En raison de leur polyvalence et de leur haute efficacité, les bandes de lumière LED ont gagné en popularité dans les scénarios d'éclairage résidentiel, commercial et industriel. De l'éclairage ambiant à l'éclairage fonctionnel à haut indice de couleur (CRI), ils sont devenus un choix populaire parmi les concepteurs et les ingénieurs.

Cependant, en utilisation pratique, malgré les nombreux avantages des sommiers à LED, il existe également certains inconvénients potentiels qui peuvent affecter leur performance et leur adaptabilité à des environnements spécifiques, en particulier dans les projets commerciaux à grande échelle où ils pourraient entraîner des retards et des dépassements de coûts.

Chez SignLiteled, nous nous engageons à fournir à nos clients les meilleures solutions d'éclairage LED. Cependant, la compréhension des inconvénients potentiels des bandes de lumière LED est cruciale pour prendre des décisions éclairées. Dans cet article de blog, nous explorerons les inconvénients des bandes lumineuses LED, les causes sous-jacentes et la manière d'atténuer les risques grâce à la sélection et à l'amélioration, vous aidant à prendre des décisions plus éclairées.

Inconvénients des socles LED

Alors que les sommiers à LED offrent de nombreux avantages, tels que l'efficacité énergétique et la polyvalence, il est également important de prendre en compte et de reconnaître leurs inconvénients potentiels. Quoi qu'il en soit, il est conseillé de développer de bonnes habitudes et d'inspecter en profondeur tous les aspects des slips LED avant de faire un investissement. Examinons maintenant certains des inconvénients des sommiers à LED.

Coût initial élevé

Grâce à la technologie de fabrication avancée et aux matériaux utilisés dans les bandes lumineuses LED, leurs coûts initiaux sont généralement plus élevés que ceux des solutions d'éclairage traditionnelles telles que les lampes à incandescence ou fluorescentes. De plus, la qualité des bandes de lumière LED augmente avec des performances améliorées, telles que des lumens par watt ou un meilleur rendu des couleurs. Alors que les bandes lumineuses LED peuvent réduire les coûts grâce à une efficacité énergétique améliorée et à une durée de vie prolongée, l'investissement initial peut être un obstacle pour certains consommateurs.

Suggestions d': Bien que vous puissiez obtenir des bandes lumineuses LED à moindre coût via d'autres canaux pour répondre aux exigences de votre projet, ces bandes lumineuses sont susceptibles de causer plus de problèmes et de risques en termes de qualité de la lumière, de sécurité, de durée de vie et d'expérience client.

Par conséquent, vous pouvez envisager de collaborer avec les fabricants de LED à bande LED pour réduire les coûts initiaux grâce à l'achat en gros. C'est la meilleure façon d'obtenir des produits de haute qualité à des prix plus compétitifs sans compromettre la sécurité ou les résultats du projet.

Sensibilité à la dissipation de la chaleur

Les bandes lumineuses LED génèrent de la chaleur et une dissipation de chaleur inadéquate peut entraîner d'autres problèmes, tels que la réduction de la lumière et la durée de vie. En effet, la chaleur excessive peut endommager les puces LED, entraînant une dégradation de la lumière, une atténuation et un vieillissement accéléré. Ce problème est particulièrement grave dans les espaces fermés mal ventilés, les environnements à haute température ou lorsque des bandes lumineuses sont installées sur des matériaux sensibles à la chaleur.

Recommandations d'amélioration: Pour assurer la longévité des bandes de lumière LED, une dissipation thermique adéquate est essentielle. Assurer une installation correcte et maintenir une bonne ventilation et des températures de fonctionnement appropriées. LED canaux en aluminium pour une dissipation thermique efficace. Évitez de placer des bandes de lumière LED près des sources de chaleur. De plus, vous pouvez résoudre ce problème en utilisant des produits de haute qualité ou certifiés, tels que des substrats de circuits imprimés plus épais (4 oz., généralement 1-2 oz) ou ceux avec une certification UL/ETL. Pour les mesures thermiques des bandes LED, veuillez lire l'article : Mesures thermiques des bandes LED.

