintenance teams to confirm status and plan replacement

- Maintainability, including safe service methods and modular replacement where appropriate

- Suitability for 3-phase systems, including correct modes of protection and grounding compatibility

Commercial selection priorities

- Correct SPD Type for the installation zone (Type 1/2/3)

- UL 1449 listing and appropriate Voltage Protection Rating (VPR)

- Adequate nominal discharge current (In) for the environment

- SCCR and coordination compatibility with the electrical panel

- Serviceability: indicators, remote alarms, and replacement practicality

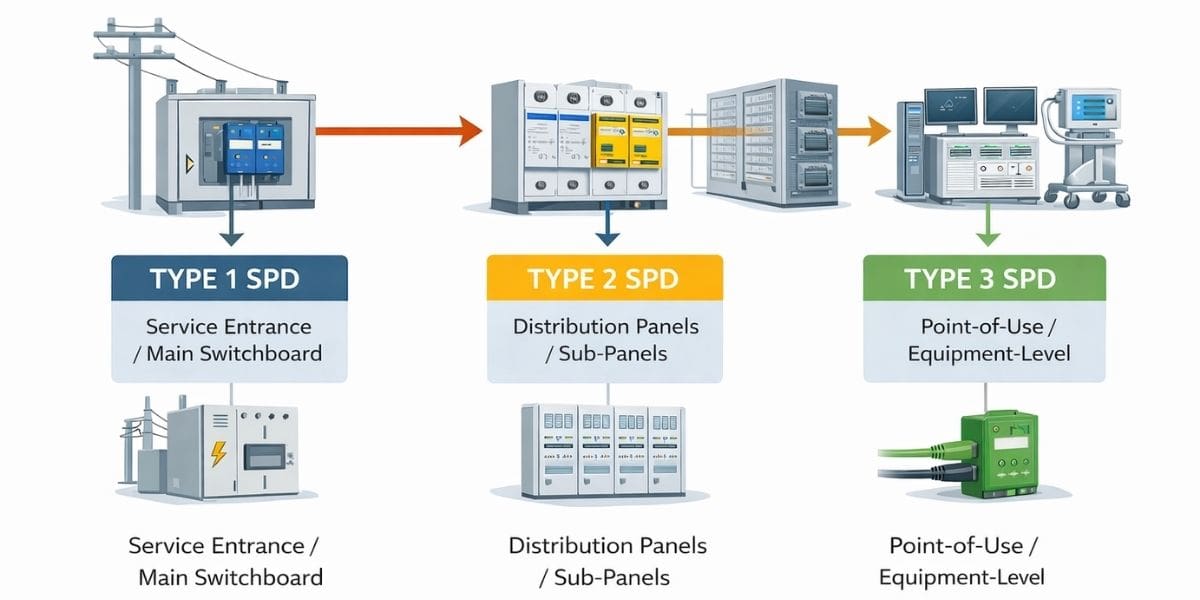

Commercial SPD Installation Zones

Commercial surge control works best when it is treated as a zoned design rather than a single component choice. The location of an SPD determines what it “sees” electrically, what it can realistically clamp, and how much surge energy it must absorb over time.

1) Service entrance / main switchboard

This is the highest-exposure zone because it is closest to incoming utility disturbances and external coupling. It is also where a facility often has the highest available fault current and the largest number of downstream circuits to protect indirectly.

2) Distribution panels and sub-panels

These panels experience both incoming disturbances and internally generated transients (especially from switching loads). Protection at this level reduces surge energy reaching branch circuits and helps limit repetitive stress on sensitive equipment throughout the building.

3) Point-of-use for sensitive equipment

Equipment-level protection targets residual transients that remain after upstream clamping, plus locally generated switching noise. In commercial sites, this is most relevant for controls, monitoring systems, and networked electronics with low tolerance to voltage disturbances.

A practical commercial design typically places surge protection devices at multiple zones so each device handles the portion of the surge environment it is best suited for.

