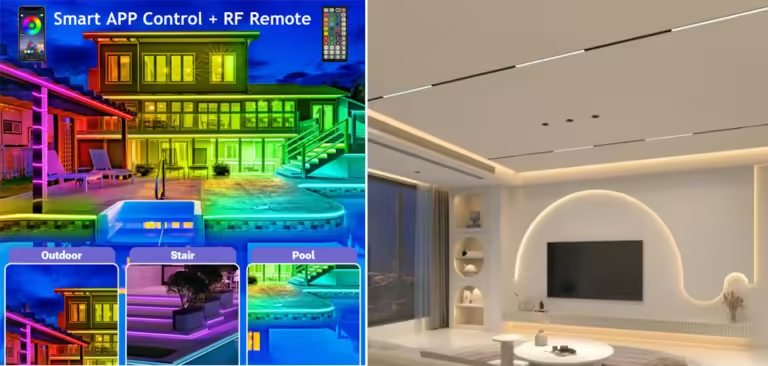

Las luces LED de neón son ampliamente utilizadas en la iluminación arquitectónica, la decoración comercial y los proyectos de señalización debido a su flexibilidad y vibrante impacto visual. Sin embargo, cuando las dimensiones reales del neón difieren significativamente de las especificaciones nominales, puede crear serios desafíos de instalación. Este problema se vuelve aún más crítico en los proyectos donde los clientes preparan espacios de instalación de manera estricta en base a las dimensiones especificadas. Un desajuste de unos pocos milímetros puede conducir a la falta de ajuste y visibles, o incluso a la incompatibilidad estructural. Por esta razón, la tolerancia a la extrusión, la variación dimensional inherente al proceso de extrusión, juega un papel crucial para garantizar la consistencia del producto y la instalación perfecta en aplicaciones de neón LED profesionales.

¿Por qué las luces de neón LED tienen tolerancias dimensionales?

Propiedades del material

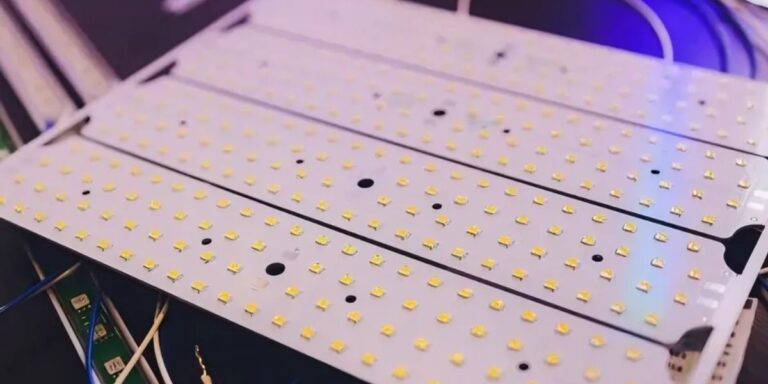

El factor más fundamental que influye en la tolerancia dimensional en Luces LED de neón es la materia prima. Los perfiles de neón flexibles suelen estar hechos de silicona o PVC, los cuales están sujetos a expansión y contracción térmica. Incluso los ligeros cambios de temperatura durante la producción o más adelante en la aplicación pueden causar variaciones en el ancho, altura o curvatura de la extrusión. Las diferencias en la dureza del material o la formulación entre lotes también pueden dar lugar a dimensiones inconsistentes, lo que hace que la estabilidad del material sea un elemento crítico en el control de la tolerancia.

Luz de neón de silicona

Luz de neón de PVC

Control de procesos de extrusión

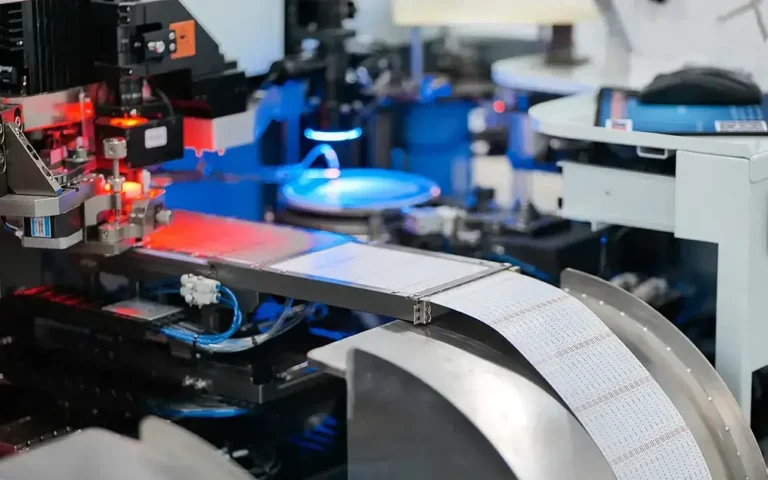

El proceso de extrusión en sí es otra fuente importante de variación dimensional. La precisión depende en gran medida de la precisión del molde de extrusión, así como de la consistencia de la temperatura, la presión y la velocidad de extrusión. Por ejemplo, si las condiciones de enfriamiento son inestables, como el enfriamiento por agua inconsistente o el flujo de aire, el perfil puede encogerse o deformarse de manera desigual. Estas pequeñas desviaciones pueden acumularse, lo que resulta en un producto final que queda fuera del rango de tolerancia especificado.

