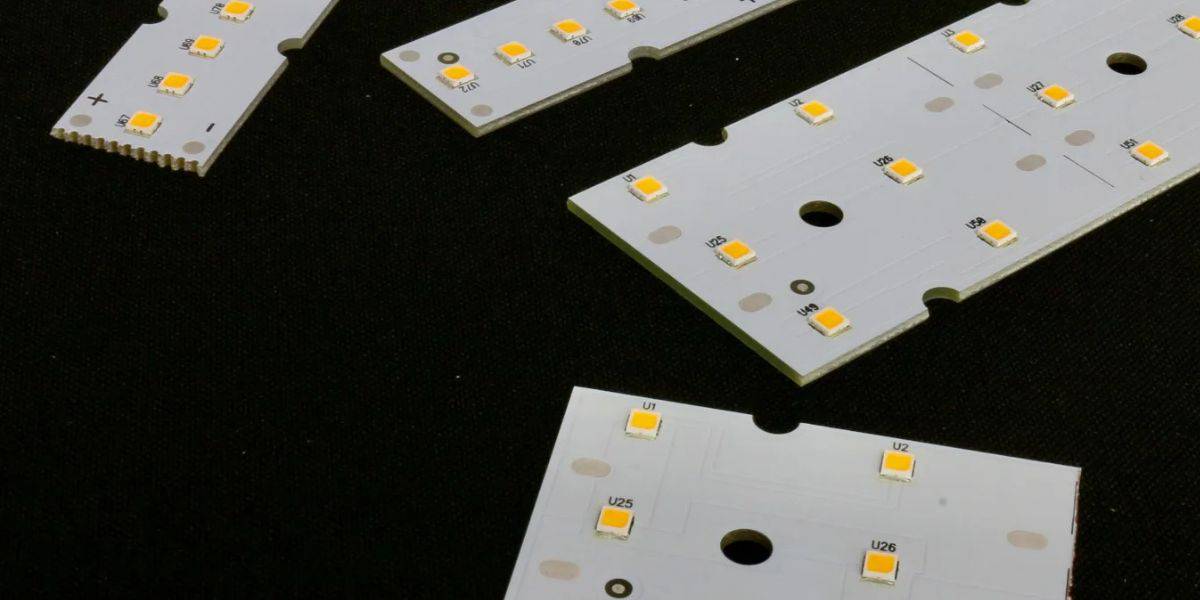

Un partenaire d'assemblage de circuits imprimés LED fiable est un partenaire qui peut systématiquement placer les LED avec une grande précision, gérer la chaleur au niveau de la carte et produire des résultats répétables sur les prototypes et les séries de production. L'assemblage de circuits imprimés LED est plus complexe que le SMT standard, car les petites erreurs de placement, la mauvaise gestion thermique ou la variation des composants peuvent directement réduire la puissance lumineuse et la durée de vie. La fiabilité dans ce contexte signifie un contrôle des processus, une qualité prévisible et une transparence de la décision plutôt que de la vitesse ou du prix seul.

Les 10 questions clés pour évaluer un partenaire d'assemblage de PCB LED PCB

1 — Quelle expérience avez-vous avec les cartes de circuits imprimés LED et de noyau métallique ?

L'expérience directe avec les circuits imprimés LED est importante, car les assemblages LED se comportent différemment sous la chaleur et le stress actuel. Un partenaire familier avec l'aluminium et d'autres panneaux métalliques comprend comment la disposition, les profils de soudure et la manipulation affectent les trajectoires thermiques. Sans cette expérience, même un fabricant de PCB personnalisé capable peut sous-estimer les risques spécifiques aux LED, entraînant des défaillances précoces ou des performances optiques incohérentes.

2 — Quel équipement SMT utilisez-vous pour la précision du placement des LED ?

La fiabilité des LED dépend du placement et de l'orientation précis, en particulier pour les réseaux à haute densité et les modules linéaires. L'équipement SMT approprié garantit un alignement cohérent, un contrôle du volume de soudure et une refonte minimale. Cette question vous permet d'évaluer si un fabricant de PCB personnalisé peut maintenir la précision du placement à l'échelle ou si la qualité varie d'un lot à l'autre, ce qui augmente le risque de défaillance du champ.