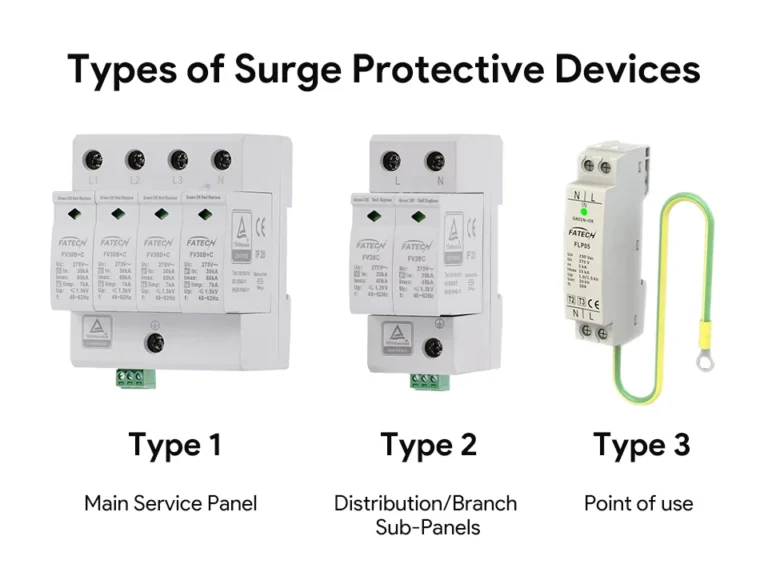

Type 1 vs Type 2 vs Type 3 — Which Type Is “Top” for Which Location?

In commercial systems, “top” depends on matching the SPD type to its electrical role. Each type is designed for a different exposure profile and installation point, and each has limits that matter in real panel layouts.

Type 1 Surge Protection Device

A Type 1 surge protection device is intended for installation at the service entrance side of the system, where surge exposure is highest. In commercial facilities, this device is selected to handle large external disturbances and provide the first stage of clamping before transients propagate through feeders.

Key engineering considerations include the ability to tolerate high surge currents repeatedly and the ability to operate correctly in a high fault-level environment. Type 1 devices are often chosen when the incoming service is long, overhead, or exposed to frequent utility switching activity.

However, Type 1 protection is not a complete solution alone. Even a strong service entrance device cannot prevent all residual transients from reaching downstream panels, especially when long feeders and internal switching loads exist. It is best treated as the “front line,” not the only line.

Type 2 Surge Protection Device

- FDS20C/2-275 Class II

- Designation: Type2

- Classification: Class II

- Protection mode: L1 , L2 , L3-PE

- Nominal Voltage Un: 230/400 Vac/50(60)Hz

- Max. continuous operating voltage Uc (L-N): 275 Vac/50(60)Hz

- Short-circuit withstand capability: 20 kA

- Continuous operating current Ic: <20 µA

- Standby power consumption Pc: ≤25 mVA

- Max discharge current (8/20μs) Imax: 40 kA

- Nominal discharge current (8/20μs) In: 20 kA

- Voltage protective level Up: ≤1.3 kV

- Isolation resistance: >1000 MΩ

- Housing material: UL94V-0

- Degree of protection: IP20

A Type 2 surge protection device is typically installed on distribution panels and sub-panels. In most commercial buildings, Type 2 is the practical workhorse because it directly protects branch circuits feeding common loads: lighting panels, receptacle panels, mechanical equipment panels, and local distribution for office floors.

Commercial systems generate many switching transients internally: contactor operations, motor starts, elevator drives, HVAC cycling, and power supply switching. Type 2 devices reduce the stress from these repetitive events where it matters most, closer to the load and closer to the panels that distribute energy across occupied areas.

A surge protective device Type 2 is usually “top” for commercial reliability because it can be deployed consistently across a facility: main distribution, sub-distribution, and critical branch panels. When coordinated with a Type 1 device upstream, it improves protection consistency across floors and departments.

Type 3 Surge Protection Device

- SPD05-AC275i-D ClassII+III

- Designation: Type2+3

- Classification: Class III

- Protection mode: L-N , N-PE , L-PE

- Rated input voltage Un(L-N): 230VAC, 50/60Hz

- Max. continuous operating voltage Uc (L-N): 275VAC, 50/60Hz

- Max discharge current (8/20μs) Imax:15 kA

- Nominal discharge current (8/20μs) In:5 kA

- Voltage protective level Up: L-N ≤1.3 kV, N-PE ≤0.5 kV, L-PE ≤1.5 kV

- Open circuit voltage Uoc: 10 kV

- Backup fuse: 20A

- Housing material: UL94V-0

- Degree of protection: IP20

A Type 3 surge protection device is used near the equipment level to manage residual transients after upstream protection has done the heavy work. It is most effective when installed close to sensitive electronics, where lead length is minimized and the protection is targeted to the device’s power entry point.

A surge protective device Type 3 should be selected with the understanding that it depends heavily on upstream protection. If Type 3 is used without upstream staging, it may experience more stress than intended and may not provide stable long-term performance.

In commercial environments, Type 3 placement is typically reserved for loads where operational continuity is important and equipment sensitivity is high, such as control cabinets, monitoring systems, and networked devices.

