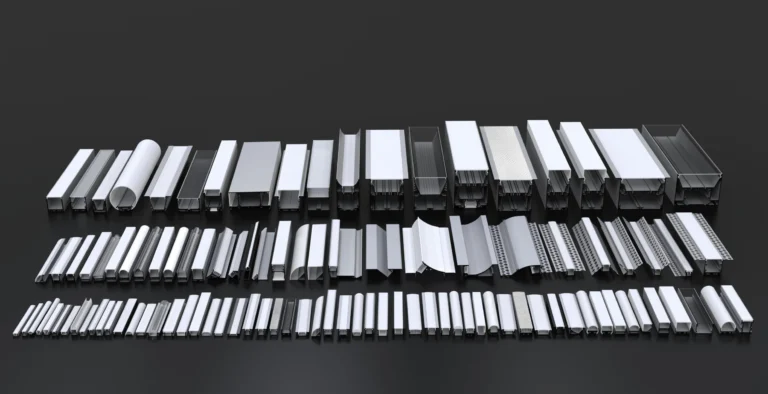

COB LED strip lighting has become an increasingly popular solution for both indoor and outdoor applications due to its uniform light output and clean linear appearance. However, not all COB LED strips are designed to perform the same way once installation environments change. Factors such as moisture exposure, temperature variation, electrical loading, and long-term reliability can significantly affect performance and service life. Understanding the fundamental differences between COB LED strips intended for indoor use and those engineered for outdoor conditions is essential for lighting designers, engineers, and project specifiers seeking stable and durable lighting solutions.

Fundamental Differences Between Indoor and Outdoor COB LED Strips

Indoor COB LED strips are designed for stable, controlled environments with minimal exposure to moisture and temperature changes, while outdoor COB LED strips are engineered with higher protection levels, enhanced electrical insulation, and stronger environmental resistance to ensure long-term reliability in harsh conditions.

