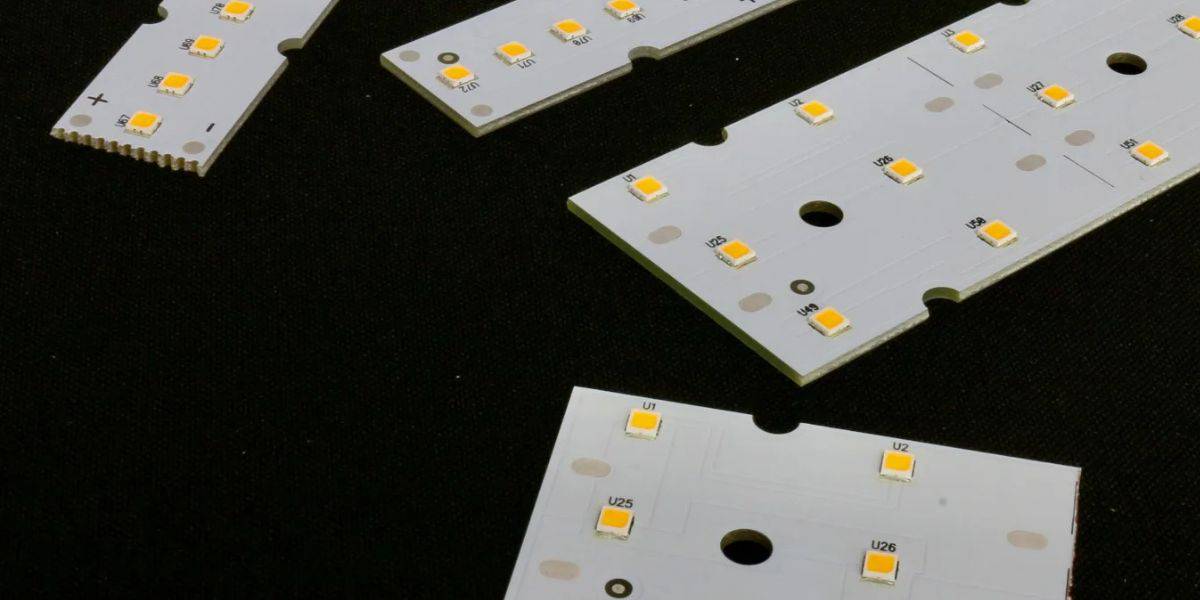

Un socio de ensamblaje de PCB LED confiable es aquel que puede colocar LED de manera consistente con alta precisión, administrar el calor a nivel de placa y ofrecer resultados repetibles en prototipos y series de producción. El ensamblaje de PCB LED es más complejo que el SMT estándar porque los pequeños errores de colocación, la mala gestión térmica o la variación de los componentes pueden reducir directamente la salida de luz y la vida útil. La fiabilidad en este contexto significa control de procesos, calidad predecible y transparencia de la decisión en lugar de la velocidad o el precio solo.

Las 10 preguntas clave para evaluar un socio de ensamblaje de PCB LED SMT

1 — ¿Qué experiencia tienes con PCB LED y placas de metal-core?

La experiencia directa con los PCB LED es importante porque los ensamblajes de LED se comportan de manera diferente bajo el estrés del calor y la corriente. Un socio familiarizado con el aluminio y otras placas de metal con núcleo entiende cómo el diseño, los perfiles de soldadura y el manejo afectan las trayectorias térmicas. Sin esta experiencia, incluso un fabricante de PCB personalizado capaz puede subestimar los riesgos específicos de LED, lo que provoca fallas tempranas o un rendimiento óptico inconsistente.

2 — ¿Qué equipo SMT utiliza para la precisión de la colocación de LED?

La fiabilidad del LED depende de la colocación y orientación precisas, especialmente para los arreglos de alta densidad y los módulos lineales. El equipo SMT adecuado garantiza una alineación consistente, control de volumen de soldadura y una reelaboración mínima. Esta pregunta le ayuda a evaluar si un fabricante de PCB personalizado puede mantener la precisión de la colocación a escala o si la calidad variará entre lotes, lo que aumenta el riesgo de fallas de campo.

