Ya sea que esté fabricando o comprando tiras de luz LED, es crucial comprender los fundamentos de los LED.

Como componente de emisión de luz central, las características de los LED determinan directamente el rendimiento de las tiras de luz. Para los fabricantes, este conocimiento guía la selección de chips LED, el diseño de circuitos y el control de procesos. Para los compradores, es clave distinguir entre productos de alta calidad y de baja calidad y evitar la trampa de las "especificaciones engañosas".

Solo entendiendo los principios subyacentes de los LED se puede garantizar que las tiras de luces LED cumplan con las expectativas en las métricas centrales, como el brillo, la eficiencia energética y la vida útil. A continuación, lo llevaré a través de algunos conocimientos básicos sobre LED.

¿Qué es un LED?

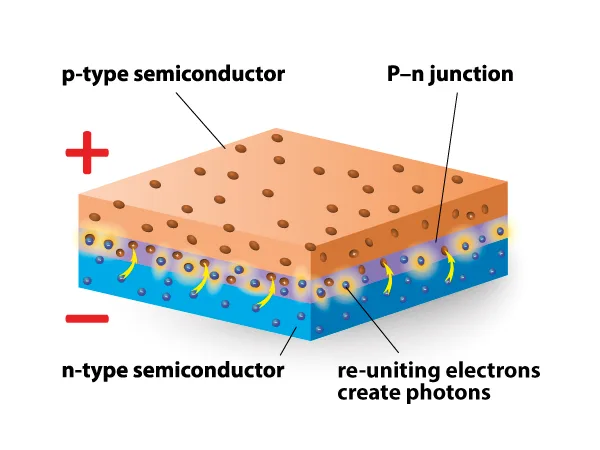

LED (diodo emisor de luz) es una fuente de luz de estado sólido semiconductor El chip semiconductor consta de dos partes: una es un semiconductor tipo p, donde dominan los agujeros y el otro es un semiconductor de tipo n, donde dominan los electrones. Cuando estos dos semiconductores están conectados, forman una unión P-N. Cuando la corriente fluye a través del cable y actúa sobre el chip, los electrones se empujan hacia la región de tipo p. En la región de tipo p, los electrones se recombinan con agujeros, liberando energía en forma de fotones. Este proceso es el principio detrás de la iluminación LED. La longitud de onda de la luz, que determina su color, está determinada por los materiales utilizados para formar la unión p-n.

