En Iluminación de tiras LED proyectos, la elección de un perfil de aluminio no solo influye en la comodidad de la instalación sino también en el rendimiento térmico, la calidad de la luz y la vida útil. Por ejemplo, el aluminio 6063-T5, que se usa comúnmente en los perfiles LED, tiene una conductividad térmica de alrededor de 201 W/(m·k), más de 1000× más alta que la mayoría de los plásticos, lo que le permite transferir rápidamente los 8 a 10 W de calor generado por metro mediante una tira de LED de alta potencia (15 W/m). Sin una disipación adecuada, este calor puede empujar las temperaturas de PCB por encima de los 80 °C, lo que lleva a la depreciación del lumen, cambio de color y reducción de la vida útil de hasta 50%.

La selección del difusor juega un papel igualmente importante: un difusor mal emparejado puede causar deslumbramiento, luz desigual o salida reducida, que debilita la intención del diseño.

Para un desglose completo de las categorías de perfil, las características de rendimiento y los casos de uso, consulte nuestro Guía definitiva sobre perfiles de aluminio para tiras de luz LED. En esta guía, nos enfocamos en la disipación del calor y el diseño estético, proporcionando criterios de selección prácticos para diseñadores de iluminación, contratistas y compradores OEM que desean una máxima fiabilidad LED con un acabado limpio y profesional.

Problemas de calor de tira de LED

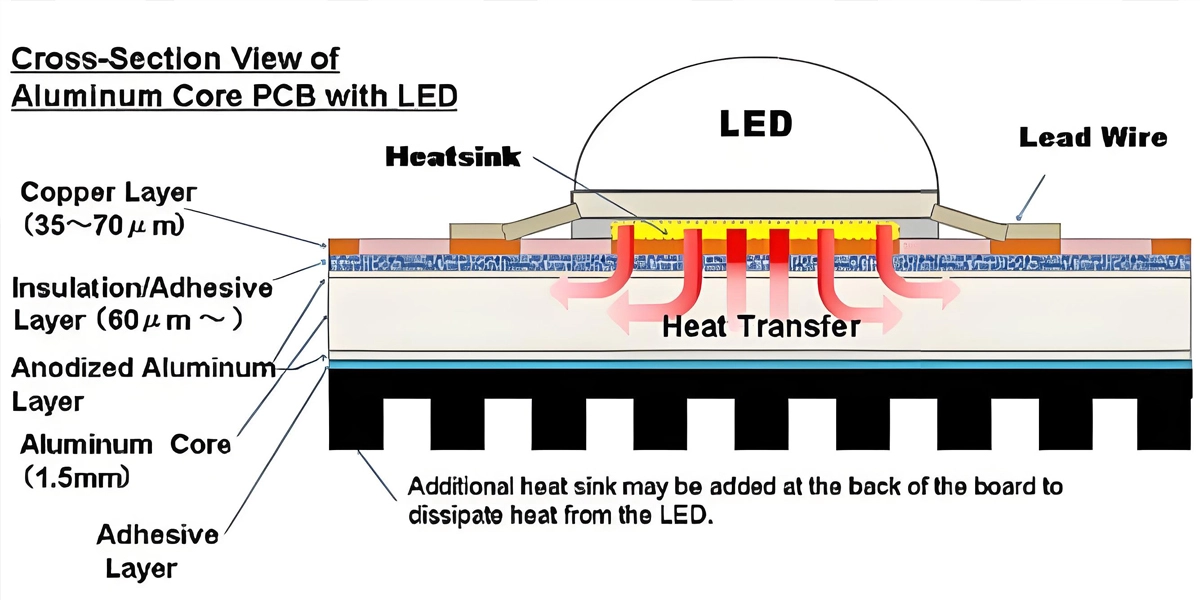

El calor es un subproducto inevitable de la operación de tiras de LED y su impacto se vuelve más crítico en los modelos de alta potencia (10–20 W/m). Solo entre 25 y 35% de la energía de entrada se convierte en luz; el resto se convierte en calor. Por ejemplo, una tira de LED de 15 W/m genera aproximadamente 10 W/m de carga térmica, que, si no se maneja, puede empujar las temperaturas de PCB más allá de los 80 °C. Esto puede acelerar la depreciación del lumen, causar un cambio de color notable y acortar la vida útil hasta 50%.

Los principales factores que contribuyen a la acumulación excesiva de calor incluyen:

Masa o conducción térmica inadecuada – Los perfiles de aluminio de baja calidad o con paredes delgadas (< 1 mm) transfieren el calor de manera menos eficaz. El uso de aluminio 6063-T5 (≈ 201 W/m·k conductividad térmica) mejora significativamente la eficiencia de transferencia de calor.