Variabilidad de lotes de producción

Incluso con el mismo molde y material, la tolerancia dimensional puede variar entre lotes de producción. Factores como la calibración de la máquina, los ajustes del operador y las condiciones ambientales como la humedad pueden influir sutilmente en el resultado. En grandes volúmenes de producción, estas variaciones pueden afectar directamente la compatibilidad de LED Neon con canales de montaje y accesorios.

Presión de precio y costo

Otro factor que a menudo se pasa por alto es el precio. En mercados altamente competitivos, algunos proveedores de bajo costo pueden comprometer la calidad del material o reducir los pasos de producción para reducir los costos. El uso de silicona más barata, PVC reciclado o equipo de extrusión menos preciso aumenta inevitablemente la variación dimensional. Si bien el precio inicial puede ser atractivo, el riesgo a largo plazo de un ajuste deficiente, una vida útil más baja y costos de mantenimiento más altos hacen que tales compromisos sean costosos para proyectos profesionales.

Rangos de tolerancia comunes para extrusión de neón LED

Estándares de tolerancia de la

En la industria de neón LED, la tolerancia a la extrusión generalmente se define dentro de un pequeño margen para garantizar un ajuste fiable y una apariencia uniforme. La mayoría de los fabricantes adoptan una tolerancia dimensional entre ±0,3 mm y ±1,0 mm, dependiendo del tamaño y la forma del perfil. Si bien no existe un estándar global único, estos rangos generalmente se aceptan en proyectos profesionales en aplicaciones de arquitectura y señalización.

Diferencias entre los tipos de emisión de luz

Los requisitos de tolerancia también pueden variar con diferentes estructuras de emisión. El neón emisor de frente tiene un control más estricto ya que la superficie visible afecta directamente la uniformidad de la iluminación, mientras que los tipos de flexión de neón y flexión superior permiten una tolerancia ligeramente más amplia debido a la flexibilidad estructural. Los perfiles de cobertura más grandes, como los neón que emiten 270° o 360°, requieren un monitoreo más detallado durante la extrusión porque los cambios dimensionales afectan tanto la distribución de la luz como la estabilidad de la instalación.

Rangos de tolerancia típicos por tamaño y tipo de neón

| Tipo de neón LED | Tamaño común (W×H o diámetro) | Tolerancia típica de extrusión |

| Mini Neón (delgado) | 4×8 mm | ±0,3 mm |

| Mini neón emisor lateral | 6×12 mm | ±0,4 mm |

| Emisor de frente estándar | 8×16 mm | ±0,5 mm |

| Emisor lateral estándar | 10×20 mm | ±0,5 mm |

| Neón de primera curva | 12×20 mm | ±0,5 mm |

| Neón de emisión frontal amplia | 12×25 mm | ±0,6 mm |

| Neón redondo de 270° | Ø16 mm | ±0,6 mm |

| Grande neón de 270° | Ø20 mm | ±0,8 mm |

| Neón flexible de 360° (pequeño) | Ø15 mm | ±0,5 mm |

| Neón flexible de 360° (grande) | Ø25 mm | ±1,0 mm |

Cómo afecta la tolerancia dimensional a las aplicaciones de neón

1. Desafíos de instalación

Cuando la tolerancia a la extrusión de las luces LED de neón no está bien controlada, la instalación se vuelve problemática. Incluso las ligeras variaciones dimensionales pueden hacer que el perfil sea demasiado apretado o demasiado flojo dentro de los canales de aluminio o de las ranuras de montaje. Esto a menudo conduce a brechas visibles, alineación desigual o aumento del trabajo durante el ajuste en el sitio. Para proyectos arquitectónicos a gran escala, las dimensiones consistentes son esenciales para lograr una instalación perfecta y reducir el retrabajo.

2. Impacto en la uniformidad de la luz

La tolerancia a la extrusión también afecta la uniformidad de la salida de luz. Las variaciones en el espesor de la encapsulación de silicona o PVC pueden provocar una difusión inconsistente, dando lugar a áreas que parecen más brillantes o más tenues. En el neón emisor de frente, esta distribución de luz desigual se vuelve especialmente notable, reduciendo la calidad visual general de la instalación.

