Überspannungsschutzgeräte (SPDs) werden als Typ 1, Typ 2 und Typ 3 klassifiziert, um zu reflektieren, wo sie innerhalb eines elektrischen Systems arbeiten und wie sie die Überspannung an diesem Ort verwalten. Diese Typen sind nicht austauschbar. Jedes ist für eine bestimmte Überspannungsumgebung und -schutzfunktion ausgelegt und funktioniert nur dann korrekt, wenn es als Teil eines koordinierten Systems angewendet wird.

Dieser Artikel ist ein vergleichender technischer Leitfaden. Es werden keine Grundlagen für den Überspannungsschutz wieder eingeführt. Stattdessen konzentriert es sich darauf, wie sich Typ 1, Typ 2 und Typ 3 SPDs in Rolle, Fähigkeit und Systeminteraktion unterscheiden und wie Ingenieure die korrekte Platzierung in realen elektrischen Installationen bestimmen.

Vergleichsrahmen: Wie SPD-Typen differenziert werden

Die SPD-Klassifizierung basiert nicht auf der Produktgröße, dem Preis oder der wahrgenommenen Robustheit. Es basiert auf der Einbaulage und der erwarteten Überspannungsbelastung.

Wenn die Überspannungsenergie durch ein elektrisches System wandert, ändern sich ihre Eigenschaften:

- Überspannungsstromstärke nimmt ab

- Wellenform entwickelt sich

- Restspannung bleibt gefährlich für empfindliche Geräte

Aufgrund dieses Verhaltens wird der Überspannungsschutz in Zonen unterteilt. Jeder SPD-Typ ist für den Betrieb innerhalb einer bestimmten Zone ausgelegt, wo er Überspannungsbelastungen bewältigen kann, ohne überbetont oder unterdurchschnittlich zu sein.

Der Vergleich zwischen Typ 1, Typ 2 und Typ 3 SPDs sollte immer berücksichtigt werden:

- Einbauort

- Erwartetes Überspannungsenergieniveau

- Primäre Schutzfunktion

- Abhängigkeit von anderen SPD-Typen

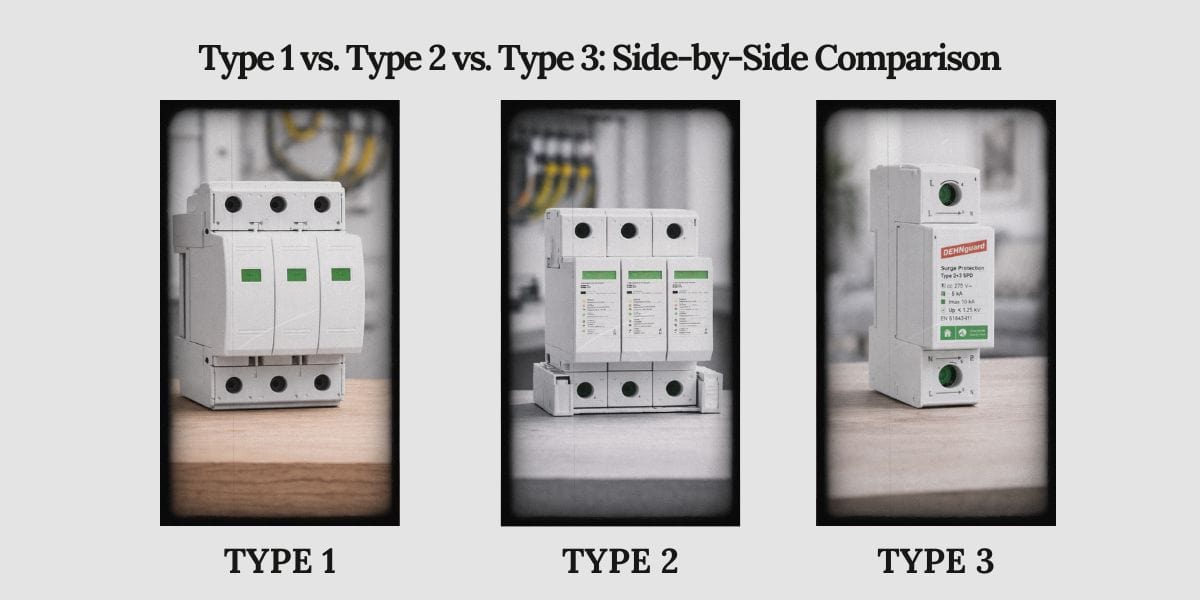

Typ 1 vs. Typ 2 vs. Typ 3: Side-by-Side-Vergleich

| Parameter | Typ 1 SPD | Typ 2 SPD | Typ 3 SPD |

| Typischer Installationsort | Serviceeingang, Linie Seite der Haupttrennung | Verteilerpaneele, Lastseite der Trennung | Nahe empfindliche Geräte |