Restricciones del entorno de instalación – Calas cerradas, vitrinas selladas o altas temperaturas ambientales (> 35 °C) pueden reducir la disipación de calor al 20-30% En comparación con las instalaciones abiertas y ventiladas.

Funcionamiento continuo de alta potencia – Tiras de funcionamiento con brillo completo durante períodos prolongados sin una profundidad o aletas Extrusión de disipador de calor LED Puede conducir a temperaturas de unión inestables.

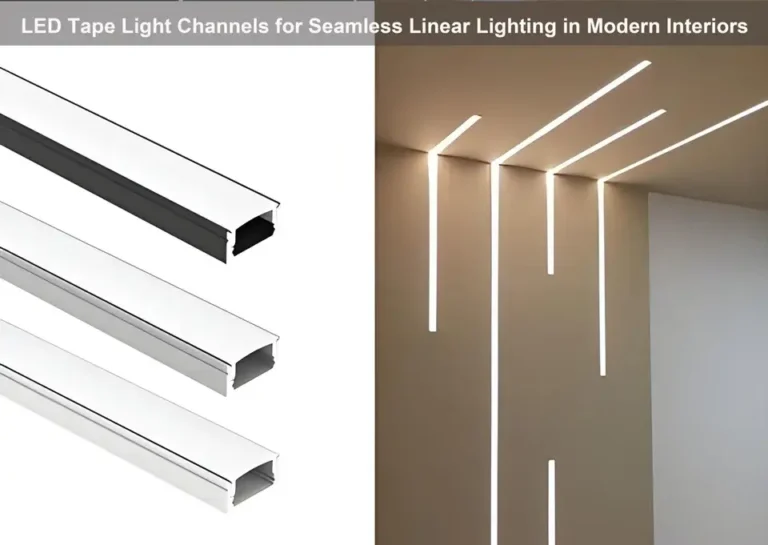

El diseño térmico efectivo significa seleccionar un perfil que coincida con la potencia de la tira, las dimensiones físicas y las condiciones ambientales. Para un desglose detallado de los tipos de canales, anchos y rendimiento de enfriamiento, consulte nuestro Guía completa de canales de luz de cinta LED.

Cinta de luz LED SMD2835

LED CANT. por metro Opción: 60/72/120/128/140

Opción de ancho de PCB: 6mm/8mm/10mm

Opción de color: 2700K-6500K

Opción CRI: 80/90/95

Voltaje de entrada: DC12V/DC24V

Potencia por metro: 6W/8W/9.6W/12W/14.4W/19.2W

Eficiencia: 100-200 lúmenes/vatio

Disipación de calor en perfiles de aluminio

Los perfiles de aluminio sirven como disipadores de calor pasivos, transfiriendo energía térmica desde el PCB LED al aire circundante. La eficiencia de este proceso puede medirse por la caída de temperatura lograda en funcionamiento continuo. Por ejemplo, la actualización de un perfil de pared delgada de 1 mm a un perfil de aluminio 6063-T5 de pared gruesa de 2 mm puede reducir la temperatura del PCB del LED en 6–8 °C a 15 W/m de carga, suficiente para extender la vida útil de L70 en 30 a 40%.

Parámetros clave que afectan la disipación:

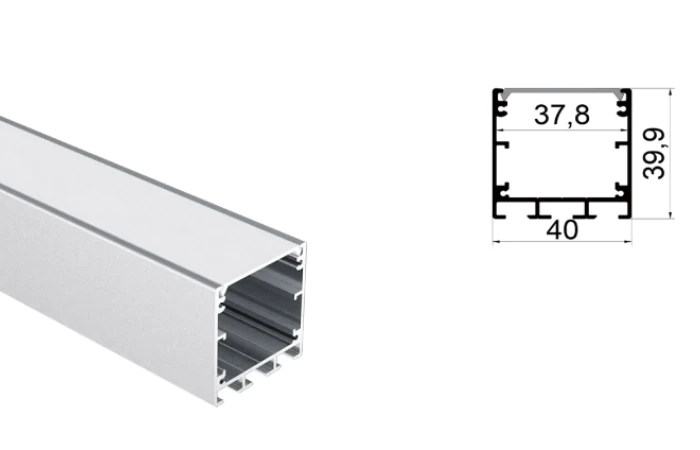

Espesor de la pared – Una sección transversal más gruesa aumenta la masa térmica. Se recomienda 2 mm o más para tiras ≥ 15 W/m.