3. Clasificación y fiabilidad de la impermeabilidad

Los problemas de tolerancia influyen aún más en la impermeabilización y la fiabilidad a largo plazo de los productos LED Neon. Si las dimensiones del perfil se desvían del rango especificado, es posible que el sellado alrededor de las tapas, conectores o juntas de los extremos no sea completamente efectivo. Esto compromete la clasificación de IP y aumenta el riesgo de entrada de agua, lo que puede acortar la vida útil del producto y causar fallas en aplicaciones al aire libre.

Cómo controlar y resolver problemas de tolerancia en luces de neón LED

1. Optimización del proceso de fabricación

El primer paso para reducir la tolerancia a la extrusión es el control preciso del proceso de fabricación. Los moldes de alta precisión, la velocidad de extrusión estable y la regulación adecuada de la temperatura juegan un papel vital en el mantenimiento de dimensiones consistentes. El mantenimiento y la calibración regulares de los equipos de extrusión garantizan aún más la precisión.

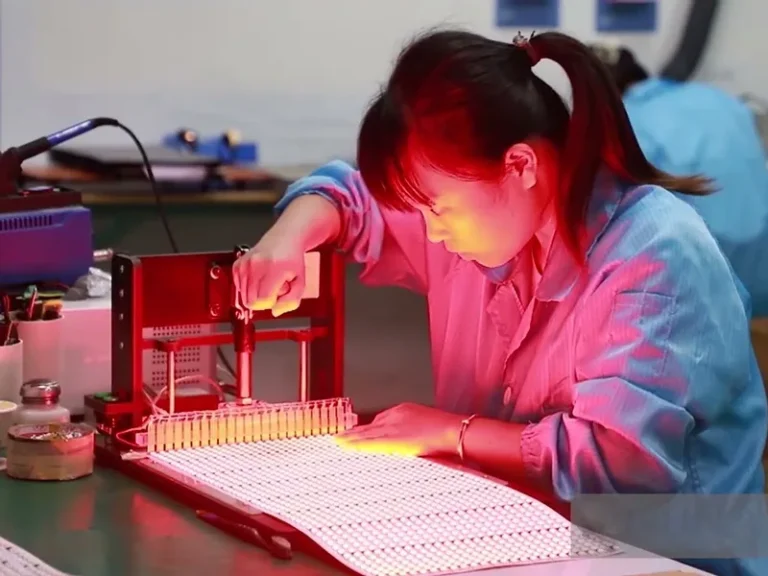

2 Medidas de control de calidad

El estricto control de calidad es igualmente importante. Los fabricantes deben implementar el monitoreo en línea durante la extrusión y realizar inspecciones dimensionales finales en luces de neón LED terminadas. La grabación de datos de tolerancia ayuda a detectar tendencias y a evitar que los lotes defectuosos lleguen a los clientes.

3. Consideraciones sobre el diseño y la instalación del proyecto

Desde la perspectiva del proyecto, los diseñadores e instaladores pueden minimizar los riesgos al permitir márgenes de tolerancia en tamaños de ranuras, canales de aluminio y accesorios. La planificación con las variaciones de extrusión en mente garantiza una instalación más suave en el sitio y reduce los ajustes inesperados.

4. Elegir un proveedor confiable

Finalmente, es fundamental seleccionar un proveedor con experiencia comprobada en tolerancia a la extrusión de neón LED. Los fabricantes profesionales con equipos avanzados, certificación y un sistema de calidad fuerte proporcionan productos más estables, lo que brinda a los propietarios de proyectos confianza en el rendimiento a largo plazo.

Conclusión: garantizar la coherencia en los proyectos de neón dirigidos por profesionales

La tolerancia dimensional es un factor inevitable en la fabricación de luces de neón LED, pero con los materiales adecuados, el estricto control de extrusión y la gestión de la calidad profesional, se puede minimizar de manera efectiva. Para arquitectos, diseñadores y contratistas, trabajar con un proveedor confiable es la clave para garantizar una instalación sin problemas y un rendimiento a largo plazo.

En SignliteLED, utilizamos silicona ahumada de alta calidad en toda nuestra extrusión de neón, garantizando dimensiones estables que cumplen plenamente con los estándares de tolerancia de la industria. Si su proyecto requiere tamaños únicos o tolerancias más estrictas, nuestro equipo puede proporcionar soluciones personalizadas para adaptarse a sus especificaciones exactas. Contáctenos hoy para discutir sus requisitos y asegurar luces de neón LED de alta calidad a medida para aplicaciones profesionales.