Les néons LED sont largement utilisés dans l'éclairage architectural, la décoration commerciale et les projets de signalisation en raison de leur flexibilité et de leur impact visuel. Cependant, lorsque les dimensions réelles du néon diffèrent considérablement des spécifications nominales, cela peut créer de sérieux défis d'installation. Ce problème devient encore plus critique dans les projets où les clients préparent des emplacements d'installation strictement basés sur les dimensions spécifiées. Une incompatibilité de quelques millimètres seulement peut entraîner une mauvaise adaptation, des lacunes visibles ou même une incompatibilité structurelle. Pour cette raison, la tolérance à l'extrusion, la variation dimensionnelle inhérente au processus d'extrusion, joue un rôle crucial pour assurer la cohérence du produit et une installation transparente dans les applications professionnelles de néons LED.

Pourquoi les néons LED ont-ils des tolérances dimensionnelles ?

Propriétés des matériaux

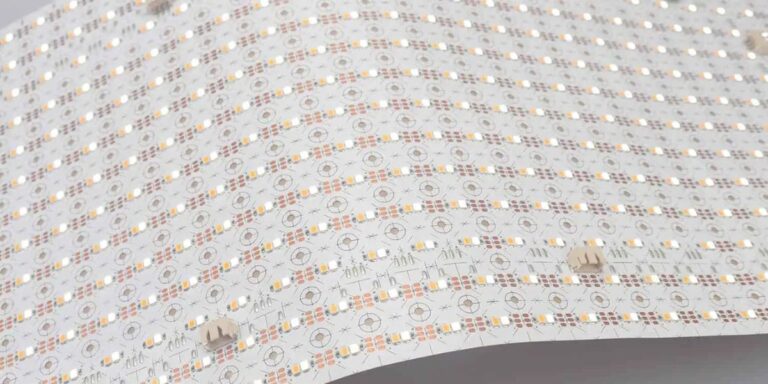

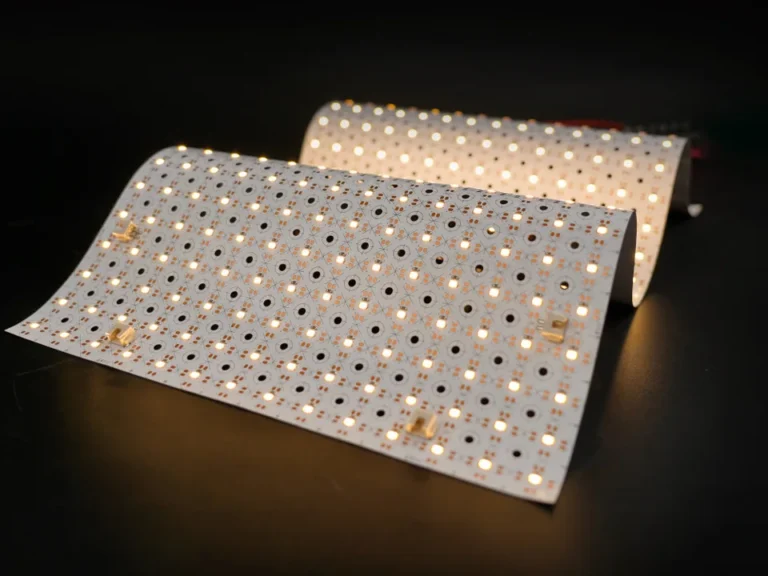

Le facteur le plus fondamental influant sur la tolérance dimensionnelle dans Néons LED est la matière première. Les profils de néons flexibles sont généralement constitués de silicone ou de PVC, tous deux soumis à une dilatation et à une contraction thermiques. Même de légers changements de température pendant la production ou plus tard dans l'application peuvent entraîner des variations de largeur, de hauteur ou de courbure de l'extrusion. Les différences de dureté des matériaux ou de formulation entre les lots peuvent également entraîner des dimensions incohérentes, faisant de la stabilité des matériaux un élément essentiel dans le contrôle de la tolérance.

néon en silicone

Lumière au néon en PVC

Contrôle des processus d'extrusion

Le processus d'extrusion lui-même est une autre source majeure de variation dimensionnelle. La précision dépend fortement de la précision du moule d'extrusion, ainsi que de la consistance de la température, de la pression et de la vitesse d'extrusion. Par exemple, si les conditions de refroidissement sont instables, comme un refroidissement par eau ou un débit d'air incohérent, le profil peut se rétrécir ou se déformer de manière inégale. Ces petits écarts peuvent s'accumuler, ce qui entraîne un produit final qui ne dépasse pas la plage de tolérance spécifiée.