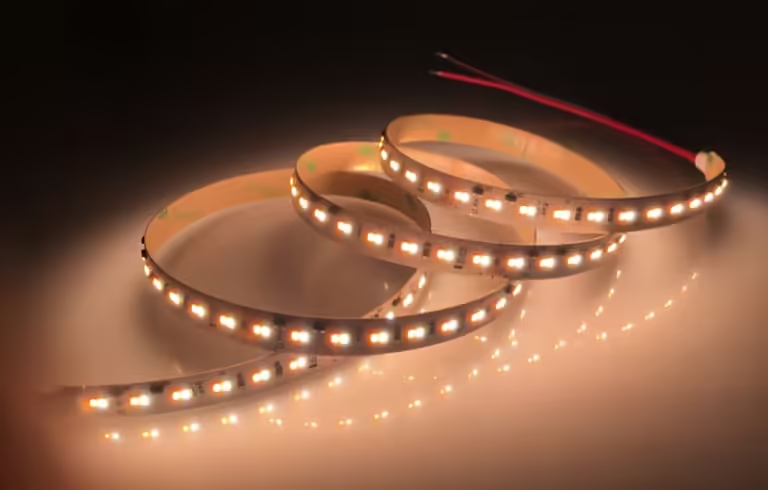

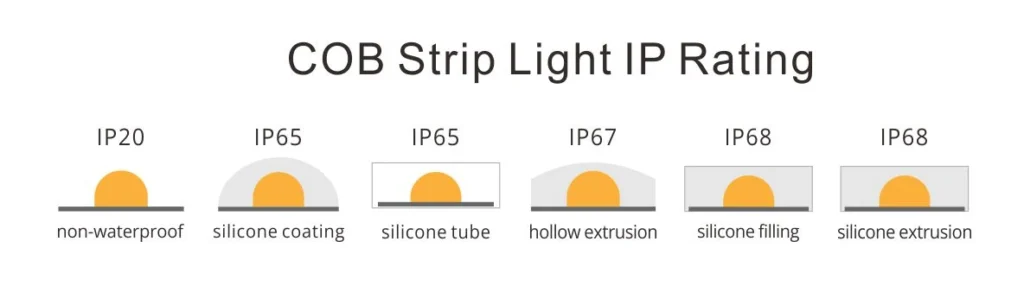

Although indoor and outdoor COB LED strips may look similar in appearance and brightness, their internal design and application focus differ significantly. Indoor COB LED strip lighting is typically used in dry interior spaces such as offices, retail stores, and residential areas. These products usually feature IP20 protection, simpler PCB layouts, and standard insulation levels optimized for consistent indoor temperatures.

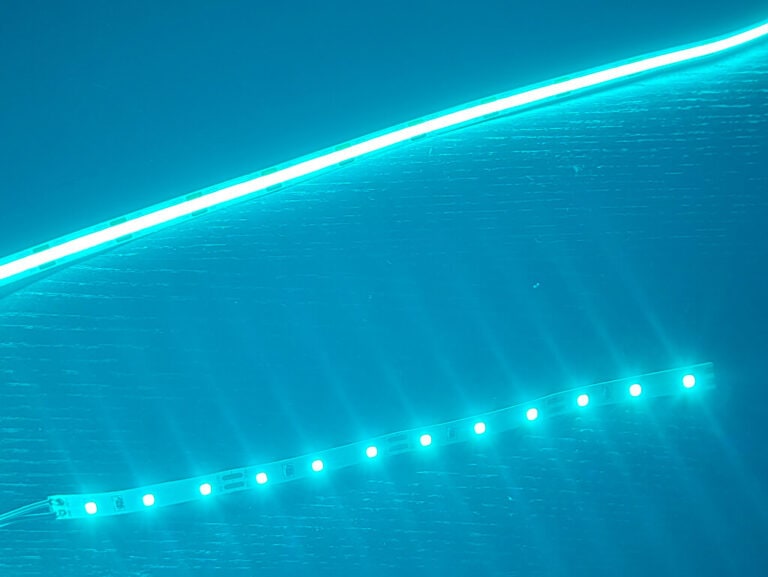

Outdoor COB LED strip lights, on the other hand, must withstand rain, humidity, dust, UV exposure, and temperature fluctuations. To meet these requirements, outdoor COB LED strips are commonly designed with higher ingress protection ratings such as IP65 silicone dropping, IP67 hollow extrusion or IP68 silicone extrusion, reinforced encapsulation materials, and improved electrical and thermal performance. Selecting the appropriate COB LED strip for indoor or outdoor use is essential to achieve stable performance and extended service life.

IP20 COB LED Strip for Indoor

IP68 COB LED Strip for Outdoor

Environmental and Electrical Design Differences

Outdoor COB LED strips require higher environmental protection and more robust electrical design than indoor COB LED strips, primarily due to exposure to moisture, dust, UV radiation, and temperature fluctuations.

Environmental conditions play a critical role in determining the structural and electrical design of COB LED strip lighting. Indoor COB LED strips are typically installed in dry, temperature-controlled spaces, allowing for simpler construction and lower protection requirements. Most indoor COB LED strip lights operate with IP20 ratings, standard insulation distances, and basic moisture resistance, which are sufficient for interior applications.

Outdoor COB LED strip lights, however, must be engineered to operate reliably in challenging environments. Higher ingress protection ratings such as IP65 or IP67 are commonly required to prevent water and dust penetration. In addition, outdoor COB LED strips often feature enhanced electrical insulation, sealed solder joints, and protective encapsulation to reduce the risk of corrosion, leakage current, and short circuits caused by humidity or condensation.

Electrical design also differs significantly between indoor and outdoor applications. Outdoor COB LED strips are more frequently designed for 24V or 48V systems to minimize voltage drop over longer installation lengths and improve operational stability. Proper consideration of environmental and electrical design differences is essential to ensure safe operation, consistent performance, and long-term durability in both indoor and outdoor lighting projects.