Quick Comparison Table

Table 1: SPD Type Selection for Commercial Electrical Installations

| SPD Type | Typical Installation Location | Main Surge Source | What It Does Best | What It Cannot Replace | Best-Fit Commercial Use Case |

| Type 1 | Service entrance / main switchboard | Utility-side disturbances, external coupling | High exposure handling and first-stage clamping | Downstream panel protection and equipment-level residual control | Main service in offices, hospitals, factories, mixed-use buildings |

| Type 2 | Distribution panels and sub-panels | Internal switching surges + residual from upstream | Branch-level protection and staged coordination | Service entrance high-exposure role and close-to-load suppression | Floor panels, mechanical panels, lighting panels, data room subfeeds |

| Type 3 | Point-of-use / equipment cabinets | Residual transients, local switching noise | Close-to-equipment protection with low lead length | High-energy surge handling and whole-building coordination | Sensitive electronics, controls, monitoring systems, networked loads |

Key Performance Specs Buyers Should Compare

Commercial selection should be specification-driven. The goal is not to chase extreme numbers, but to choose values that match the facility’s exposure, distribution topology, and maintenance model.

UL 1449 surge protective device relevance

A commercial SPD should be evaluated as a UL 1449 listed device for the intended application. UL 1449 provides a standardized framework for comparing protection levels and verifying performance claims. In commercial projects, this supports engineering submittals, inspections, and consistent procurement across sites.

VPR (Voltage Protection Rating)

VPR indicates the measured let-through voltage under standardized test conditions. Lower is not automatically “better” if it comes with tradeoffs that reduce durability or cause misapplication. A practical approach is to select a VPR compatible with system voltage and the sensitivity of connected loads.

Nominal discharge current (In)

In reflects the SPD’s ability to withstand repeated surge currents over time. In commercial buildings with frequent switching and a dense mix of electronic loads, a higher In rating generally supports better endurance under repetitive events.

Lead length impact (system-level reality)

Even an excellent SPD can perform poorly if installed with long conductors. Longer leads increase inductive voltage drop during fast transients, effectively raising the voltage seen by protected equipment. In commercial panels, physical layout and wiring discipline are performance factors, not just “installation details.”

SCCR and coordination

Short-circuit current rating (SCCR) and coordination with the panel’s available fault current should be verified. This is especially important at main switchboards and large distribution gear where fault levels can be high.

Spec checklist for comparing surge protection devices

- UL 1449 listing + published VPR values for the system voltage

- Nominal discharge current (In) appropriate for the exposure level

- SCCR compatible with available fault current at the panel

- Protection modes that match the grounding arrangement (L-N, L-G, N-G, L-L where applicable)

- Mechanical/service features: indicators, remote signaling, and replaceable modules