Variabilité des lots de production

Même avec le même moule et le même matériau, la tolérance dimensionnelle peut varier d'un lot de production à l'autre. Des facteurs tels que l'étalonnage de la machine, les ajustements de l'opérateur et les conditions environnementales comme l'humidité peuvent influer subtilement sur le résultat. Sur de grands volumes de production, ces variations peuvent affecter directement la compatibilité du néon LED avec les canaux de montage et les accessoires.

Prix et pression des coûts

Un autre facteur souvent négligé est le prix. Sur des marchés hautement concurrentiels, certains fournisseurs à faible coût peuvent faire des compromis sur la qualité des matériaux ou réduire les étapes de production pour réduire les coûts. L'utilisation d'un silicone, d'un PVC recyclé ou d'un équipement d'extrusion moins précis augmente inévitablement la variation dimensionnelle. Bien que le prix initial puisse être attractif, le risque à long terme de mauvaise adaptation, de durée de vie réduite et de coûts de maintenance plus élevés rendent de tels compromis coûteux pour des projets professionnels.

Plages de tolérances communes pour l'extrusion de néons LED

Normes de tolérance de l'industrie

Dans l'industrie du néon LED, la tolérance à l'extrusion est généralement définie dans une petite marge pour assurer un ajustement fiable et un aspect uniforme. La plupart des fabricants adoptent une tolérance dimensionnelle comprise entre ±0,3 mm et ±1,0 mm, selon la taille et la forme du profil. Bien qu'il n'existe pas de norme mondiale unique, ces gammes sont généralement acceptées dans les projets professionnels dans les applications d'architecture et de signalisation.

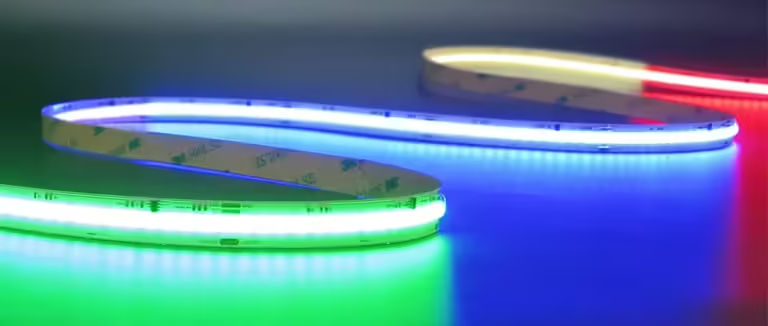

Différences entre les types d'émission de lumière

Les exigences de tolérance peuvent également varier avec différentes structures d'émission. Le néon à émission frontale a souvent un contrôle plus strict, car la surface visible a un impact direct sur l'uniformité de l'éclairage, tandis que les types de néons et de flexion supérieures permettent une tolérance légèrement plus grande en raison de la flexibilité structurelle. Les profils de couverture plus importants, tels que le néon à 270° ou 360°, nécessitent une surveillance plus étroite pendant l'extrusion, car les changements dimensionnels affectent à la fois la répartition de la lumière et la stabilité de l'installation.

Plages de tolérances typiques par taille et type de néon

| Type de néon LED | Taille commune (W×H ou dia.) | Tolérance d'extrusion typique |