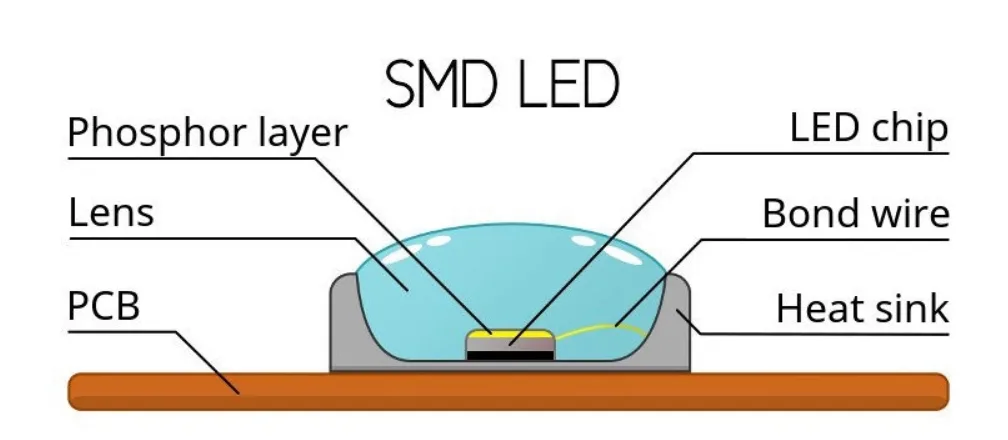

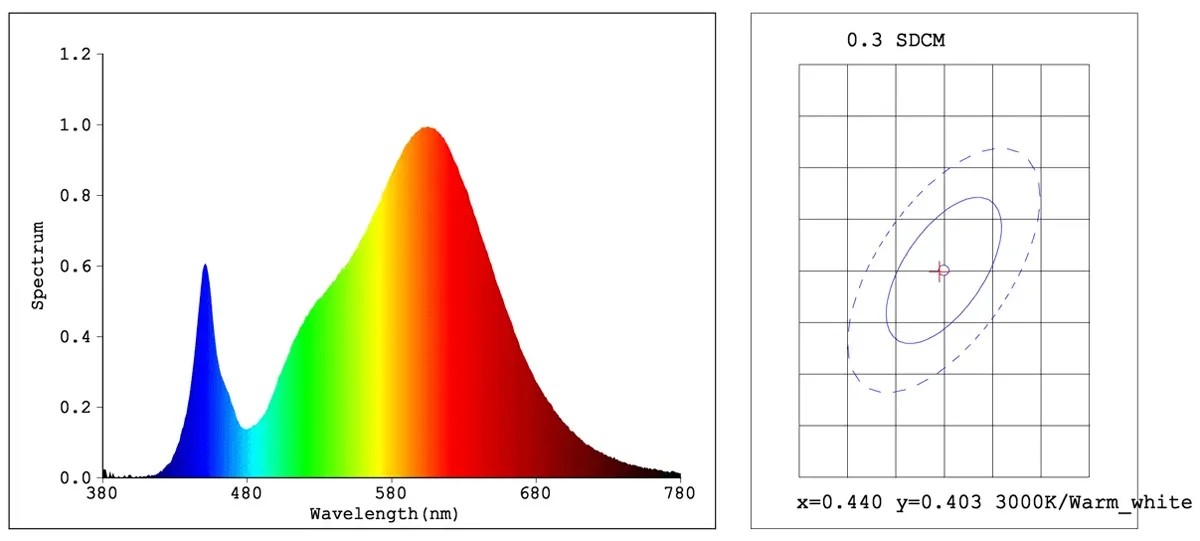

Los LED pueden emitir directamente luz roja, amarilla, azul, verde, cian, naranja, violeta y blanca. Un paquete LED es una carcasa de plástico que contiene un chip LED y un fósforo. El chip LED es un material semiconductor que emite luz (luz azul), mientras que el material de fósforo convierte parte de esta luz en longitudes de onda verdes y rojas. La luz blanca resultante se emite desde el paquete LED. El material de envasado juega un papel importante en la disipación de calor de los LED (por ejemplo, PPA, PCT y cerámica).

Las fuentes de luz LED ofrecen ventajas como la fuente de alimentación de bajo voltaje, bajo consumo de energía, alta adaptabilidad, alta estabilidad, corto tiempo de respuesta, respetuosidad del medio ambiente y emisión multicolor, lo que las convierte en una opción ideal para la iluminación moderna.

¿Cuáles son los principales tipos de envases LED?

Los formularios de empaquetado LED incluyen inmersión de orificio pasante, SMD de montaje en superficie y COB integrado.

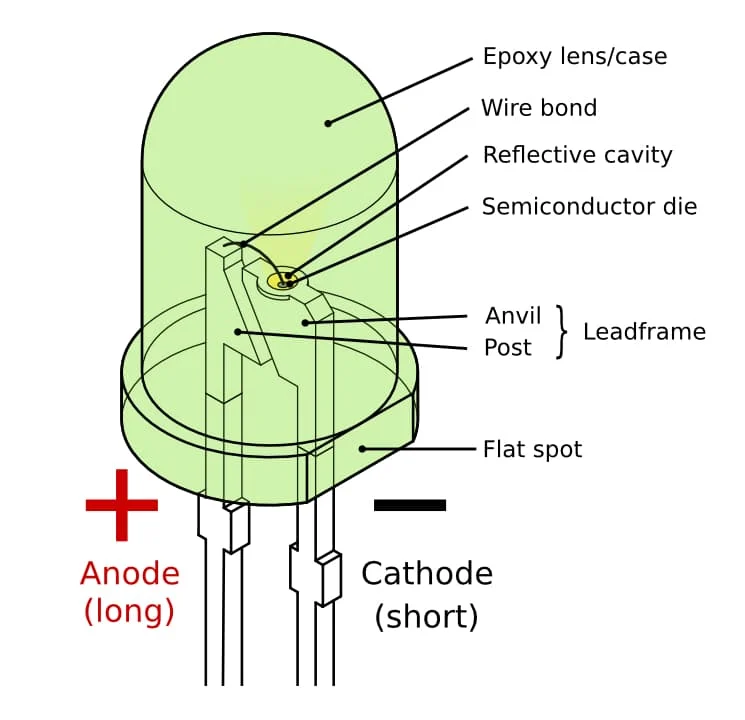

agujero (dip): El embalaje LED DIP tiene una forma cilíndrica con cables largos, con el chip ubicado dentro de la carcasa de plástico. Los LED DIP tienen dos cables metálicos paralelos. Si bien algunos productos todavía usan este diseño en la actualidad, en comparación con el empaque LED más nuevo, los LED DIP tienen una menor salida de luz e índice de reproducción de color. Estos LED se utilizan principalmente para luces de señalización y aplicaciones decorativas, como las cuerdas de luces navideñas. Sin embargo, tienen una disipación de calor deficiente y baja eficacia luminosa (<50 lm/W) y se están eliminando gradualmente.

Montado en superficie (SMD): Los LED SMD se desarrollaron después de los LED DIP. En comparación con los LED DIP, los LED SMD ofrecen una mayor eficacia luminosa y un menor consumo de energía. En comparación con los LED DIP, tienen un diseño más pequeño, menor altura, mayor vida útil, menor consumo de energía hasta 75% y menores costos de mantenimiento. Los tipos de montaje en superficie convencionales (como 2835, 3030, 5050, etc.) cuentan con un tamaño compacto, una disipación de calor superior y una eficiencia de luz >120 lm/W, lo que los hace ampliamente utilizados en iluminación. Para obtener más información sobre los LED SMD, lea el blog: SMD3528 vs SMD2835 vs SMD5050: ¿Qué tira de luz LED es la mejor para la iluminación comercial y arquitectónica?

