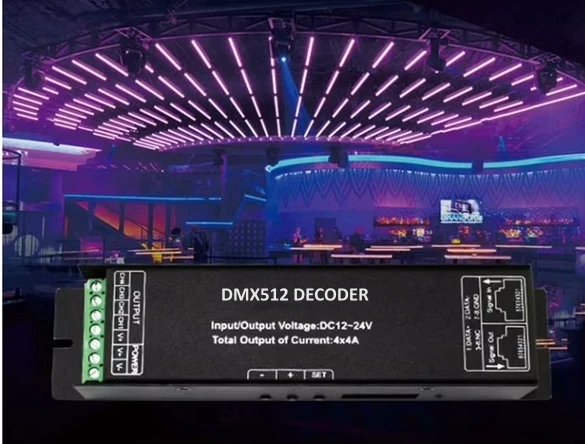

In recent years, flexible DMX512 neon LED strips have become a cornerstone of creative architectural and façade lighting. Unlike conventional LED strips, these products combine the flexibility of silicone neon housing with the precision of DMX512 digital control, enabling pixel-level dynamic effects, smooth gradients, and unlimited design possibilities. However, this sophistication also makes their installation and commissioning more demanding. A minor mistake during wiring or addressing can result in signal loss, color distortion, or unsynchronized effects.

This guide provides a comprehensive roadmap—from preparation to final acceptance—for contractors and lighting professionals undertaking DMX512 neon LED strip projects.

Preparation Before Installation: “Plan Before You Build”

A successful DMX512 lighting project begins long before the first strip is mounted.

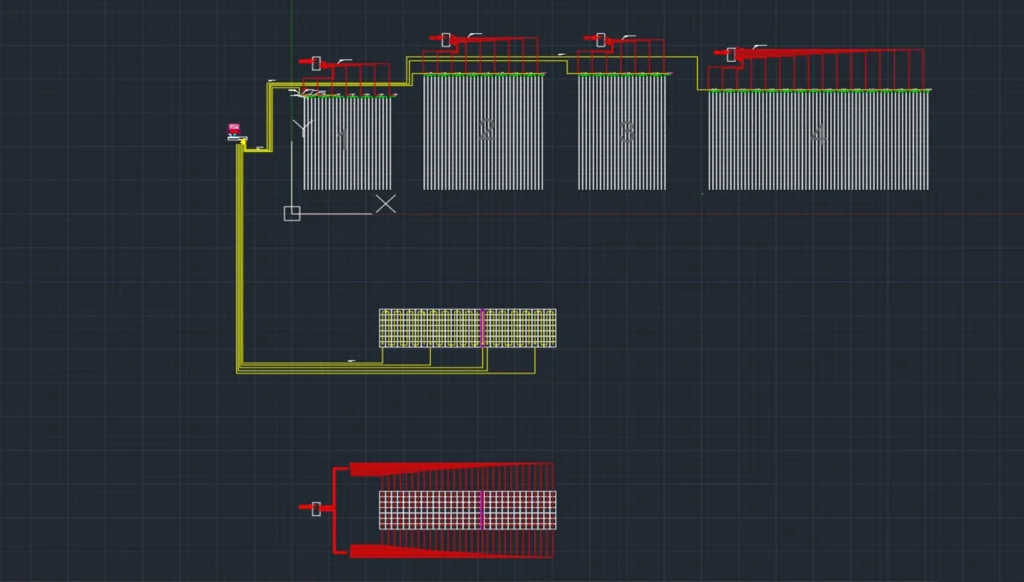

Understand the design drawings thoroughly

Before entering the site, review the lighting design, wiring diagrams, and animation previews. Identify strip groupings, controller locations, and power distribution points. With this mental “map,” the on-site work becomes predictable and efficient.

Material inspection is critical

LED strips: Verify models, lengths, and specifications against the design. Always cut and power a test segment on-site to check for dead pixels, color consistency, and brightness. Early detection of defects prevents costly rework.