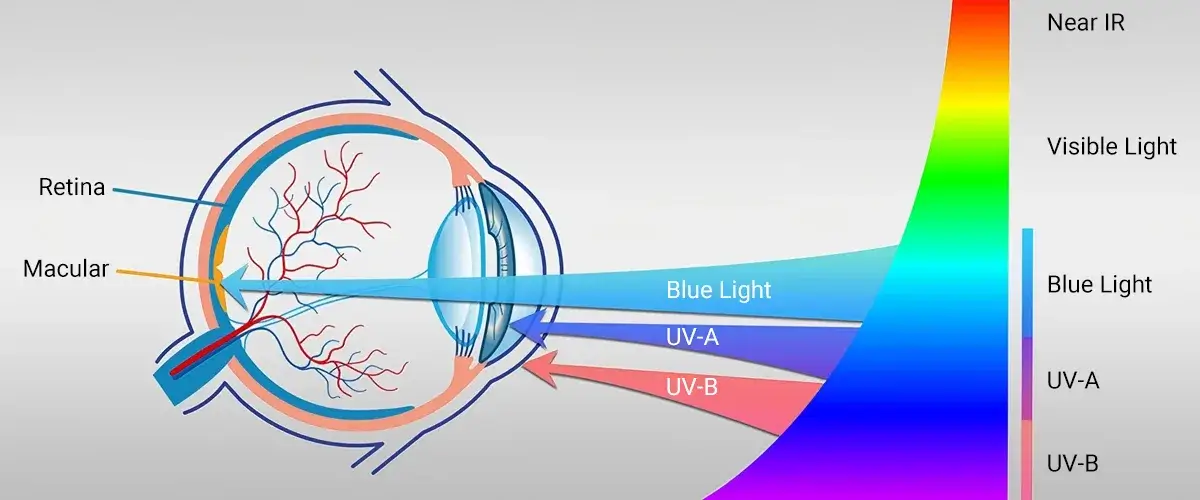

Risques de lumière bleue

Certaines bandes de lumière LED avec des températures de couleur plus élevées (principalement des LED blanches froides) émettent une lumière bleue. La lumière bleue, également connue sous le nom de «lumière bleue à longueur d'onde courte à haute énergie», est un faisceau de lumière avec une intensité relativement élevée, avec une longueur d'onde comprise entre 400 et 480 nanomètres. La lumière bleue peut être une cause de lésions photochimiques de la rétine et peut également provoquer une dégénérescence maculaire de la peau. Une exposition prolongée à la lumière bleue, surtout la nuit, peut perturber le sommeil et provoquer une fatigue oculaire.

En fait, presque tous les types de luminaires LED sont confrontés à ce problème. La principale cause de risques de lumière bleue est que l'intensité de la lumière bleue varie avec la température de couleur. L'intensité de la lumière bleue est directement proportionnelle à la température de couleur. Plus la température de couleur est élevée, plus le risque de lumière bleue est élevé.

Suggestions d': Le contrôle de la température de couleur est l'une des méthodes appropriées pour réduire les risques de lumière bleue. Pour cela, vous pouvez choisir des bandes de lumière LED avec un rayonnement lumineux bleu inférieur (comme ceux dont la température de couleur est inférieure à 4 000 000) ou les utiliser modérément. Dans les zones où vous passez de longues périodes, surtout la nuit, vous pouvez également utiliser des solutions d'éclairage aux tons chauds.