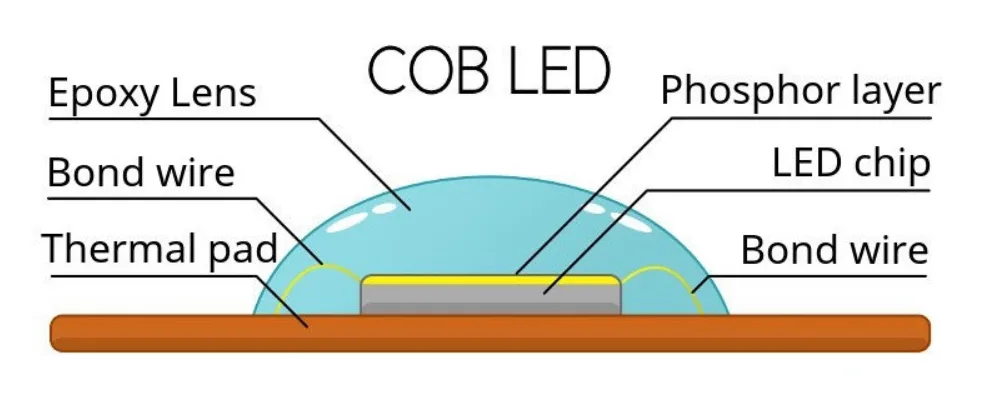

Integrado (COB): El envasado COB implica colocar varios chips (típicamente 9 o más) sobre un sustrato de aluminio, integrando más chips en un espacio limitado para lograr una mayor intensidad luminosa en un área más pequeña. Este diseño ocupa menos espacio y maximiza el potencial de iluminación. Esta tecnología elimina la necesidad de una base y soldadura, reduciendo el tiempo de montaje en casi un tercio y bajando los costos. Los tipos de COB se utilizan típicamente en accesorios de iluminación de alta eficiencia, como luces industriales, farolas, estacionamientos y espacios abiertos que requieren grandes áreas de iluminación. Debido a su alto brillo por unidad de área, también generan un calor significativo, por lo que deben usarse con grandes disipadores de calor. Para obtener más información sobre las diferencias entre los LED COB y los LED SMD, lea el blog: Diferencia entre LED SMD y LED COB: ¿Cuál es mejor?

¿Qué es el índice de representación de color (CRI)?

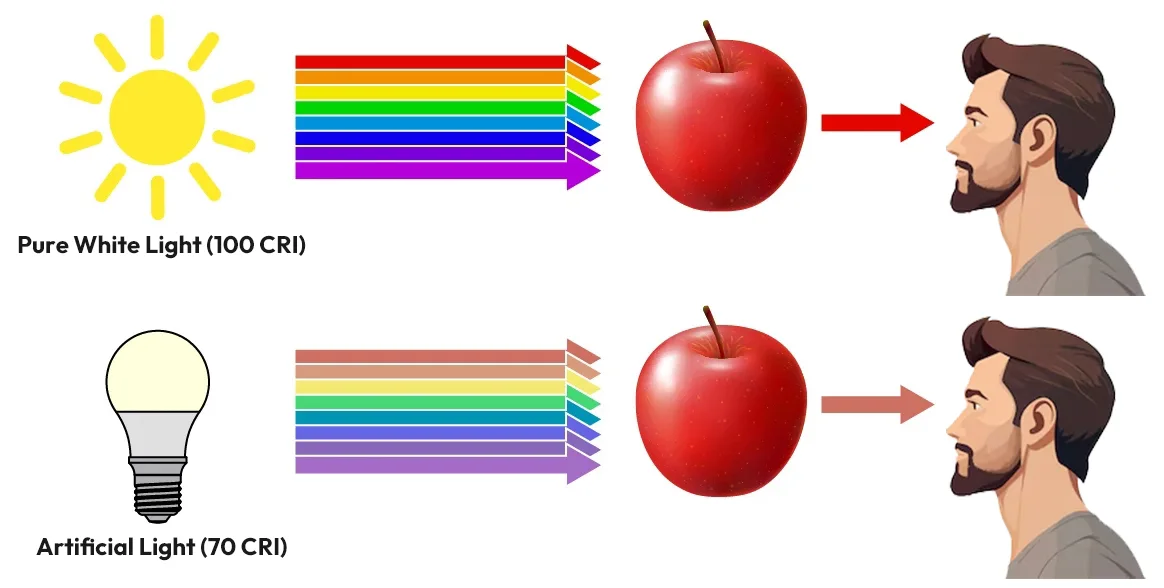

El Índice de representación de color (CRI) es una medida de la capacidad de una fuente de luz para reproducir con precisión los colores de los objetos. Describe principalmente qué tan cerca aparecen los colores de los objetos bajo una fuente de luz en comparación con sus colores bajo la luz natural (como la luz solar). Cuanto mayor sea el valor de CRI, más fuerte es la capacidad de la fuente de luz para reproducir colores, y más se asemejan los colores de los objetos bajo esa fuente de luz para parecerse a sus colores bajo la luz natural. Para más información sobre CRI, lea el blog: ¿Qué importancia tiene el índice de reproducción cromática de las tiras de luz LED?

Las fuentes de luz con la misma temperatura de color pueden tener diferentes composiciones espectrales. Las fuentes de luz con composiciones espectrales más amplias tienen más probabilidades de proporcionar una mejor calidad de representación del color. Cuando el espectro de una fuente de luz carece o tiene muy poca longitud de onda dominante reflejada por un objeto bajo una fuente de luz de referencia, puede causar diferencias de color significativas. Cuanto mayor sea la diferencia de color, más pobre es el rendimiento de reproducción de color de la fuente de luz para ese color. El coeficiente de CRI es un método ampliamente utilizado para evaluar el rendimiento de representación del color de una fuente de luz.

El CIE define el radiador Planckian como fuente de luz de referencia, configurando su índice de representación de color en 100 y especifica ocho muestras de color. Si, bajo una fuente de luz, el color de la muestra coincide con el de la fuente de luz de referencia, el índice de representación de color de la fuente de luz es 100; si el color cambia, el índice de representación de color de la fuente de luz es inferior a 100.

