Test Objectives

1) Document changes in luminous efficiency, color temperature, and CRI data across three distinct production stages of edge-lit LED strips: bare LED board → LED with lens → lens with potting compound. Provide data support for product development.

2) Evaluate the impact of varying power levels and strip lengths on brightness, color temperature, and other parameters for edge-lit LED strips.

Test Samples

| Item | Length | Number of LEDs | Power | Pitch of the LED | Number of Samples |

| 1 | 782mm | 14 LEDs/unit | 13W | 55.86mm | 1PCS |

| 2 | 970mm | 20 LEDs/unit | 20W | 48.50mm | 1PCS |

| 3 | 1300mm | 28 LEDs/unit | 26W | 46.43mm | 1PCS |

| 4 | 1550mm | 32 LEDs/unit | 30W | 48.44mm | 1PCS |

Test Method

Record raw LED data: Sample light strips are tested using an integrating sphere and spectrophotometer to record corresponding brightness, luminous efficacy, color rendering index, color temperature, and other data.

Measurement Equipment and Environment

- Integrating sphere optical testing system / High-precision spectrophotometer

- Temperature: 28°C ±5°C

- Humidity: 65% ± 5%

- Test Voltage: DC 24V

- Test Date: 2024-04-15

LED Integrating Sphere Test Data

LED Chip Type for This Sample: SMD2835; Sample Supplier: MASTER OPTRONICS LED

| Master Optronics LED Test Data | |||||||||||

| CCT | Power | LED Current | LED Voltage | Luminance | Test Brightness | Voltage | lm/W | CCT | Ra | Wave Length | Remark |

| 6500K | 1W | 100mA | 8.3-8.8V | 150-1601m | 151 | 8.62 | 175.18 | 6814 | 81.1 | 453.1 | SMD2835 Round Cup |

| 6500K | 1W | 100mA | 8.3-8.8V | 150-1601m | 151.8 | 8.66 | 175.27 | 6645 | 80.5 | 450.4 | |

| 6500K | 1W | 100mA | 8.3-8.8V | 150-1601m | 148.3 | 8.6 | 172.78 | 6755 | 80.9 | 450.4 | |

| 6500K | 1W | 100mA | 8.3-8.8V | 150-1601m | 145.8 | 8.61 | 169.51 | 6757 | 81.9 | 452.2 | |

| 6500K | 1W | 100mA | 8.3-8.8V | 150-1601m | 150.4 | 8.67 | 173.71 | 6417 | 80.1 | 451.4 | |

| Average Value | 149.46 | 8.632 | 173.29 | 6677.6 | 80.9 | 451.5 | |||||

Edge-lit LED Strip: Test Data for Light Output and Color Temperature of Bare Lamps/Lens/Potted Versions

| Edge-lit LED Strips:Bare/Lens/Potted Light Performance & Color Temperature Assessment | |||||||||||||

| Number | Length | LED Number | Input Voltage | Input Current | Power | Resistors | LED Current | Flux(Im) | Eff(Im/w) | Wave Length | Ra | CCT | Technology |

| 1 | 782mm | 14pcs | DC24V | 0.535A | 12.84W | 0.27+0.3Ω | 76.4mA | 1794.1 | 139.73 | 492.4nm | 80.00 | 6365K | Bare |

| 1736.0 | 135.17 | 492.4nm | 80.00 | 6365K | Lens | ||||||||

| 1804.7 | 139.25 | 493.6nm | 79.90 | 6293K | Potted | ||||||||

| 2 | 970mm | 20pcs | DC24V | 0.815A | 19.56W | 0.39+0.39Ω | 81.5mA | 2631.9 | 134.56 | 491.4nm | 80.30 | 6435K | Bare |

| 2588.0 | 133.11 | 491.4nm | 80.30 | 6435K | Lens | ||||||||

| 2646.0 | 132.19 | 494.3nm | 79.80 | 6273K | Potted | ||||||||

| 3 | 650mm | 14pcs | DC24V | 0.529A | 12.7W | 0.27+0.3Ω | 75.6mA | 1776.7 | 139.94 | 492.8nm | 80.10 | 6351K | Bare |

| 650mm | 14pcs | 0.529A | 12.7W | 1718.0 | 135.32 | 492.8nm | 80.10 | 6351k | Lens | ||||

| 13000m | 28pcs | 1.07A | 25.7W | 3520.6 | 136.97 | 494.5nm | 79.80 | 6266K | Potted | ||||

| 4 | 775mm | 16pcs | DC24V | 0.615A | 14.76W | 0.24+0.24Ω | 76.9mA | 2080.5 | 140.95 | 492.4nm | 80.10 | 6363K | Bare |

| 775mm | 16pcs | 0.615A | 14.76W | 2074.0 | 138.28 | 492.4nm | 80.10 | 6363K | Lens | ||||

| 1550mm | 32pcs | 1.28A | 30.72W | 4135.0 | 134.60 | 493.9nm | 79.90 | 6300K | Potted | ||||