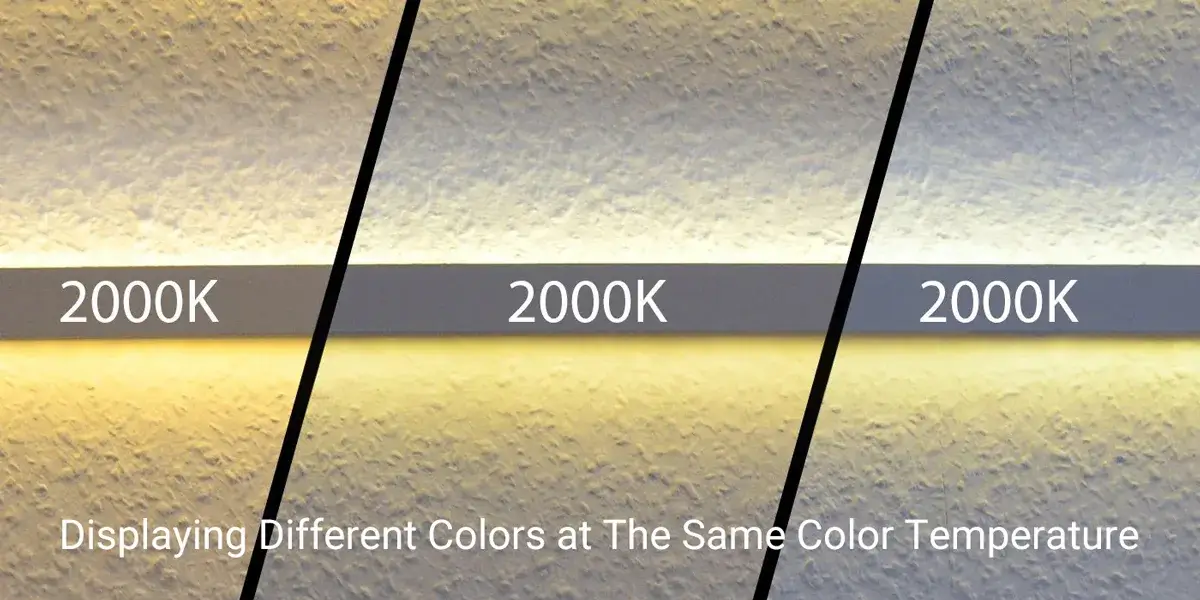

Cohérence des couleurs

Les bandes de lumière LED bas de gamme peuvent présenter des écarts de température de couleur importants ou des tonalités de couleur incohérentes entre les lots, ou même des décalages de couleur au sein d'une seule bande. Cela est dû au manque de contrôle strict des fabricants sur la combinaison de température de couleur et les tests de rendu des couleurs pendant la production. Les différences de matières premières telles que les puces et les luminophores entre les lots entraînent des performances de rendu des couleurs instables. Par conséquent, lorsque plusieurs bandes sont utilisées ensemble, ces différences deviennent plus visibles. De plus, les bandes de lumière LED avec des indices de rendu des couleurs faibles peuvent empêcher les objets éclairés par les lumières de paraître inexacts.

Recommandations d'amélioration: Sélectionnez des produits fiables, de haute qualité et certifiés auprès de fabricants de bandes LED réputés, tels que ceux qui ont de bonnes cotes de CRI, des valeurs de SDCM faibles, une large gamme de produits, des options OEM ou des solutions personnalisées adaptées à votre projet.

Le SDCM est une mesure très importante. Plus la valeur de correspondance des couleurs (écart type de la correspondance des couleurs) est faible, meilleure est la cohérence des couleurs. Lors de l'achat d'un projet, plusieurs lots d'échantillons doivent être testés pour être comparés afin de garantir que les paramètres tels que la température de couleur et le CRI répondent aux exigences de tous les lots. Pour plus d'informations sur le SDM, lisez le blog : Tout savoir sur le DDCM pour les bandes LED.

Compatibilité de gradation

En règle générale, les bandes lumineuses LED nécessitent des alimentations et des variateurs compatibles pour fonctionner correctement. Des alimentations ou des variateurs inadéquates ou inadéquates peuvent entraîner des scintillements, une durée de vie raccourcie ou même des dommages aux bandes de lumière LED. Par exemple, certaines bandes lumineuses RGB et bicolores sont incompatibles avec les gradateurs standard, ce qui entraîne un contrôle ou une défaillance incohérent. En effet, les bandes de LED et les gradateurs de différents fabricants utilisent des protocoles de contrôle et des normes de signal différents, les empêchant de communiquer et de fonctionner correctement ensemble.

Recommandations d'amélioration: Utilisation Systèmes de contrôle de qualité industrielle Comme DMX, DALI ou 0-10V. Ces protocoles offrent une bonne compatibilité et une bonne stabilité, assurant une communication fiable entre les bandes lumineuses et les gradateurs. Avant la mise en œuvre du projet, effectuez des tests de compatibilité sur les bandes lumineuses et les gradateurs pour garantir une fonctionnalité de contrôle de la gradation appropriée. Si nécessaire, consultez un expert en éclairage.