El índice de reproducción cromática es de gran importancia en el diseño de iluminación y las aplicaciones, particularmente en escenarios que requieren una reproducción precisa del color de los objetos, como galerías de arte, estudios de fotografía e instalaciones médicas. En estos ajustes, seleccionar fuentes de luz con altos índices de color garantiza la autenticidad y la precisión de los colores de los objetos. Es importante señalar que el índice de reproducción de color no es el único criterio para evaluar la calidad de la fuente de luz; se centra principalmente en la capacidad de la fuente de luz para reproducir colores. Al seleccionar una fuente de luz, también se deben considerar de manera integral otros factores como el brillo, la temperatura del color y la eficiencia energética.

¿Cuál es la temperatura de color?

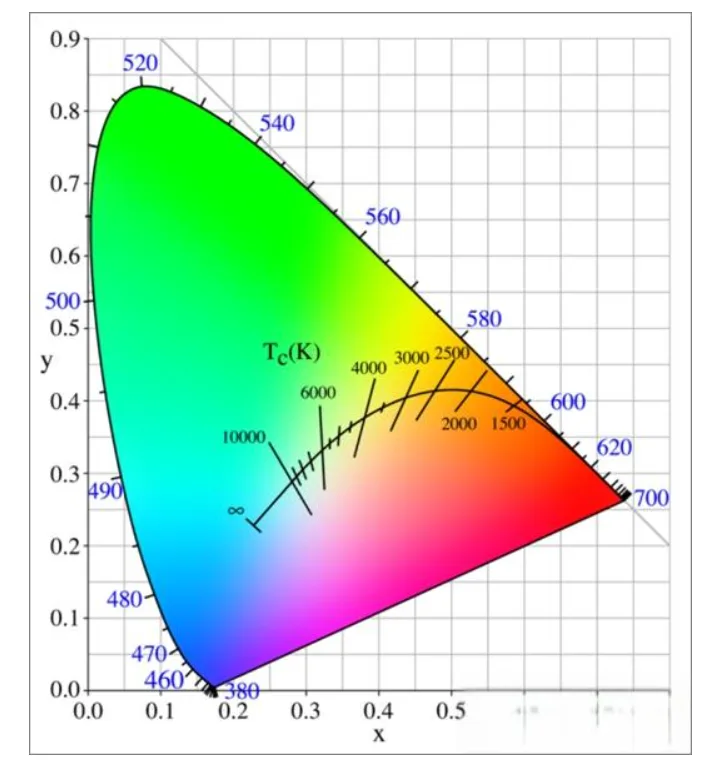

La temperatura del color es una unidad de medida que indica los componentes de color contenidos en la luz. Teóricamente, la temperatura de color de un cuerpo negro se refiere al color que presenta cuando se calienta desde cero absoluto (-273°C). Cuando el color de una fuente de luz coincide con el color de un cuerpo negro a una determinada temperatura, la temperatura absoluta de ese cuerpo negro se denomina temperatura de color de la fuente de luz. También se conoce como "temperatura colorimétrica". La unidad es Kelvin (K).

La gama de colores de la iluminación de uso común es de aproximadamente 2700K a 6500K. Cuanto menor sea el valor de la temperatura del color, más rojizo es el color; más alto es el valor, más azulado es el color; los valores intermedios aparecen más blancos. Las temperaturas de color entre 2200K y 3750K se denominan luz blanca cálida; 4000K a 5000K es blanco neutro; y 5700K a 8000K es una luz blanca fría.

1. Las coordenadas de color y temperatura de color tienen una relación de uno a varios; la misma temperatura de color puede tener diferentes valores de x e y.

2 . En otras palabras, solo puede llamarse temperatura de color cuando cae sobre la curva de radiación de cuerpo negro.

3. La misma temperatura de color puede producir diferentes percepciones de color.

Para más información sobre la temperatura de color, lea el blog:

3000K vs 4000K vs 5000K vs 6000K: ¿Cuál es la diferencia?

Comparación de la temperatura de color de la iluminación LED: 5000K vs. 6000K

Comparación de la temperatura de color de la iluminación LED: 4000K vs. 5000K

Comparación de la temperatura de color de la iluminación LED: 3000K vs. 4000K

Comparación de la temperatura de color de la iluminación LED: 2700K frente a 3000K

¿Qué es la temperatura de color correlacionada?

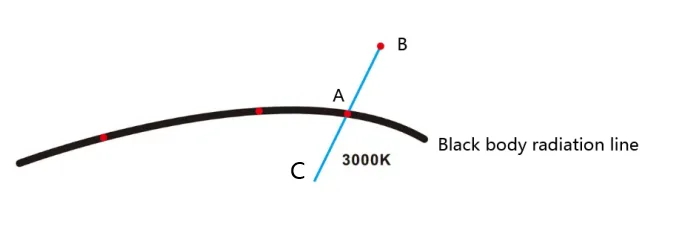

Cuando el punto de cromaticidad de una fuente de luz no está en la trayectoria del cuerpo negro, y la cromaticidad de la fuente de luz es más cercana a la de un cuerpo negro a una temperatura determinada, la temperatura absoluta de ese cuerpo negro es la temperatura de color correlacionada (CC) de la fuente de luz. La unidad es Kelvin (K).

En el uso diario, vemos los datos de prueba de instrumentos espectroscópicos. Esta es la temperatura de color correlacionada (CCT), no la temperatura del color. ¿Cuál es la diferencia entre ellos? Por supuesto, existe: la temperatura de color de una fuente de luz es la temperatura de un radiador de cuerpo negro ideal cuya luz emitida corresponde al color de la fuente de luz. En otras palabras, solo cuando cae sobre la línea de radiación de cuerpo negro se puede llamar temperatura de color.