3 — ¿Cómo se gestiona el rendimiento térmico durante el ensamblaje de PCB LED?

La gestión térmica es fundamental para la vida útil del LED y la estabilidad del color. Un socio confiable considera el calor durante la soldadura, el accesorio de componentes y el manejo posterior al ensamblaje. Esta pregunta revela si el control térmico se trata como una preocupación a nivel de sistema o una ocurrencia tardía. Las prácticas térmicas deficientes durante el ensamblaje pueden negar incluso un diseño personalizado de PCB bien diseñado.

4 — ¿Qué procesos de inspección y control de calidad aplica?

La inspección no se trata solo de detectar defectos obvios, sino de detectar problemas sutiles que afectan el rendimiento de los LED a lo largo del tiempo. El control de calidad constante ayuda a prevenir fallas latentes causadas por los huecos de soldadura o desalineación. Esta pregunta lo ayuda a comparar socios en función de la disciplina del proceso en lugar de las promesas, especialmente al evaluar el ensamblaje de PCB personalizado para sistemas de iluminación de misión crítica.

5 — ¿Cómo maneja la consistencia de los binning y los componentes de LED?

El binning de LED afecta el brillo, la temperatura del color y la uniformidad visual. Un socio confiable tiene procesos para gestionar la variación de componentes y mantener la coherencia dentro de un solo tablero y en los lotes de producción. Esta pregunta es esencial para aplicaciones donde las diferencias visuales son inaceptables y donde el abastecimiento inconsistente puede socavar un proceso de ensamblaje sólido.

6 — ¿Puedes soportar tanto la creación de prototipos como la producción de volumen?

La capacidad de pasar del prototipo al volumen sin cambiar de pareja reduce el riesgo y la falta de comunicación. Esta pregunta evalúa si los mismos estándares y controles se aplican a diferentes escalas. Para los proyectos LED, las inconsistencias entre las primeras construcciones y la producción en masa a menudo se remontan a los socios que tratan el prototipo y el volumen como procesos no relacionados.

7 — ¿Cuál es su tiempo de entrega típico y la confiabilidad de la programación?

La confiabilidad del tiempo de entrega es más importante que la velocidad nominal en los proyectos de PCB LED vinculados a los horarios de instalación. Esta pregunta le ayuda a comprender qué tan bien un socio planifica la capacidad y gestiona el cambio. Los horarios perdidos pueden forzar decisiones apresuradas o sustituciones que afectan el rendimiento de los LED, incluso cuando se trabaja con un experimentado Fabricante de PCB personalizado.

8 — ¿Cómo proporciona comentarios DFM para proyectos de PCB LED?

El diseño para la fabricación de capacidad La retroalimentación es fundamental en los ensamblajes de LED porque las decisiones de diseño pequeños afectan el flujo de calor y el rendimiento de colocación. Un socio confiable ofrece comentarios tempranos claros y enfocados en la reducción de riesgos en lugar de comentarios genéricos. Esta pregunta muestra si DFM se utiliza como herramienta de decisión o se trata como una formalidad en los flujos de trabajo de ensamblaje de PCB personalizado.

9 — ¿Cómo gestiona los riesgos de la cadena de suministro y el abastecimiento de componentes?

Los componentes LED son sensibles a sustituciones y escasez. Un socio confiable tiene procesos definidos para el abastecimiento, la trazabilidad y la notificación de cambios. Esta pregunta lo ayuda a evaluar cómo se manejan las interrupciones del suministro y si se le informará antes de que las decisiones afecten el rendimiento o el cumplimiento de los proyectos personalizados de PCB.

10 — ¿Qué tipo de comunicación, documentación y apoyo posterior a la asamblea proporciona?

La comunicación clara reduce el riesgo a lo largo del ciclo de vida del proyecto. Esta pregunta evalúa cómo se documentan los problemas, cómo se aprueban los cambios y cómo se manejan las preguntas posteriores al ensamblado. Los socios confiables brindan registros y soporte consistentes que lo ayudan a diagnosticar problemas sin conjeturas, lo cual es fundamental para la estabilidad del sistema LED a largo plazo.