Thermal Management and PCB Design Considerations

Thermal management and PCB design are key factors that differentiate indoor and outdoor COB LED strip performance and long-term reliability. While both applications require adequate heat dissipation, outdoor COB LED strips are exposed to higher thermal stress due to direct sunlight, fluctuating ambient temperatures, and limited airflow in sealed installations.

Indoor COB LED strip lighting typically operates in relatively stable environments, allowing the use of standard flexible PCBs with moderate copper thickness, commonly around 2oz. Heat generated by the LEDs can be efficiently transferred through aluminum profiles or mounting surfaces, maintaining acceptable junction temperatures and stable light output over time.

Outdoor COB LED strip lights, however, often demand more robust thermal and structural design. Higher power densities, combined with waterproof encapsulation, can significantly restrict heat dissipation. To compensate, outdoor COB LED strips frequently utilize thicker copper PCBs, optimized thermal pathways, and carefully selected encapsulation materials that balance protection with heat transfer efficiency. In some applications, reinforced mounting systems or dedicated aluminum channels are essential to maintain safe operating temperatures.

Proper evaluation of thermal management and PCB design is critical when selecting COB LED strips for indoor or outdoor use, as insufficient heat dissipation can accelerate lumen depreciation, color shift, and premature product failure.

Typical Applications of Indoor and Outdoor COB LED Strip Lighting

COB LED strip lighting is widely used in both indoor and outdoor environments, but the application focus differs significantly depending on installation conditions and lighting objectives. Indoor COB LED strips are primarily selected for visual comfort, color consistency, and seamless linear illumination, while outdoor COB LED strips are chosen for durability, weather resistance, and dynamic visual impact under challenging environmental conditions.

In indoor applications, COB LED strips are commonly used in commercial spaces such as retail stores, offices, hotels, and residential interiors. Typical installations include cove lighting, cabinet lighting, shelving, and architectural linear accents, where uniform light output and precise color control are essential. For example, SignliteLED IP20 tunable white COB LED strip FYT10T608C is well suited for interior lighting projects. This product features smooth dot-free illumination, dual color temperature adjustment, and stable performance in dry indoor environments, making it ideal for functional and ambient lighting combinations.

Ra90 Tunable White COB LED Strip Light

Model No.: FYT10T608X

Input Voltage: DC12V/24V

Power: 7W/m + 7W/m

LED QTY: 608LEDs/m

CCT: 2700K-6500K, tunable white

CRI: >90

Efficiency: 110lm/W

Beam Angle: 180°

Cut Section: 26.31mm

IP Rating: IP20/IP65/IP67/IP68

Warranty: 3years

Outdoor COB LED strip lighting is more frequently applied in architectural facade lighting, landscape illumination, and semi-outdoor areas such as walkways, canopies, and building outlines. These applications require higher protection levels and enhanced resistance to moisture and temperature variation. A typical example is SignliteLED IP67 RGB pixel COB LED strip EYA10T576C, which offers waterproof construction, dynamic color-changing effects, and reliable operation in outdoor and wet locations. Such products are commonly used to create eye-catching visual effects while maintaining long-term durability.

Understanding application-specific requirements helps ensure the correct COB LED strip selection for both indoor and outdoor lighting projects.

Application-Based Selection Guidelines for COB LED Strips

Choosing the appropriate COB LED strip should be driven by application requirements rather than product appearance alone. Key factors such as installation environment, power supply method, protection level, and maintenance accessibility determine whether an indoor-grade or outdoor-grade COB LED strip is suitable. Matching the strip design to the actual usage scenario is essential for achieving stable performance and long service life.

For indoor applications, COB LED strips are typically selected based on lighting quality, installation convenience, and electrical compatibility. Low-voltage options such as 12V or 24V COB LED strips are widely used for cabinets, shelves, and architectural details where drivers can be concealed. In large commercial interiors or continuous linear installations, 220V or 110V high-voltage COB LED strips are often preferred, as they allow longer runs without voltage drop and simplify wiring by eliminating external power supplies.