Power supplies: Calculate capacity carefully. The recommended rule is: total PSU capacity ≥ 1.5 × total strip power. This safety margin ensures long-term stability.

Accessories: Clips, end caps, waterproof adhesives, connectors, and signal cables must be complete. Missing accessories delay installation and compromise reliability.

Installation: “Details Define the Outcome”

Flexible neon strips are durable, but improper installation can quickly shorten their lifespan.

Surface preparation

Clean the installation surface with alcohol and allow it to dry completely before applying adhesive backing. For outdoor or ceiling projects, adhesive alone is insufficient—use dedicated clips for secure double fixation. Over time, adhesive will fail under heat, dust, and gravity.

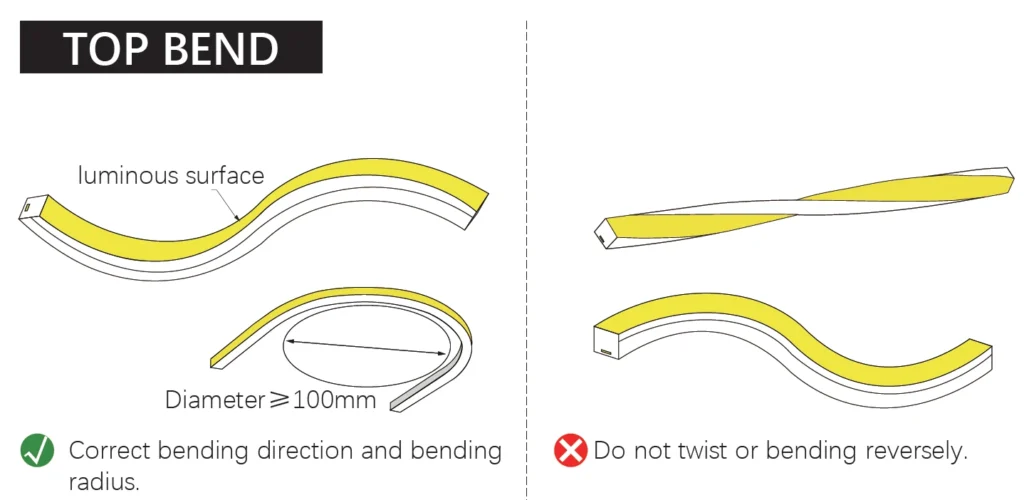

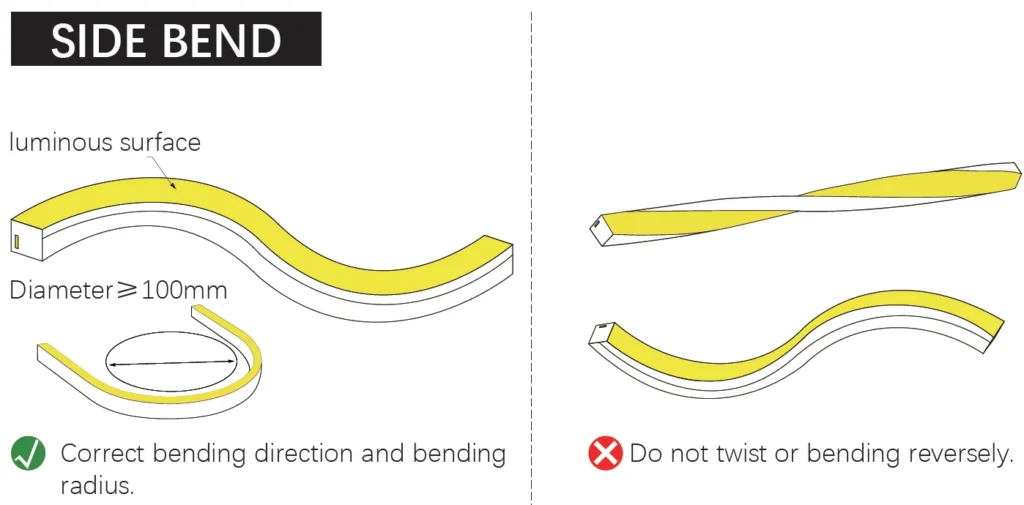

Bending and cutting

Strips can bend horizontally, but vertical twists and sharp bends are strictly forbidden. The minimum bending radius is typically ≥ 5 cm.