Complexité des installations personnalisées

Bien que les bandes de lumière LED soient faciles à installer en raison de leur adhésif et de leur flexibilité, la situation réelle peut être plus complexe, en particulier dans les projets d'installation personnalisés. Un appariement incorrect des alimentations et des câblages peut entraîner des problèmes de performances ou des dommages. Dans les projets d'installation personnalisées, les bandes lumineuses LED peuvent nécessiter une coupe, une soudure et un câblage vers des gradateurs et des alimentations compatibles. Pour ceux qui n'ont pas d'expérience en électricité, cela peut nécessiter une installation professionnelle, ce qui augmente les coûts globaux.

Suggestions d': Assurez-vous d'abord que l'alimentation électrique répond aux exigences de tension et de puissance des bandes LED. Deuxièmement, vous pouvez utiliser Connecteurs de lumière de bande LED Pour simplifier les connexions, réduire le temps et les efforts nécessaires pour souder ces points de connexion. Enfin, pour les passionnés, vous aurez besoin de l'aide professionnelle d'un électricien, d'un installateur LED, d'un intégrateur ou d'un entrepreneur. Cela garantit la sécurité, la fiabilité et une installation correcte.

Si vous souhaitez en savoir plus et les installer vous-même, lisez les blogs connexes suivants :

Guide complet sur le câblage des bandes LED

Peut-on connecter plusieurs bandes de LED ?

Comment connecter une bande de LED à une alimentation électrique ?

Durabilité adhésive

Le support adhésif sur les bandes de lumière LED se dégrade généralement avec le temps, en particulier dans les environnements à haute température, poussiéreux/humides ou sur des surfaces rugueuses, entraînant une défaillance et provoquant le détachement des bandes lumineuses. Cela affecte non seulement les performances de l'éclairage, mais pose également des risques pour la sécurité. De plus, les adhésifs en mousse standard ont une adhérence et une durabilité limitées, ne répondant pas aux exigences d'une utilisation à long terme. De plus, de nombreuses bandes de lumière LED à faible coût et de faible qualité utilisent souvent un support adhésif inférieur pour réduire les coûts.

Suggestions d': En plus d'utiliser Ruban VHB de qualité industrielle, Des méthodes d'installation auxiliaires telles que des clips et des supports peuvent être adoptées. Les clips et les supports fournissent une force de maintien supplémentaire, garantissant que la bande lumineuse reste solidement installée, même dans des environnements difficiles. Avant l'installation, la surface d'installation doit être nettoyée et préparée pour assurer qu'elle est plate et sèche, ce qui améliore la résistance de l'adhésif. Pour obtenir des conseils sur la sélection du support adhésif approprié, veuillez vous référer au blog : Quel est le meilleur ruban adhésif double face pour les bandes LED ?