| Überspannungsbelichtung | hoch | Mittel bis hoch | Niedrig |

| Hauptfunktion | Eingehenden Überspannungsstrom umleiten | Residual- und Schaltüberspannungen klemmen | Feine Spannungsbegrenzung |

| Überspannungsstrombehandlung | hoch | Mäßig bis hoch | Niedrig |

| Spannungsspanngenauigkeit | Niedrig | Mittel | Hoch |

| Standalone-Eignung | Nein | begrenzt | Nein |

| Abhängigkeit von anderen SPDs | Benötigt Typ 2 stromabwärts | Oft gepaart mit Typ 1 und Typ 3 | Erfordert Upstream Typ 1 oder Typ 2 |

| Typisches Risiko bei falscher Anwendung | Unzureichender Geräteschutz | Überlastung und verkürzte Lebensdauer | Katastrophaler Fehler |

Dieser Vergleich unterstreicht ein Schlüsselprinzip: SPD-Typen werden durch Funktion und Platzierung definiert, nicht durch Leistungsranking.

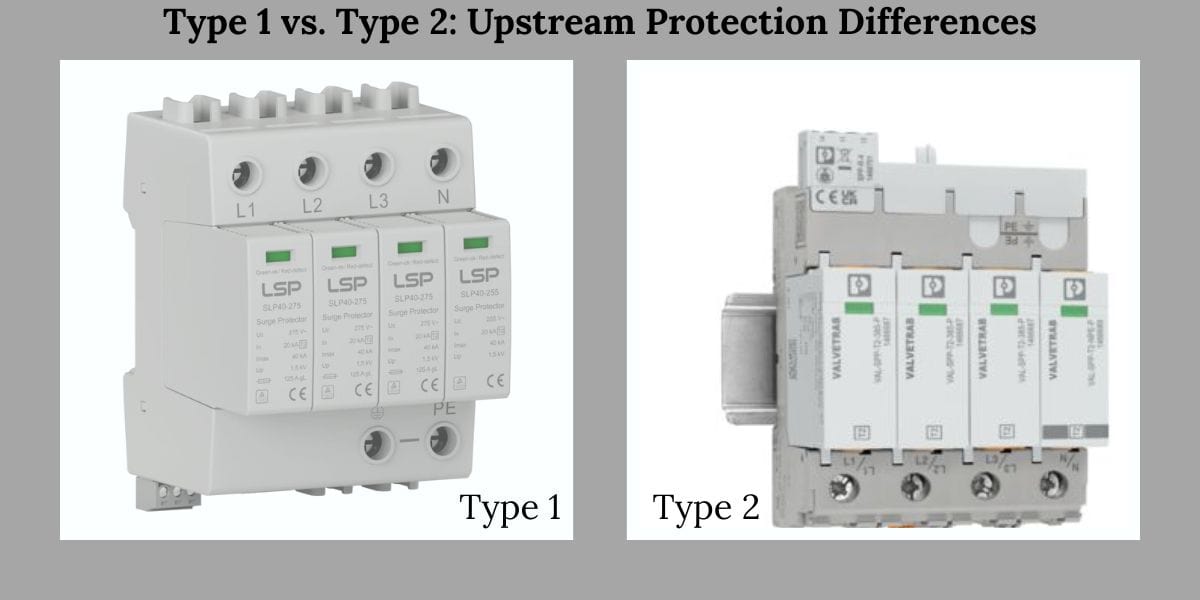

Typ 1 vs. Typ 2: Vorwärts-Schutzunterschiede

Installationskontext

Am Serviceeingang werden Typ-1-SPDs installiert, bei denen die externe Überspannung am höchsten ist. Typ-2-SPDs werden nachgeschaltet innerhalb des internen Verteilungssystems installiert.

Dieser Positionsunterschied ändert grundlegend, was jedes Gerät von jedem Gerät erwartet.

Überspannungsenergieprofil

- Typ 1 SPDs Begegnen Sie energiegeladenen Impulsen, die mit blitzbedingten Ereignissen verbunden sind, die vom Versorgungsnetz eintreten.

- Typ 2 SPDs stoßen Restblitzenergie und häufige intern erzeugte Schalttransienten auf.