Cutting must only be done at designated scissor-mark points. Cutting elsewhere renders the entire segment unusable.

Power and Signal Wiring: “The Core of DMX512 Systems”

DMX512 neon strips are more sensitive to wiring quality than conventional strips.

Power supply strategy

Adopt a multi-point power injection approach. For long runs, never power from one end only—voltage drop will cause brightness falloff and color shift at the far end. Instead, inject power every 10–15 meters directly from the PSU.

Signal wiring standards

Always use shielded twisted-pair DMX cables with 120 Ω impedance. Network cables are not suitable; they lack shielding and proper impedance, making them prone to interference.

Maintain at least 30 cm separation between DMX signal cables and high-voltage (220V) power lines. Parallel routing increases electromagnetic interference risk.

DMX addressing and termination

Address setting: Every strip segment must have a unique starting address. Use DIP switches or software configuration based on the formula:

Start Address = (N – 1) × Channel Count + 1

Termination resistor: Install a 120 Ω resistor at the last fixture in each DMX line. Without this, reflections cause flickering, signal instability, or random behavior. This small component is the “guardian” of system stability.

Commissioning and Testing: “Lighting Up the Vision”

Once wiring is complete, careful commissioning ensures the installation matches the design intent.

Power-up procedure

Never energize the entire system at once. Instead, test segment by segment. Begin with the controller and PSU, then gradually connect strips, verifying each section works properly before proceeding. This approach isolates problems quickly.

Software configuration

In the control software (e.g., Madrix, Resolume, Arkaos), set the correct Universe, output ports, and channel mapping (RGB or RGBW depending on strip type). Confirm each segment’s DMX address matches the design.

Effect verification

Use pure static colors (red, green, blue, white) to confirm uniformity and eliminate dead pixels.

Run dynamic effects such as chasing, gradients, or strobe to check for synchronization issues. Delays or jitter indicate signal integrity problems.

Finally, compare live results with the original design animation to ensure the client’s vision is fully realized.

Best Practices and Professional Tips

From practical experience, four golden rules summarize a reliable DMX512 neon installation:

Power generously, feed locally – Use sufficient PSU capacity and inject power at multiple points.

Protect signal integrity – Use shielded DMX cables and install termination resistors.

Address logically, test methodically – Assign and confirm addresses carefully, segment by segment.

Install securely, protect against the elements – Clips, waterproofing, and thermal management are critical for outdoor durability.

Additionally:

Always allow for expansion joints in long runs to account for thermal expansion of silicone housings.

Label both power and signal cables during installation—this small step saves hours in troubleshooting later.

Keep spare power supplies and connectors on-site for immediate replacement during commissioning.

Conclusion

The appeal of flexible DMX512 neon LED strips lies in their ability to transform static architecture into a dynamic canvas of light. Yet, this capability comes with complexity. By respecting the principles of adequate power distribution, robust signal wiring, careful addressing, and secure installation, lighting professionals can deliver flawless results that match the most ambitious design visions.

In façade lighting, themed entertainment, or city landmarks, success is measured not only by how brightly the lights shine, but by how seamlessly they perform night after night. With thorough preparation, meticulous execution, and disciplined testing, DMX512 neon projects can move from potential pitfalls to illuminated masterpieces.

Partner with SignliteLED for Your Next Project

At SignliteLED, we specialize in high-quality DMX512 flexible neon strips and complete control solutions. With over 15 years of experience, global certifications, and a strong engineering team, we provide not only reliable products but also expert technical support for complex installations. Whether you are an engineering contractor, distributor, or lighting designer, we can deliver custom solutions tailored to your project’s needs.