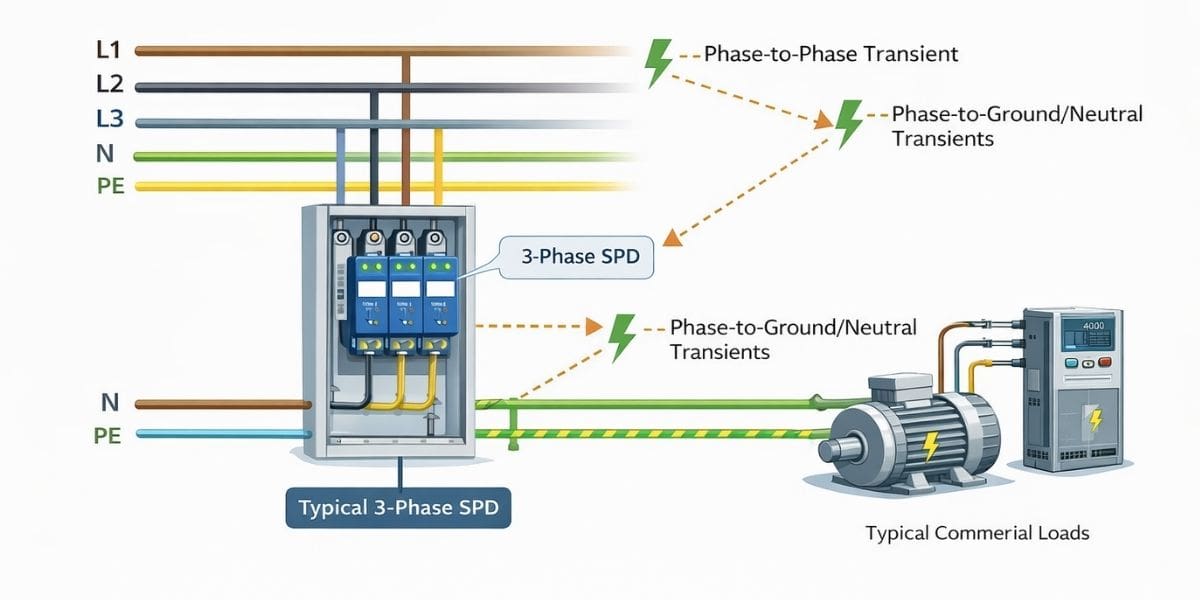

Choosing SPDs for 3-Phase Commercial Systems

Selecting a 3 phase surge protective device is not just selecting the same product in a different voltage rating. Three-phase commercial systems experience a broader range of surge modes: phase-to-ground, phase-to-neutral (where applicable), and phase-to-phase transients. The distribution network also tends to be more complex, with more panels, longer feeders, and larger switching loads.

Neutral and grounding arrangements strongly influence SPD selection because they determine which surge paths are most relevant. A device must match the system’s voltage configuration and grounding method to provide meaningful protection without leaving critical modes unprotected.

- FDS20C/4-275 Class II

- Designation: Type2

- Classification: Class II

- Protection mode: L→PE , N→PE

- Nominal Voltage Un: 230 Vac/50(60)Hz

- Max. continuous operating voltage Uc (L-N): 275 Vac/50(60)Hz

- Short-circuit withstand capability: 20 kA

- Continuous operating current Ic: <20 µA

- Standby power consumption Pc: ≤25 mVA

- Max discharge current (8/20μs) Imax: 40 kA

- Nominal discharge current (8/20μs) In: 20 kA

- Voltage protective level Up: ≤1.3 kV

- Isolation resistance: >1000 MΩ

- Housing material: UL94V-0

- Degree of protection: IP20

In typical commercial facilities, three-phase distribution feeds mechanical loads, lighting, and local panels for office areas. The SPD approach should remain consistent: stage protection at the main service, reinforce at distribution panels, and add equipment-level protection where sensitivity or uptime requirements justify it.

Selecting SPDs for Electrical Panels

A surge protection device for electrical panel applications should be selected with panel role in mind.

At the main panel, the SPD’s job is to reduce the magnitude of incoming disturbances and prevent large surge energy from traveling freely into the building distribution. The main panel device should be chosen for high exposure tolerance, suitable SCCR, and practical service monitoring.

At sub-distribution, the SPD’s job shifts. It must handle residual transients plus locally generated switching events. This is often where Type 2 devices deliver the most consistent results because they protect the circuits that directly feed occupied spaces and sensitive loads.

A staged approach reduces stress on each device. Instead of forcing one SPD to handle everything, multiple devices share the workload and improve predictability across the facility.

A common commercial mistake is installing only one SPD at the main board and assuming all downstream equipment is protected equally. In reality, feeder impedance, panel distances, and localized switching loads create different surge environments across the same building.