Comparación de un socio de ensamblaje de PCB LED estándar frente a un LED fiable

| Área de evaluación | Socio estándar | Socio confiable |

| Experiencia de PCB LED | Exposición general de SMT | Enfoque LED y núcleo metálico probado |

| Capacidad de gestión térmica | asumido por el diseño | gestionado activamente durante el montaje |

| Métodos de inspección | Comprobaciones visuales básicas | Estrategia de inspección impulsada por procesos |

| Velocidad de prototipo | Rápido pero inconsistente | controlado y repetible |

| Escalabilidad de producción | Separar de la creación de prototipos | Alineado en todos los volúmenes |

| Soporte de DFM | genérico o tardío | Comentarios tempranos, específicos de LED |

| Manejo de la cadena de suministro | Abastecimiento reactivo | Planificado y transparente |

Por qué estas preguntas funcionan como un marco de decisión

Estas diez preguntas están diseñadas para aflorar la realidad operativa en lugar de las afirmaciones de marketing. Cada uno se enfoca en un área de riesgo que es específica del ensamblaje de LED PCB SMT, donde las pequeñas brechas de proceso pueden causar grandes problemas descendentes. La evaluación de las respuestas lado a lado le permite comparar socios en indicadores de fiabilidad que importan en todo el ciclo de vida del producto, no solo durante las compilaciones iniciales.

El uso de este marco también ayuda a alinear las partes interesadas internas. Los equipos de ingeniería pueden centrarse en el riesgo técnico, mientras que la adquisición puede evaluar la previsibilidad y la comunicación. El resultado es una base compartida para la toma de decisiones que reduce el juicio subjetivo y el pensamiento a corto plazo.

Errores de evaluación comunes que se deben evitar

Un error común es asumir que cualquier proveedor de SMT experimentado es adecuado para PCB LED. Otro es priorizar el tiempo de entrega o el costo unitario citado sin comprender el control del proceso. Algunos equipos también sobrevaloran las listas de equipos sin preguntar cómo se usan esas herramientas en la práctica. Evitar estas trampas requiere un cuestionamiento disciplinado y un enfoque en cómo las decisiones afectan el rendimiento de los liderados a lo largo del tiempo.

Estructura de costos de ensamblaje de PCB y SMT LED

La evaluación de costos para el ensamblaje de PCB LED SMT depende principalmente de la clasificación de PCB, el material base, el número de capas, la complejidad del ensamblaje y el tiempo de entrega de la fabricación. A diferencia de los proyectos generales de SMT, los ensamblajes de PCB LED introducen restricciones adicionales de precisión térmica y de colocación que influyen directamente tanto en los costos de fabricación como en el ensamblaje.

Las siguientes referencias de precios se basan en datos disponibles públicamente de las plataformas de fabricación de PCB, calculadoras de precios en línea y puntos de referencia de la industria comúnmente referenciados por los compradores durante la evaluación del proveedor. Todos los valores son Rangos de referencia aproximados Destinado a presupuestos, comparación y planificación temprana de adquisiciones, no cotizaciones formales.

Clasificación de PCB y rangos de costos de fabricación típicos

| Clasificación de PCB | Recuento de capas típico | material de base | Aplicaciones LED comunes | Costo aproximado de fabricación de PCB (USD / Unidad, volúmenes de prototipo) |

| PCB monocapa | 1 | fr4 | LED indicadores, iluminación de baja potencia | $1 – $5 |

| PCB de doble capa | 2 | fr4 | Tableros LED lineales, accesorios compactos | $3 – $10 |

| MCPCB de aluminio | 1-2 | núcleo de aluminio | Iluminación LED de alta potencia, diseños térmicos | $5 – $20 |

| PCB de 4 capas | 4 | FR4 (estándar o alto TG) | Denso LED Control y placas de conductor | $10 – $25 |

| PCB HDI | 4–6+ | FR4 / TG de alta | Módulos LED compactos de alta densidad | $30 – $60+ |

Los rangos de costos reflejan especificaciones estándar sin producción acelerada, acabados especiales o requisitos eléctricos avanzados.