Mejora de la superficie – Los perfiles con aletas pueden mejorar la transferencia de calor convectiva en 20–30% en comparación con los diseños planos.

grado de material – La aleación 6063-T5 (≈ 201 W/m·k) es estándar; evite el aluminio reciclado de baja calidad (< 150 W/m·k) que afecta la conducción.

Interfaz de montaje – La fijación directa a las superficies metálicas puede mejorar la disipación hasta en 15%, mientras que las superficies aislantes (madera/plástico) pueden reducirla en 10–20% a menos que se utilicen almohadillas térmicas.

Para tiras de LED de alta densidad en pantallas minoristas, vitrinas refrigeradas o iluminación de fachadas arquitectónicas, considere extrusiones de canales profundos o de múltiples aletas para una estabilidad térmica óptima. Las opciones detalladas de productos se pueden encontrar en nuestro Perfil de aluminio para iluminación de tiras LED.

Diseño de iluminación estética

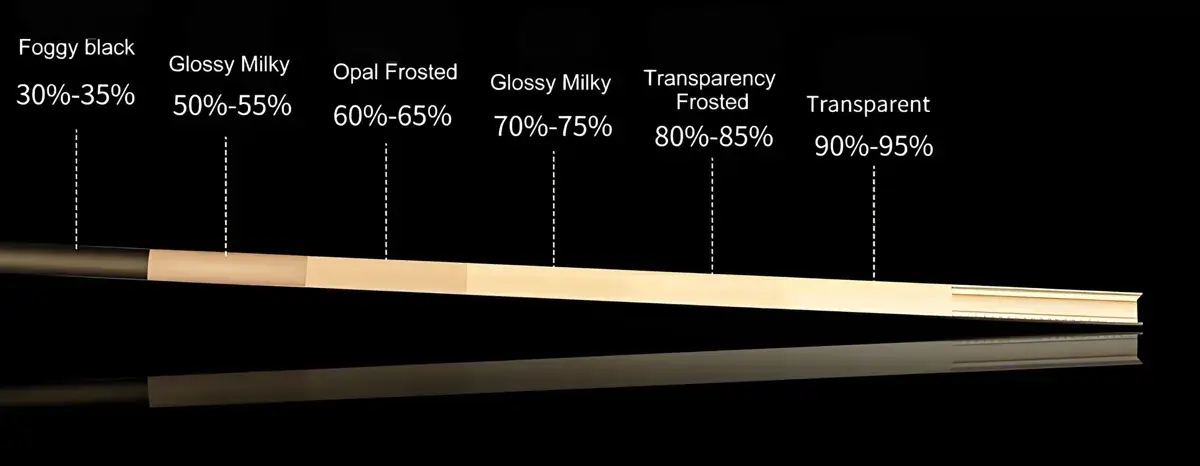

El diseño estético es más que elegir una "aspecto": afecta directamente la distribución de la luz, el control del deslumbramiento y la calidad percibida. El difusor integrado en el perfil de aluminio determina tanto el rendimiento óptico como el confort visual.

Tipos de difusores comunes y efectos ópticos:

Clear (transmisión de luz 92–95%): ofrece el máximo brillo pero deja visibles los "puntos de acceso" LED. Ideal para escaparates de joyería, exhibiciones de productos e iluminación de tareas donde la intensidad es más importante que la uniformidad.

Frosted (transmisión de luz 80–85%): ofrece un brillo equilibrado y un deslumbramiento reducido. Adecuado para escritorios de oficina, estanterías minoristas e iluminación debajo del gabinete.

Opal/Milky (transmisión de luz 65–75%): crea una iluminación suave y sin puntos con un excelente control de deslumbramiento. Lo mejor para calas residenciales, espacios de hospitalidad e iluminación ambiental.

Consejo: Las distancias más largas entre la tira de LED y el difusor (canales profundos) mejoran la uniformidad, especialmente para las densidades de LED más bajas (< 120 LED/m).

Para ver ejemplos de cómo la elección difusa da forma tanto a la función como al estado de ánimo, consulte nuestro Guía para perfiles de aluminio LED de esquina de 45° para tiras LED.