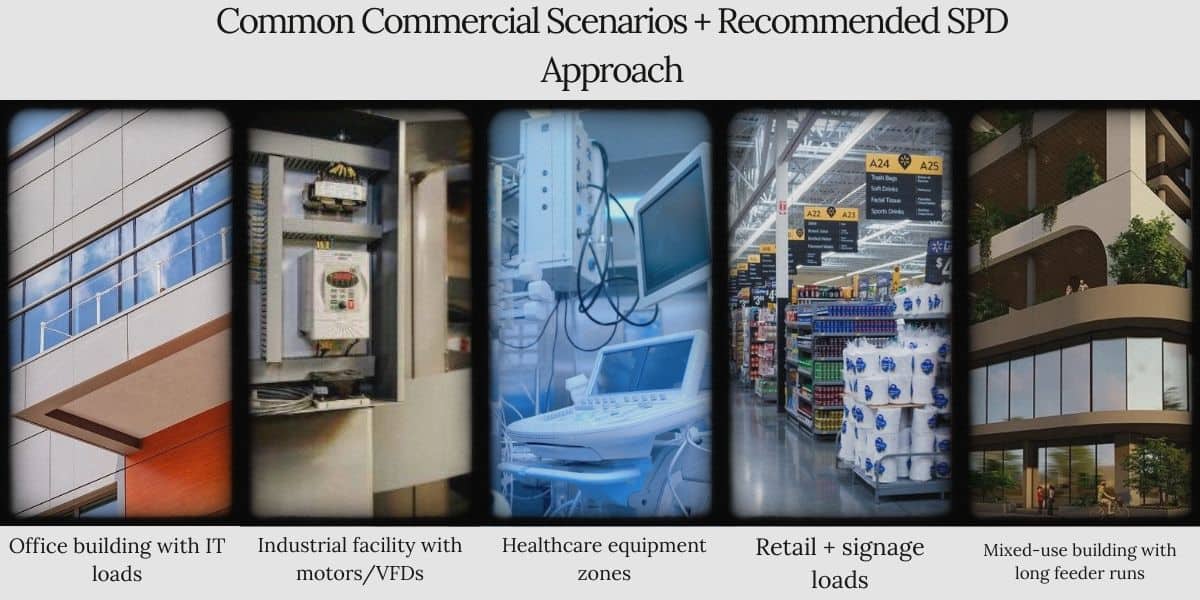

Common Commercial Scenarios + Recommended SPD Approach

Office building with IT loads

Office floors often include dense switching power supplies, networked equipment, and long branch circuits. A staged approach using a service entrance device plus Type 2 devices at floor distribution panels is typically the most stable method. Type 3 can be reserved for critical IT cabinets where uptime and equipment sensitivity are highest.

Industrial facility with motors/VFDs

Industrial sites generate frequent switching transients due to motor controls, contactors, and variable frequency drives. Type 2 devices at motor control distribution panels help manage repetitive stress. A robust upstream device at the main service reduces incoming exposure, while selective equipment-level protection supports sensitive controls and instrumentation.

Healthcare equipment zones

Healthcare environments often include critical equipment where nuisance resets or downtime are unacceptable. The focus should be predictable coordination: service entrance protection, Type 2 at distribution panels serving clinical areas, and equipment-level protection for sensitive systems where needed. Monitoring and maintenance visibility are especially important.

Retail + signage loads

Retail sites combine lighting, HVAC cycling, POS equipment, and signage drivers. Type 2 devices at distribution panels reduce switching-related stress and improve consistency across tenant spaces. Equipment-level protection may be justified for networked POS systems and control gear where transient-related faults are disruptive.

Mixed-use building with long feeder runs

Long feeders increase impedance and can change how surges propagate and clamp across panels. Staging becomes more important: protect at the main service, then reinforce at downstream distribution points closer to loads. This reduces the chance that remote panels see higher residual voltages due to conductor effects.

Maintenance and Monitoring in Commercial Installations

Surge protection devices are not “install and forget.” They degrade over time because protective components absorb energy during surge events. In commercial facilities with frequent switching, the cumulative stress can be significant even if no single event appears dramatic.

Status indicators help, but they should not be treated as proof of full protection capability. A device may still show “operational” while having reduced protective margin due to prior surge exposure. This is why facilities often benefit from planned inspection cycles, event tracking where available, and standardized replacement planning for high-exposure panels.

Maintainability is a practical selection factor. Modular designs can reduce downtime by allowing faster replacement during maintenance windows. Remote signaling can help facility teams detect a failed module without repeatedly opening panels, supporting safer and more efficient operations.

Final Recommendation Framework

A neutral, engineering-based recommendation process starts with the building’s distribution design and then maps protection layers to exposure zones. The goal is to avoid under-protecting critical loads and avoid overcomplicating the system with uncoordinated devices.

5-step commercial SPD selection framework

- Define exposure level and entry points (utility, feeders, switching load density)

- Decide staged protection using Type 1 and Type 2 at appropriate panels

- Identify sensitive loads that benefit from Type 3 placement near equipment

- Verify UL 1449 ratings, VPR suitability, In endurance, and SCCR compatibility

- Ensure installation quality: short leads, correct placement, and coordination across panels

Conclusion

In commercial electrical installations, the “top” surge protection devices are the ones correctly matched to type, location, and verified performance. A UL 1449 listed surge protective device strategy works best when it is staged across the service entrance, distribution panels, and sensitive equipment zones. Coordination and installation quality usually matter more than oversizing, and commercial systems benefit most from protection that is predictable, monitorable, and maintainable over time.

FAQS

A type 2 surge protection device is the most common because it protects distribution and sub-panels where most branch circuits and switching surges occur.

Often yes. Type 1 handles service entrance exposure, while Type 2 improves downstream coordination and reduces residual surges at distribution panels.

Yes. A UL 1449 surge protective device listing helps confirm standardized performance ratings like VPR and supports compliant commercial specifications.

Not reliably. Commercial systems typically need staged protection across main and sub-panels because distance, feeder length, and internal switching loads change surge behavior.

Focus on correct system voltage/configuration, protection modes (phase-to-phase and phase-to-ground), SCCR compatibility, and short lead installation for best real-world performance.