| Mini néon (mince) | 4×8 mm | ±0,3 mm |

| Mini néon à émission latérale | 6×12 MM | ±0,4 mm |

| Emission avant standard | 8×16 mm | ±0,5 mm |

| Émission latérale standard | 10×20 mm | ±0,5 mm |

| Néon de flexion optimale | 12×20 mm | ±0,5 mm |

| Néon large devant émettant | 12×25 mm | ±0,6 mm |

| Néon rond à 270° | Ø16 mm | ±0,6 mm |

| Grand néon à 270° | Ø20 mm | ±0,8 mm |

| Néon flexible à 360° (petit) | Ø15 mm | ±0,5 mm |

| Néon flexible à 360° (grand) | Ø25 mm | ±1,0 mm |

Comment la tolérance dimensionnelle affecte les applications au néon

1. Défis d'installation

Lorsque la tolérance à l'extrusion des néons à LED n'est pas bien contrôlée, l'installation devient problématique. Même de légères variations dimensionnelles peuvent rendre le profil trop serré ou trop lâche à l'intérieur des canaux ou des fentes de montage. Cela entraîne souvent des lacunes visibles, un alignement inégaux ou une augmentation de la main-d'œuvre lors de l'ajustement sur place. Pour les projets architecturaux à grande échelle, des dimensions cohérentes sont essentielles pour obtenir une installation transparente et réduire les retouches.

2. Impact sur l'uniformité légère

La tolérance à l'extrusion affecte également l'uniformité du rendement lumineux. Les variations de l'épaisseur de l'encapsulation de silicone ou de PVC peuvent provoquer une diffusion incohérente, ce qui entraîne des zones qui semblent plus lumineuses ou plus sombres. Dans le néon avant-d'émission, cette distribution de lumière inégale devient particulièrement visible, réduisant la qualité visuelle globale de l'installation.

3. Évaluation et fiabilité de l'étanchéité

Les problèmes de tolérance influencent davantage l'imperméabilisation et la fiabilité à long terme des produits néons LED. Si les dimensions du profilé s'écartent de la plage spécifiée, l'étanchéité autour des embouts, des connecteurs ou des joints peut ne pas être pleinement efficace. Cela compromet la cote IP et augmente le risque d'infiltration d'eau, ce qui peut raccourcir la durée de vie du produit et provoquer des défaillances dans les applications extérieures.

Comment contrôler et résoudre les problèmes de tolérance dans les lampes néon à LED

1. Optimisation des processus de fabrication

La première étape de la réduction de la tolérance à l'extrusion est la maîtrise précise du processus de fabrication. Les moules de haute précision, la vitesse d'extrusion stable et la bonne régulation de la température jouent tous un rôle essentiel dans le maintien de dimensions cohérentes. L'entretien et l'étalonnage réguliers des équipements d'extrusion garantissent davantage la précision.

2 Mesures de contrôle de la qualité

Un contrôle qualité strict est tout aussi important. Les fabricants doivent mettre en œuvre une surveillance en ligne lors de l'extrusion et effectuer des inspections dimensionnelles finales sur les lampes néon à LED finies. L'enregistrement des données de tolérance permet de détecter les tendances et d'empêcher les lots défectueux d'atteindre les clients.

3. Considérations sur la conception et l'installation du projet

Du point de vue du projet, les concepteurs et les installateurs peuvent minimiser les risques en permettant des marges de tolérance dans les tailles de fentes, les canaux en aluminium et les accessoires. La planification avec des variations d'extrusion à l'esprit garantit une installation plus fluide sur le site et réduit les ajustements inattendus.

4. Choisir un fournisseur fiable

Enfin, la sélection d'un fournisseur avec une expertise éprouvée dans la tolérance au néon par extrusion de néons est essentielle. Les fabricants professionnels dotés d'équipements avancés, de certifications et d'un système de qualité solide fournissent des produits plus stables, donnant aux propriétaires de projets une confiance dans les performances à long terme.

Conclusion : Assurer la cohérence des projets néon professionnels dirigés par des professionnels

La tolérance dimensionnelle est un facteur inévitable dans la fabrication de néons LED, mais avec les bons matériaux, un contrôle strict de l'extrusion et une gestion professionnelle de la qualité, elle peut être efficacement minimisée. Pour les architectes, les concepteurs et les entrepreneurs, travailler avec un fournisseur fiable est la clé pour assurer une installation fluide et des performances à long terme.

Au SignliteLED, nous utilisons du silicone de haute qualité dans toute notre extrusion au néon, assurant des dimensions stables qui répondent pleinement aux normes de tolérance de l'industrie. Si votre projet nécessite des tailles uniques ou des tolérances plus strictes, notre équipe peut fournir des solutions personnalisées pour correspondre à vos spécifications exactes. Contactez-nous dès aujourd'hui pour discuter de vos exigences et sécuriser les néons LED de haute qualité, adaptés aux applications professionnelles.