La temperatura de color se define en la línea estándar, mientras que la temperatura de color correlacionada se define en relación con esta temperatura de color estándar. La luz blanca que producimos puede no alinearse exactamente con la línea de temperatura de color estándar; en cambio, encontramos el punto "más cercano" y leemos su temperatura de color, que se conoce como "temperatura de color correlacionada".

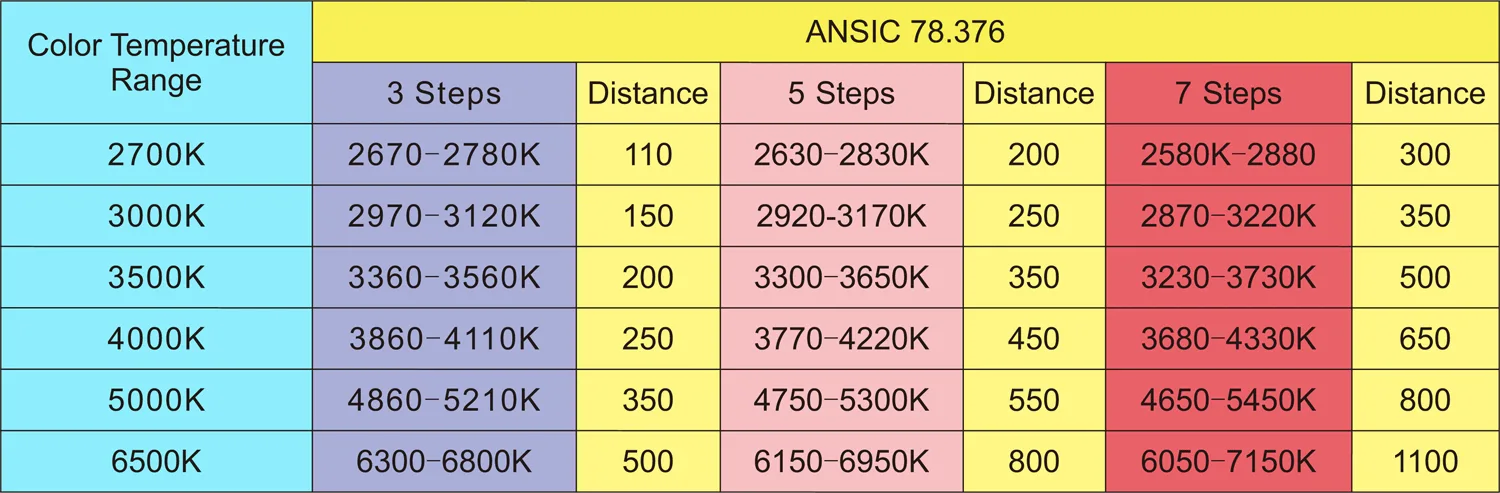

Por lo tanto, incluso si la temperatura de color correlacionada es la misma, como 3000K, si la tolerancia al color es de 7 pasos, el rango de temperatura del color puede ser de 2870-3220K, con una diferencia de casi 350K, lo que puede resultar en diferencias visuales significativas.

¿Qué es la tolerancia al color?

La tolerancia al color se utiliza para caracterizar la diferencia entre los valores de X e Y calculados por el software del sistema de medición de color y la fuente de luz estándar. Cuanto menor sea el valor, más cerca están las coordenadas de color del producto a los valores estándar. Cuanto menor sea la brecha entre el espectro de la fuente de luz y el espectro estándar, mayor será la precisión y más puro el color de la luz.

Puede que estés confundido: hay muchas combinaciones XY para la misma temperatura de color. ¿Qué temperatura de color y coordenadas cumplen con los requisitos de comodidad sensorial de la iluminación de estado sólido y el ojo humano? ¿Cómo se puede resolver este problema? Para abordar este problema, se debe introducir el concepto de tolerancia al color.

Debido a las diferentes densidades de fósforos rojo, verde y azul, las diferencias de temperatura del color pueden ocurrir fácilmente durante la producción. Una vez que surgen tales diferencias, deben ajustarse mediante la tolerancia al color para garantizar el color de la luz de la lámpara. Como fuente de iluminación, la iluminación LED blanca debe cumplir con los estándares de tolerancia al color para guiar el desarrollo y la aplicación de nuevas fuentes de iluminación LED blancas.

La relación entre la temperatura de color y la tolerancia al color

La temperatura de color es una unidad de medida que indica los componentes de color presentes en la luz. Teóricamente, la temperatura de color de un cuerpo negro se refiere al color que emite cuando se calienta desde cero absoluto (-273°C). Cuando un cuerpo negro se calienta a una determinada temperatura y el color de la luz que emite coincide con el color de la luz emitido por una fuente de luz específica, la temperatura a la que se calienta el cuerpo negro se denomina temperatura de color de esa fuente de luz, es decir, la temperatura del color, siendo la unidad de medida "K". Cuanto más pequeño es el valor, más rojizo el color; mayor el valor, más azulado el color; los valores intermedios tienden hacia el blanco. El rango de temperatura de color típico para la iluminación en uso normal es de aproximadamente 2700K a 6500K, correspondiente a la luz blanca cálida y la luz blanca neutra.