Test Data Analysis

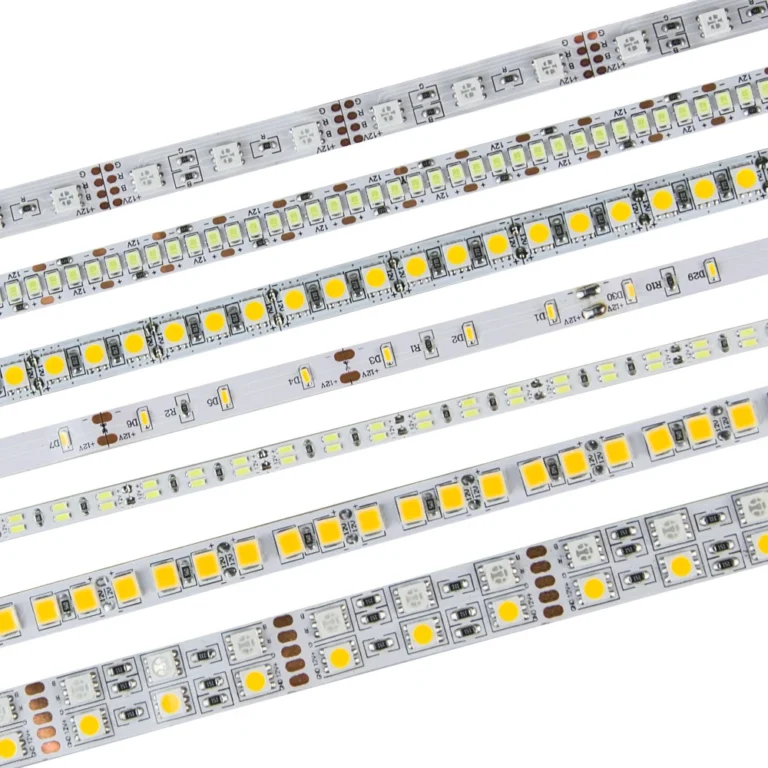

Below are the luminous efficacy, color temperature, and CRI data along with technical analysis for side-lit LED strips across three production stages: bare LED chip boards, LEDs with lenses, and lenses with potting compound:

1. Luminous Efficacy Variation

- Bare PCB → Lens: Four data sets were sampled: Set 1 showed a 3.3% efficacy drop, Set 2 a 1.1% drop, Set 3 a 3.3% drop, and Set 4 a 1.9% drop. The average efficacy reduction was approximately 2.4%.

- Lens → Potting: We extracted data from four groups: Group 1 showed a luminous efficacy decrease of approximately 0.34%, Group 2 decreased by 1.8%, Group 3 decreased by approximately 2.1%, and Group 4 decreased by approximately 4.5%. Taking the average, the luminous efficacy decrease was approximately 2.2%.

2. Color Temperature Changes

- Bare PCB → Lens: As shown in the charts above, the color temperature remains essentially unchanged when adding a lens to the bare PCB. This variation is negligible.

- Lens → Potting: Color temperature variation is also minimal. Groups 1, 3, and 4 show shifts of only about 80K. The largest change occurs in Group 2, where color temperature drops from 6435K to 6273K after encapsulation, a difference of 162K.

3. Color Rendering Index (CRI) Changes

- Bare PCB → Adding Lens: CRI remains unchanged.

- Adding Lens → Potting: Only a minor change of 0.1 to 0.2.

Summary

Test results are summarized in the table below: Effects of lensing and potting processes on luminous efficacy, color temperature, and CRI of side-lit light strips: Lensing reduces luminous efficacy by approximately 2.4%, with no change in color temperature or CRI. Potting with silicone reduces luminous efficacy by about 2.2%, lowers color temperature by 70-165K, and decreases CRI by 0.1-0.2.

| Production Chain | lm/W | CCT | Ra |

| Bare | 0 | 0 | 0 |

| Add Lens | Decreased ≈ 2.4% | The same value | The same value |

| Potting Silicone | Decreased ≈ 2.2% | Decreased 70-165K | Decreased 0.1-0.2 |