3 — Comment gérez-vous les performances thermiques lors de l'assemblage de circuits imprimés LED ?

La gestion thermique est au cœur de la durée de vie des LED et de la stabilité des couleurs. Un partenaire fiable considère la chaleur lors de la soudure, de la fixation des composants et de la manipulation après l'assemblage. Cette question révèle si le contrôle thermique est traité comme une préoccupation au niveau du système ou une réflexion après coup. Les mauvaises pratiques thermiques lors de l'assemblage peuvent annuler même une mise en page personnalisée de PCB bien conçue.

4 — Quels processus d'inspection et de contrôle de la qualité appliquez-vous ?

L'inspection ne consiste pas seulement à détecter des défauts évidents, mais aussi à détecter les problèmes subtils qui affectent les performances des LED au fil du temps. Un contrôle de qualité cohérent aide à prévenir les défaillances latentes causées par des vides de soudure ou un désalignement. Cette question vous aide à comparer des partenaires basés sur la discipline de processus plutôt que sur les promesses, en particulier lors de l'évaluation de l'assemblage de circuits imprimés personnalisés pour les systèmes d'éclairage critiques.

5 — Comment gérez-vous la binning et la cohérence des composants ?

Le binning LED affecte la luminosité, la température de couleur et l'uniformité visuelle. Un partenaire fiable a des processus pour gérer la variation des composants et maintenir la cohérence au sein d'un même tableau et sur les lots de production. Cette question est essentielle pour les applications où les différences visuelles sont inacceptables et où une source incohérente peut saper un processus d'assemblage autrement sain.

6 — Pouvez-vous prendre en charge à la fois le prototypage et la production de volume ?

La possibilité de passer du prototype au volume sans changer de partenaire réduit le risque et la mauvaise communication. Cette question évalue si les mêmes normes et contrôles s'appliquent à différentes échelles. Pour les projets LED, les incohérences entre les constructions précoces et la production de masse remontent souvent à des partenaires qui traitent le prototypage et le volume comme des processus sans rapport.

7 — Quel est votre délai typique et votre fiabilité de planification ?

Délai de fiabilité Les délais de fiabilité sont plus importants que la vitesse nominale dans les projets de circuits imprimés LED liés aux calendriers d'installation. Cette question vous aide à comprendre dans quelle mesure un partenaire planifie la capacité et gère le changement. Les horaires manqués peuvent forcer les décisions ou les substitutions qui affectent les performances des LED, même lorsque vous travaillez avec un Fabricant de PCB personnalisé.

8 — Comment fournissez-vous des commentaires DFM pour les projets de circuits imprimés LED ?

La conception de la rétroaction de la fabrication est essentielle dans les assemblages LED, car les petites décisions de disposition affectent le flux de chaleur et le rendement de placement. Un partenaire fiable offre des commentaires clairs et précoces axés sur la réduction des risques plutôt que sur les commentaires génériques. Cette question montre si DFM est utilisé comme outil de décision ou comme formalité dans les flux de travail d'assemblage de circuits imprimés personnalisés.

9 — Comment gérez-vous les risques liés à la chaîne d'approvisionnement et aux composants ?

Les composants LED sont sensibles aux substitutions et aux pénuries. Un partenaire fiable a défini des processus de sourcing, de traçabilité et de notification de modifications. Cette question vous aide à évaluer la manière dont les interruptions de l'approvisionnement sont gérées et si vous serez informé avant que les décisions n'aient un impact sur les performances ou la conformité dans les projets personnalisés de PCB.

10 — Quel type de communication, de documentation et de soutien post-assemblage fournissez-vous ?

Une communication claire réduit les risques tout au long du cycle de vie du projet. Cette question évalue la façon dont les problèmes sont documentés, la manière dont les modifications sont approuvées et la manière dont les questions post-assemblage sont traitées. Des partenaires fiables fournissent des enregistrements et une assistance cohérents qui vous aident à diagnostiquer des problèmes sans hypothèse, ce qui est essentiel pour la stabilité du système LED à long terme.