Outdoor and semi-outdoor applications require COB LED strips with enhanced environmental protection and electrical safety. Higher ingress protection ratings, waterproof encapsulation, and reliable insulation are critical when exposure to moisture, dust, or temperature variation is expected. In these scenarios, proper mounting, sealing, and thermal considerations become just as important as light output or color control.

The table below summarizes common indoor and outdoor applications and the corresponding COB LED strip requirements.

Typical COB LED Strip Applications and Recommendations

| Application Scenario | Indoor / Outdoor | Recommended Voltage | IP Rating | Key Selection Focus |

| Cabinet lighting | Indoor | 12V / 24V | IP20 | Uniform light, compact size |

| Cove lighting | Indoor | 24V | IP20 | Long runs, smooth linear effect |

| Retail display shelves | Indoor | 24V | IP20 | High CRI, visual comfort |

| Large indoor corridors | Indoor | 110V / 220V | IP20 | Reduced voltage drop, easy wiring |

| Building facade outline | Outdoor | 24V / 48V | IP65 / IP67 | Waterproofing, durability |

| Landscape lighting | Outdoor | 24V | IP67 | Moisture resistance, stability |

| Canopies & walkways | Semi-outdoor | 24V | IP65 | Environmental protection |

Conclusion

Selecting the right COB LED strip for indoor or outdoor applications requires a clear understanding of environmental conditions, electrical design, and long-term reliability requirements. Proper matching of product specifications to real-world applications helps ensure stable performance, extended lifespan, and reduced maintenance costs across different lighting projects.

SignliteLED is a professional COB LED strip manufacturer with over four years of dedicated production experience. As a direct source factory, SignliteLED offers a wide range of COB LED strip solutions for indoor and outdoor use, including customizable options to meet project-specific requirements. With stable quality control and proven performance, SignliteLED products have earned strong satisfaction from customers worldwide.

Frequently Asked Questions (FAQ)

1. What is the main difference between indoor and outdoor COB LED strips?

The primary difference lies in environmental protection and electrical design. Indoor COB LED strips are designed for dry, controlled environments, while outdoor COB LED strips require higher IP ratings, waterproof construction, and enhanced insulation to withstand moisture, dust, and temperature changes.

2. Can indoor COB LED strips be used outdoors?

Indoor COB LED strips are not recommended for outdoor use. Without proper waterproofing and environmental protection, they are vulnerable to moisture, corrosion, and premature failure when exposed to outdoor conditions.

3. What IP rating is required for outdoor COB LED strip lighting?

Most outdoor applications require at least IP65 protection. For areas exposed to heavy rain or standing water, IP67 or higher is recommended to ensure reliable long-term performance.

4. Are 110V or 220V COB LED strips suitable for indoor applications?

Yes. High-voltage 110V or 220V COB LED strips are commonly used in large indoor spaces or long linear installations, as they reduce voltage drop and eliminate the need for external drivers.

5. How does thermal management affect COB LED strip lifespan?

Proper heat dissipation is critical for maintaining LED junction temperature. Insufficient thermal management can accelerate lumen depreciation, color shift, and reduce the overall lifespan of COB LED strip lighting.

6. What are typical applications for RGB COB LED strips outdoors?

Outdoor RGB COB LED strips are widely used for architectural façade lighting, landscape accents, and decorative installations where dynamic color effects and weather resistance are required.

7. How long do COB LED strips typically last?

When correctly selected and installed, high-quality COB LED strips can achieve a lifespan of 30,000 to 50,000 hours. Environmental conditions and thermal design play a significant role in actual service life.

8. Can COB LED strips be customized for specific projects?

Yes. COB LED strips can be customized in terms of voltage, color temperature, IP rating, length, and control methods to meet the technical requirements of different indoor and outdoor lighting projects.