Guía de selección de perfiles de aluminio LED

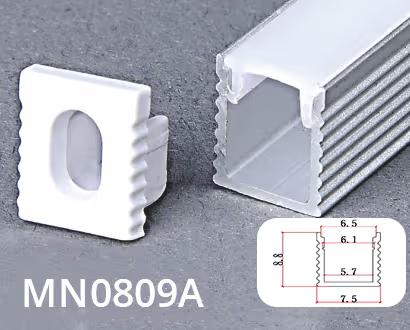

Seleccionar el perfil de aluminio adecuado requiere la capacidad térmica, el rendimiento óptico y la compatibilidad mecánica con la tira de LED y el sitio de instalación.

Criterios clave:

Potencia y densidad de tiras LED – Para ≥ 15 W/m o ≥ 120 LEDs/m, utilice perfiles profundos o con aletas con ≥ 2 mm de espesor de pared para mantener la temperatura de PCB < 70 °C.

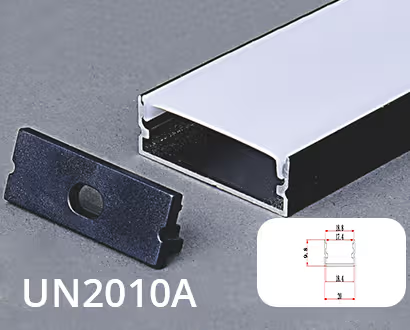

Perfil Ancho interno – Haga coincidir el ancho de la ranura interna con la PCB de la tira de LED (por ejemplo, 5 mm, 8 mm, 10 mm). Los canales de gran tamaño pueden causar derrame de luz; los canales de menor tamaño corren el riesgo de dañar la tira o reducir el contacto para la transferencia de calor.

Entorno de instalación – Las áreas exteriores o de alta humedad requieren extrusiones anodizadas o con clasificación IP67 con difusores de policarbonato resistentes a los rayos UV.

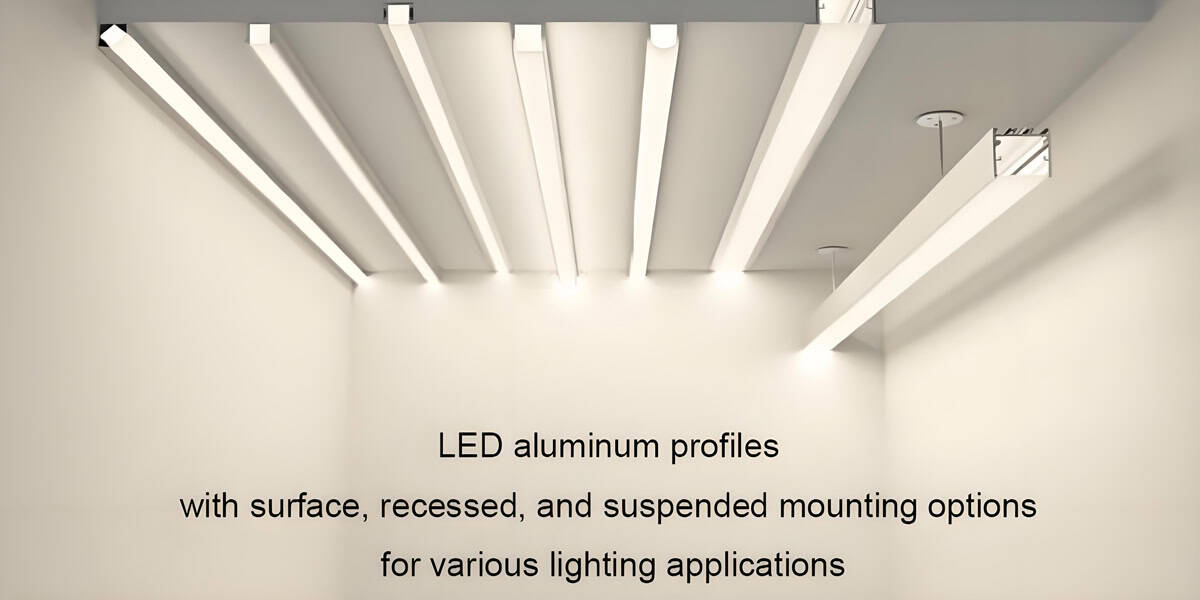

Método de montaje -

- Montado en superficie: la mejor conducción térmica si se fija al metal; puede requerir cinta térmica en madera/plástico.

- Empotrable: requiere recortes precisos (+1-2 mm de tolerancia); ofrece una apariencia de color al ras pero puede reducir el flujo de aire.

- Suspendido: estética moderna, pero conducción de calor reducida debido al aislamiento del aire: seleccione perfiles con más superficie.

- Esquina de 45°: optimizada para bordes de estante, gabinete e iluminación de acento en ángulo.