Comparaison d'un partenaire d'assemblage SMT standard et fiable pour PCB LED

| Domaine d'évaluation | Partenaire standard | Partenaire fiable |

| Expérience de circuit imprimé LED | Exposition générale SMT | LED et mise au point en métal éprouvées |

| Capacité de gestion thermique | supposé de la conception | Géré activement lors de l'assemblage |

| Méthodes d'inspection | Vérifications visuelles de base | Stratégie d'inspection axée sur les processus |

| Vitesse de prototypage | Rapide mais incohérent | contrôlé et répétable |

| Évolutivité de la production | Séparer du prototypage | Aligné sur tous les volumes |

| Prise en charge de DFM | générique ou en retard | Commentaires précoces, spécifiques aux LED |

| Gestion de la chaîne d'approvisionnement | Sourcing réactif | Planifié et transparent |

Pourquoi ces questions fonctionnent comme un cadre de décision

Ces dix questions sont conçues pour faire apparaître la réalité opérationnelle plutôt que sur des allégations marketing. Chacun se concentre sur un domaine de risque spécifique à l'assemblage de SMT de circuits imprimés LED, où de petites lacunes de processus peuvent causer de grands problèmes en aval. L'évaluation côte à côte des réponses vous permet de comparer les partenaires sur des indicateurs de fiabilité qui comptent tout au long du cycle de vie du produit, et pas seulement lors des constructions initiales.

L'utilisation de ce cadre permet également d'aligner les parties prenantes internes. Les équipes d'ingénieurs peuvent se concentrer sur le risque technique, tandis que les achats peuvent évaluer la prévisibilité et la communication. Le résultat est une base partagée pour la prise de décision qui réduit le jugement subjectif et la pensée à court terme.

Erreurs d'évaluation courantes à éviter

Une erreur courante consiste à supposer que tout fournisseur SMT expérimenté convient aux PCB LED. Un autre est de donner la priorité aux délais de livraison ou au coût unitaire sans comprendre le contrôle des processus. Certaines équipes surévaluent également les listes d'équipements sans se demander comment ces outils sont utilisés dans la pratique. Éviter ces pièges nécessite un questionnement discipliné et une concentration sur la façon dont les décisions affectent les performances des LED au fil du temps.

Structure de coûts d'assemblage de circuits imprimés LED et de SMT

L'évaluation des coûts pour l'assemblage du PCB LED SMT dépend principalement de la classification des PCB, du matériau de base, du nombre de couches, de la complexité de l'assemblage et du délai de fabrication. Contrairement aux projets SMT généraux, les assemblages de circuits imprimés LED introduisent des contraintes supplémentaires de précision thermique et de placement qui influencent directement à la fois les coûts de fabrication et d'assemblage.

Les références de prix suivantes sont basées sur des données accessibles au public des plates-formes de fabrication de circuits imprimés, des calculatrices de prix en ligne et des références de l'industrie couramment référencées par les acheteurs lors de l'évaluation des fournisseurs. Toutes les valeurs sont Plages de référence approximatives Conçu pour la budgétisation, la comparaison et la planification des achats précoces, et non pour les devis formels.

Classification des PCB et plages de coûts typiques de fabrication

| Classification des PCB | Nombre de couches typique | matériau de base | Applications LED courantes | Coût de fabrication approximatif de PCB (USD / unité, volumes prototypes) |

| PCB monocouche | 1 | fr4 | Voyants LED, éclairage de faible puissance | $1 – $5 |

| PCB à double couche | 2 | fr4 | Cartes LED linéaires, luminaires compacts | $3 – $10 |

| MCPCB en aluminium | 1–2 | Noyau en aluminium | Éclairage LED haute puissance, conceptions critiques thermiques | $5 – $20 |

| PCB à 4 couches | 4 | FR4 (standard ou haute TG) | Commandes LED et cartes de conduite denses | $10 – $25 |

| PCB HDI | 4 à 6 ans | FR4 / Haute TG | Modules LED compacts et haute densité | $30 – $60+ |

Les gammes de coûts reflètent les spécifications standard sans production accélérée, finitions spécialisées ou exigences électriques avancées.