Controladores de costes de montaje de PCB LED

El costo de montaje de SMT para los PCB LED está influenciado por varias variables de nivel de proceso que afectan el tiempo de la máquina, el esfuerzo de inspección y el control térmico durante la producción.

| conductor de precio | Impacto de costes típico (USD / tablero, volúmenes de prototipo) | explicación |

| Densidad de colocación de LED | +$1.50 – $4.00 | Los recuentos de LED más altos aumentan los ciclos de colocación, el uso del alimentador y el tiempo de inspección |

| Material base de PCB (MCPCB vs FR4) | +$2.00 – $6.00 | Las placas de aluminio-núcleo requieren perfiles térmicos controlados y procesos de reflujo más lentos |

| Tamaño del paquete LED (formatos SMD pequeños) | +$1.00 – $3.00 | Los paquetes más pequeños exigen tolerancias de colocación más estrictas y pasos de verificación |

| Control de binning LED | +$0.50 – $2.00 | La separación, el seguimiento y el manejo de lotes introducen una sobrecarga de procesos adicional |

| Nivel de inspección (AOI y comprobaciones manuales) | +$1.00 – $3.00 | Las etapas de inspección adicionales aumentan la utilización de mano de obra y equipo |

Los impactos de costos de montaje son referencias indicativas por tablero derivadas de modelos de precios de SMT comúnmente publicados.

Impacto de tiempo y costes de entrega en proyectos de PCB LED

La selección del tiempo de entrega de fabricación tiene un impacto medible en el costo total de montaje de PCB LED de PCB, particularmente para proyectos que requieren un estricto control térmico y de colocación.

| Tiempo de respuesta de fabricación | Aumento de costos típico | Caso de uso común |

| Estándar (10 a 15 días hábiles) | línea de saque | Construcciones de producción planificadas y ejecuciones de calificación |

| Acelerado (5–7 días hábiles) | +20% a +40% | Programas piloto de producción y cronograma |

| Expreso (24-72 horas) | +50% a +100% | Reemplazos urgentes o implementaciones críticas en el tiempo |

Interpretación de costos para equipos de adquisición e ingeniería

Estas referencias de costos permiten que los equipos de adquisición e ingeniería evalúen los socios de ensamblaje de PCB SMT LED utilizando expectativas de precios realistas basadas en la clasificación. Al comprender cómo el tipo de PCB, la elección de material, la complejidad del ensamblaje y el tiempo de entrega afectan el costo total, los compradores pueden tomar decisiones más informadas y evitar las selecciones basadas únicamente en los precios de los titulares sin tener en cuenta la confiabilidad a largo plazo y la estabilidad de la producción.

Conclusión

Elegir un socio de ensamblaje de PCB LED confiable es una decisión de gestión de riesgos en lugar de una tarea de compra. Las diez preguntas de esta guía brindan una forma estructurada de evaluar la experiencia, el control de procesos y la consistencia sin desviarse a la teoría de la fabricación o a las reclamaciones de ventas. Al centrarse en los riesgos específicos de LED, la calidad de la comunicación y la estabilidad a largo plazo, los tomadores de decisiones pueden seleccionar socios que respalden el rendimiento predecible en todo el ciclo de vida de sus productos de iluminación.

Preguntas frecuentes

El ensamblaje de PCB LED SMT es diferente porque los LED son sensibles al calor, la precisión de la ubicación y la variación de los componentes. Los problemas de ensamblaje pequeños pueden reducir la producción de luz o la vida útil, lo que hace que el control de procesos sea más crítico que en muchas aplicaciones SMT estándar.

Los principales riesgos incluyen fallas prematuras de LED, brillo inconsistente, variación de color y retrasos de retrabajo. Estos problemas a menudo aparecen después de la instalación, cuando las correcciones son costosas y el impacto de la reputación es alto.

El manejo térmico es fundamental para la confiabilidad de los LED. El estrés por calor relacionado con el ensamblaje puede dañar los LED o debilitar las trayectorias térmicas, incluso si el diseño del PCB es sólido.

Sí. Los errores de colocación menores, los defectos de soldadura o la exposición al calor no controlada pueden acortar significativamente la vida útil del LED y reducir la estabilidad del sistema con el tiempo.

Debe considerar cambiar de socios cuando se repiten los problemas de calidad, la comunicación carece de transparencia o los resultados de producción varían entre ejecuciones a pesar de los diseños sin cambios.