Da Geräte vom Typ 2 nicht für die höchsten Energieimpulse ausgelegt sind, können sie den Schutz des Typs 1 am Serviceeingang nicht ersetzen.

Funktionsunterscheidung

- Typ 1 konzentriert sich auf Überspannungsstromumleitung

- Typ 2 konzentriert sich auf Spannungsbegrenzung und wiederholte Überspannungskontrolle

Die Installation von Schutztyp 2 in Umgebungen mit hoher Belichtung verlagert übermäßige Belastung auf Geräte, die nicht dafür ausgelegt sind, was zu einer vorzeitigen Verschlechterung führt.

Typ 2 vs. Typ 3: Verteilung vs. Schutz auf Geräteebene

Installationsnähe

SPDs vom Typ 2 schützen Verteilungsnetze, während SPDs vom Typ 3 einzelne Geräte oder Schaltkreise schützen. Der Abstand zwischen der SPD und der geschützten Last ist ein kritischer Unterscheidungsmerkmal.

Restspannungsregelung

Nach dem vorgeschalteten Schutz kann die Restspannung die Impulsbeständigkeit der empfindlichen Elektronik noch überschreiten. Typ-3-SPDs bieten eine feine Spannungsverfeinerung am Einsatzort.

Einschränkung der Energiehandhabung

Typ-3-SPDs sind nicht zur Absorption von Stoßenergie ausgelegt. Bei direkter Einwirkung von energiereichen Ereignissen können sie schnell versagen. Deshalb dürfen sie niemals ohne vorgeschalteten Schutz verwendet werden.

Der Vergleich zwischen Typ 2 und Typ 3 geht nicht darum, was „besser“ ist, sondern darum, wo die Präzision die Energiehandhabung ersetzt.

Warum ist kein einzelner SPD-Typ genug

Überspannungsschutz ist nicht additiv. Die Installation mehrerer Geräte des gleichen Typs bietet keinen Schichtschutz.

Jeder SPD-Typ arbeitet optimal nur innerhalb seines vorgesehenen Spannungsbereichs:

- Typ 1 reduziert die ankommende Überspannungsenergie

- Typ 2 verwaltet die verbleibende Überspannung

- Typ 3 Grenzen Endrestspannung

Der Versuch, alle diese Funktionen mit einem einzigen Gerät auszuführen, führt zu einem gefährdeten Schutz, einer verkürzten Lebensdauer oder beidem.

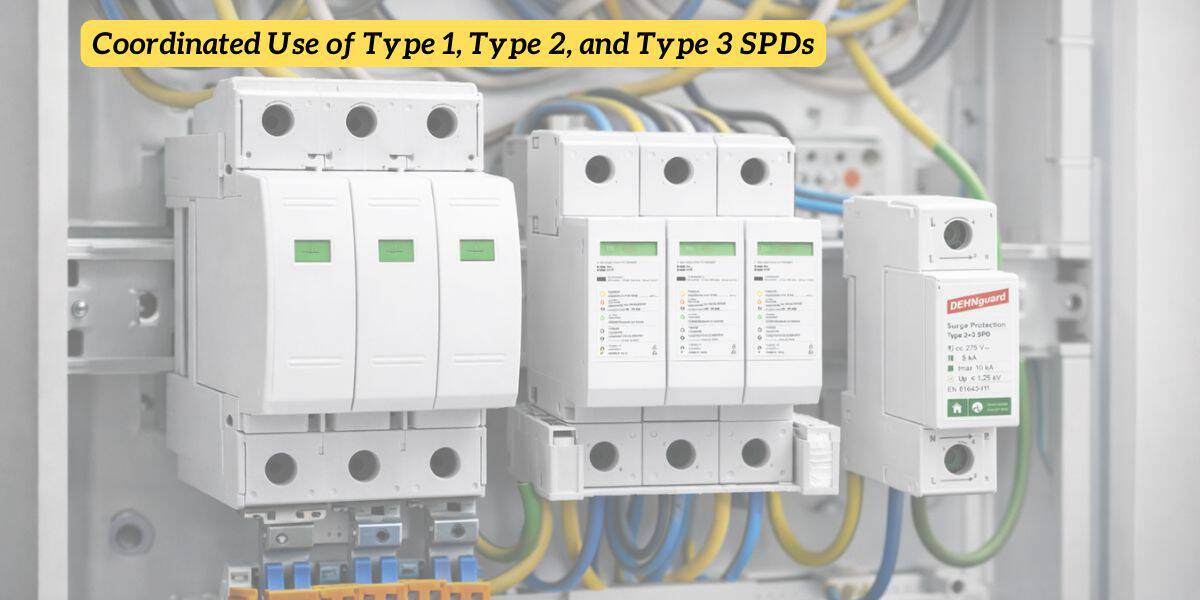

Koordinierter Einsatz von Typ 1, Typ 2 und Typ 3 SPDs

Wie die Koordination funktioniert

Ein abgestimmtes Überspannungsschutzsystem spiegelt die Art und Weise wider, wie sich die Überspannungsenergie ausbreitet:

- Typ 1 leitet energiereiche Impulse beim Systemeintritt um

- Typ 2 Verbleibt die restlichen Überspannungen innerhalb des Verteilungssystems

- Typ 3 Schützt empfindliche Lasten vor Restspannung

Jede Stufe reduziert den Stress auf die nächste.

Warum Koordination wichtiger ist als Quantität

Unsachgemäße Koordination kann verursachen:

- ungleichmäßiger Energieaustausch

- Lokalisierte Überhitzung

- Unvorhersehbares Fehlerverhalten

Korrekte Platzierung und Impedanztrennung sind mehr als die Installation zusätzlicher Geräte.

Anwendungsbasierte Vergleichsszenarien

Serviceeingang mit externer Belichtung

Einrichtungen mit Freileitungsleitungen oder elektrischer Außeninfrastruktur erfordern am Serviceeingang Schutz des Typs 1, gefolgt von Schutzart 2 nachgeschaltet.

Handels- und Industrieverteilsysteme

Schaltvorgänge dominieren die Überspannungsaktivität. Typ-2-SPDs bieten die primäre Schutzrolle, die häufig mit vorgelagerten Typ-1-Geräten koordiniert wird.

Empfindliche elektronische Systeme

Automatisierungssteuerungen, Instrumenten- und Kommunikationsschnittstellen erfordern Schutzart 3, jedoch nur, wenn die Upstream-Stoßenergie bereits reduziert wurde.

Einphasen- und Dreiphasensysteme

eine 3-Phase Überspannungsschutzgerät Muss Phase-zu-Phase- und Phase-Erde-Transienten konsistent verwalten. Die Auswahl des SPD-Typs muss mit der Systemkonfiguration übereinstimmen, nicht nur der Nennspannung.

Häufige Vergleichsfehler, die Ingenieure machen

- Angenommen, Typ 3-Geräte können eigenständig arbeiten

- Überdimensionieren einer SPD, anstatt mehrere Typen zu koordinieren

- Installieren mehrerer Typ-2-Geräte ohne Berücksichtigung der Impedanz

- SPD-Typen als Leistungsstufen und nicht als funktionale Rollen behandeln

Diese Fehler verringern die Schutzwirksamkeit und erhöhen das Wartungsrisiko.

Standards Kontext

Standards wie UL 1449 und IEC 61643 definieren Prüfbedingungen und Klassifizierungskriterien für SPD-Typen. Sie unterstützen einen konsistenten Vergleich, ersetzen jedoch nicht die Beurteilung der technischen Beurteilung auf Systemebene in Bezug auf Platzierung und Koordination.

Abschluss

Überspannungsschutzvorrichtungen vom Typ 1, Typ 2 und Typ 3 erfüllen unterschiedliche und ergänzende Rollen innerhalb eines elektrischen Systems. Ihre Unterschiede werden durch den Installationsort, die Überspannungsbelastung und die Schutzfunktion definiert, nicht nach Produktklasse oder Marketingposition.

Ein wirksamer Überspannungsschutz hängt von der Koordination ab, nicht von Überdimensionierung oder Redundanz. Wenn jeder SPD-Typ angewendet wird, wo er am besten arbeitet, wird die Überspannungsenergie schrittweise kontrolliert, der Gerätestress wird verringert und die langfristige Systemzuverlässigkeit verbessert sich.

FAQs

kein drohen Typ-2-Geräte sind nicht für die höchsten Expositionswerte für die Exposition bei Systemeingabe ausgelegt.

Nur indirekt und nur dann, wenn der vorgelagerte Schutz bereits die Überspannungsenergie reduziert hat.

In Umgebungen mit geringer Belichtung kann es akzeptabel sein, aber das Risiko steigt ohne vorgelagerten Schutz erheblich.

Weil eine falsche Platzierung Geräte unabhängig von der Bewertung überlasten kann.

Nicht immer, aber die meisten modernen Installationen profitieren von mindestens Typ 1 und Typ 2 Koordination.