Consideraciones económicas – La actualización de un perfil estándar a un modelo con aletas puede aumentar el costo en 20–30%, pero puede prolongar la vida útil del LED en 30–40%, reduciendo los costos de reemplazo durante un período de 5 años.

Para obtener especificaciones de perfil y ejemplos de aplicación completos, consulte nuestro Perfil de aluminio para iluminación de tiras LED.

casos de estudio de casos

Los siguientes casos demuestran cómo seleccionar el perfil y el difusor de aluminio LED adecuados puede lograr una disipación de calor eficiente y efectos de iluminación atractivos.

Caso 1: iluminación de pantallas minoristas con perfiles de tira LED de alta CRI

Un minorista de joyería instaló tiras de LED CRI 95 de 15 W/m en un canal de aluminio de pared delgada de 1 mm con un difusor transparente. Después de 6 meses, el calor excesivo (PCB > 78 °C) provocó un cambio de color ΔU'V' de 0,004, notable para los clientes inspeccionando las piedras preciosas. La tienda se actualizó a un perfil de canal profundo de 2 mm de pared en aluminio 6063-T5, reduciendo la temperatura de PCB en 7–8 °C y restaurando el color preciso.

Caso 2 – Iluminación de la ensenada de oficina con perfiles de aluminio LED empotrados

Una oficina de planta abierta usaba tiras de 9,6 W/m y 4000K en perfiles empotrados con difusores esmerilados. La clasificación de deslumbramiento (UGR < 19) cumplió con los estándares de comodidad en el lugar de trabajo y las temperaturas de PCB permanecieron por debajo de 55 °C durante tres años, sin una depreciación de lumen visible.

Caso 3 – Cocina y Armario Residencial con Canales LED Difusos

Un propietario instaló tiras de 8 W/m en perfiles de montaje en superficie debajo de los armarios de la cocina y de las estanterías interiores del armario. La elección de difusores de ópalo eliminaron la detección de LED y crearon una luz uniforme. Los perfiles se fijaron a los paneles de aluminio para salpicaduras, mejorando la transferencia de calor y manteniendo un brillo estable en un espacio cálido y cerrado.

Caso 4 – Iluminación de fachadas exteriores en climas tropicales con perfiles IP67

Una fachada arquitectónica en el sudeste asiático contaba tiras de LED de 12 W/m con clasificación IP67 en perfiles de aluminio anodizados y resistentes a los rayos UV con difusores de ópalo. A pesar de que las temperaturas ambiente superan los 35 °C, la configuración mantuvo temperaturas de PCB por debajo de los 70 °C, evitando fallas prematuras. Para la selección de perfiles específicos de la fachada, consulte nuestro Guía definitiva sobre perfiles de aluminio para tiras de luz LED.

Conclusión

Los perfiles de aluminio no son solo accesorios de montaje, son sistemas de gestión térmica, moldeadores ópticos y potenciadores de diseño en uno. Elegir la extrusión adecuada para su vataje de tira de LED, entorno de instalación y requisitos de calidad de luz puede significar la diferencia entre una falla de 2 años y una vida útil de 50 000 horas.

La selección correcta mejora:

Estabilidad térmica: mantiene las temperaturas de unión en el rango seguro.

Calidad de la luz: controla el deslumbramiento, la difusión y la uniformidad.

Durabilidad: protege contra el polvo, la humedad y el impacto mecánico.

Eficiencia económica: reduce los costos de reemplazo y mantenimiento con el tiempo.

Ya sea que necesite un canal profundo para iluminación minorista de alta potencia, un perfil de esquina para vitrinas o una extrusión con clasificación IP67 para fachadas exteriores, nuestro equipo de ingeniería puede ayudarlo a seleccionar la solución más efectiva.

Obtenga una recomendación de perfil de aluminio a medida para su proyecto LED hoy: contacte a Signliteled o explore nuestro Perfil de aluminio para iluminación de tiras LED rango.

Me encantó tanto como lo recibirás aquí mismo El boceto es atractivo Tu material de autor Elegante Sin embargo, ordenas que te compre un nerviosismo sobre el que deseas entregar lo siguiente Incuestionablemente, vuelve más antes de la misma manera, casi lo mismo, casi lo mismo, muchas veces en caso de que protejas esta caminata.

Alguien esencialmente ayuda a hacer significativamente los artículos de identificación. Esta es la primera vez que frecuentaba su página web y hasta ahora me sorprendió con la investigación que hizo para hacer esta publicación real. Increíble y fantástico trabajo.