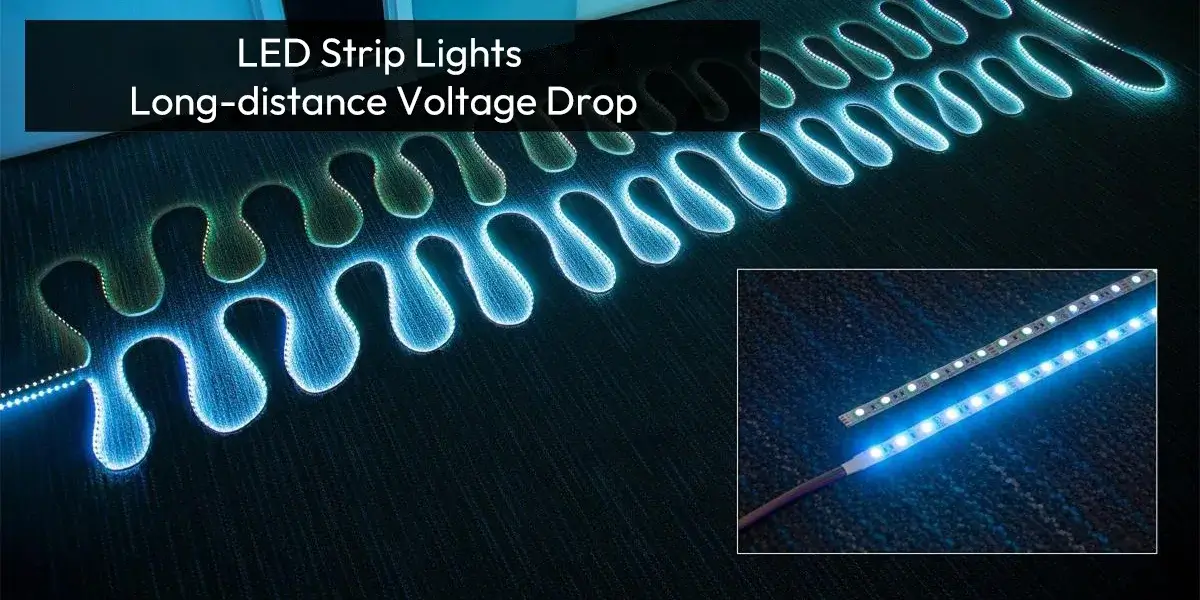

Chute de tension longue distance

Lorsque les bandes lumineuses LED dépassent 5 mètres ou 10 mètres avec une alimentation à une extrémité, les extrémités peuvent présenter une gradation ou un changement de couleur notables, affectant l'uniformité globale de l'éclairage et l'attrait esthétique. En effet, les fils eux-mêmes ont une résistance et, à mesure que la distance d'alimentation augmente, la perte de courant dans les fils augmente progressivement, ce qui entraîne une diminution de la tension à la fin, entraînant une insuffisance de courant pour que les LED fonctionnent, entraînant une réduction de la luminosité et des problèmes de décalage de couleur.

Suggestions d': Utilisez une alimentation à double extrémité, fournissant l'alimentation des deux extrémités de la bande LED simultanément, ce qui peut réduire efficacement la chute de tension causée par la résistance du fil. Vous pouvez également augmenter la jauge de fil pour sélectionner des fils avec une résistance inférieure, réduisant ainsi la perte de courant. De plus, la puissance d'injection tous les 5 mètres est une solution efficace pour garantir que toutes les sections de la bande reçoivent une tension et un courant stables. Pour plus d'informations sur les causes de la chute de tension et des solutions, veuillez lire l'article : Chute de tension sur les bandes LED : Causes et solutions.

Conclusion : Reconnaissez le DBacks bruts et Choose un Rligature Solution

Les bandes LED, en tant que produit largement utilisé dans l'éclairage moderne, ne sont pas sans défauts. Bien qu'il y ait toujours quelques inconvénients, nous devons les reconnaître car il existe toujours des moyens de les résoudre. Cependant, les avantages des bandes de lumière LED dépassent de loin les inconvénients, il n'est donc pas nécessaire de s'inquiéter de manière excessive.

En lisant cet article, vous avez acquis une compréhension plus approfondie des problèmes qui peuvent survenir lors de l'utilisation réelle de bandes de lumière LED et de leurs causes sous-jacentes, ce qui peut nous aider à atténuer les risques dans les projets commerciaux et à éviter des problèmes tels que la luminosité ou les retards insuffisants dus aux retouches. Si vous avez d'autres questions sur l'utilisation de la lumière de bande LED, vous pouvez lire notre blog [Guide des problèmes courants et des solutions pour les bandes LED] pour voir si cela répond à vos préoccupations.

Signiteled s'engage à fournir une haute fiabilité et une grande cohérence bande lumineuse LED Produits pour des projets commerciaux. Avec une technologie de pointe, un contrôle de qualité strict et un service après-vente complet, nous offrons une assistance complète pour vos projets. Veuillez nous contacter pour des échantillons d'ingénierie ou des recommandations de sélection de produits afin de collaborer à la création d'une solution d'éclairage idéale.

Cet article donne un aperçu clair des problèmes courants liés à Bande LED Et comment les réparer. J'aime la façon dont cela explique chaque problème, comme la chaleur et la cohérence des couleurs, en termes simples. Les conseils pour choisir des produits de qualité et une installation appropriée sont très utiles pour tous ceux qui planifient des projets d'éclairage.