El espectro estándar cambia con la temperatura del color. Para la misma fuente de luz, si el espectro estándar difiere, la diferencia de color también varía. Sin embargo, durante la medición, un sistema de análisis de color de luz estándar generalmente identifica automáticamente el rango de temperatura de color de la fuente de luz medida para determinar el valor de temperatura del color del espectro estándar. A la misma temperatura de color, si el espectro estándar de referencia es consistente pero las coordenadas de color X e Y difieren, la diferencia de color también variará.

Las coordenadas de color y la diferencia de color están relacionadas. Las coordenadas de color se calculan en función de la tabla de colores, y la diferencia de color es la diferencia entre las coordenadas de color reales medidos y el estándar. La diferencia de color es la diferencia entre los valores X e Y del producto y los valores X e Y de la fuente de luz estándar. Cuanto menor sea la distancia, menor será el SDCM. Para más información sobre SDCM, lea el blog: Todo sobre SDCM para tiras de LED

Usamos SDCM para evaluar el color de la luz, entonces, ¿cómo medimos este parámetro? Por lo general, se puede usar un espectrofotómetro como el que se muestra en la siguiente figura para probar la temperatura de color y la diferencia de color.

Factores que afectan la tolerancia al color

1) Variación de chip: Los chips LED de diferentes lotes o modelos tienen diferencias inherentes en sus características emisoras de luz, lo que lleva a cambios en las coordenadas de color.

2) Influencia del proceso: Distribución desigual de fósforo causada por dispensación, con desviaciones de espesor de capa adhesiva que superan los 5%, reduce significativamente la consistencia de las coordenadas de color.

3) Efectos materiales: La composición del material, la relación y la uniformidad del recubrimiento de los fósforos afectan directamente la distribución espectral y la consistencia de la temperatura del color.

4) Efectos de instrumentación: Por ejemplo, las diferencias entre espectrofotómetros y esferas de integración, o entre diferentes modelos del mismo instrumento, pueden dar como resultado una variación de los resultados de la medición. Además, las discrepancias en los parámetros críticos establecidos por los clientes frente a los fabricantes de equipos originales (OEM), como los diferentes tiempos de integración para integrar esferas, también pueden introducir errores de medición.

5) Impacto de la gestión térmica: Si la gestión térmica de la lámpara es insuficiente, los aumentos de temperatura pueden causar una deriva de color. Los materiales emisores de luz LED exhiben características significativas dependientes de la temperatura; a medida que aumenta la temperatura de emisión, el espectro de emisión se desplaza hacia el rojo, el pico de emisión se ensancha y, a cierta temperatura, cesa la emisión. Para garantizar que la vida útil de la lámpara y el flujo luminoso cumplan con los requisitos, la temperatura de unión de la lámpara LED debe mantenerse dentro de un rango específico.

6) Efectos actuales: A medida que cambia la corriente de accionamiento, también se ven afectadas las propiedades del material emisor de luz. Cuanto mayor sea la estabilidad emisora de luz, menor será el efecto de temperatura de color y menor será la tolerancia del color.

¿Por qué las luces LED con la misma temperatura de color parecen tener diferentes colores?

Algunos se preguntan por qué, a pesar de tener la misma temperatura de color de 3000k, las luces muestran diferentes colores, lo que sugiere que las tolerancias de la temperatura del color pueden no abordar el problema de manera efectiva. De hecho, dentro del rango de tolerancia de temperatura de color especificado, los fabricantes de iluminación LED se han enfrentado constantemente a desafíos relacionados con la inconsistencia de la temperatura del color. Este fenómeno no solo se manifiesta como diferencias significativas de color a pesar de los valores de temperatura de color idénticos, conocidos como "mismo temperatura, color diferente", sino que también existe en los casos en que los colores son similares, sino que los valores de temperatura de color probados son muy diferentes, conocidos como "mismo color, diferente temperatura".

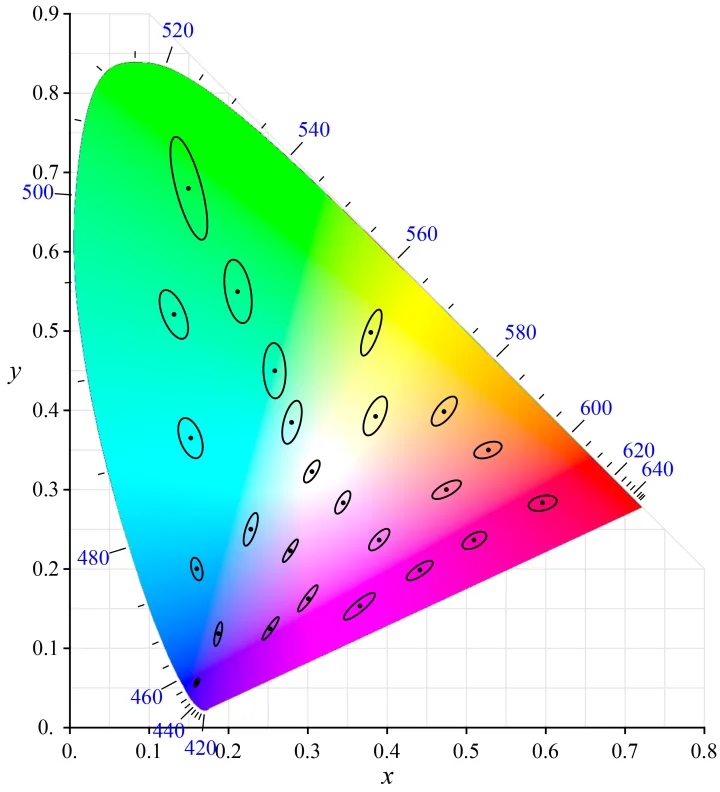

Como se muestra en la figura siguiente, los tres puntos A, B y C de la línea azul pertenecen a la misma temperatura de color de 3000K. El punto A es exactamente 3000 K de luz blanca cálida, mientras que el punto B es ligeramente verdoso a 3050 K, y el punto C es ligeramente rojizo a 2950 K. Difieren en aproximadamente 50K. Aunque la diferencia de temperatura del color no es significativa, los colores percibidos reales son distintos.