Pilotes de coûts d'assemblage de PCB de PCB LED

Le coût d'assemblage SMT pour les circuits imprimés LED est influencé par plusieurs variables au niveau du processus qui affectent le temps de la machine, l'effort d'inspection et le contrôle thermique pendant la production.

| opérateur | Impact typique des coûts (USD / carte, volumes prototypes) | explication |

| Densité de placement des LED | +$1.50 – $4.00 | Des nombres de LED plus élevés augmentent les cycles de placement, l'utilisation du chargeur et le temps d'inspection |

| Matériau de base de circuits imprimés (MCPCB vs FR4) | +$2.00 – $6.00 | Les panneaux en aluminium nécessitent des profils thermiques contrôlés et des processus de refusion plus lents |

| Taille du paquet LED (petits formats SMD) | +$1.00 – $3.00 | Les petits colis exigent des tolérances de placement plus serrées et des étapes de vérification |

| Contrôle de la jonction LED | +$0.50 – $2.00 | La séparation, le suivi et la manipulation des lots introduisent des frais généraux de processus supplémentaires |

| Niveau d'inspection (AOI et vérifications manuelles) | +$1.00 – $3.00 | Des étapes d'inspection supplémentaires augmentent l'utilisation de la main-d'œuvre et de l'équipement |

Les impacts sur les coûts d'assemblage sont des références indicatives par tableau dérivées de modèles de tarification SMT communément publiés.

Délai d'exécution et impact des coûts sur les projets de circuits imprimés LED

La sélection des délais de fabrication a un impact mesurable sur le coût total d'assemblage des PCB LED, en particulier pour les projets nécessitant un contrôle thermique et de placement strict.

| Délai d'exécution de fabrication | Augmentation de coût typique | cas d'utilisation courant |

| Standard (10 à 15 jours ouvrables) | ligne de base | Constructions de production et cycles de qualification |

| Accéléré (5 à 7 jours ouvrables) | +20% à +40% | Production pilote et programmes axés sur le calendrier |

| Express (24 à 72 heures) | +50% à +100% | Remplacements urgents ou déploiements urgents |

Interprétation des coûts pour les équipes d'approvisionnement et d'

Ces références de coûts permettent aux équipes d'approvisionnement et d'ingénierie d'évaluer les partenaires d'assemblage de PCB SMT LED à l'aide d'attentes de prix réalistes et basées sur la classification. En comprenant comment le type de PCB, le choix du matériau, la complexité de l'assemblage et le délai d'exécution affectent le coût total, les acheteurs peuvent prendre des décisions plus éclairées et éviter les sélections basées uniquement sur la tarification des gros titres sans tenir compte de la fiabilité à long terme et de la stabilité de la production.

Conclusion

Le choix d'un partenaire d'assemblage de PCB LED fiable est une décision de gestion des risques plutôt qu'une tâche d'achat. Les dix questions de ce guide offrent une manière structurée d'évaluer l'expérience, le contrôle des processus et la cohérence sans s'orienter vers la théorie de la fabrication ou les revendications de vente. En se concentrant sur les risques spécifiques aux LED, la qualité de la communication et la stabilité à long terme, les décideurs peuvent sélectionner des partenaires qui prennent en charge des performances prévisibles tout au long du cycle de vie de leurs produits d'éclairage.

FAQ

Le montage de la carte PCB SMT est différent car les LED sont sensibles à la chaleur, à la précision de placement et à la variation des composants. Les petits problèmes d'assemblage peuvent réduire la puissance de la lumière ou la durée de vie, ce qui rend le contrôle des processus plus critique que dans de nombreuses applications SMT standard.

Les principaux risques comprennent une défaillance prématurée des LED, une luminosité incohérente, une variation de couleur et des délais de reprise. Ces problèmes apparaissent souvent après l'installation, lorsque les correctifs sont coûteux et que l'impact sur la réputation est élevé.

La manipulation thermique est au cœur de la fiabilité des LED. Le stress thermique lié à l'assemblage peut endommager les LED ou affaiblir les trajectoires thermiques, même si la conception du PCB elle-même est saine.

Oui. Des erreurs de placement mineures, des défauts de soudure ou une exposition à la chaleur incontrôlée peuvent réduire considérablement la durée de vie des LED et réduire la stabilité du système au fil du temps.

Vous devriez envisager de changer de partenaire lorsque les problèmes de qualité se répètent, que la communication manque de transparence ou que les résultats de production varient d'une exécution à l'autre malgré des conceptions inchangées.