Además, a medida que disminuye la temperatura del color, los fenómenos de "mismo temperatura, diferente color" y "mismo color, diferente temperatura" se hacen cada vez más pronunciados. Por lo tanto, si desea que los colores de su producto logren consistencia, debemos usar Tolerancia de diferencia de color (SDCM) para abordar esto. Si el punto central del producto coincide con el punto central de la tolerancia de diferencia de color, entonces se puede usar la tolerancia de diferencia de color para caracterizar las diferencias de color; cuanto mayor sea la tolerancia de la diferencia de color, mayor será la diferencia de color.

Veamos primero la siguiente comparación de imágenes de diferencia de color para luces LED de temperatura de color de 3000K: Si las dos coordenadas de color caen dentro de una elipse de 2 pasos, el ojo humano apenas puede discernir la diferencia entre ellas. Si se trata de una elipse de 5 pasos, la diferencia de color se vuelve notable; si se trata de una elipse de 3 pasos, la diferencia entre el color de límite y el color central no es inmediatamente obvia de un vistazo. Por lo tanto, para la iluminación de temperatura de color de 3000 K, si el objetivo es lograr una diferencia de color casi cero, la tolerancia del color debería establecerse normalmente en 3 pasos.

Del análisis anterior, queda claro cuán importante es la diferencia de color. Si no se controla la diferencia de color, las tiras de luz LED producidas pueden mostrar un color inconsistente cuando se iluminan. Imagine una tira de luz lineal; si hay diferencias de color entre los LED, pueden ser detectados fácilmente por el ojo humano. Cuando el color de toda la tira de luz es inconsistente, se produce una experiencia de iluminación deficiente. Para lograr efectos de iluminación de alta calidad, debe comprar tiras de luz con mayor eficacia luminosa y valores SDCM más pequeños.

Estándares de tolerancia al color de la industria LED

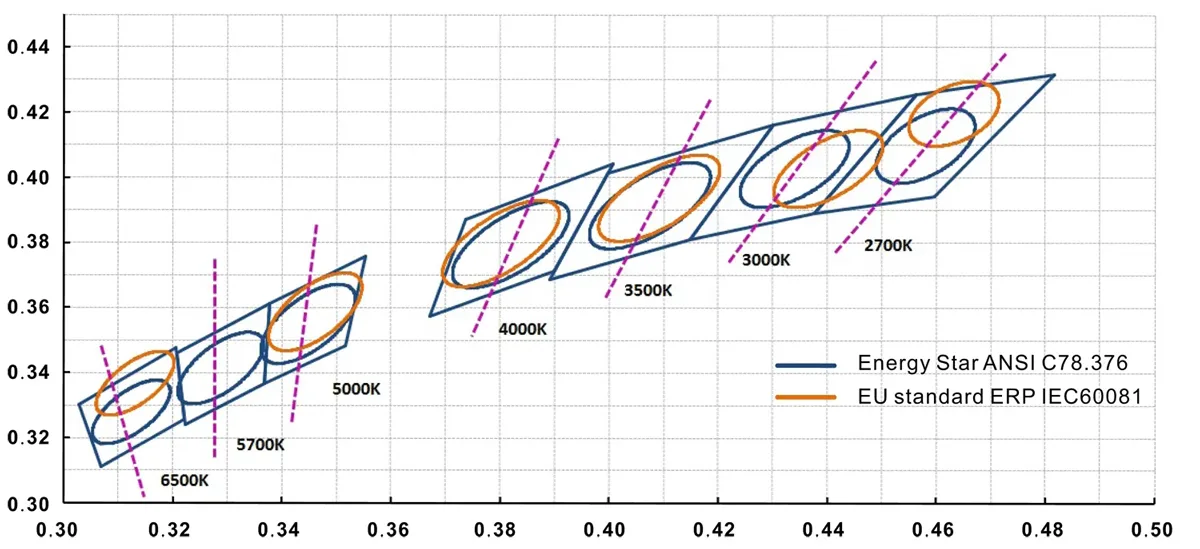

En 1942, el científico Macadam realizó experimentos en 25 colores utilizando principios relacionados, midiendo de 5 a 9 lados relativos de cada punto de color y registrando los dos puntos en los que podrían distinguir las diferencias de color. El resultado fue una elipse de diferente tamaño y longitud, conocida como la elipse de macadam.

Dentro de la elipse de macadam, aunque haya diferencias de color, nuestros ojos no pueden detectarlas. Sin embargo, una vez que el color cae fuera de esta elipse, podemos discernir fácilmente la diferencia de color. Por lo tanto, dentro de la elipse de macadam, podemos considerar que los colores de los puntos son consistentes.

El tamaño de la elipse de macadam también se conoce como la desviación estándar de la coincidencia de color (SDCM), una métrica importante para evaluar la consistencia del color. Al aumentar la proporción de los ejes mayores y menores de la elipse de macadam, podemos obtener elipses de macadam de diferentes órdenes, como el segundo orden, de tercer orden, etc. Estas elipses de diferentes pedidos nos brindan estándares más detallados para evaluar la consistencia del color.

1. Temperatura de color europea y americana Puntos estándar de coordinación X.Y

Los principales estándares de diferencia de color actualmente en uso son el estándar ANSI de América del Norte y el estándar europeo IEC. Los puntos centrales de diferencia de color correspondientes se resumen de la siguiente manera:

| Rango de temperatura de color | ANSI C78.376 | UE CEI60081 | ||||

| incógn | su | CCT | incógn | su | CCT | |

| 2700K | 0.4578 | 0.4101 | 2722k | 0.4630 | 0.4200 | 2726k |

| 3000K | 0.4338 | 0.4030 | 3041k | 0.4400 | 0.4030 | 2937k |

| 3500K | 0.4073 | 0.3917 | 3460k | 0.4090 | 0.3940 | 3443k |

| 4000K | 0.3818 | 0.3797 | 3985K | 0.3800 | 0.3800 | 4035k |

| 4500K | 0.3611 | 0.3658 | 4503k | — | — | — |

| 5000K | 0.3447 | 0.3553 | 5024k | 0.3460 | 0.3590 | 4988k |

| 5700k | 0.3287 | 0.3417 | 5665K | — | — | — |

| 6500K | 0.3123 | 0.3282 | 6531k | 0.3130 | 0.3370 | 6430K |

2. Energy Star y rangos estándar de diferencia de color europeo

● Energy Star ANSI C78.376, diferencia de color ≤7 SDCM, dividida en regiones según características LED.

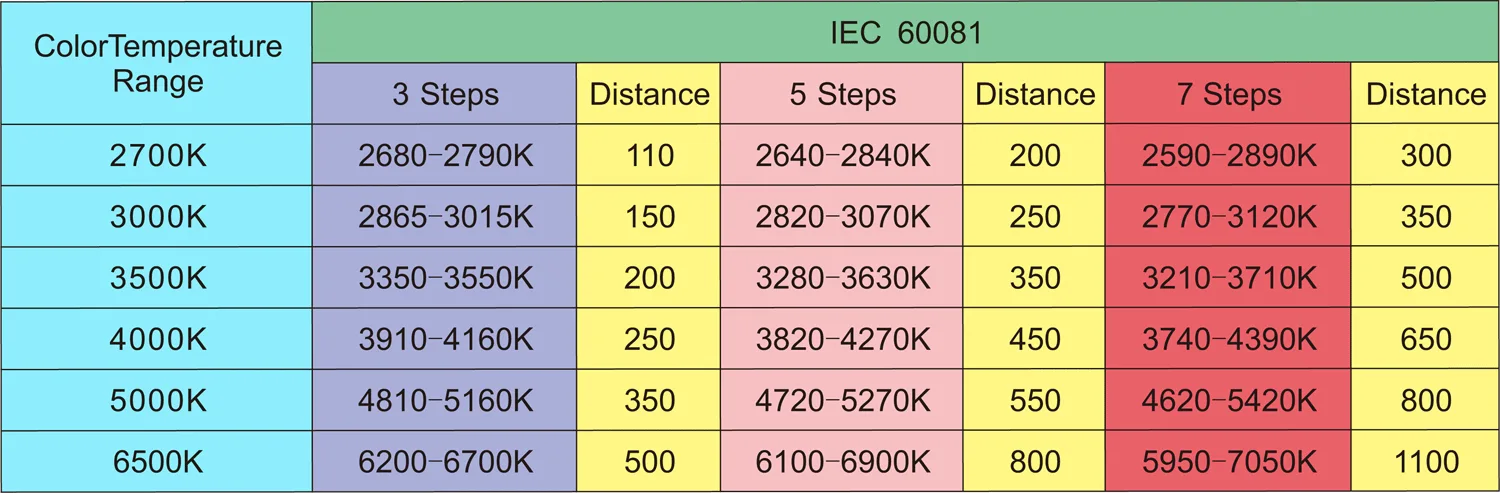

● Norma Europea IEC 60081 Norma, tolerancia al color ≤7 SDCM, con regiones LED definidas según requisitos técnicos luminosos.

Resumen

Después de la introducción anterior, creo que todos ahora tienen una mejor comprensión de la temperatura del color del LED.

SignLiteled es una empresa de alta tecnología especializada en la investigación, desarrollo y fabricación de tiras de luces LED, con innovación tecnológica y pruebas rigurosas como sus competencias básicas. La empresa cuenta con un sistema completo de I+D, asegurando que la desviación de la temperatura de color de todas las luces de tiras LED se controle dentro de 3 pasos para temperaturas de color cálidas y dentro de 5 pasos para temperaturas de color blanco frío.

Desde la selección de chips hasta el diseño del circuito del conductor, todo se controla internamente. La gama de productos incluye Tiras de luz LED flexibles, Tiras de luz LED COB, Tiras de luz de neón LEDy otras categorías de alto valor agregado. Al equipar a la empresa con espectrofotómetros, cámaras de prueba de temperatura y humedad constantes y otros dispositivos, ha establecido más de 20 estándares de prueba, incluidas las pruebas de antigüedad de 72 horas y las clasificaciones de impermeabilidad IP, para garantizar la estabilidad y la fiabilidad del rendimiento del producto. Si está interesado en estos productos, póngase en contacto con nuestro equipo de negocios.